ASTM D4503-08

(Practice)Standard Practice for Dissolution of Solid Waste by Lithium Metaborate Fusion (Withdrawn 2012)

Standard Practice for Dissolution of Solid Waste by Lithium Metaborate Fusion (Withdrawn 2012)

SIGNIFICANCE AND USE

A knowledge of the inorganic constituent composition in a waste is often required for the selection of appropriate waste disposal practices. Solid waste may exist in a variety of forms and contain a range of organic and inorganic constituents. This practice describes a drying and ashing step that may be applied to remove moisture and volatile and nonvolatile organic constituents prior to determining nonvolatile metals. Generation of a dry ash concentrates the inorganic constituents of interest and makes the LiBO2 fusion feasible for a greater variety of waste samples. Acidification of the LiBO2 fusion mix results in a solution amenable to inductively coupled plasma (ICP) or atomic absorption spectrometry (AAS) analysis.

SCOPE

1.1 This practice covers the drying, ashing, and solubilization of solid waste using a lithium metaborate (LiBO2) fusion for the subsequent determination of inorganic constituents by argon plasma emission spectroscopy or atomic absorption spectroscopy.

1.2 The following elements may be solubilized by this practice:

aluminumchromiumsilicon bariumirontitanium cadmiummagnesiumvanadium calciummanganesezinc coppernickel

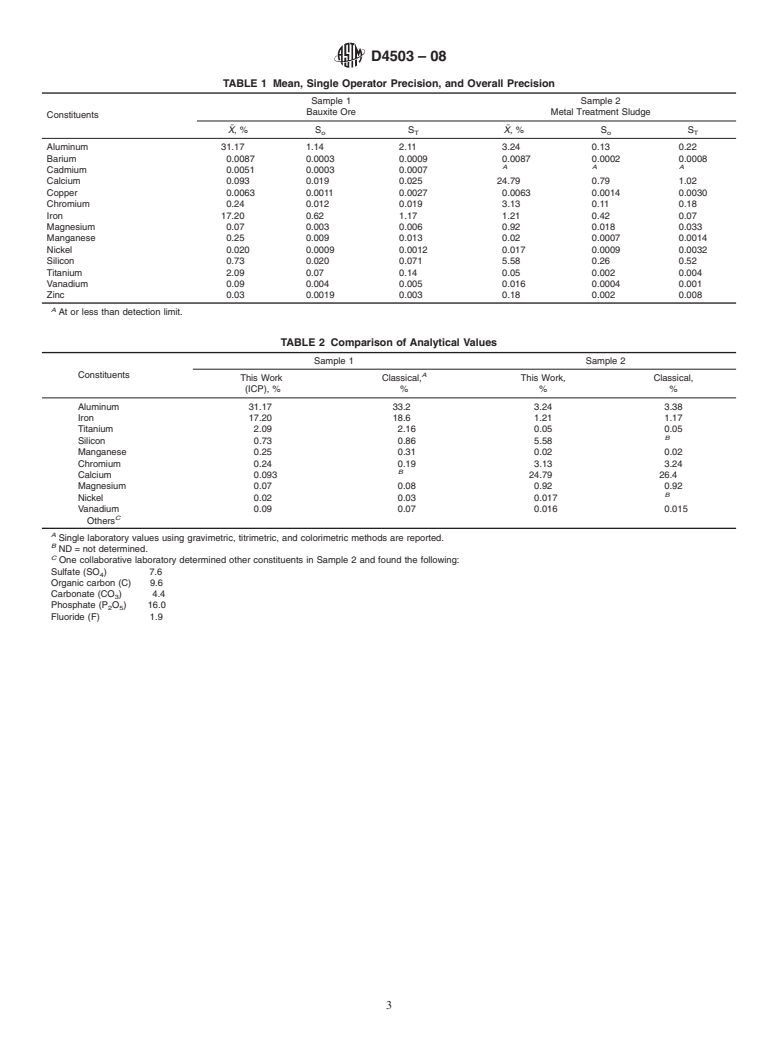

1.3 This practice has been used successfully with a bauxite ore and a neutralized metal treatment sludge. The practice may be applicable to other elements not listed above. Some metals, such as cadmium and zinc, may volatilize from some samples during the drying, ashing, or fusion steps. The analyst is responsible for determining whether the practice is applicable to the solid waste being tested.

1.4 This practice is intended for the solubilization of nonvolatile inorganic constituents in solid waste. The LiBO2 fusion is appropriate for a silicate matrix or acid resistant samples.

