ASTM A1119-20e1

(Specification)Standard Specification for Welded Partially Corrugated Tube for Potable Water and General Service

Standard Specification for Welded Partially Corrugated Tube for Potable Water and General Service

SCOPE

1.1 This specification describes welded austenitic and duplex stainless steel tube on which the external and internal surface has been modified by a cold forming process to produce an intermittent corrugation for improved formability and resistance to seismic and other environmental distortions. The tubes are used for potable water service lines and other liquid delivery systems in nominal diameters from 1/2 to 2 in.

1.2 The tube sizes and thicknesses usually furnished to this specification are 0.625 to 2.125 in. outside diameter and 0.028 to 0.049 in., inclusive, in wall thickness.

1.3 The grades of austenitic and duplex stainless steels included in this specification shall conform to materials listed in the governing straight tube Specifications A269/A269M or A789/A789M. Selection will depend upon design and service requirements.

1.4 The following safety hazards statement pertains only to the test methods of this specification. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation:A1119 −20

Standard Specification for

Welded Partially Corrugated Tube for Potable Water and

1

General Service

This standard is issued under the fixed designation A1119; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1

ε NOTE—Corrected 3.2 editorially in February 2021.

1. Scope 2. Referenced Documents

2

1.1 This specification describes welded austenitic and du- 2.1 ASTM Standards:

A269/A269M Specification for Seamless and Welded Aus-

plex stainless steel tube on which the external and internal

surface has been modified by a cold forming process to tenitic Stainless Steel Tubing for General Service

A789/A789M Specification for Seamless and Welded

produce an intermittent corrugation for improved formability

and resistance to seismic and other environmental distortions. Ferritic/Austenitic Stainless Steel Tubing for General

Service

The tubes are used for potable water service lines and other

1

liquid delivery systems in nominal diameters from ⁄2 to 2 in. A1016/A1016M Specification for General Requirements for

Ferritic Alloy Steel, Austenitic Alloy Steel, and Stainless

1.2 The tube sizes and thicknesses usually furnished to this

Steel Tubes

specification are 0.625 to 2.125 in. outside diameter and 0.028

A1047/A1047M Test Method for Pneumatic LeakTesting of

to 0.049 in., inclusive, in wall thickness.

Tubing

1.3 The grades of austenitic and duplex stainless steels

E384 Test Method for Microindentation Hardness of Mate-

included in this specification shall conform to materials listed

rials

in the governing straight tube Specifications A269/A269M or

2.2 Other Standard:

A789/A789M. Selection will depend upon design and service

JWWA G 119 Corrugated Stainless Steel Tubes for Water

requirements.

Supply

1.4 The following safety hazards statement pertains only to

3. Terminology and Symbols

the test methods of this specification. This standard does not

3.1 Definitions—For definition of general terms used in this

purport to address all of the safety concerns, if any, associated

specification, refer to Specification A1016/A1016M.

