ASTM D470-99

(Test Method)Standard Test Methods for Crosslinked Insulations and Jackets for Wire and Cable

Standard Test Methods for Crosslinked Insulations and Jackets for Wire and Cable

SCOPE

1.1 These test methods cover procedures for testing crosslinked insulations and jackets for wire and cable. To determine the test to be made on the particular insulation or jacket, reference should be made to the product specification for that type. These test methods do not apply to the class of products known as flexible cords.

1.2 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific hazards see Section 4.

1.3. In this standard the temperature appearing first is the commonly used temperature.

1.4 The values stated in inch-pound units are standard. The values given in parentheses are provided for informational purposes only. See 1.3 for temperatures.

1.5 The procedures appear in the following sections: Sections AC and DC Voltage Withstand Tests 23 to 30 Capacitance and Dissipation Factor Tests 83 to 88 Cold Bend 107 Cold Bend, Long-Time Voltage Test on Short Specimens 41 to 44 Double AC Voltage Test on Short Specimens 39 to 40 Electrical Tests of Insulation 18 to 22 Heat Distortion Test 106 Horizontal Flame Test 89 to 93 Insulation Resistance Tests on Completed Cable 31 to 38 Mineral Filler Content, Determination of 99 to 101 Ozone Resistance Test 71 to 82 Partial-Discharge Test 45 to 51 Physical Tests of Insulation and Jacket Compounds 5 to 17 Surface Resistivity Test 102 to 104 Track Resistance Test 109 to 111 U-Bend Discharge Test 102 to 104 Water Absorption Test 52 to 57 Water Absorption Tests, Accelerated 58 to 60 Water Absorption Test on Fibrous Coverings 94 to 98

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation:D470–99

Standard Test Methods for

Crosslinked Insulations and Jackets for Wire and Cable

This standard is issued under the fixed designation D470; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope

U-Bend Discharge Test 121 to 125

Water Absorption Test 65 to 71

1.1 These test methods cover procedures for testing

Water Absorption Test, Accelerated 72 to 86

crosslinked insulations and jackets for wire and cable. To

Water Absorption Test on Fibrous Coverings 105 to 110

determine the test to be made on the particular insulation or

2. Referenced Documents

jacket, reference should be made to the product specification

2.1 ASTM Standards:

for that type. These test methods do not apply to the class of

D149 Test Method for Dielectric Breakdown Voltage and

products known as flexible cords.

Dielectric Strength of Solid Electrical Insulating Materials

1.2 This standard does not purport to address all of the

at Commercial Power Frequencies

safety problems, if any, associated with its use. It is the

D150 Test Methods for AC Loss Characteristics and Per-

responsibility of the user of this standard to establish appro-

mittivity (Dielectric Constant) of Solid Electrical Insulat-

priate safety and health practices and determine the applica-

ing Materials

bilityofregulatorylimitationspriortouse.Forspecifichazards

D257 Test Methods for D-C Resistance or Conductance of

see Section 4.

Insulating Materials

1.3 Whenever two sets of values are presented, in different

D412 Test Methods for Vulcanized Rubber and Thermo-

units, the values in the first set are the standard, while those in

plastic Rubbers and Thermostatic Elastomers—Tension

the parentheses are for information only.

D454 Test Method for Rubber Deterioration by Heat and

1.4 In many instances the insulation or jacket cannot be

Air Pressure

tested unless it has been formed around a conductor or cable.

D572 Test Method for Rubber Deterioration by Heat and

Therefore, tests are done on insulated or jacketed wire or cable

Oxygen

in these test methods solely to determine the relevant property

D573 Test Method for Rubber—Deterioration in an Air

of the insulation or jacket and not to test the conductor or

Oven

completed cable.

D1193 Specification for Reagent Water

1.5 The procedures appear in the following sections:

D1711 Terminology Relating to Electrical Insulation

Sections

AC and DC Voltage Withstand Tests 22 to 29

D2132 Test Method for Dust-and-Fog Tracking and Ero-

Capacitance and Dissipation Factor Tests 38 to 44 2

sion Resistance of Electrical Insulating Materials

Cold Bend 128

D3755 Test Method for Dielectric Breakdown Voltage and

Cold Bend, Long-Time Voltage Test on Short Specimens 51 to 57

Double AC Voltage Test on Short Specimens 45 to 50 Dielectric Strength of Solid Electrical Insulating Materials

