ASTM D4326-04

(Test Method)Standard Test Method for Major and Minor Elements in Coal and Coke Ash By X-Ray Fluorescence

Standard Test Method for Major and Minor Elements in Coal and Coke Ash By X-Ray Fluorescence

SCOPE

1.1 This test method covers the analysis of the commonly determined major and minor elements in ash from coal or coke using X-ray fluorescence (XRF) techniques.

Note 1—Test Method D 1757 is used for determination of sulfur.

Note 2—Although not included in the present method, the determination of barium, strontium, and manganese may be required to yield adequate totals.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D4326–04

Standard Test Method for

Major and Minor Elements in Coal and Coke Ash By X-Ray

1

Fluorescence

This standard is issued under the fixed designation D4326; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

Note—Section 13 Precision and Bias, was corrected and the year date was changed on May 26, 2004.

1. Scope 3. Summary of Test Method

1.1 This test method covers the analysis of the commonly 3.1 The coal or coke to be analyzed is ashed under standard

determined major and minor elements in ash from coal or coke conditions and ignited to constant weight. Previously ashed

using X-ray fluorescence (XRF) techniques. materials are ignited to constant weight under standard condi-

tions. The ash is fused with lithium tetraborate (Li B O)or

2 4 7

NOTE 1—Test Method D1757 is used for determination of sulfur.

other suitable flux and either ground and pressed into a pellet

NOTE 2—Although not included in the present method, the determina-

or cast into a glass disk. The pellet or disk is then irradiated by

tion of barium, strontium, and manganese may be required to yield

an X-ray beam of short wavelength (high energy). The char-

adequate totals.

acteristic X-rays of the atom that are emitted or fluoresced

1.2 The values stated in SI units are to be regarded as the

uponabsorptionoftheprimaryorincidentX-raysaredispersed

standard. The values given in parentheses are for information

and intensities at selected wavelengths are measured by sensi-

only.

tive detectors. Detector output is related to concentration by

1.3 This standard does not purport to address all of the

calibration curves or by computerized data-handling equip-

safety concerns, if any, associated with its use. It is the

ment.

responsibility of the user of this standard to establish appro-

3.2 The K spectral lines are used for all of the elements

priate safety and health practices and determine the applica-

determined by this procedure.

bility of regulatory limitations prior to use.

3.3 All elements are determined as the element and reported

2. Referenced Documents as the oxide and include Si, Al, Fe, Ca, Mg, Na, K, P, Ti, Mn,

2 Sr, and Ba.

2.1 ASTM Standards:

D1757 TestMethodforSulfateSulfurinAshfromCoaland

4. Significance and Use

3

Coke

4.1 Acompositionalanalysisofashisusedindescribingthe

D3174 Test Method forAsh in theAnalysis Sample of Coal

quality of coal for its complete characterization. Ash compo-

and Coke from Coal

sition is useful in predicting slagging and fouling characteris-

E2 Methods of Preparation of Micrographs of Metals and

tics of combusted materials as well as the potential utilization

Alloys (Including Recommended Practice for Photography

3 of ash by-products.

as Applied to Metallography)

4.2 The chemical composition of laboratory prepared coal

E11 SpecificationforWovenWireTestSieveClothandTest

or coke ash is rarely, if ever, representative of the composition

Sieves

ofthemineralmatterinthecoalbecausetheashingprocesscan

alter some minerals. However, it can approximate the compo-

1

This test method is under the jurisdiction of ASTM Committee D05 on Coal

sition of the fly ash and slag resulting from commercial

and Coke and is the direct responsibility of Subcommittee D05.29 on Major

combustion of coal or coke.

Elements in Ash and Trace Elements of Coal.

Current edition approved May 26, 2004. Published June 2004. Originally

5. Apparatus

approved in 1984. Last previous edition approved 2003 as D4326 – 03. DOI:

10.1520/D4326-04.

5.1 Ashing Furnace, with air circulation as specified in Test

2

Annual Book of ASTM Standards, Vol 05.05.

MethodD3174andcapableofhavingitstemperatureregulated

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

between 700 and 750°C.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on 5.2 Fusion Furnace or Fluxing Device, with an operating

the ASTM website.

temperature of at least 1000°C.

3

Withdrawn. The last approved version of this historical standard is referenced

on www.astm.org.

Copyright ©ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA19428-2959, United States.

