ASTM E1922-04(2015)

(Test Method)Standard Test Method for Translaminar Fracture Toughness of Laminated and Pultruded Polymer Matrix Composite Materials

Standard Test Method for Translaminar Fracture Toughness of Laminated and Pultruded Polymer Matrix Composite Materials

SIGNIFICANCE AND USE

5.1 The parameter KTL determined by this test method is a measure of the resistance of a polymer matrix composite laminate to notch-tip damage and effective translaminar crack growth under opening mode loading. The result is valid only for conditions in which the damage zone at the notch tip is small compared with the notch length and the in-plane specimen dimensions.

5.2 This test method can serve the following purposes. In research and development, KTL data can quantitatively establish the effects of fiber and matrix variables and stacking sequence of the laminate on the translaminar fracture resistance of composite laminates. In acceptance and quality control specifications, KTL data can be used to establish criteria for material processing and component inspection.

5.3 The translaminar fracture toughness, KTL, determined by this test method may be a function of the testing speed and temperature. This test method is intended for room temperature and quasi-static conditions, but it can apply to other test conditions provided that the requirements of 9.2 and 9.3 are met. Application of KTL in the design of service components should be made with awareness that the test parameters specified by this test may differ from service conditions, possibly resulting in a different material response than that seen in service.

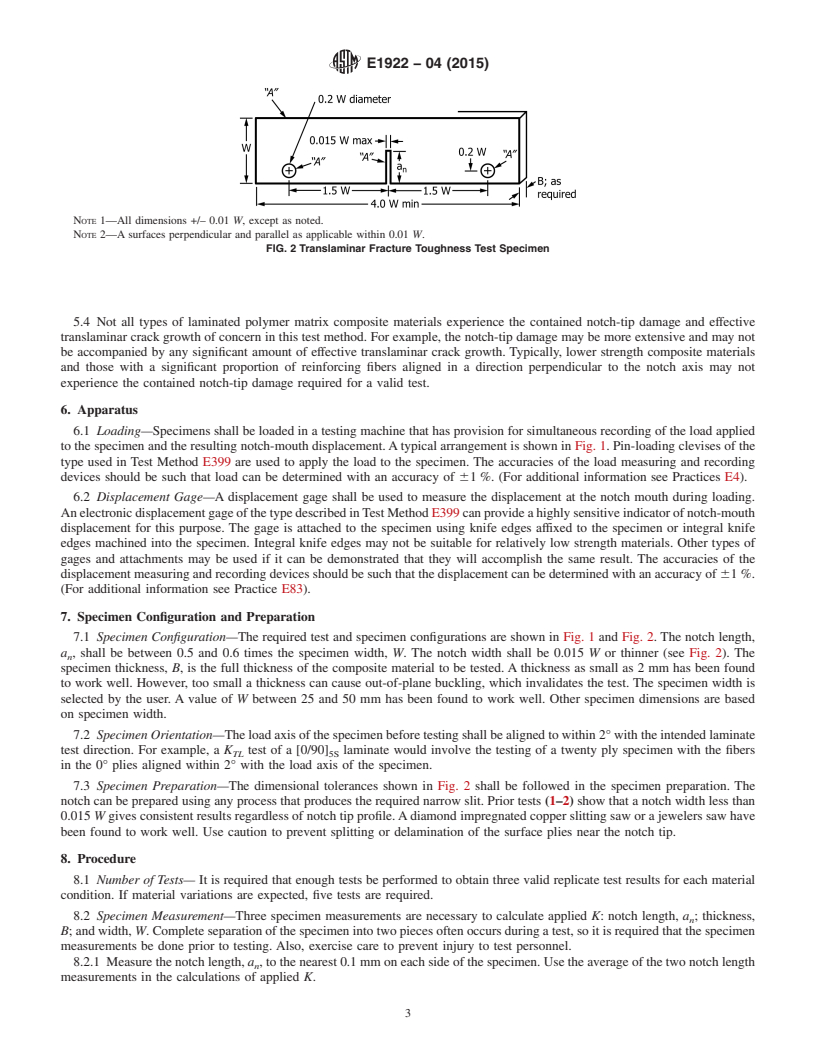

5.4 Not all types of laminated polymer matrix composite materials experience the contained notch-tip damage and effective translaminar crack growth of concern in this test method. For example, the notch-tip damage may be more extensive and may not be accompanied by any significant amount of effective translaminar crack growth. Typically, lower strength composite materials and those with a significant proportion of reinforcing fibers aligned in a direction perpendicular to the notch axis may not experience the contained notch-tip damage required for a valid test.

SCOPE

1.1 This test method covers the determination of translaminar fracture toughness, KTL, for laminated and pultruded polymer matrix composite materials of various ply orientations using test results from monotonically loaded notched specimens.

1.2 This test method is applicable to room temperature laboratory air environments.

1.3 Composite materials that can be tested by this test method are not limited by thickness or by type of polymer matrix or fiber, provided that the specimen sizes and the test results meet the requirements of this test method. This test method was developed primarily from test results of various carbon fiber – epoxy matrix laminates and from additional results of glass fiber – epoxy matrix, glass fiber-polyester matrix pultrusions and carbon fiber – bismaleimide matrix laminates (1-4, 5, 6).2

