ASTM F1515-03(2008)

(Test Method)Standard Test Method for Measuring Light Stability of Resilient Flooring by Color Change

Standard Test Method for Measuring Light Stability of Resilient Flooring by Color Change

SIGNIFICANCE AND USE

Resilient floor covering is made by fusing polymer materials under heat or pressure, or both, in various manufacturing and decorating processes. The polymer material may be compounded with plasticizers, stabilizers, fillers, and other ingredients for processability and product performance characteristics. The formulation of the compound can be varied considerably depending on the desired performance characteristics and methods of processing.

Light stability, which is resistance to discoloration from light, is a basic requirement for functional use.

This test method provides a means of measuring the amount of color change in flooring products when subjected to accelerated light exposure over a period of time (functional use of the flooring product).

This test method specifies that a sample is measured by a spectrophotometer and expressed in ΔE* units before and after accelerated light exposure.

Note 1—It is the intent that this test method be used for testing light stability performance properties to be referenced in resilient flooring specifications.

SCOPE

1.1 This test method covers a procedure for determining the resistance of resilient floor covering to color change from exposure to light over a specified period of time.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F1515 − 03(Reapproved 2008)

Standard Test Method for

Measuring Light Stability of Resilient Flooring by Color

Change

This standard is issued under the fixed designation F1515; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope radiant-energy source. The filters selected are to simulate

indoor exposure conditions behind window glass. See Practice

1.1 This test method covers a procedure for determining the

D4459.

resistance of resilient floor covering to color change from

exposure to light over a specified period of time. 3.2 Toensureuniformexposure,thespecimensaremounted

on a cylindrical framework that rotates around the xenon lamp

1.2 This standard does not purport to address all of the

suspended in the center.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

3.3 The effect of radiation (actinic and thermal) on the

priate safety and health practices and determine the applica-

specimen shall be the color difference between the specimen

bility of regulatory limitations prior to use.

before and after exposure.

2. Referenced Documents

4. Significance and Use

2.1 ASTM Standards:

4.1 Resilient floor covering is made by fusing polymer

D2244 Practice for Calculation of Color Tolerances and

materials under heat or pressure, or both, in various manufac-

Color Differences from Instrumentally Measured Color

turing and decorating processes. The polymer material may be

Coordinates

compounded with plasticizers, stabilizers, fillers, and other

D2565 Practice for Xenon-Arc Exposure of Plastics In-

ingredients for processability and product performance char-

tended for Outdoor Applications

acteristics. The formulation of the compound can be varied

D4459 Practice for Xenon-Arc Exposure of Plastics In-

considerably depending on the desired performance character-

tended for Indoor Applications

istics and methods of processing.

E177 Practice for Use of the Terms Precision and Bias in

4.2 Light stability, which is resistance to discoloration from

ASTM Test Methods

light, is a basic requirement for functional use.

E691 Practice for Conducting an Interlaboratory Study to

4.3 This test method provides a means of measuring the

Determine the Precision of a Test Method

amount of color change in flooring products when subjected to

G155 Practice for Operating XenonArc LightApparatus for

acceleratedlightexposureoveraperiodoftime(functionaluse

Exposure of Non-Metallic Materials

of the flooring product).

2.2 DIN Standard:

DIN 53384 Artificial Weathering and Aging of Plastics by

4.4 This test method specifies that a sample is measured by

Exposure to Laboratory UV Radiation Sources, April

a spectrophotometer and expressed in ∆E* units before and

after accelerated light exposure.

3. Summary of Practice NOTE 1—It is the intent that this test method be used for testing light

stability performance properties to be referenced in resilient flooring

3.1 Specimens are exposed continuously at a controlled

specifications.

temperature and humidity to a properly filtered xenon-arc

5. Apparatus

ThistestmethodisunderthejurisdictionofASTMCommitteeF06onResilient

5.1 The apparatus employed shall utilize either a water-

Floor Coverings and is the direct responsibility of Subcommittee F06.30 on Test

cooled or air-cooled xenon-arc lamp as the source of radiation

Methods - Performance.

and should be of Type AH, BH, or E as described in Practices

CurrenteditionapprovedMay1,2008.PublishedJuly2008.Originallyapproved

D2565 or G155.

in 1995. Last previous edition approved in 2003 as F1515 – 03. DOI: 10.1520/

F1515-03R08.

