ASTM A519-96

(Specification)Standard Specification for Seamless Carbon and Alloy Steel Mechanical Tubing

Standard Specification for Seamless Carbon and Alloy Steel Mechanical Tubing

SCOPE

1.1 This specification covers several grades of carbon and alloy steel seamless mechanical tubing. The grades are listed in Tables 1-3. When welding is used for joining the weldable mechanical tube grades, the welding procedure shall be suitable for the grade, the condition of the components, and the intended service.

1.2 This specification covers both seamless hot-finished mechanical tubing and seamless cold-finished mechanical tubing in sizes up to and including 12 3/4 in. (323.8 mm) outside diameter for round tubes with wall thicknesses as required.

1.3 The tubes shall be furnished in the following shapes, as specified by the purchaser: round, square, rectangular, and special sections.

1.4 Supplementary requirements of an optional nature are provided and when desired shall be so stated in the order.

1.5 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or

withdrawn. Contact ASTM International (www.astm.org) for the latest information.

Designation: A 519 – 96 An American National Standard

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Standard Specification for

1

Seamless Carbon and Alloy Steel Mechanical Tubing

This standard is issued under the fixed designation A 519; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense. Consult the DoD Index of Specifications and

Standards for the specific year of issue which has been adopted by the Department of Defense. This standard replaces QQ-T-00825 and

QQ-T-830.

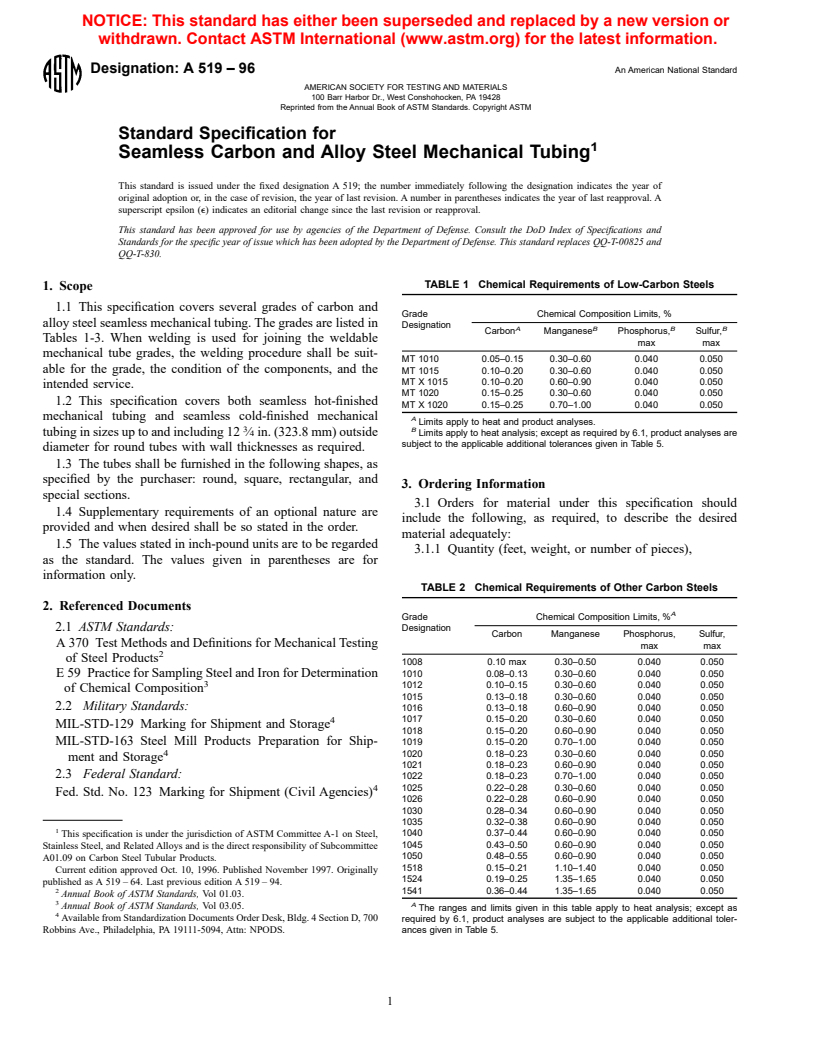

TABLE 1 Chemical Requirements of Low-Carbon Steels

1. Scope

1.1 This specification covers several grades of carbon and

Grade Chemical Composition Limits, %

alloy steel seamless mechanical tubing. The grades are listed in

Designation

A B B B

Carbon Manganese Phosphorus, Sulfur,

Tables 1-3. When welding is used for joining the weldable

max max

mechanical tube grades, the welding procedure shall be suit-

MT 1010 0.05–0.15 0.30–0.60 0.040 0.050

able for the grade, the condition of the components, and the

MT 1015 0.10–0.20 0.30–0.60 0.040 0.050

MT X 1015 0.10–0.20 0.60–0.90 0.040 0.050

intended service.