1.4 A range of eccentrically loaded, single-edge-notch tension, ESE(T), specimen sizes with proportional planar dimensions is provided, but planar size may be variable and adjusted, with associated changes in the applied test load. Specimen thickness is a variable, independent of planar size.

1.5 Specimen configurations other than those contained in this test method may be used, provided that stress intensity calibrations are available and that the test results meet the requirements of this test method. It is particularly important that the requirements discussed in 5.1 and 5.4 regarding contained notch-tip damage be met when using alternative specimen configurations.

1.6 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and to determine the applicability of regulatory limitations prior to use.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E1922 − 04 (Reapproved 2015)

Standard Test Method for

Translaminar Fracture Toughness of Laminated and

1

Pultruded Polymer Matrix Composite Materials

This standard is issued under the fixed designation E1922; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 1.7 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

1.1 This test method covers the determination of translami-

responsibility of the user of this standard to establish appro-

nar fracture toughness, K , for laminated and pultruded

TL

priate safety and health practices and to determine the

polymer matrix composite materials of various ply orientations

applicability of regulatory limitations prior to use.

using test results from monotonically loaded notched speci-

mens.

2. Referenced Documents

3

1.2 This test method is applicable to room temperature

2.1 ASTM Standards:

laboratory air environments.

D883 Terminology Relating to Plastics

D3039/D3039M Test Method for Tensile Properties of Poly-

1.3 Composite materials that can be tested by this test

mer Matrix Composite Materials

method are not limited by thickness or by type of polymer

D3878 Terminology for Composite Materials

matrix or fiber, provided that the specimen sizes and the test

D5229/D5229M TestMethodforMoistureAbsorptionProp-

results meet the requirements of this test method. This test

erties and Equilibrium Conditioning of Polymer Matrix

method was developed primarily from test results of various

Composite Materials

carbon fiber – epoxy matrix laminates and from additional

D5528 TestMethodforModeIInterlaminarFractureTough-

results of glass fiber – epoxy matrix, glass fiber-polyester

ness of Unidirectional Fiber-Reinforced Polymer Matrix

matrix pultrusions and carbon fiber – bismaleimide matrix

2

Composites

laminates (1-4, 5, 6).

E4 Practices for Force Verification of Testing Machines

1.4 A range of eccentrically loaded, single-edge-notch

E6 Terminology Relating to Methods of Mechanical Testing

tension, ESE(T), specimen sizes with proportional planar

E83 Practice for Verification and Classification of Exten-

dimensions is provided, but planar size may be variable and

someter Systems

adjusted, with associated changes in the applied test load.

E399 Test Method for Linear-Elastic Plane-Strain Fracture

Specimen thickness is a variable, independent of planar size.