1

---------------------- Page: 1 ----------------------

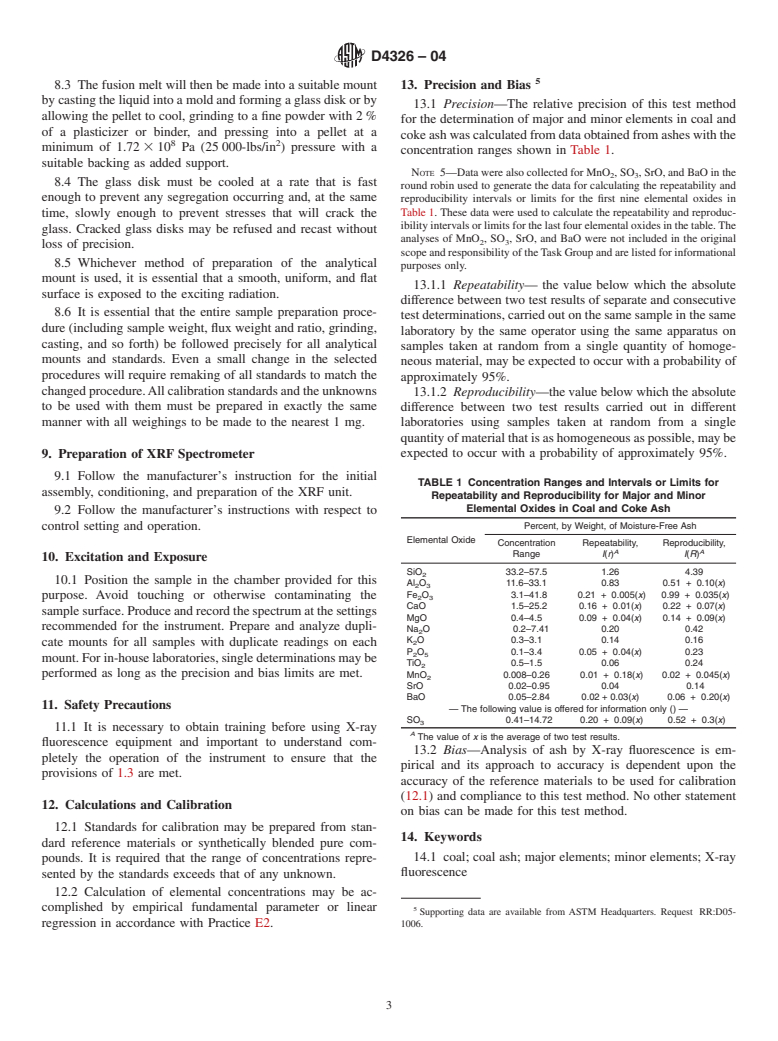

D4326–04

1

5.3 Fusion Crucibles, either high-purity graphite (22 mm coal or coke in a layer not over 6 mm ( ⁄4 in.) in depth in a

high and 19 mm wide, inside diameter) or platinum-gold alloy fireclay, porcelain, or platinum roasting dish. Place the ash in a

of a similar or larger capacity. cold muffle furnace and heat gradually so

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:D4326–01 Designation:D4326–04

Standard Test Method for

Major and Minor Elements in Coal and Coke Ash By X-Ray

1

Fluorescence

This standard is issued under the fixed designation D 4326; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

Note—Section 13 Precision and Bias, was corrected and the year date was changed on May 26, 2004.

1. Scope

1.1 This test method covers the analysis of the commonly determined major and minor elements in ash from coal or coke using

X-ray fluorescence (XRF) techniques.

NOTE 1—Test Method D 1757 is used for determination of sulfur.

NOTE 2—Although not included in the present method, the determination of barium, strontium, and manganese may be required to yield adequate

totals.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D 1757 Test Methods for Sulfur in Ash from Coal and Coke

D 3174 Test Method for Ash in the Analysis Sample of Coal and Coke from Coal

E2 Methods of Preparation of Micrographs of Metals and Alloys (Including Recommended Practice for Photography as

3

Applied to Metallography)

E11 Specification for Wire-Cloth Sieves for Testing Purposes

3. Summary of Test Method

3.1 The coal or coke to be analyzed is ashed under standard conditions and ignited to constant weight. Previously ashed

materials are ignited to constant weight under standard conditions. The ash is fused with lithium tetraborate (Li B O ) or other

2 4 7

suitable flux and either ground and pressed into a pellet or cast into a glass disk. The pellet or disk is then irradiated by an X-ray

beam of short wavelength (high energy). The characteristic X-rays of the atom that are emitted or fluoresced upon absorption of

the primary or incident X-rays are dispersed and intensities at selected wavelengths are measured by sensitive detectors. Detector

output is related to concentration by calibration curves or by computerized data-handling equipment.

3.2 The K spectral lines are used for all of the elements determined by this procedure.

3.3 All elements are determined as the element and reported as the oxide and include Si,Al, Fe, Ca, Mg, Na, K, P, Ti, Mn, Sr,

and Ba.

4. Significance and Use

4.1 Acompositional analysis of ash is used in describing the quality of coal for its complete characterization.Ash composition

is useful in predicting slagging and fouling characteristics of combusted materials as well as the potential utilization of ash

by-products.

1

This test method is under the jurisdiction of ASTM Committee D05 on Coal and Coke and is the direct responsibility of Subcommittee D05.29 on Major Elements in

Ash and Trace Elements of Coal.

Current edition approved Oct. 10, 2001. Published October 2001. Originally published as D4326–84. Last previous edition D4326–97.

Current edition approved May 26, 2004. Published June 2004. Originally approved in 1984. Last previous edition approved 2003 as D 4326 – 03.

2

Annual Book of ASTM Standards, Vol 05.05.

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Discontinued, see 1982 Annual Book of ASTM Standards, Part 11.

3

Withdrawn.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D4326–04

4.2 The chemical composition of laboratory prepared coal or coke ash is rarely, if ever, representative of the composition of the

mineral matter in the coal because the ashing process can alter some minerals. However, it can approximate the composition of

the fly ash and slag resulting from commercial combustion of coal or coke.

5. Apparatus

5.1 Ashing Furnace, with air circulation as specified in Test Method D 3174 and capable of having its temperature regulated

between 700 and 750°C.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.