5.1.1 Type AH—An exposure apparatus in which the source

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

of radiant energy shall be a water-cooled xenon-arc vertically

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

located at the central axis of either a 20-in. (508-mm) diameter

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. vertical specimen rack, or of a 25.5-in. (648-mm) diameter

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F1515 − 03 (2008)

inclined rack. Means shall be provided to control temperature, cannotbetotallycoveredwithinthe0.25in.spectrophotometer

relative humidity, and spectral irradiance. The specimen rack opening, then the largest spectrophotometer opening shall be

shall rotate at approximately 1 rpm. used. See Test Method D2244.

5.1.2 Type BH—An exposure apparatus in which the source

6. Hazards

of radiant energy shall be a water-cooled xenon-arc vertically

located at the central axis of a 37.75-in. (960-mm) diameter

6.1 Check to be sure the apparatus is operating properly at

inclined or vertical specimen rack. Means shall be provided to

the start of each test. Check the lamp condition at weekly

control temperature, relative humidity and spectral irradiance.

intervals to be sure that the burner tube and optical filters are

The specimen rack shall rotate at approximately 1 rpm.

clean and that they have not exceeded the maximum recom-

5.1.3 TypeE—Anexposureapparatusinwhichthesourceof

mended period of use.

radiant energy shall be three air-cooled xenon-arc lamps

6.2 Be sure specimens are held flat when measuring color.

operating simultaneously at a nominal 4500 watts each. The

lamps shall be located within a central core, which shall be

7. Procedure

positioned at the center of a 610-mm (24.1-in.) diameter

7.1 The test specimens shall be flat and of uniform thick-

specimenrack.Meansshallbeprovidedtocontroltemperature,

ness. Dimensions are not critical. However, the specimens

relative humidity, and irradiance intensity. The specimen rack

should be capable of fitting the exposure rack and covering the

shall rotate around the light source.

aperture (usually 2.0 in. by 2.0 in. (50.8 mm by 50.8 mm) of

NOTE 2—Type AH, Type BH, and Type E may not yield equivalent

the color-measuring apparatus used.

results.

7.2 For each exposure time cut three specimens or cut one

5.2 Xenon Light Source—The xenon light source consists of

specimen and mark three test areas from each sample. All

a quartz-jacketed burner tube charged with xenon gas.

specimens shall be of similar color, pattern and texture.

5.3 GlassFilters—Table1showstherelativespectralpower

NOTE 3—White, monochromatic, flat material is preferred for testing.

distribution limits of xenon-arcs filtered for simulating a

behind window-glass exposure. For water-cooled xenon, an 7.3 ObtainandrecordinitialL*,a*,andb*readingsoneach

inner borosilicate-glass cylinder is used in combination with a of the three specimens or areas with the color measuring

soda-lime-glass outer cylinder to selectively screen radiation equipmentbeforeplacinginthexenon-arctestapparatus.Mark

output. For air-cooled xenon, the filters shall be an infrared the exact area of the measurement for future location in the

(IR) reflecting inner glass filter, quartz middle filter, and a color measurement equipment.

soda-lime-glass outer filter.

7.4 Program the instrument to operate in the continuous

5.4 Light Monitor—The light monitor shall be capable of light-on mode without water spray at an irradiance equivalent

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:F1515–98 Designation:F1515–03 (Reapproved 2008)

Standard Test Method for

Measuring Light Stability of Resilient Flooring by Color

Change

This standard is issued under the fixed designation F 1515; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers a procedure for determining the resistance of resilient floor covering to color change from exposure

to light over a specified period of time.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

D 2244Test Method Practice for Calculation of Color Tolerances and Color Differences from Instrumentally Measured Color

Coordinates

D 2565Practice for Operating Xenon Arc-Type Light-Exposure Apparatus With and Without Water for Exposure of Plastics

Practice for Xenon-Arc Exposure of Plastics Intended for Outdoor Applications

D 4459Practice for Operating anAccelerated Lightfastness Xenon-Arc Type (Water-Cooled) Light-ExposureApparatus for the