Toughness K of Metallic Materials

Ic

1.5 Specimen configurations other than those contained in

E1823 TerminologyRelatingtoFatigueandFractureTesting

this test method may be used, provided that stress intensity

3. Terminology

calibrations are available and that the test results meet the

requirements of this test method. It is particularly important

3.1 Definitions:

that the requirements discussed in 5.1 and 5.4 regarding

3.1.1 Terminology E6, E1823, and D3878 are applicable to

contained notch-tip damage be met when using alternative

this test method.

specimen configurations.

3.2 Definitions of Terms Specific to This Standard:

1.6 The values stated in SI units are to be regarded as

3.2.1 notch-mouth displacement, V [L]—the Mode I (also

n

standard. No other units of measurement are included in this

called opening mode) component of crack or notch displace-

standard.

ment due to elastic and permanent deformation. The displace-

ment is measured across the mouth of the notch on the

specimen edge (see Fig. 1).

1

This test method is under the jurisdiction of ASTM Committee D30 on

3.2.2 notch length, a [L]—the distance from a reference

n

Composite Materials and is the direct responsibility of Subcommittee D30.05 on

plane to the front of the machined notch. The reference plane

Structural Test Methods.

Current edition approved May 1, 2015. Published August 2015. Originally

ε1

3

approved in 1997. Last previous edition approved in 2010 as E1922–04(2010) . For referenced ASTM standards, visit the ASTM website, www.astm.org, or

DOI: 10.1520/E1922-04R15. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

2

The boldface numbers in parentheses refer to the list of references at the end of Standards volume information, refer to the standard’s Document Summary page on

this standard. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E1922 − 04 (2015)

