ASTM E1321-97a(2002)e1

(Test Method)Standard Test Method for Determining Material Ignition and Flame Spread Properties

Standard Test Method for Determining Material Ignition and Flame Spread Properties

SIGNIFICANCE AND USE

This test method addresses the fundamental aspects of piloted ignition and flame spread. The procedure is suitable for the derivation of relevant material flammability parameters that include minimum exposure levels for ignition, thermal-inertia values, and flame-spread properties.

This test method is used to measure some material-flammability properties that are scientifically constant and compatible and to derive specific properties that allow the prediction and explanation of the flame-spread characteristics of materials. They are considered effective properties that are dependent on the correlations used and when combined with theory can be used over a wide range of fire conditions for predicting material ignition and flame-spread behavior.

Do not use this test method for products that do not have planar, or nearly planar, external surfaces and those products and assemblies in which physical performance such as joint separation and fastening methods has a significant influence on flame propagation in actual fire conditions.

5.4 In this procedure, the specimens are subjected to one or more specific sets of laboratory test conditions. If different test conditions are substituted or the end-use conditions are changed, it is not always possible by or from this test method to predict changes in the fire-test-response characteristics measured. Therefore, the results are valid only for the fire test exposure conditions described in this procedure (see also 1.6).

SCOPE

DESIG: E1321 97a (Reapproved 2002) ^TITLE: Standard Test Method for Determining Material Ignition and Flame Spread Properties ^SCOPE:1. Scope

1.1 This fire test response standard determines material properties related to piloted ignition of a vertically oriented sample under a constant and uniform heat flux and to lateral flame spread on a vertical surface due to an externally applied radiant-heat flux.

1.2 The results of this test method provide a minimum surface flux and temperature necessary for ignition ( q"o,ig, Tig) and for lateral spread ( q"o,s, Ts,min), an effective material thermal inertia value (kc), and a flame-heating parameter () pertinent to lateral flame spread.

1.3 The results of this test method are potentially useful to predict the time to ignition, t ig, and the velocity, V, of lateral flame spread on a vertical surface under a specified external flux without forced lateral airflow. Use the equations in that govern the ignition and flame-spread processes and which have been used to correlate the data.

1.4 This test method is potentially useful to obtain results of ignition and flame spread for materials. Data are reported in units for convenient use in current fire growth models.

1.5 SI units are used throughout the standard.

1.6 This standard is used to measure and describe the response of materials, products, or assemblies to heat and flame under controlled conditions, but does not by itself incorporate all factors required for fire hazard or fire risk assessment of the materials, products, or assemblies under actual fire conditions

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific hazard statements, see Section .

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

e1

Designation: E 1321 – 97a (Reapproved 2002)

Standard Test Method for

Determining Material Ignition and Flame Spread Properties

This standard is issued under the fixed designation E1321; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

e NOTE—In the last sentence of 4.1.2, the word “deviation” was replaced by “derivation” editorially in July 2006.

1. Scope 2. Referenced Documents

1.1 This fire test response standard determines material 2.1 ASTM Standards:

properties related to piloted ignition of a vertically oriented E84 Test Method for Surface Burning Characteristics of

sample under a constant and uniform heat flux and to lateral Building Materials

flame spread on a vertical surface due to an externally applied E162 Test Method for Surface Flammability of Materials

radiant-heat flux. Using a Radiant Heat Energy Source

1.2 The results of this test method provide a minimum E176 Terminology of Fire Standards

surface flux and temperature necessary for ignition ( q˙9 , T ) E286 Method ofTest for Surface Flammability of Building

o,ig ig

and for lateral spread ( q˙9 , T ), an effective material Materials Using an 8-ft. (2.44 m) Tunnel Furnace

o,s s,min

thermal inertia value (krc), and a flame-heating parameter (F) E648 Test Method for Critical Radiant Flux of Floor-

pertinent to lateral flame spread. Covering Systems Using a Radiant Heat Energy Source

1.3 The results of this test method are potentially useful to E970 Test Method for Critical Radiant Flux of Exposed

predict the time to ignition, t , and the velocity, V, of lateral AtticFloorInsulationUsingaRadiantHeatEnergySource

ig

flame spread on a vertical surface under a specified external E1317 Test Method for Flammability of Marine Surface

flux without forced lateral airflow. Use the equations in Finishes

Appendix X1 that govern the ignition and flame-spread pro- 2.2 ASTM Adjuncts:ASTM

cesses and which have been used to correlate the data. Detailed drawings (19), construction information, and parts

1.4 Thistestmethodispotentiallyusefultoobtainresultsof list (Adjunct to E1317)

ignition and flame spread for materials. Data are reported in

3. Terminology

units for convenient use in current fire growth models.