1.5 This standard does not purport to address all of the safety problems associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific hazard statements see Section 7.

WITHDRAWN RATIONALE

This practice covers the drying, ashing, and solubilization of solid waste using a lithium metaborate (LiBO2) fusion for the subsequent determination of inorganic constituents by argon plasma emission spectroscopy or atomic absorption spectroscopy.

Formerly under the jurisdiction of Committee D34 on Waste Management, this practice was withdrawn in January 2012. This standard is being withdrawn with no replacement because the practice adds no new technology and there are no plans to run a round robin study to determine precision and bias.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D4503–08

Standard Practice for

1

Dissolution of Solid Waste by Lithium Metaborate Fusion

This standard is issued under the fixed designation D4503; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Applicable Test Methods of Committee D19 on Water

D3682 Test Method for Major and Minor Elements in

1.1 This practice covers the drying, ashing, and solubiliza-

Combustion Residues from Coal Utilization Processes

tion of solid waste using a lithium metaborate (LiBO ) fusion

2

E50 Practices for Apparatus, Reagents, and Safety Consid-

for the subsequent determination of inorganic constituents by

erations for Chemical Analysis of Metals, Ores, and

argon plasma emission spectroscopy or atomic absorption

Related Materials

spectroscopy.

1.2 The following elements may be solubilized by this

3. Summary of Practice

practice:

3.1 Thesolidwasteisweighed,dried,andashedat550°Cto

aluminum chromium silicon

remove water and organic constituents, and reweighed. A

barium iron titanium

cadmium magnesium vanadium

known portion of the ground ash is mixed with LiBO in a

2

calcium manganese zinc

graphite crucible and fused at 1000°C. Immediately after

copper nickel

fusion, the molten mass is poured directly into stirred dilute

1.3 This practice has been used successfully with a bauxite

HNO solution, dissolved, filtered, and made to appropriate

3

ore and a neutralized metal treatment sludge. The practice may

volume for subsequent analysis.

be applicable to other elements not listed above. Some metals,

4. Significance and Use

such as cadmium and zinc, may volatilize from some samples

during the drying, ashing, or fusion steps. The analyst is

4.1 A knowledge of the inorganic constituent composition

responsible for determining whether the practice is applicable

in a waste is often required for the selection of appropriate

to the solid waste being tested.

waste disposal practices. Solid waste may exist in a variety of

1.4 This practice is intended for the solubilization of non-

forms and contain a range of organic and inorganic constitu-

volatile inorganic constituents in solid waste. The LiBO

2 ents. This practice describes a drying and ashing step that may

fusion is appropriate for a silicate matrix or acid resistant

be applied to remove moisture and volatile and nonvolatile

samples.

organic constituents prior to determining nonvolatile metals.

1.5 This standard does not purport to address all of the

Generation of a dry ash concentrates the inorganic constituents

safety problems associated with its use. It is the responsibility

of interest and makes the LiBO fusion feasible for a greater

2

of the user of this standard to establish appropriate safety and

variety of waste samples. Acidification of the LiBO fusion

2

health practices and determine the applicability of regulatory

mix results in a solution amenable to inductively coupled

limitations prior to use. For specific hazard statements see

plasma (ICP) or atomic absorption spectrometry (AAS) analy-

Section 7.

sis.

2. Referenced Documents

5. Apparatus

2

2.1 ASTM Standards:

5.1 Analytical Balance, sensitive to 0.1 mg.

D1193 Specification for Reagent Water

5.2 Fusion Muffle Furnace, electrically heated, capable of

D2777 Practice for Determination of Precision and Bias of

maintaining a temperature of 1000°C.

5.3 Ashing Muffle Furnace, electrically heated, capable of

maintaining a temperature of 550°C6 30°C and with an

1

This practice is under the jurisdiction of ASTM Committee D34 on Waste

adequate air circulation. This may be accomplished by con-

Management and is the direct responsibility of Subcommittee D34.01.06 on

necting rubber tubing to a controlled source of clean dry air.

Analytical Methods.

Then, via a ceramic tube inserted into a convenient muffle

Current edition approved Feb. 1, 2008. Published March 2008. Originally

opening, flow approximately 4 L/min of air into the furnace.

approvedin1986.Lastpreviouseditionapprovedin2003asD4503-86(2003).DOI:

10.1520/D4503-08.

5.4 Drying Oven, capable of operating at a temperature up

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

to 150°C.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

5.5 Evaporating/Ashing Dish, 50 to 100-mL capacity, made

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. of platinum, silica, or porcelain.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D4503–08

5.6 Fusion Cr

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.