ASTM D2291/D2291M-22

(Practice)Standard Practice for Fabrication of Ring Test Specimens for Glass-Resin Composites

Standard Practice for Fabrication of Ring Test Specimens for Glass-Resin Composites

SIGNIFICANCE AND USE

4.1 This practice provides a uniform procedure for fabricating glass fiber/thermoset resin ring samples for use as test specimens. Specimens so prepared can be used in Test Methods D2290 and D2344/D2344M.

SCOPE

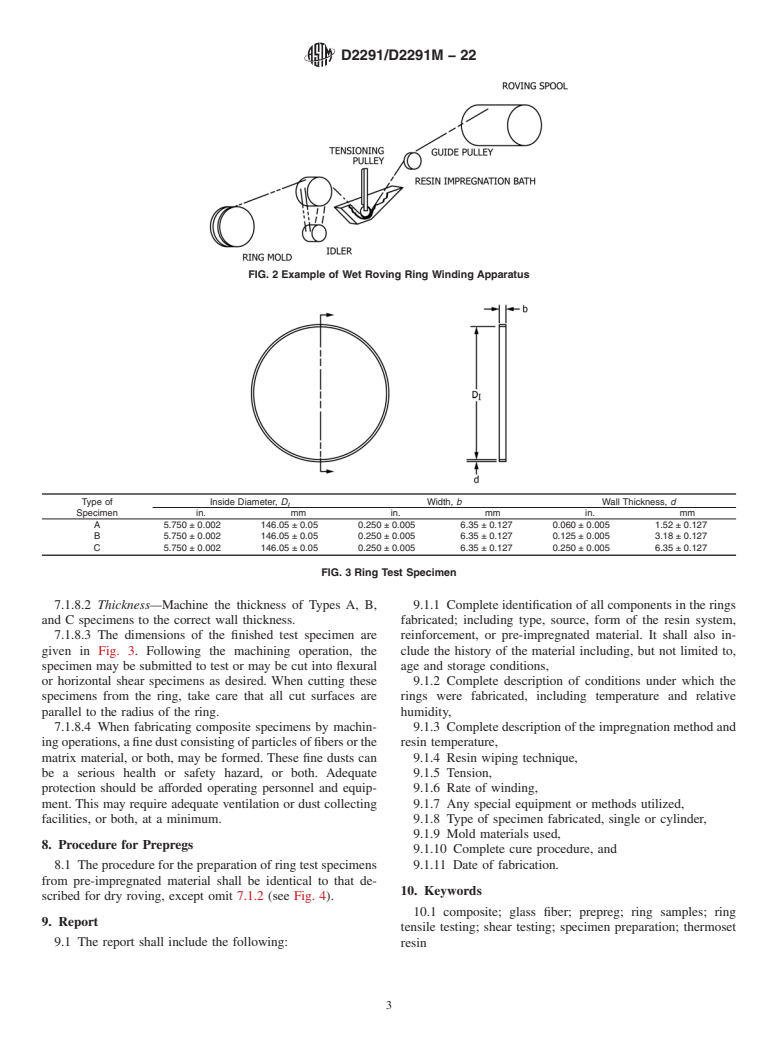

1.1 This practice is intended for use in the fabrication of ring-type test specimens to be used in the evaluation of the mechanical properties of reinforcement and resins in a composite structure. The practice outlines the steps in the preparation of the test specimens, including the final specimen machining where applicable. Three final ring configurations are included.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in nonconformance with the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

Note 1: There is no known ISO equivalent to this practice.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D2291/D2291M − 22

Standard Practice for

Fabrication of Ring Test Specimens for Glass-Resin

1

Composites

This standard is issued under the fixed designation D2291/D2291M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope* D883 Terminology Relating to Plastics

D2290 Test Method for Apparent Hoop Tensile Strength of

1.1 This practice is intended for use in the fabrication of

Plastic or Reinforced Plastic Pipe

ring-type test specimens to be used in the evaluation of the

D2344/D2344M Test Method for Short-Beam Strength of

mechanical properties of reinforcement and resins in a com-

PolymerMatrixCompositeMaterialsandTheirLaminates

posite structure. The practice outlines the steps in the prepara-

tion of the test specimens, including the final specimen

3. Terminology

machining where applicable. Three final ring configurations

3.1 For definitions of terms which apply to this practice, see

are included.

Terminology D883.

1.2 The values stated in either SI units or inch-pound units

are to be regarded separately as standard. The values stated in

4. Significance and Use

each system may not be exact equivalents; therefore, each

4.1 This practice provides a uniform procedure for fabricat-

system shall be used independently of the other. Combining

ing glass fiber/thermoset resin ring samples for use as test

values from the two systems may result in nonconformance

specimens.SpecimenssopreparedcanbeusedinTestMethods

with the standard.

D2290 and D2344/D2344M.

