ASTM D2158-04

(Test Method)Standard Test Method for Residues in Liquefied Petroleum (LP) Gases

Standard Test Method for Residues in Liquefied Petroleum (LP) Gases

SCOPE

1.1 This test method covers the determination of the extraneous materials weathering above 38°C that are present in liquefied petroleum gases.

1.2 Liquefied petroleum gases that contain alcohols to enhance their anti-icing behaviour can give erroneous results by this test method.

1.3 The result can be expressed in terms of measured volumes or indices derived from these volumes. In either case, the test method provides an indication of the quantity and nature of materials in the product that are substantially less volatile than the liquefied petroleum gas hydrocarbons.

1.4 Although this test method has been used to verify cleanliness and lack of heavy contaminants in propane for many years, it may not be sensitive enough to protect some equipment from operational problems or increased maintenance. A more sensitive test, able to detect lower levels of dissolved contaminants, may be required for some applications.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation: D 2158 – 04

Designation: 317/95

Standard Test Method for

1

Residues in Liquefied Petroleum (LP) Gases

This standard is issued under the fixed designation D2158; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope* E1 Specification forASTM Liquid-in-GlassThermometers

2.2 Other Documents:

1.1 This test method covers the determination of the extra-

4

IPAppendix A

neous materials weathering above 38°C that are present in

liquefied petroleum gases.

3. Terminology

1.2 Liquefied petroleum gases that contain alcohols to

3.1 Definitions of Terms Specific to This Standard:

enhance their anti-icing behavior can give erroneous results by

3.1.1 O Number —10 divided by the oil stain observation.

this test method.

3.1.2 oil stain observation—the volume of solvent-residue

1.3 The result can be expressed in terms of measured

mixture required to yield an oil ring that persists for 2 min

volumes or indices derived from these volumes. In either case,

under specified conditions on a prescribed filter paper.

the test method provides an indication of the quantity and

3.1.3 R Number —the residue multiplied by 200.

nature of materials in the product that are substantially less

3.1.4 residue—the volume, measured to the nearest 0.05

volatile than the liquefied petroleum gas hydrocarbons.

mL,oftheresidualmaterialboilingabove38°Cresultingfrom

1.4 Although this test method has been used to verify

the evaporation of 100 mL of sample under the specified

cleanliness and lack of heavy contaminants in propane for

conditions of this test method.

many years, it may not be sensitive enough to protect some

equipment from operational problems or increased mainte-

4. Summary of Test Method

nance. A more sensitive test, able to detect lower levels of

4.1 A 100-mL sample of liquefied petroleum gas is weath-

dissolved contaminants, may be required for some applica-

ered in a 100-mL centrifuge tube. The volume of residue

tions.

remaining at 38°C is measured and recorded as is also the

1.5 This standard does not purport to address all of the

appearance of a filter paper to which the residue has been

safety concerns, if any, associated with its use. It is the

added in measured increments.

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

5. Significance and Use

bility of regulatory limitations prior to use.

5.1 Control over the residue content (required by Specifica-

tion D1835) is of considerable importance in end-use appli-

2. Referenced Documents

2 cations. In liquid feed systems residues may lead to trouble-

2.1 ASTM Standards:

some deposits and, in vapor offtake systems, residues that are

D96 TestMethods forWater and Sediment in CrudeOilby

3 carried over can foul regulating equipment. Those that remain

Centrifuge Method (Field Procedure)

will accumulate, can be corrosive, and will contaminate

D1796 TestMethodforWaterandSedimentinFuelOilsby

following product. Water, particularly if alkaline, can cause

the Centrifuge Method (Laboratory Procedure)

failure of regulating equipment and corrosion of metals.

