ASTM D3028-95

(Test Method)Standard Test Method for Kinetic Coefficient of Friction of Plastic Solids (Withdrawn 2000)

Standard Test Method for Kinetic Coefficient of Friction of Plastic Solids (Withdrawn 2000)

SCOPE

1.1 This test method covers the determination of sliding (kinetic) friction of plastic solids or sheeting (as moving specimens) when sliding against similar or dissimilar substances (Note 1) (as fixed specimens) through the speed range of approximately 0.10 to 3.00 m/s. The instrument used is a variable speed, variable normal-force frictionometer. , Note 1-The physical form for these fixed specimens should be that of rigid or self-supporting solids. Attempts to mount thin sheeting, film, foil, etc., are not recommended due to the difficulty encountered when attempting to meet the weight and concentricity requirements (see 4.1.1).

1.2 Rigid or self-supporting specimens must be machined to specified dimensions. Normally, sheeting exceeding 1.00 mm (0.040 in.) in thickness should not be tested on a mounting wheel of standard diameter. Note 2-An error accumulation of 1% per 0.50 mm (0.020 in.) of sheeting thickness results as the standard diameter of the test surface is increased. If the resulting error is not tolerable, undersize mounting wheels can be employed.

1.3 Two testing procedures are included. Selection of a procedure is determined by the specific interests of the investigator. The procedures are:

1.3.1 Procedure A -Determination of variable-velocity kinetic coefficients, and

1.3.2 Procedure B -Determination of constant-velocity kinetic coefficients over an extended period of time.

1.4 Test data obtained by this test method is relevant and appropriate for use in engineering design.

1.5 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use .

General Information

Standards Content (Sample)

Designation: D 3028 – 95 An American National Standard

Standard Test Method for

1

Kinetic Coefficient of Friction of Plastic Solids

This standard is issued under the fixed designation D 3028; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope bility of regulatory limitations prior to use.

1.1 This test method covers the determination of sliding

2. Referenced Documents

(kinetic) friction of plastic solids or sheeting (as moving

2.1 ASTM Standards:

specimens) when sliding against similar or dissimilar sub-

D 618 Practice for Conditioning Plastics and Electrical

stances (Note 1) (as fixed specimens) through the speed range

4

Insulating Materials for Testing

of approximately 0.10 to 3.00 m/s. The instrument used is a

2, 3

D 4000 Classification System for Specifying Plastic Mate-

variable speed, variable normal-force frictionometer.

5

rials

NOTE 1—The physical form for these fixed specimens should be that of

rigid or self-supporting solids. Attempts to mount thin sheeting, film, foil,

3. Significance and Use

etc., are not recommended due to the difficulty encountered when

3.1 Kinetic coefficients of friction serve as indexes for

attempting to meet the weight and concentricity requirements (see 4.1.1).

characterizing materials that are subjected to conditions of slip.

1.2 Rigid or self-supporting specimens must be machined to

Many variables affect the frictional behavior of materials and

specified dimensions. Normally, sheeting exceeding 1.00 mm

by offering more than a single method of test the influence of

(0.040 in.) in thickness should not be tested on a mounting

these variables can be more readily observed.

wheel of standard diameter.

3.2 The specific procedures offer investigators an opportu-

nity to select a method of testing that is best suited to their

NOTE 2—An error accumulation of 1 % per 0.50 mm (0.020 in.) of

sheeting thickness results as the standard diameter of the test surface is particular interests. Diversified applications of frictional infor-

increased. If the resulting error is not tolerable, undersize mounting

mation can thus be served and a closer correlation between test

wheels can be employed.

results and actual performance might be expected.

1.3 Two testing procedures are included. Selection of a 3.3 Procedure A provides data with respect to many differ-

ent velocities within a specified range. Effects of wear and

procedure is determined by the specific interests of the inves-

tigator. The procedures are: temperature are kept to a minimum. Although these effects are

minimized, their influence is often recognized when the values

1.3.1 Procedure A—Determination of variable-velocity ki-

netic coefficients, and obtained while descending the velocity scale (see 8.1) consis-

tently differ with those obtained while ascending the velocity

1.3.2 Procedure B—Determination of constant-velocity ki-

netic coefficients over an extended period of time. scale.