1.5 SI units are used throughout the standard. 3.1 Definitions—For definitions of terms used in this test

method, refer to Terminology E176.

1.6 This standard is used to measure and describe the

response of materials, products, or assemblies to heat and 3.2 Definitions of Terms Specific to This Standard:

3.2.1 backing board, n—anoncombustibleinsulatingboard,

flame under controlled conditions, but does not by itself

incorporate all factors required for fire hazard or fire risk mounted behind the specimen during actual testing to satisfy

the theoretical analysis assumption of no heat loss through the

assessment of the materials, products, or assemblies under

actual fire conditions. specimen. It shall be roughly 25 6 5 mm thick with a density

no greater than 200 6 50 kg/m .

1.7 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the 3.2.2 dummy specimen, n—a noncombustible insulating

board used for stabilizing the operating condition of the

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica- equipment, mounted in the apparatus in the position of the

specimen and removed only when a test specimen is to be

bility of regulatory limitations prior to use. For specific hazard

statements, see Section 7.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

This test method is under the jurisdiction of ASTM Committee E05 on Fire contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards and is the direct responsibility of Subcommittee E05.22 on Surface Standards volume information, refer to the standard’s Document Summary page on

Burning. the ASTM website.

Current edition approved June 10, 1997. Published August 1997. Originally Withdrawn.

published as E1321–90. Last previous edition E1321–97. Available from ASTM Headquarters. Order ADJE1317.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

e1

E 1321 – 97a (2002)

inserted. It shall be roughly 20 6 5 mm in thickness with a 4. Summary of Test Method

density of 750 6 100 kg/m .

4.1 This test method consists of two procedures; one to

3.2.2.1 Discussion—For the ignition tests, the dummy

measure ignition and one to measure lateral-flame spread.

specimen board shall have a hole at the 50-mm position for

Vertically mounted specimens are exposed to the heat from a

mounting the fluxmeter.

vertical air-gas fueled radiant-heat energy source inclined at

3.2.3 effective thermal property, n—thermal properties de- 15° to the specimen (see Fig. 1).

4.1.1 For the ignition test, a series of 155,+0,−5 mm by

rived from heat-conduction theory applied to ignition/ flame-

spread data treating the material as homogenous in structure. 155,+0,−5 mm specimens (see Fig. 1) are exposed to a

nearly uniform heat flux (see Fig. 2) and the time to flame

3.2.4 mirror assembly, n—a mirror, marked and aligned

attachment, using piloted ignition (see Fig. 3), is determined.

with the viewing rakes, used as an aid for quickly identifying

4.1.2 For the flame spread test, a 155,+0,−5 mm by

and tracking the flame-front progress.

800,+0,−5 mm specimen (see Fig. 1) is exposed to a

3.2.5 special calibration board, n—a specially assembled

graduated heat flux (see Fig. 2) that is approximately 5 kW/m

noncombustible insulating board used for standardizing the

higher at the hot end than the minimum heat flux necessary for

operating condition of the equipment which is used only to

ignition; this flux being determined from the ignition test (see

measure the flux distribution at specified intervals along the

11.2). The specimen is preheated to thermal equilibrium; the

specimen surface. It shall be roughly 206 5 mm in thickness

preheat time being derived from the ignition test (see 12.1).

with a density of 750 6 100 kg/m .

After using piloted ignition, the pyrolyzing flame-front pro-

3.2.6 thermally thick, n—the thickness of a medium that is

gression along the horizontal length of the specimen as a

large enough to have the predominate thermal (temperature)

function of time is tracked. The data are correlated with a

effects experienced within that distance, that is, negligible heat

theory of ignition and flame spread for the derivation of

is lost from its unexposed side.

material flammability properties.

3.2.7 thermal operating level, n—the operating condition at

which the radiance of the heat source produces a specified

5. Significance and Use

constant heat flux to some specified position at the specimen

5.1 This test method addresses the fundamental aspects of

surface.

pilotedignitionandflamespread.Theprocedureissuitablefor

3.2.8 viewing rakes, n—a set of bars with wires spaced at

thederivationofrelevantmaterialflammabilityparametersthat

50-mm intervals for the purpose of increasing the precision of

include minimum exposure levels for ignition, thermal-inertia

timing flame-front progress along the specimen.

values, and flame-spread properties.

3.3 Symbols:Symbols:

5.2 This test method is used to measure some material-

flammability properties that are scientifically constant and

−1/2 compatible and to derive specific properties that allow the

b = ignition correlation parameter, s .

s/2 1/2 prediction and explanation of the flame-spread characteristics

C = flame heat transfer factor, m /kW·s .

of materials. They are considered effective properties that are

CF = ratio of radiation pyrometer signal to flux inci-

dependent on the correlations used and when combined with

dent on dummy specimen as measured during

theory can be used over a wide range of fire conditions for

calibration; a linear correlation is assumed, mV/

predicting material ignition and flame-spread behavior.