1.3 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

5. Apparatus

responsibility of the user of this standard to establish appro-

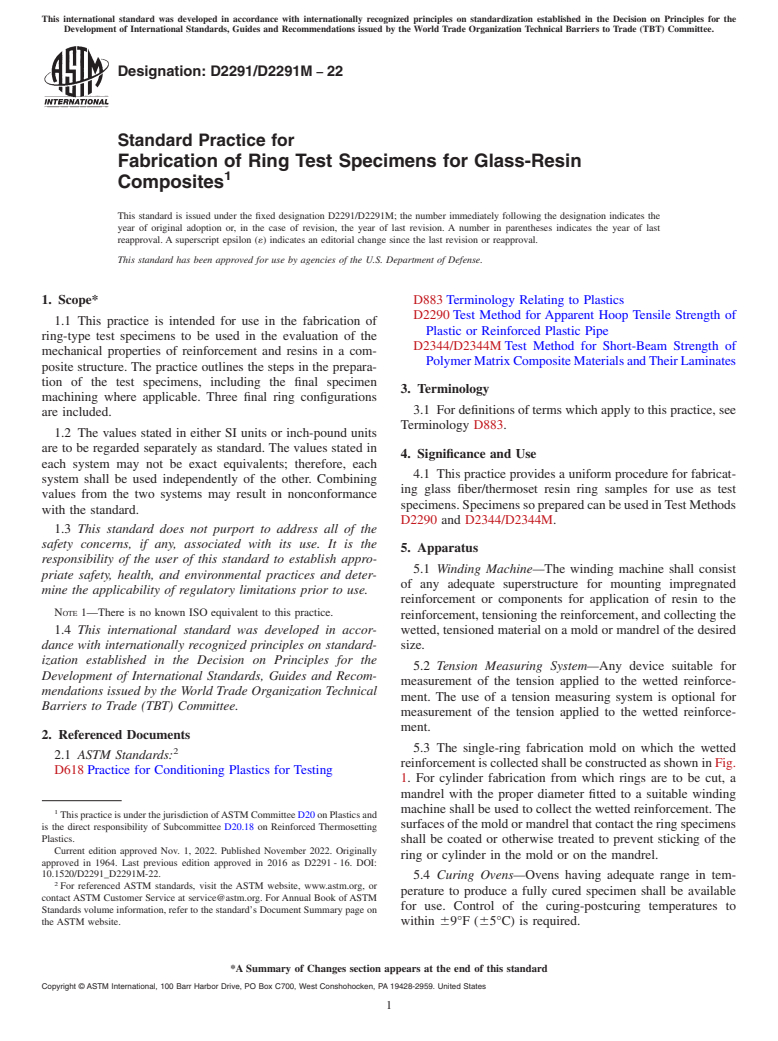

5.1 Winding Machine—The winding machine shall consist

priate safety, health, and environmental practices and deter-

of any adequate superstructure for mounting impregnated

mine the applicability of regulatory limitations prior to use.

reinforcement or components for application of resin to the

NOTE 1—There is no known ISO equivalent to this practice.

reinforcement, tensioning the reinforcement, and collecting the

1.4 This international standard was developed in accor-

wetted, tensioned material on a mold or mandrel of the desired

dance with internationally recognized principles on standard- size.

ization established in the Decision on Principles for the

5.2 Tension Measuring System—Any device suitable for

Development of International Standards, Guides and Recom-

measurement of the tension applied to the wetted reinforce-

mendations issued by the World Trade Organization Technical

ment. The use of a tension measuring system is optional for

Barriers to Trade (TBT) Committee.

measurement of the tension applied to the wetted reinforce-

ment.

2. Referenced Documents

5.3 The single-ring fabrication mold on which the wetted

2

2.1 ASTM Standards:

reinforcementiscollectedshallbeconstructedasshowninFig.

D618 Practice for Conditioning Plastics for Testing

1. For cylinder fabrication from which rings are to be cut, a

mandrel with the proper diameter fitted to a suitable winding

machine shall be used to collect the wetted reinforcement. The

1

This practice is under the jurisdiction ofASTM Committee D20 on Plastics and

surfacesofthemoldormandrelthatcontacttheringspecimens

is the direct responsibility of Subcommittee D20.18 on Reinforced Thermosetting

Plastics.

shall be coated or otherwise treated to prevent sticking of the

Current edition approved Nov. 1, 2022. Published November 2022. Originally

ring or cylinder in the mold or on the mandrel.

approved in 1964. Last previous edition approved in 2016 as D2291 - 16. DOI:

10.1520/D2291_D2291M-22.