D1835 Specification for Liquefied Petroleum (LP) Gases

6. Apparatus

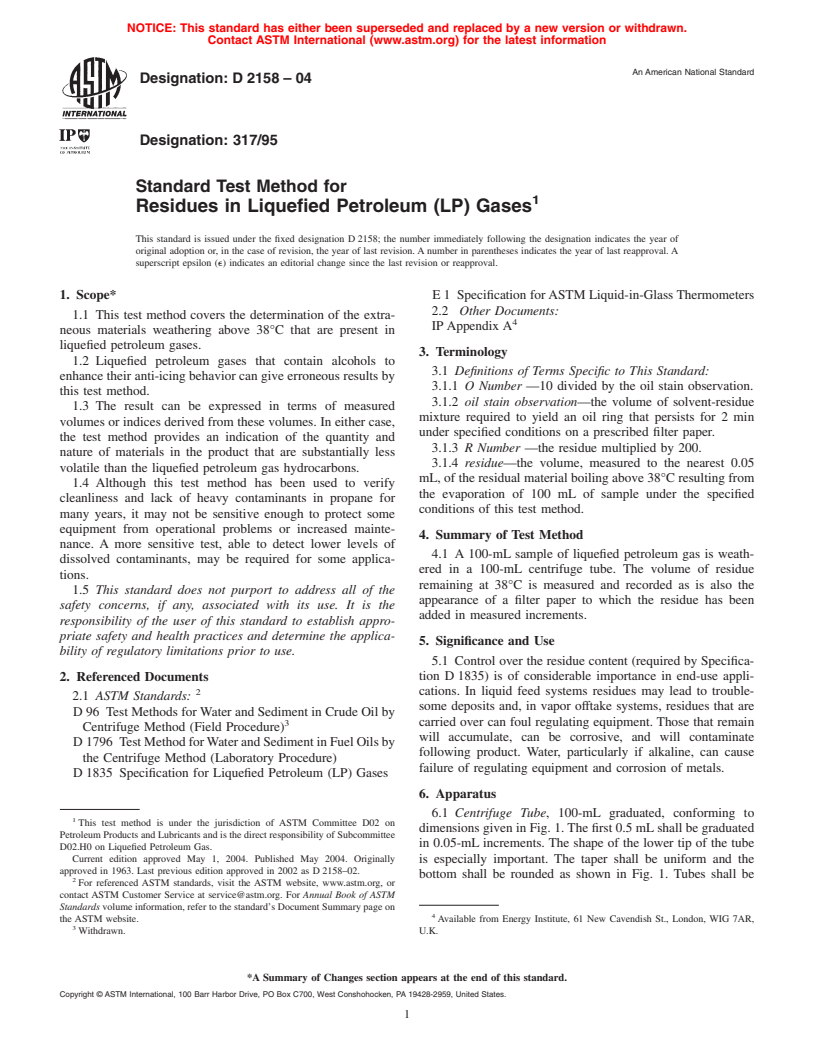

6.1 Centrifuge Tube, 100-mL graduated, conforming to

1

This test method is under the jurisdiction of ASTM Committee D02 on

dimensionsgiveninFig.1.Thefirst0.5mLshallbegraduated

PetroleumProductsandLubricantsandisthedirectresponsibilityofSubcommittee

in 0.05-mL increments. The shape of the lower tip of the tube

D02.H0 on Liquefied Petroleum Gas.

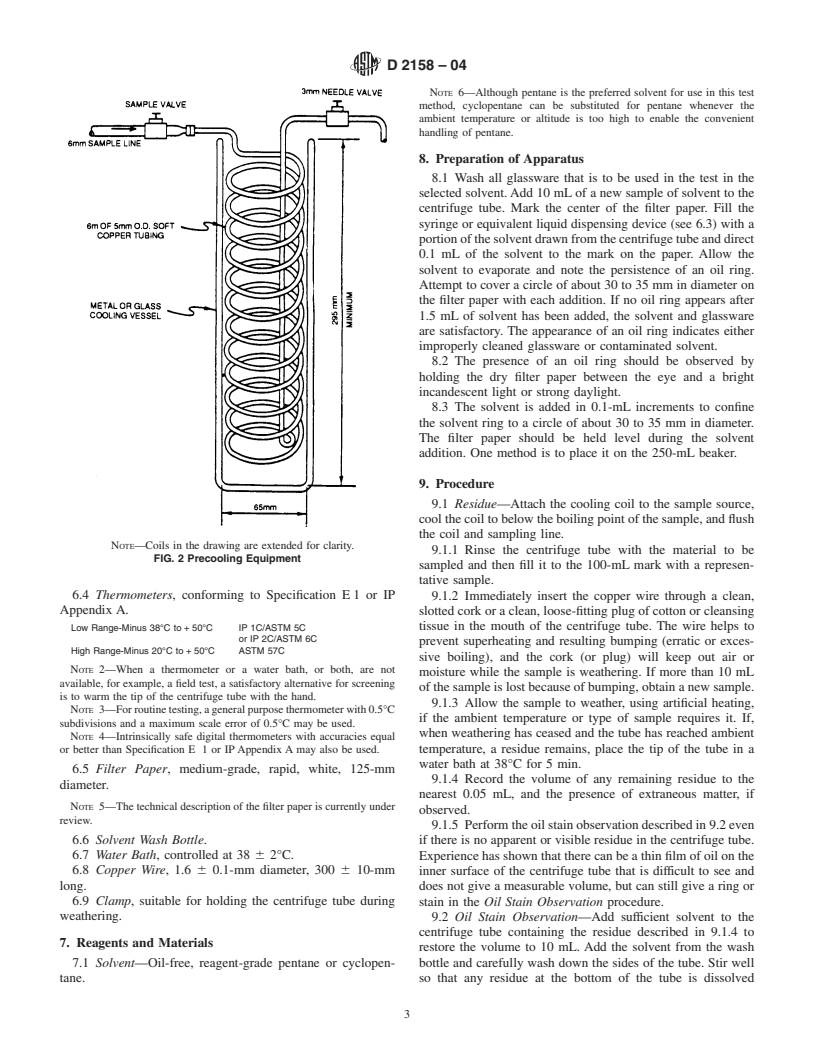

Current edition approved May 1, 2004. Published May 2004. Originally

is especially important. The taper shall be uniform and the

approved in 1963. Last previous edition approved in 2002 as D2158–02.

bottom shall be rounded as shown in Fig. 1. Tubes shall be

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

4

the ASTM website. Available from Energy Institute, 61 New Cavendish St., London, WIG 7AR,

3

Withdrawn. U.K.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D2158–04

FIG. 1 Cone–Shaped Centrifuge Tube, 203 mm

made of thoroughly annealed heat-resistant glass. Volumetric appear in Test Methods D96 and D1796.

graduation tolerances, based on air-free water at 20°C, are

6

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.