(kW/m ).

5.3 Donotusethistestmethodforproductsthatdonothave

F(t) = specimen thermal response function.

planar, or nearly planar, external surfaces and those products

F(x) = surface flux configuration invariant, (kW/m )/

and assemblies in which physical performance such as joint

mV.

separationandfasteningmethodshasasignificantinfluenceon

h = heat loss coefficient, kW/m ·K.

flame propagation in actual fire conditions.

q˙9 = measured incident flux, kW/m .

e

q˙9o,ig = critical flux for ignition, kW/m .

q˙9o,s = critical flux for spread, kW/m .

t = time, s.

t* = characteristic equilibrium time, s.

t = time at sample insertion, s.

t = time at ignition, s.

t = ignition time under incident flux, s.

ig

T = ignition temperature, °C.

ig

T = minimum temperature for spread, °C.

s,min

T = ambient and initial temperature, °C.

`

V = flame (pyrolysis front) velocity, m/s.

x = longitudinal position along centerline of speci-

men, m.

2 3

F = flame heating parameter, (kW) /m .

2 2

krc = thermal heating property, (kW/m ·K) s.

e = surface emissivity.

2 4

s = Stefan-Boltzmann constant, kW/m ·K .

FIG. 1 Schematic of Apparatus With Ignition Specimen

e1

E 1321 – 97a (2002)

to predict changes in the fire-test-response characteristics

measured. Therefore, the results are valid only for the fire test

exposure conditions described in this procedure (see also 1.6).

6. Apparatus

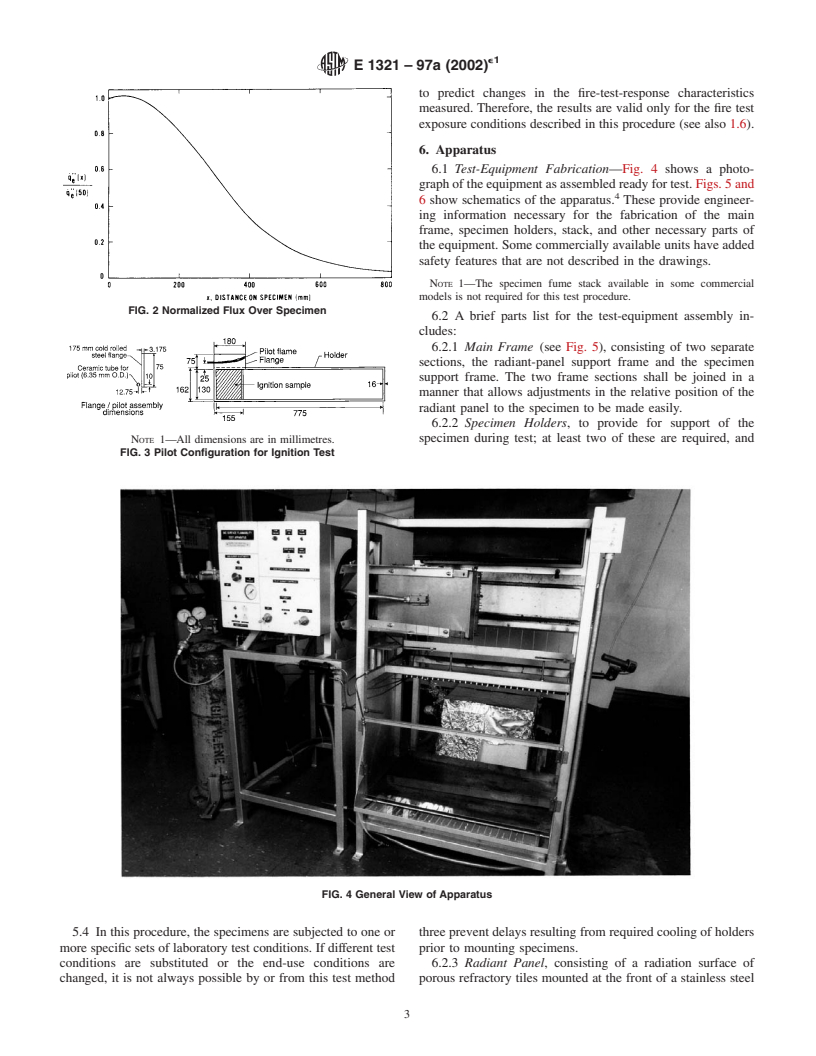

6.1 Test-Equipment Fabrication—Fig. 4 shows a photo-

graphoftheequipmentasassembledreadyfortest.Figs.5and

6 show schematics of the apparatus. These provide engineer-

ing information necessary for the fabrication of the main

frame, specimen holders, stack, and other necessary parts of

the equipment. Some commercially available units have added

safety features that are not described in the drawings.

