ASTM D4791-05e1

(Test Method)Standard Test Method for Flat Particles, Elongated Particles, or Flat and Elongated Particles in Coarse Aggregate

Standard Test Method for Flat Particles, Elongated Particles, or Flat and Elongated Particles in Coarse Aggregate

SIGNIFICANCE AND USE

Flat or elongated particles of aggregates, for some construction uses, may interfere with consolidation and result in harsh, difficult to place materials.

This test method provides a means for checking compliance with specifications that limit such particles or to determine the relative shape characteristics of coarse aggregates.

SCOPE

1.1 This test method covers the determination of the percentages of flat particles, elongated particles, or flat and elongated particles in coarse aggregates.

1.2 The values stated in inch-pound units are to be regarded as the standard except in regard to sieve size and the size of aggregate, which are given in SI units in accordance with Specification E 11. The SI units in parentheses are for information purposes only.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation:D4791–05

Standard Test Method for

Flat Particles, Elongated Particles, or Flat and Elongated

1

Particles in Coarse Aggregate

This standard is issued under the fixed designation D4791; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1

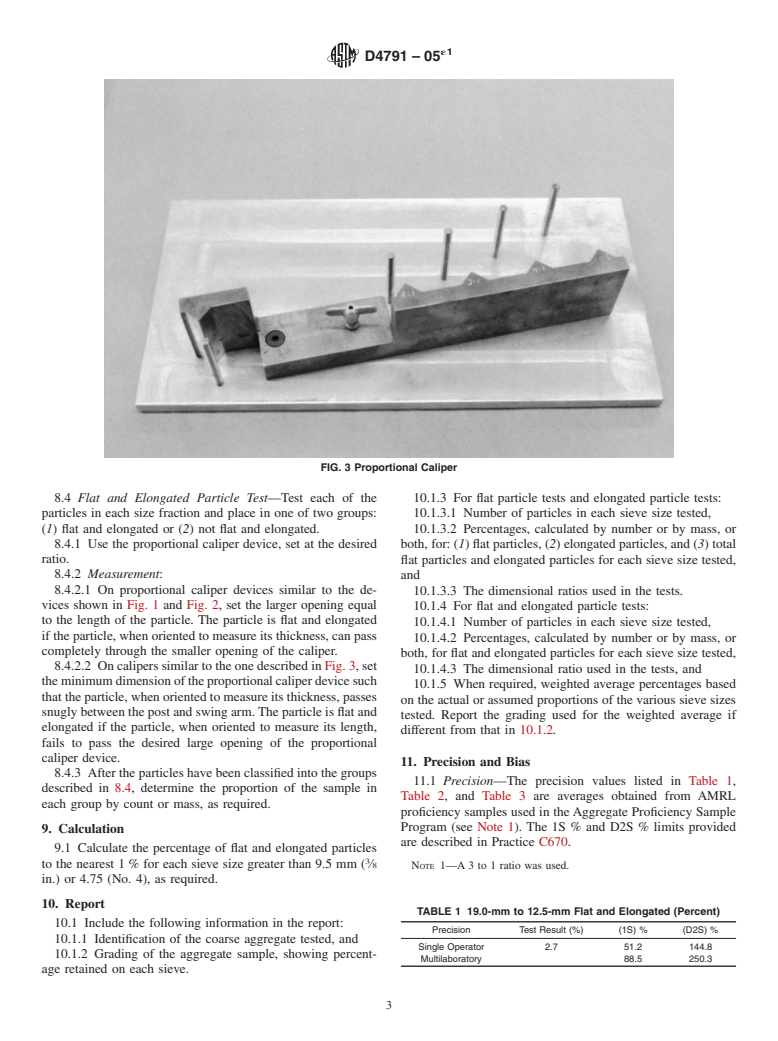

´ NOTE—Information corrected editorially in Table 3 in August 2007.

1. Scope 3.1.1 flat and elongated particles of aggregate—those par-

ticles having a ratio of length to thickness greater than a

1.1 This test method covers the determination of the per-

specified value.

centages of flat particles, elongated particles, or flat and

3.1.2 flat or elongated particles of aggregate—those par-

elongated particles in coarse aggregates.

ticlesofaggregatehavingaratioofwidthtothicknessorlength

1.2 The values stated in inch-pound units are to be regarded

towidthgreaterthanaspecifiedvalue(seeTerminologyC125).

as the standard except in regard to sieve size and the size of

3.1.3 length—maximum dimension of the particle.

aggregate, which are given in SI units in accordance with

3.1.4 thickness—maximum dimension perpendicular to the

Specification E11. The SI units in parentheses are for informa-

length and width.

tion purposes only.

3.1.5 width—maximum dimension in the plane perpendicu-

1.3 This standard does not purport to address all of the

lar to the length

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

4. Summary of Test Method

priate safety and health practices and determine the applica-

4.1 Individual particles of aggregate of specific sieve sizes

bility of regulatory limitations prior to use.

are measured to determine the ratios of width to thickness,

2. Referenced Documents length to width, or length to thickness.

2

2.1 ASTM Standards:

5. Significance and Use

C125 Terminology Relating to Concrete and Concrete Ag-

5.1 Flat or elongated particles of aggregates, for some

gregates

construction uses, may interfere with consolidation and result

C136 Test Method for Sieve Analysis of Fine and Coarse

in harsh, difficult to place materials.