1.4 Test data obtained by this test method is relevant and 3.4 Procedure B provides data with respect to wear and

temperature. Effects of changing velocities are eliminated since

appropriate for use in engineering design.

1.5 The values stated in SI units are to be regarded as the the testing velocity is held constant.

3.5 Since frictional properties often depend on surface

standard. The values given in parentheses are for information

only. conditions, it should not necessarily be expected that identical

results between like specimens will always occur. Surface

1.6 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the properties of materials under study can vary greatly when they

are produced by different processes or by like processes on

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica- different equipment. In the case of film testing, the time-

dependent blooming of lubricants or other processing additives

can produce varying surface conditions.

1

This test method is under the jurisdiction of ASTM Committee D-20 on Plastics

3.6 For many materials, there may be a specification that

and is the direct responsibility of Subcommittee D20.10 on Mechanical Properties.

Current edition approved Oct. 10, 1995. Published December 1995. Originally requires the use of this test method, but with some procedural

published as D 3028 – 72. Last previous edition D 3028 – 93.

2

Available from Custom Scientific Instruments Inc., Whippany, NJ.

3

Westover, R. F., and Vroom, W. I., “A Variable Speed Frictionometer for

4

Plastics, Rubbers, Metals, and other Materials,” S.P.E. Journal, Vol 19, No. 10, Annual Book of ASTM Standards, Vol 08.01.

5

October 1963. Annual Book of ASTM Standards, Vol 08.

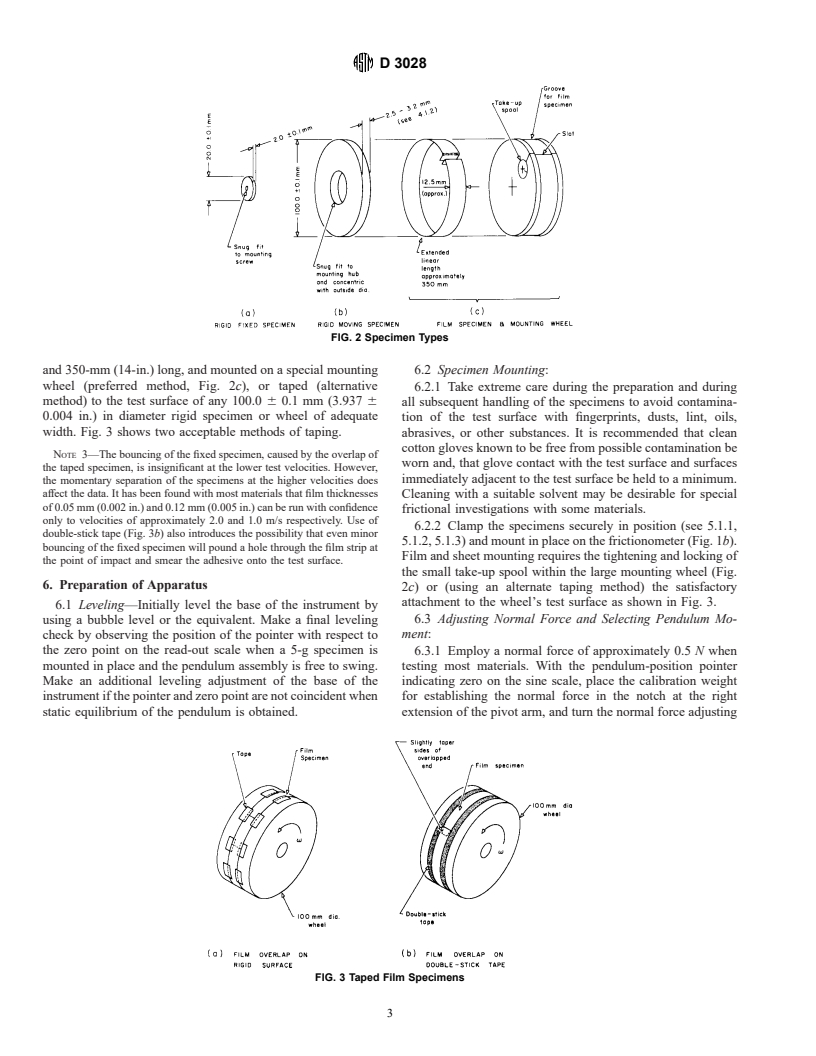

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.