NOTE 1—The specimen fume stack available in some commercial

models is not required for this test procedure.

FIG. 2 Normalized Flux Over Specimen

6.2 A brief parts list for the test-equipment assembly in-

cludes:

6.2.1 Main Frame (see Fig. 5), consisting of two separate

sections, the radiant-panel support frame and the specimen

support frame. The two frame sections shall be joined in a

manner that allows adjustments in the relative position of the

radiant panel to the specimen to be made easily.

6.2.2 Specimen Holders, to provide for support of the

NOTE 1—All dimensions are in millimetres. specimen during test; at least two of these are required, and

FIG. 3 Pilot Configuration for Ignition Test

FIG. 4 General View of Apparatus

5.4 In this procedure, the specimens are subjected to one or three prevent delays resulting from required cooling of holders

more specific sets of laboratory test conditions. If different test prior to mounting specimens.

conditions are substituted or the end-use conditions are 6.2.3 Radiant Panel, consisting of a radiation surface of

changed, it is not always possible by or from this test method porous refractory tiles mounted at the front of a stainless steel

e1

E 1321 – 97a (2002)

6.2.4.2 The fuel gas used shall be either natural gas or

methane. A pressure regulator shall be provided to maintain a

constant supply pressure. Gas is controlled by either a manu-

allyadjustedneedlevalveoraventurimixer.Theventurimixer

willallowonetocontrolthefluxlevelofthepanelbyadjusting

only the air valve. The fuel gas-flow requirements are roughly

−3 3

0.26 to 1.03 by 10 m /s at a pressure sufficient to overcome

line pressure losses.

NOTE 2—Ifaventurimixerisused,theregulatedairandfuelgassupply

shall be sufficient for efficient operation of the venturi mixer.

6.2.5 The Specimen Holder Support Frame Guides, Pilot

Flame Holder, Fume Stack (optional), Flame Front Viewing

Rakes, Radiation Pyrometer, and Mirror are all assembled on

the specimen support frame. The arrangement of parts on this

frame is shown in Figs. 4-6.

FIG. 5 Test Apparatus Main Frame, Front View

6.2.6 Dummy Specimen,ofnoncombustibleinsulatingboard

of the thickness and density specified in the test procedure,

shall be mounted on the apparatus in the position of the

specimen except during actual testing or calibration.

6.3 Instrumentation:

6.3.1 Total Radiation Pyrometer, compensated for its tem-

peraturevariationandhavinganominalsensitivitybetweenthe

thermal wavelengths of 1 and 9 µm that shall view a centrally

locatedareaontheradiantpanelofabout150by300mm.The

instrument shall be securely mounted on the specimen support

frame in such a manner that it can view the radiant panel

surface oriented for specimens in the vertical position.

6.3.2 Heat Fluxmeters—Have available at least three

fluxmeters for this test method. One of these shall be retained

as a laboratory reference standard. The fluxmeters shall be of

thethermopiletypewithanominalrangeof0to50kW/m and

have a sensitivity of approximately 10 mV at 50 kW/m . They

shall have been calibrated to an accuracy of 5% over this

FIG. 6 Test Apparatus, Side View

range.Thetimeconstantoftheseinstrumentsshallnotbemore

than 290 ms (corresponding to a time to reach 95% of final

outputofnotmorethan1s).Thetargetsensingtheappliedflux

plenum chamber to provide a flat radiating surface of approxi-

shall occupy an area not more than 4 by 4 mm and be located

mately 280 by 483 mm. The plenum chamber shall include

flushwithandatthecenterofthewater-cooled25-mmcircular

baffle plates and diffusers to distribute the gas/air mixture

exposed metallic end of the fluxmeter. If fluxmeters of smaller

evenly over the radiation surface. The gas/air mixture enters

diameters are to be used, these shall be inserted into a copper

the plenum chamber at one of the short sides to facilitate easy

sleeve of 25-mm outside diameter in such a way that good

connection when the panel is mounted from the frame. A

thermal contact is maintained between the sleeve and water-

reverberatory screen (see Fig. 6) is provided immediately in

cooled fluxmeter body. The end of the sleeve and exposed

front of the radiating surface to enhance the combustion

surface of the fluxmeter shall lie in the same plane. Radiation

efficiency and increase the radiant output.

shall not pass through any window before reaching the target.

6.2.4 Air and Fuel Supply, to support combustion of the

6.3.3 Timing Devices, such as a chronograph, a digital

radiant panel. The appropriate air and fuel flow-metering

clock,astopwatch,ataperecorder,adataacquisition/computer

devices, gas control valves, pressure reducer, and safe

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.