Exposure of Plastics for Indoor Applications Practice for Xenon-Arc Exposure of Plastics Intended for Indoor Applications

E 177 Practice for Use of the Terms Precision and Bias in ASTM Test Methods

E 691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

G26Practice for Operating Light-ExposureApparatus (Xenon-Arc Type) With and Without Water for Exposure of Nonmetallic

Materials 155 Practice for Operating Xenon Arc Light Apparatus for Exposure of Non-Metallic Materials

2.2 DIN Standard:

DIN 53384 Artificial Weathering and Aging of Plastics by Exposure to Laboratory UV Radiation Sources, April 1989

3. Summary of Practice

3.1 Specimens are exposed continuously at a controlled temperature and humidity to a properly filtered xenon-arc

radiant-energy source. The filters selected are to simulate indoor exposure conditions behind window glass. See Practice D 4459.

3.2 To ensure uniform exposure, the specimens are mounted on a cylindrical framework that rotates around the xenon lamp

suspended in the center.

3.3 The effect of radiation (actinic and thermal) on the specimen shall be the color difference between the specimen before and

after exposure.

4. Significance and Use

4.1 Resilient floor covering is made by fusing polymer materials under heat or pressure, or both, in various manufacturing and

decorating processes. The polymer material may be compounded with plasticizers, stabilizers, fillers, and other ingredients for

processability and product performance characteristics. The formulation of the compound can be varied considerably depending

on the desired performance characteristics and methods of processing.

4.2 Light stability, which is resistance to discoloration from light, is a basic requirement for functional use.

4.3 This test method provides a means of measuring the amount of color change in flooring products when subjected to

This test method is under the jurisdiction of ASTM Committee F-6 on Resilient Floor Coverings and is the direct responsibility of Subcommittee F06.30 on Physical

Service Properties.

Current edition approved March 10, 1998. Published June 1998. Originally published as F1515–95. Last previous edition F1515–97.

ThistestmethodisunderthejurisdictionofASTMCommitteeF06onResilientFloorCoveringsandisthedirectresponsibilityofSubcommitteeF06.30onTestMethods

- Performance.

Current edition approved May 1, 2008. Published July 2008. Originally approved in 1995. Last previous edition approved in 2003 as F 1515 – 03.

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. ForAnnualBookofASTMStandards

, Vol 06.01.volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F1515–03 (2008)

accelerated light exposure over a period of time (functional use of the flooring product).

4.4 This test method specifies that a sample is measured by a spectrophotometer and expressed in DE* units before and after

accelerated light exposure.

NOTE 1—It is the intent that this test method be used for testing light stability performance properties to be referenced in resilient flooring

specifications.

5. Apparatus

5.1 The apparatus employed shall utilize either a water-cooled or air-cooled xenon-arc lamp as the source of radiation and

should be of Type AH, BH, or E as described in Practices D 2565 or G26G 155.

5.1.1 Type AH—An exposure apparatus in which the source of radiant energy shall be a water-cooled xenon-arc vertically

locatedatthecentralaxisofeithera20-in.(508-mm)diameterverticalspecimenrack,orofa25.5-in.(648-mm)diameterinclined

rack. Means shall be provided to control temperature, relative humidity, and spectral irradiance. The specimen rack shall rotate at

approximately 1 rpm.

5.1.2 Type BH—An exposure apparatus in which the source of radiant energy shall be a water-cooled xenon-arc vertically

located at the central axis of a 37.75-in. (960-mm) diameter inclined or vertical specimen rack. Means shall be provided to control

temperature, relative humidity and spectral irradiance. The specimen rack shall rotate at approximately 1 rpm.

5.1.3 TypeE—An exposure apparatus in which the source of radiant energy shall be three air-cooled xenon-arc lamps operating

simultaneously at a nominal 4500 watts each. The lamps shall be located within a central core, which shall be positioned at the

center of a 610-mm (24.1-in.) diameter specimen rack. Means shall be provided to control temperature, relative humidity, and

irradiance intensity. The specimen rack shall rotate around the light source.

NOTE 2—Type AH, Type BH, and Type E may not yield equivalent results.