Electrical Tests of Insulation 17 to 64 5

Under Direct-Voltage Stress

Heat Distortion Test 127

D5025 Specification for a Laboratory Burner Used for

Horizontal Flame Test 100 to 104

Insulation Resistance Tests on Completed Cable 30 to 37

Small-Scale Burning Tests on Plastic Materials

Mineral Filler Content, Determination of 111 to 115

D5207 Practice for Calibration of 20 and 125 mm Test

Ozone Resistance Test 87 to 99

Flames for Small-Scale Burning Tests on Plastic Materi-

Partial-Discharge Test 58 to 64

Physical Tests of Insulation and Jacket Compounds 5 to 16

als

Surface Resistivity Test 116 to 120

D 5423 Specification for Forced-Convection Laboratory

Track Resistance Test 129 to 132

Ovens for Evaluation of Electrical Insulation

These test methods are under the jurisdiction of ASTM Committee D-9 on

Electrical and Electronic Insulating Materials and are the direct responsibility of Annual Book of ASTM Standards, Vol 10.01.

Subcommittee D09.18 on Solid Insulations, Non-Metallic Shieldings, and Cover- Annual Book of ASTM Standards, Vol 09.01.

ings for Electrical and Telecommunications Wire and Cables. Annual Book of ASTM Standards, Vol 11.01.

Current edition approved March 10, 1999. Published June 1999. Originally Annual Book of ASTM Standards, Vol 10.02.

published as D470–37 T. Last previous edition D470–93. Annual Book of ASTM Standards, Vol 08.03.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D470–99

2.2 ICEA Standard: agencies and are usually based upon recommendations made

T-24-380 Guide for Partial-Discharge Procedure by the American Conference of Governmental Industrial Hy-

gienists. Ozoneislikelytobepresentwhenevervoltagesexist

3. Terminology

which are suffıcient to cause partial, or complete, discharges in

air or other atmospheres that contain oxygen. Ozone has a

3.1 Definitions—For definitions of terms used in these test

distinctive odor which is initially discernible at low concen-

methods, refer to Terminology D1711.

trations but sustained inhalation of ozone can cause temporary

3.2 Definition of Term Specific to this Standard:

loss of sensitivity to the scent of ozone. Because of this it is

3.2.1 aging (act of), n—exposure of material to air or oil at

important to measure the concentration of ozone in the

a temperature and time as specified in the relevant material

atmosphere, using commercially available monitoring devices,

specification for that material.

whenever the odor of ozone is persistently present or when

3.3 Symbol:

ozone generating conditions continue. Use appropriate means,

3.3.1 kcmil—thousands of circular mils.

such as exhaust vents, to reduce ozone concentrations to

4. Hazards

acceptable levels in working areas. See Section 90.

4.1 Mercury:

PHYSICAL TESTS OF INSULATIONS AND

4.1.1 Mercury metal vapor poisoning has long been recog-

JACKETS

nized as a hazard in industry. The exposure limits are set by

governmental agencies and are usually based upon recommen-

5. Significance and Use

dations made by the American Conference of Governmental

Industrial Hygienists. The concentration of mercury vapor

5.1 Physical tests, properly interpreted, provide information

over spills from broken thermometers, barometers, and other with regard to the physical properties of the insulation or

instruments using mercury can easily exceed these exposure

jacket. The physical test values give an approximation of how

limits. Mercury, being a liquid with high surface tension and the insulation will physically perform in its service life.

quite heavy, will disperse into small droplets and seep into

Physical tests may provide data for research and development,

cracks and crevices in the floor. This increased area of engineeringdesign,qualitycontrol,andacceptanceorrejection

exposure adds significantly to the mercury vapor concentration

under specifications.

in air. The use of a commercially available emergency spill kit

is recommended whenever a spill occurs. Mercury vapor

6. Physical Tests

concentration is easily monitored using commercially avail-

6.1 Physical tests shall include determination of the follow-

able sniffers. Make spot checks periodically around operations

ing:

where mercury is exposed to the atmosphere. Make thorough

6.1.1 Tensile strength,

checks after spills. See 8.3.2 and 8.3.3.

6.1.2 Tensile stress,

4.2 High Voltage:

6.1.3 Ultimate elongation,

4.2.1 Lethal voltages may be present during these tests. It is

6.1.4 Permanent set,

essential that the test apparatus, and all associated equipment

6.1.5 Accelerated aging,

that may be electrically connected to it, be properly designed

6.1.6 Tear resistance,

and installed for safe operation. Solidly ground all electrically

6.1.7 Effects of oil immersion, and

conductive parts that any person might come in contact with

6.1.8 Thickness of insulations and jackets.

during the test. Provide means for use at the completion of any

test to ground any parts which: were at high voltage during the

7. Sampling

test;mayhaveacquiredaninducedchargeduringthetest;may

7.1 Number of Samples—Unless otherwise required by the

retain a charge even after disconnection of the voltage source.