with its use. It is the responsibility of the user of this standard

to establish appropriate safety, health, and environmental

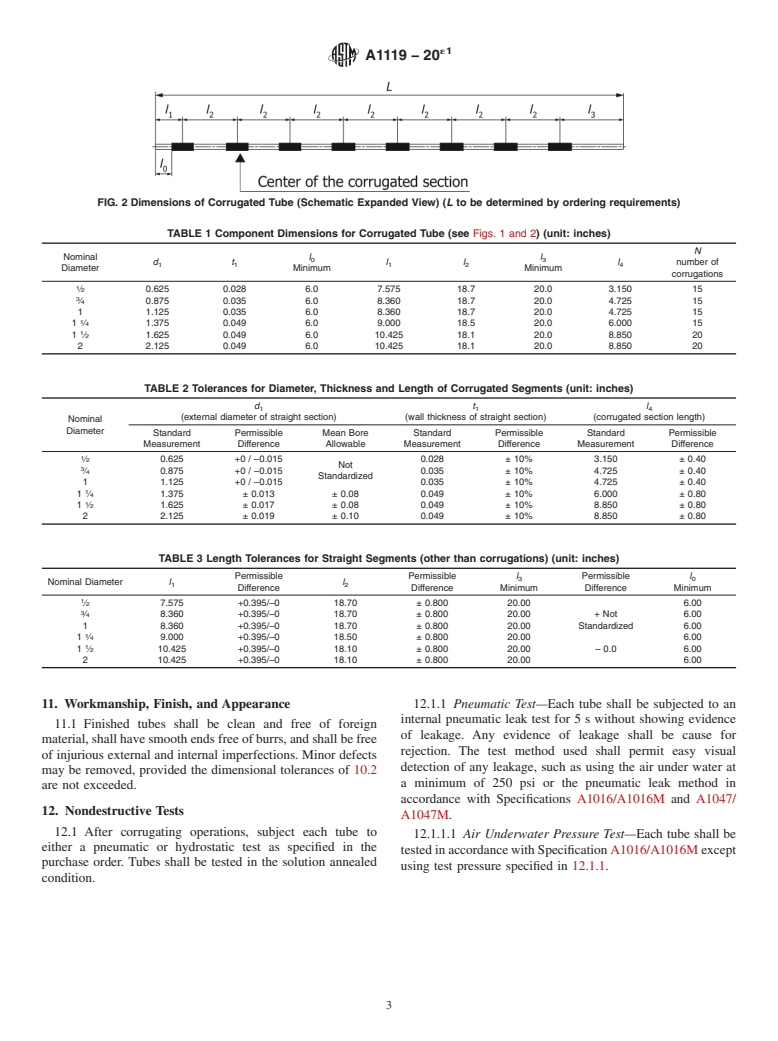

3.2 Symbols (Corrugation Nomenclature):

practices and determine the applicability of regulatory limita-

d = outside diameter of straight section

1

tions prior to use.

d = outside diameter of corrugated section

2

1.5 This international standard was developed in accor-

L = total tube length

dance with internationally recognized principles on standard-

l = end to first corrugation

0

ization established in the Decision on Principles for the

l = end to center of first corrugation

1

Development of International Standards, Guides and Recom-

l = corrugation centerline to corrugation centerline

2

mendations issued by the World Trade Organization Technical

l = last corrugation centerline to tube end

3

Barriers to Trade (TBT) Committee.

l = length of corrugation

4

t = wall thickness of straight section

1

N = number of corrugations in a corrugated section

1

This specification is under the jurisdiction ofASTM Committee A01 on Steel,

2

Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee For referenced ASTM standards, visit the ASTM website, www.astm.org, or

A01.10 on Stainless and Alloy Steel Tubular Products. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Current edition approved Nov. 15, 2020. Published December 2020. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/A1119-20E01. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

´1

A1119 − 20

4. Ordering Information one of the following Specifications: A269/A269M or A789/

A789M.Thecorrugationsareformedusingthehydraulicbulge

4.1 It is the responsibility of the purchaser to specify all

forming method.

requirements that are necessary for material ordered under this

specification. Such requirements may include, but are not

7. Heat Treatment

limited to, the following:

7.1 Heat treatment of the partially corrugated tube shall be

4.1.1 ASTM designation and year of issue (this specifica-

in accordance with the governing straight tube specification.

tion);

4.1.2 ASTM designation and year of issue (straight tube

8. Chemical Composition

specification);

8.1 The tubing specified shall conform to the chemical

4.1.3 Alloy grade and UNS designation;

requirements prescribed in the governing straight tube spec

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation: A1119 − 20 A1119 − 20

Standard Specification for

Welded Partially Corrugated Tube for Potable Water and

1

General Service

This standard is issued under the fixed designation A1119; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1

ε NOTE—Corrected 3.2 editorially in February 2021.

1. Scope

1.1 This specification describes welded austenitic and duplex stainless steel tube on which the external and internal surface has

been modified by a cold forming process to produce an intermittent corrugation for improved formability and resistance to seismic

and other environmental distortions. The tubes are used for potable water service lines and other liquid delivery systems in nominal

1

diameters from ⁄2 to 2 in.

1.2 The tube sizes and thicknesses usually furnished to this specification are 0.625 to 2.125 in. outside diameter and 0.028 to 0.049

in., inclusive, in wall thickness.

1.3 The grades of austenitic and duplex stainless steels included in this specification shall conform to materials listed in the

governing straight tube Specifications A269/A269M or A789/A789M. Selection will depend upon design and service

requirements.

1.4 The following safety hazards statement pertains only to the test methods of this specification. This standard does not purport

to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish

appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

A269/A269M Specification for Seamless and Welded Austenitic Stainless Steel Tubing for General Service

A789/A789M Specification for Seamless and Welded Ferritic/Austenitic Stainless Steel Tubing for General Service

A1016/A1016M Specification for General Requirements for Ferritic Alloy Steel, Austenitic Alloy Steel, and Stainless Steel

Tubes

A1047/A1047M Test Method for Pneumatic Leak Testing of Tubing

E384 Test Method for Microindentation Hardness of Materials

2.2 Other Standard:

JWWA G 119 Corrugated Stainless Steel Tubes for Water Supply

1

This specification is under the jurisdiction of ASTM Committee A01 on Steel, Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee A01.10

on Stainless and Alloy Steel Tubular Products.