5.2 Xenon Light Source—The xenon light source consists of a quartz-jacketed burner tube charged with xenon gas.

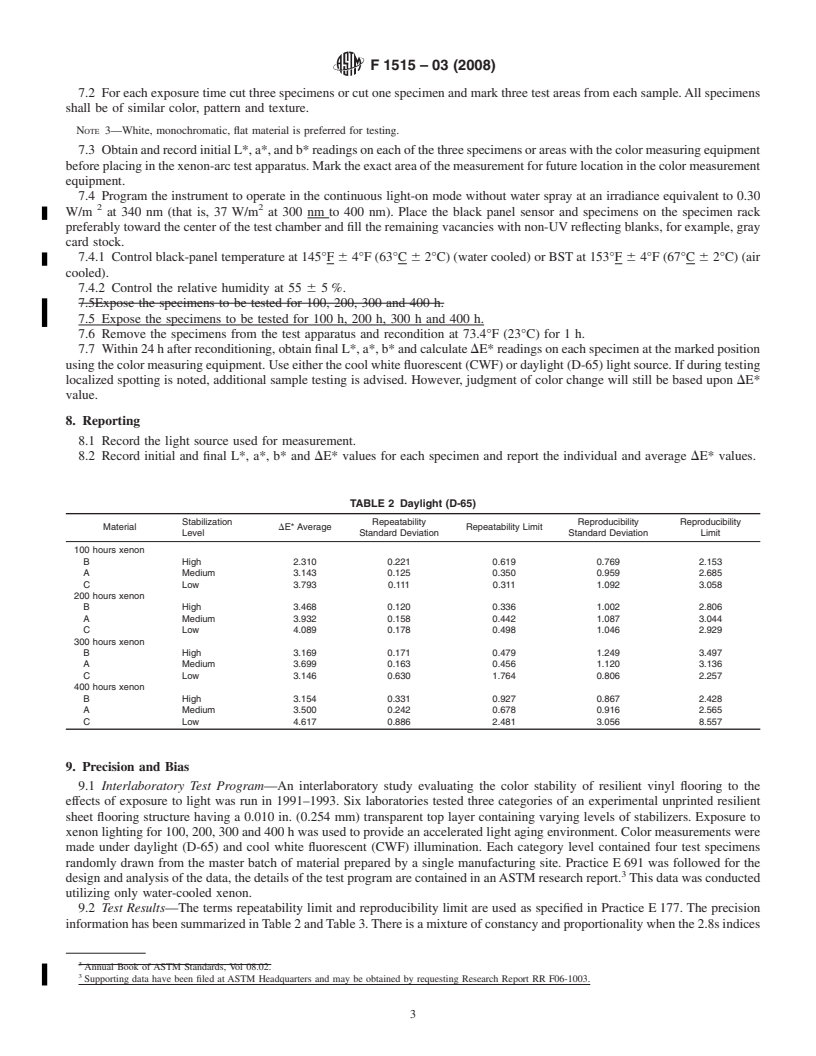

5.3 Glass Filters—Table 1 shows the relative spectral power distribution limits of xenon-arcs filtered for simulating a behind

window-glassexposure.Forwater-cooledxenon,aninnerborosilicate-glasscylinderisusedincombinationwithasoda-lime-glass

outer cylinder to selectively screen radiation output. For air-cooled xenon, the filters shall be an infrared (IR) reflecting inner glass

filter, quartz middle filter, and a soda-lime-glass outer filter.

5.4 Light Monitor—The light monitor shall be capable of measuring spectral irradiance at either 340 nm (water-cooled) or at

300–400 nm (air-cooled) incident to the specimen.

5.5 Black Panel Temperature (BPT) Sensor—Ablack-coated stainless steel panel, as specified in Practice G26G 155, should be

used as the standard reference to control test temperature. (Alternative devices such as the Black Standard Thermometer (BST)

described in DIN 53384 may be used. The BST equivalent to the BPT = 145°F (63°C) has been found to be approximately 153°F

(67°C)).

5.6 Asuitable spectrophotometer or colorimeter with a minimum 0.25-in. (6.35-mm) diameter opening having both cool white

fluorescent (CWF) and daylight (D-65) light sources that measure color in CIE L*, a*, b* using CIE 10° Standard Observer and

specular included. When an individual color cannot be totally covered within the 0.25 in. spectrophotometer opening,

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.