5.4 Curing Ovens—Ovens having adequate range in tem-

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

perature to produce a fully cured specimen shall be available

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

for use. Control of the curing-postcuring temperatures to

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. within 69°F (65°C) is required.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D2291/D229

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D2291/D2291M − 16 D2291/D2291M − 22

Standard Practice for

Fabrication of Ring Test Specimens for Glass-Resin

1

Composites

This standard is issued under the fixed designation D2291/D2291M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope*

1.1 This practice is intended for use in the fabrication of ring-type test specimens to be used in the evaluation of the mechanical

properties of reinforcement and resins in a composite structure. The practice outlines the steps in the preparation of the test

specimens, including the final specimen machining where applicable. FourThree final ring configurations are included.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each

system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the

two systems may result in nonconformance with the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

NOTE 1—There is no known ISO equivalent to this practice.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

D618 Practice for Conditioning Plastics for Testing

D883 Terminology Relating to Plastics

D2290 Test Method for Apparent Hoop Tensile Strength of Plastic or Reinforced Plastic Pipe

D2344/D2344M Test Method for Short-Beam Strength of Polymer Matrix Composite Materials and Their Laminates

3. Terminology

3.1 For definitions of terms which apply to this practice, see Terminology D883.

1

This practice is under the jurisdiction of ASTM Committee D20 on Plastics and is the direct responsibility of Subcommittee D20.18 on Reinforced Thermosetting Plastics.

Current edition approved Sept. 1, 2016Nov. 1, 2022. Published September 2016November 2022. Originally approved in 1964. Last previous edition approved in 20092016

as D2291 - 09.D2291 - 16. DOI: 10.1520/D2291_D2291M-16.10.1520/D2291_D2291M-22.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D2291/D2291M − 22

FIG. 1 Suggested Single-Ring Mold

4. Significance and Use

4.1 This practice provides a uniform procedure for fabricating glass fiber/thermoset resin ring samples for use as test specimens.

Specimens so prepared can be used in Test Methods D2290 and D2344/D2344M.

5. Apparatus

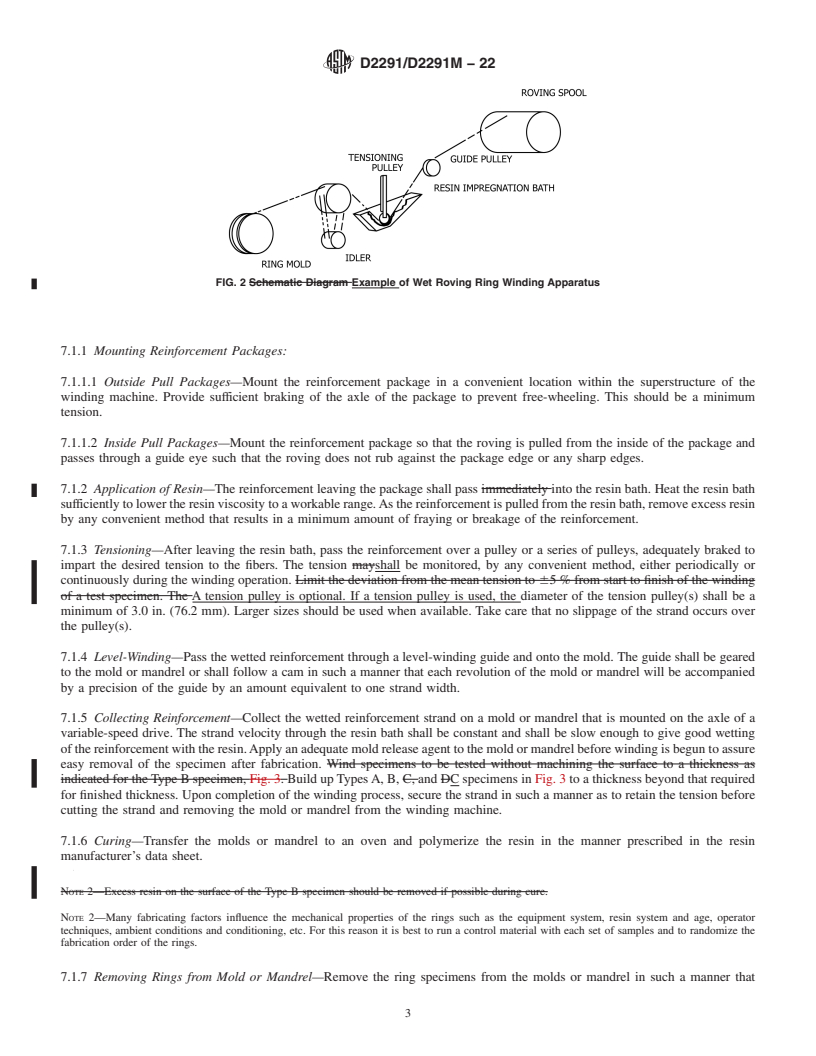

5.1 Winding Machine—The winding machine mayshall consist of any adequate superstructure for mounting impregnated

reinforcement or components for application of resin to the reinforcement, tensioning the reinforcement, and collecting the wetted,

tensioned material on a mold or mandrel of the desired size.

5.2 Tension Measuring System—Any device suitable for measurement of the tension applied to the wetted reinforcement. The

device shall be capable of measuring the tension accurately to within 65 %.use of a tension measuring system is optional for

measurement of the tension applied to the wetted reinforcement.

5.3 The single-ring fabrication mold on which the wetted reinforcement is collected shall be constructed as shown in Fig. 1. For

cylinder fabrication from which rings are to be cut, a mandrel with the proper diameter fitted to a suitable winding machine shall

be used to collect the wetted reinforcement. The surfaces of the mold or

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.