Current edition approved Nov. 15, 2020. Published December 2020. DOI: 10.1520/A1119-20.10.1520/A1119-20E01.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

´1

A1119 − 20

3. Terminology and Symbols

3.1 Definitions—For definition of general terms used in this specification, refer to Specification A1016/A1016M.

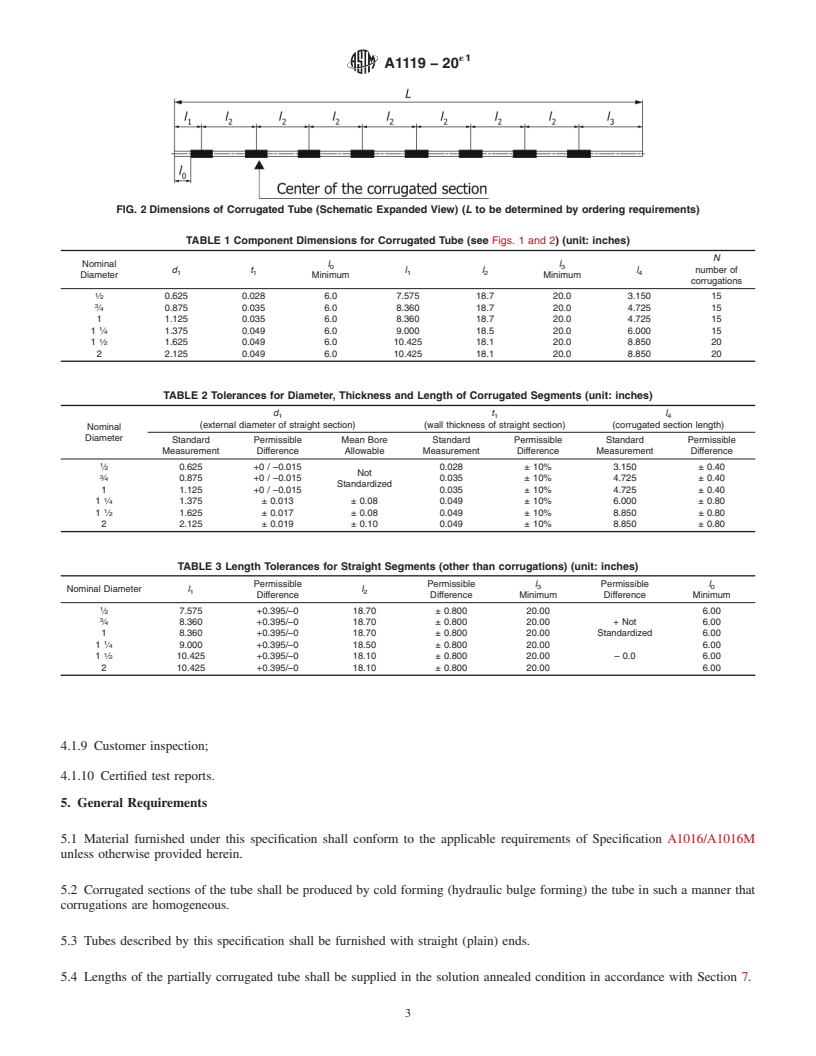

3.2 Symbols (Corrugation Nomenclature):

d = outside diameter of straight section

1

d = outside diameter of straightcorrugated section

2

L = total tube length

l = end to first corrugation

0

l = end to center of first corrugation

1

l = corrugation centerline to corrugation centerline

2

l = last corrugation centerline to tube end

3

l = length of corrugation

4

t = wall thickness of straight section

1

N = number of corrugations in a corrugated section

4. Ordering Information

4.1 It is the responsibility of the purchaser to specify all requirements that are necessary for material ordered under this

specification. Such requirements may include, but are not limited to, the following:

4.1.1 ASTM designation and year of issue (this specification);

4.1.2 ASTM designation and year of issue (straight tube specification);

4.1.3 Alloy grade and UNS designation;

4.1.4 Dimensions; straight tube outside diameter, tube wall thickness (average or minimum specified)

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.