ASTM D1555-04

(Test Method)Standard Test Method for Calculation of Volume and Weight of Industrial Aromatic Hydrocarbons and Cyclohexane

Standard Test Method for Calculation of Volume and Weight of Industrial Aromatic Hydrocarbons and Cyclohexane

SCOPE

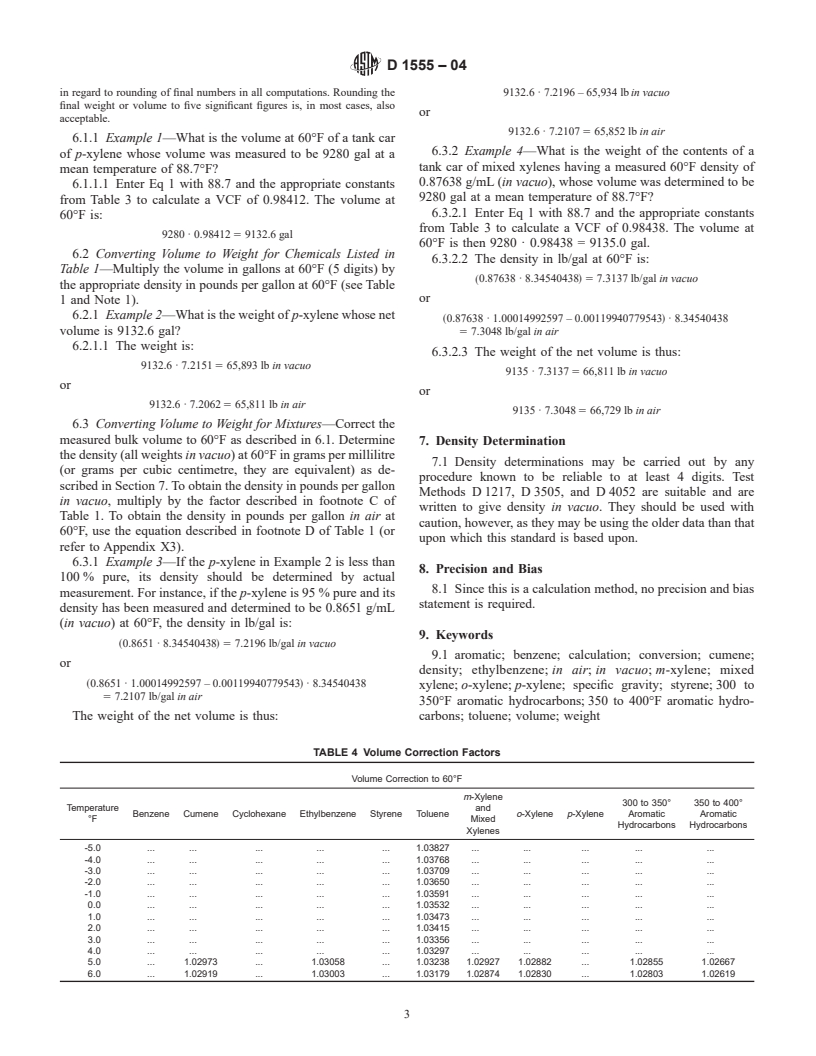

1.1 This standard is for use in calculating the weight and volume of benzene, toluene, mixed xylenes, styrene, ortho-xylene, meta-xylene, para-xylene, cumene, ethylbenzene, 300 to 350°F and 350 to 400°F aromatic hydrocarbons, and cyclohexane. A method is given for calculating the volume at 60°F from an observed volume at t°F. Table 1 lists the density in pounds per gallon at 60°F for high purity chemicals.

1.2 Calculated results shall be rounded off in accordance with the rounding-off method of Practice E 29.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 1555 – 04

Standard Method for

Calculation of Volume and Weight of Industrial Aromatic

1

Hydrocarbons and Cyclohexane

This standard is issued under the fixed designation D 1555; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope* TRC Thermodynamic Tables—Hydrocarbons, NSRDS-

NIST 75-121, Supplement No. 121, April 30, 2001

1.1 This standard is for use in calculating the weight and

volume of benzene, toluene, mixed xylenes, styrene, ortho-

3. Significance and Use

xylene, meta-xylene, para-xylene, cumene, ethylbenzene, 300

3.1 This method is suitable for use in calculating weights

to 350°F and 350 to 400°F aromatic hydrocarbons, and

and volumes of the products outlined in Section 1. The

cyclohexane. A method is given for calculating the volume at

information presented in this method can be used for deter-

60°F from an observed volume at t°F. Table 1 lists the density

mining quantities of the above-stated aromatic hydrocarbons in

in pounds per gallon at 60°F for high purity chemicals.

tanks, shipping containers, etc.

1.2 Calculated results shall be rounded off in accordance

with the rounding-off method of Practice E 29.

4. Basic Data

1.3 This standard does not purport to address all of the

4.1 Densities of pure materials at 60°F are derived from

safety concerns, if any, associated with its use. It is the

densities furnished by NSRDS-NIST 75-121 (National Stan-

responsibility of the user of this standard to establish appro-

dard Reference Data Series—National Institute of Standards

priate safety and health practices and determine the applica-

and Technology). Densities of impure materials should be

bility of regulatory limitations prior to use.

determined by actual measurement (see Section 7).

2. Referenced Documents 4.2 The VCF (Volume Correction Factor) equations pro-

2 vided below were derived from the Volume Correction Tables

2.1 ASTM Standards:

presented in the previous edition of this standard, Method

D 1217 Test Method for Density and Relative Density

D 1555-95. Although reported as based on the American

(Specific Gravity) of Liquids by Bingham Pycnometer

Petroleum Institute Research Project 44, the actual documen-

D 3505 Test Method for Density or Relative Density of

tation that could be found is incomplete. As regression of the

Pure Liquid Chemicals

NIST data (Appendix X1) provided VCFs that differ from the

D 4052 Test Method for Density and Relative Density of

historical VCFs by only 0 to 6 0.12 % (depending on the

Liquids by Digital Density Meter

compound), the decision was made to use the previous meth-

E 29 Practice for Using Significant Digits in Test Data to

od’s VCF tables.

Determine Conformance with Specifications

4.3 The VCF tables were regressed with a commercially

2.2 Other Documents:

3 available data regression program (TableCurve 2D V4). How-

American Petroleum Society Research Project 44

ever, any modern regression program should produce the same

Patterson, J. B., and Morris, E. C., Metrologia, 31, 1994,

results.

pp. 277-288

4.4 The former VCF tables were based on data for com-

pounds of the highest purity, but were reported to be usable for

materials in the ranges indicated in Table 2. The data support-

1

This method is under the jurisdiction of ASTM Committee D16 on Aromatic

ing this conclusion appears to be unavailable at the present

Hydrocarbons and Related Chemicals and is the direct responsibility of Subcom-

time; however there is no reason to change this recommenda-

mittee D16.01 on Benzene, Toluene, Xylenes, Cyclohexane and Their Derivatives.

Current edition approved June 1, 2004. Published July 2004. Originally approved

tion. If, depending on the composition of the impurities, there

in 1957. Last previous edition approved in 2000 as D 1555 – 95 (2000).

is reason to suspect that the VCF implementation procedures

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

presented below do not apply to a particular impure product, a

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

separate implementation procedure should be independently

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

determined. This may be done by measuring the density of a

3

“Selected Values of Properties of Hydrocarbons and Related Compounds,”

representative sample at different temperatures throughout the

prepared by American Petroleum Institute Research Project 44 at the Chemical

expected working temperature range, regressing the data to

Thermodynamics Center, Department of Chemistry, Texas A&M, Co

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.