detailed product specification, wire and cable shall be sampled

Thoroughly instruct all operators in the proper way to conduct

for the physical tests, other than the tests for insulation and

tests safely. When making high voltage tests, particularly in

jacket thickness, as follows:

compressed gas or in oil, the energy released at breakdown

7.1.1 Sizes Less than 250 kcmil (127 mm )—One sample

may be suffıcient to result in fire, explosion, or rupture of the

shall be selected for each quantity ordered between 2000 and

test chamber. Design test equipment, test chambers, and test

50 000 ft (600 and 15 000 m) of wire or cable and one

specimens so as to minimize the possibility of such occurrences

additional sample for each additional 50000 ft. No sample

and to eliminate the possibility of personal injury.SeeSections

shall be selected from lots of less than 2000 ft.

20, 27, 33, 42, 48, 54, 62, 68, 76, 118, 123 and 130.

7.1.2 Sizes of 250 kcmil (127 mm ) and Over—One sample

4.3 Ozone:

shall be selected for each quantity ordered between 1000 and

4.3.1 Ozone is a physiologically hazardous gas at elevated

25000ft(300and7600m)ofwireorcableandoneadditional

concentrations. The exposure limits are set by governmental

sample for each additional 25000 ft. No sample shall be

selected from lots of less than 1000 ft.

7.2 Size of Samples—Samples shall be at least 6 ft (2 m) in

Available from the Insulated Cable Engineers Assoc., P.O. Box 440, South 2

length when the wire size is less than 250 kcmil (127 mm ),

Yarmouth, MA 02664.

andatleast3ft(1m)inlengthwhenthewiresizeis250kcmil

American Conference of Governmental and Industrial Hygienists, 6500 Glen-

way Ave., Building D-7, Cincinnati, OH 45211. or over.

D470–99

8. Test Specimens the mercury. Removal of the insulation may also be facilitated

by stretching the conductor to the breaking point in a tensile-

8.1 Number of Specimens—From each of the samples se-

strength machine.

lected in accordance with Section 7, test specimens shall be

8.3.3 Caution—Mercury is a hazardous material. See 4.1.

prepared as follows:

Care should be exercised to keep mercury from the hands.The

Number of Test

use of rubber gloves is recommended for handling specimens

Specimens

For Determination of Initial Properties (Unaged):

as in 8.3.2.

Tensile strength, tensile stress, and ultimate elongation 3

8.4 Specimens of Thin-Jacketed Insulation—In the case of

Permanent set 3

wires or cables having a thin jacket crosslinked directly to the

For Aging Tests:

Air pressure, heat, or oxygen pressure 3

insulation, it is usually necessary to prepare die-cut specimens

Air oven 3

of the jacket and insulation. Make an effort to separate the

For Oil Immersion 3

jacket from the insulation by slitting the covering through to

Onespecimenofeachthreeshallbetestedandtheothertwo

the conductor and pulling the jacket and insulation apart by

specimensheldinreserve,exceptthatwhenonlyonesampleis

pliers. (This procedure may be facilitated by immersing the

selected all three specimens shall be tested and the average of

sample in hot water for a few minutes just prior to pulling off

the results reported. For the tear test, six individual specimens

thejacket.)Ifthejacketcannotberemoved,preparespecimens

as described in 8.5 shall be used.

by buffing. Equip the buffing apparatus with a cylindrical table

8.2 SizeofSpecimens—Inthecaseofwireandcablesmaller

arrangedsothatitcanbeadvancedverygradually.Removethe

than AWG 6 (13.3 mm ) having an insulation thickness less

conductor from two short lengths of wire by slitting the

than 0.090 in. (2.29 mm), the test specimen may be the entire

covering. Stretch one length of covering into the clamps of the

section of the insulation. When the full cross section is used,

buffing apparatus so that it lies flat, with the jacket toward the

the specimens shall not be cut longitudinally. In the case of

wheel. The jacket is buffed off, with due care not to buff any

wire and cable ofAWG 6 and larger, or in the case of wire and

further than necessary, or overheat the material. Repeat the

cable smaller than AWG 6 having an insulation thickness

process with the other length of covering, except that the

greater than 0.090 in., specimens approximately square in

insulation is buffed off. Die-cut specimens may be prepared

section with a cross section not greater than 0.025 in. (16

from the buffed pieces after they have been allowed to recover

mm ) shall be cut from the insulation. In extreme cases, it may

foratleast30min.(Inthecaseofspecimensfromsmallwires,

be necessary to use a segmental specimen.