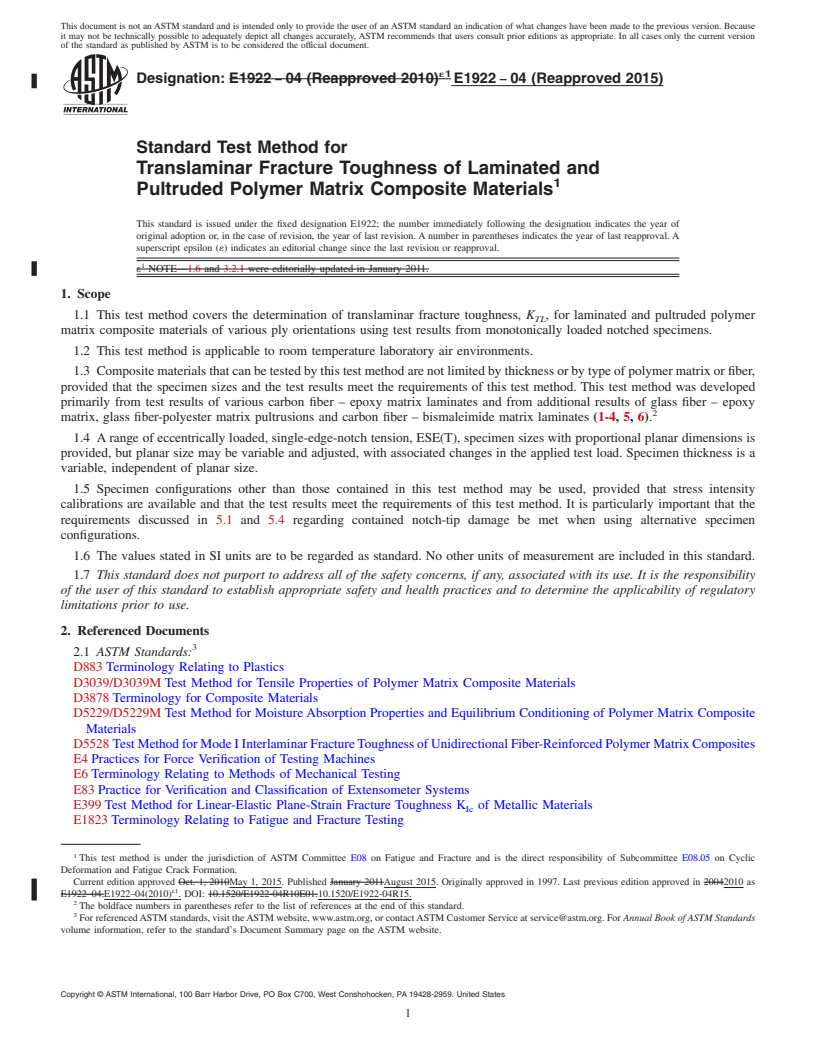

FIG. 1 Test Arrangement for Translaminar Fracture Toughness Tests

depends on the specimen form, and normally is taken to be samples and for samples with a significant prop

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation: E1922 − 04 (Reapproved 2010) E1922 − 04 (Reapproved 2015)

Standard Test Method for

Translaminar Fracture Toughness of Laminated and

1

Pultruded Polymer Matrix Composite Materials

This standard is issued under the fixed designation E1922; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1

ε NOTE—1.6 and 3.2.1 were editorially updated in January 2011.

1. Scope

1.1 This test method covers the determination of translaminar fracture toughness, K , for laminated and pultruded polymer

TL

matrix composite materials of various ply orientations using test results from monotonically loaded notched specimens.

1.2 This test method is applicable to room temperature laboratory air environments.

1.3 Composite materials that can be tested by this test method are not limited by thickness or by type of polymer matrix or fiber,

provided that the specimen sizes and the test results meet the requirements of this test method. This test method was developed

primarily from test results of various carbon fiber – epoxy matrix laminates and from additional results of glass fiber – epoxy

2

matrix, glass fiber-polyester matrix pultrusions and carbon fiber – bismaleimide matrix laminates (1-4, 5, 6).

1.4 A range of eccentrically loaded, single-edge-notch tension, ESE(T), specimen sizes with proportional planar dimensions is

provided, but planar size may be variable and adjusted, with associated changes in the applied test load. Specimen thickness is a

variable, independent of planar size.

1.5 Specimen configurations other than those contained in this test method may be used, provided that stress intensity

calibrations are available and that the test results meet the requirements of this test method. It is particularly important that the

requirements discussed in 5.1 and 5.4 regarding contained notch-tip damage be met when using alternative specimen

configurations.

1.6 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and to determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

3

2.1 ASTM Standards:

D883 Terminology Relating to Plastics

D3039/D3039M Test Method for Tensile Properties of Polymer Matrix Composite Materials

D3878 Terminology for Composite Materials

D5229/D5229M Test Method for Moisture Absorption Properties and Equilibrium Conditioning of Polymer Matrix Composite

Materials

D5528 Test Method for Mode I Interlaminar Fracture Toughness of Unidirectional Fiber-Reinforced Polymer Matrix Composites

E4 Practices for Force Verification of Testing Machines

E6 Terminology Relating to Methods of Mechanical Testing

E83 Practice for Verification and Classification of Extensometer Systems

E399 Test Method for Linear-Elastic Plane-Strain Fracture Toughness K of Metallic Materials

Ic

E1823 Terminology Relating to Fatigue and Fracture Testing

1

This test method is under the jurisdiction of ASTM Committee E08 on Fatigue and Fracture and is the direct responsibility of Subcommittee E08.05 on Cyclic

Deformation and Fatigue Crack Formation.

Current edition approved Oct. 1, 2010May 1, 2015. Published January 2011August 2015. Originally approved in 1997. Last previous edition approved in 20042010 as

ε1

E1922–04.E1922–04(2010) . DOI: 10.1520/E1922-04R10E01.10.1520/E1922-04R15.

2

The boldface numbers in parentheses refer to the list of references at the end of this standard.

3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E1922 − 04 (2015)

3. Terminology

3.1 Definitions:

3.1.1 Terminology E6, E1823, and D3878 are applicable to this test method.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 notch-mouth displacement, V [L]—the Mode I (also called opening mode) component

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.