MT 1020 0.15–0.25 0.30–0.60 0.040 0.050

1.2 This specification covers both seamless hot-finished

MT X 1020 0.15–0.25 0.70–1.00 0.040 0.050

mechanical tubing and seamless cold-finished mechanical A

Limits apply to heat and product analyses.

3 B

tubing in sizes up to and including 12 ⁄4 in. (323.8 mm) outside

Limits apply to heat analysis; except as required by 6.1, product analyses are

subject to the applicable additional tolerances given in Table 5.

diameter for round tubes with wall thicknesses as required.

1.3 The tubes shall be furnished in the following shapes, as

specified by the purchaser: round, square, rectangular, and

3. Ordering Information

special sections.

3.1 Orders for material under this specification should

1.4 Supplementary requirements of an optional nature are

include the following, as required, to describe the desired

provided and when desired shall be so stated in the order.

material adequately:

1.5 The values stated in inch-pound units are to be regarded

3.1.1 Quantity (feet, weight, or number of pieces),

as the standard. The values given in parentheses are for

information only.

TABLE 2 Chemical Requirements of Other Carbon Steels

2. Referenced Documents

A

Grade Chemical Composition Limits, %

2.1 ASTM Standards: Designation

Carbon Manganese Phosphorus, Sulfur,

A 370 Test Methods and Definitions for Mechanical Testing

max max

2

of Steel Products

1008 0.10 max 0.30–0.50 0.040 0.050

E 59 Practice for Sampling Steel and Iron for Determination 1010 0.08–0.13 0.30–0.60 0.040 0.050

3

1012 0.10–0.15 0.30–0.60 0.040 0.050

of Chemical Composition

1015 0.13–0.18 0.30–0.60 0.040 0.050

2.2 Military Standards:

1016 0.13–0.18 0.60–0.90 0.040 0.050

4 1017 0.15–0.20 0.30–0.60 0.040 0.050

MIL-STD-129 Marking for Shipment and Storage

1018 0.15–0.20 0.60–0.90 0.040 0.050

1019 0.15–0.20 0.70–1.00 0.040 0.050

MIL-STD-163 Steel Mill Products Preparation for Ship-

4

1020 0.18–0.23 0.30–0.60 0.040 0.050

ment and Storage

1021 0.18–0.23 0.60–0.90 0.040 0.050

2.3 Federal Standard:

1022 0.18–0.23 0.70–1.00 0.040 0.050

4 1025 0.22–0.28 0.30–0.60 0.040 0.050

Fed. Std. No. 123 Marking for Shipment (Civil Agencies)

1026 0.22–0.28 0.60–0.90 0.040 0.050

1030 0.28–0.34 0.60–0.90 0.040 0.050

1035 0.32–0.38 0.60–0.90 0.040 0.050

1

This specification is under the jurisdiction of ASTM Committee A-1 on Steel, 1040 0.37–0.44 0.60–0.90 0.040 0.050

1045 0.43–0.50 0.60–0.90 0.040 0.050

Stainless Steel, and Related Alloys and is the direct responsibility of Subcommittee

1050 0.48–0.55 0.60–0.90 0.040 0.050

A01.09 on Carbon Steel Tubular Products.

1518 0.15–0.21 1.10–1.40 0.040 0.050

Current edition approved Oct. 10, 1996. Published November 1997. Originally

1524 0.19–0.25 1.35–1.65 0.040 0.050

published as A 519 – 64. Last previous edition A 519 – 94.

2

1541 0.36–0.44 1.35–1.65 0.040 0.050

Annual Book of ASTM Standards, Vol 01.03.

3

A

Annual Book of ASTM Standards, Vol 03.05.

The ranges and limits given in this table apply to heat analysis; except as

4

Available from Standardization Documents Order Desk, Bldg. 4 Section D, 700

required by 6.1, product analyses are subject to the applicable additional toler-

Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS. ances given in Table 5.

1

---------------------- Page: 1 ----------------------

A 519

3.1.2 Name of material (seamless c

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.