itmaybenecessarytouseadiehavingaconstrictedportion ⁄8

8.2.1 The test specimens shall be approximately 6 in. (150

in.(3.18mm)wide.)Jacketswithathicknessoflessthan0.030

mm) in length. Specimens for tests on jackets shall be taken

in. (0.76 mm) shall not be tested.

fromthecompletedwireorcableandcutparalleltotheaxisof

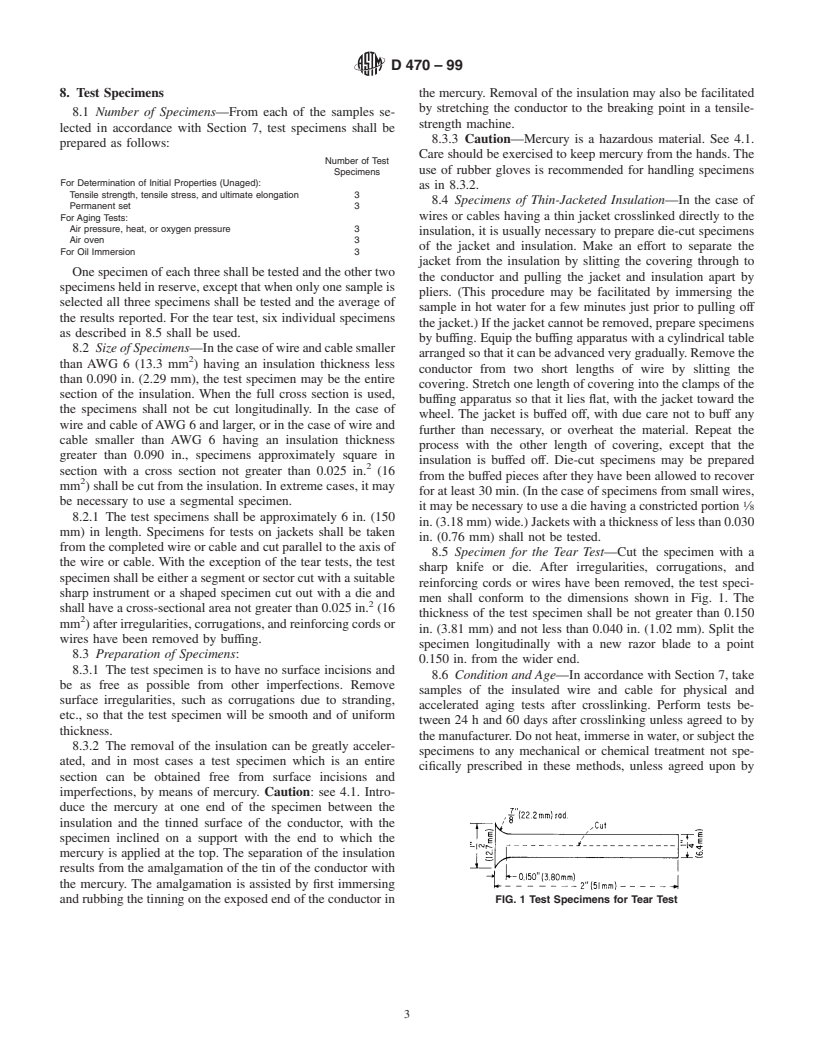

8.5 Specimen for the Tear Test—Cut the specimen with a

the wire or cable. With the exception of the tear tests, the test

sharp knife or die. After irregularities, corrugations, and

specimenshallbeeitherasegmentorsectorcutwithasuitable

reinforcing cords or wires have been removed, the test speci-

sharp instrument or a shaped specimen cut out with a die and

men shall conform to the dimensions shown in Fig. 1. The

shall have a cross-sectional area not greater than 0.025 in. (16

thickness of the test specimen shall be not greater than 0.150

mm )afterirregularities,corrugations,andreinforcingcordsor

in. (3.81 mm) and not less than 0.040 in. (1.02 mm). Split the

wires have been removed by buffing.

specimen longitudinally with a new razor blade to a point

8.3 Preparation of Specimens:

0.150 in. from the wider end.

8.3.1 The test specimen is to have no surface incisions and

8.6 Condition and Age—In accordance with Section 7, take

be as free as possible from other imperfections. Remove

samples of the insulated wire and cable for physical and

surface irregularities, such as corrugations due to stranding,

accelerated aging tests after crosslinking. Perform tests be-

etc., so that the test specimen will be smooth and of uniform

tween 24 h and 60 days after crosslinking unless agreed to by

thickness.

themanufacturer.Donotheat,immerseinwater,orsubjectthe

8.3.2 The removal of the insulation can be greatly acceler-

specimens

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.