Aggregates

5.2 This test method provides a means for checking com-

C670 Practice for Preparing Precision and Bias Statements

pliance with specifications that limit such particles or to

for Test Methods for Construction Materials

determine the relative shape characteristics of coarse aggre-

C702 Practice for Reducing Samples of Aggregate to Test-

gates.

ing Size

D75 Practice for Sampling Aggregates

6. Apparatus

E11 SpecificationforWovenWireTestSieveClothandTest

6.1 The apparatus used shall be equipment suitable for

Sieves

testing aggregate particles for compliance with the definitions

in 3.1, at the dimensional ratios desired.

3. Terminology

6.1.1 Proportional Caliper Device—The proportional cali-

3.1 Definitions:

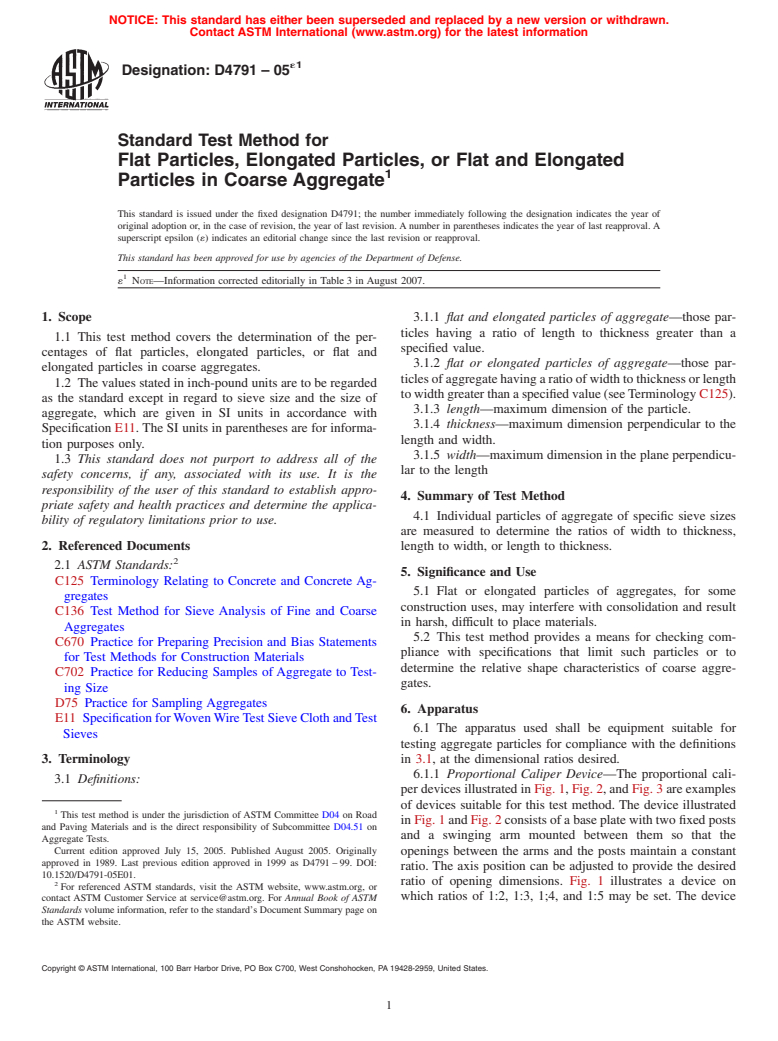

per devices illustrated in Fig. 1, Fig. 2, and Fig. 3 are examples

of devices suitable for this test method. The device illustrated

1

This test method is under the jurisdiction of ASTM Committee D04 on Road

in Fig. 1 and Fig. 2 consists of a base plate with two fixed posts

and Paving Materials and is the direct responsibility of Subcommittee D04.51 on

and a swinging arm mounted between them so that the

Aggregate Tests.

Current edition approved July 15, 2005. Published August 2005. Originally

openings between the arms and the posts maintain a constant

approved in 1989. Last previous edition approved in 1999 as D4791 – 99. DOI:

ratio. The axis position can be adjusted to provide the desired

10.1520/D4791-05E01.

2 ratio of opening dimensions. Fig. 1 illustrates a device on

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

which ratios of 1:2, 1:3, 1;4, and 1:5 may be set. The device

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

´1

D4791–05

illustrated in Fig. 3 contains several fixed posts and has the

capability of measuring various ratios simultaneously.

6.1.1.1 Verification of Ratio—The ratio settings on the

proportional caliper device shall be verified by the use of a

machined block, micrometer, or other appropriate device.

6.1.2 Balance—The balance or scales used shall be accurate

to 0.5 % of the mass of the sample.

7. Sampling

7.1 Samplethecoarseaggregateinaccordance

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.