ASTM F1515-21

(Test Method)Standard Test Method for Measuring Light Stability of Resilient Flooring by Color Change

Standard Test Method for Measuring Light Stability of Resilient Flooring by Color Change

SIGNIFICANCE AND USE

4.1 Resilient floor covering is made by fusing polymer materials under heat or pressure, or both, in various manufacturing and decorating processes. The polymer material may be compounded with plasticizers, stabilizers, fillers, and other ingredients for processability and product performance characteristics. The formulation of the compound can be varied considerably depending on the desired performance characteristics and methods of processing.

4.2 Light stability, which is resistance to discoloration from light, is a basic requirement for functional use.

4.3 This test method provides a means of measuring the amount of color change in flooring products when subjected to accelerated light exposure over a period of time (functional use of the flooring product).

4.4 This test method specifies that a sample is measured by a spectrophotometer and expressed in ΔE* units before and after accelerated light exposure.

Note 2: It is the intent that this test method be used for testing light stability performance properties to be referenced in resilient flooring specifications.

SCOPE

1.1 This test method covers a procedure for determining the resistance of resilient floor covering to color change from exposure to light over a specified period of time.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.3 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: F1515 − 21

Standard Test Method for

Measuring Light Stability of Resilient Flooring by Color

1

Change

This standard is issued under the fixed designation F1515; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope butions: Hemispherical on 37° Tilted Surface

1.1 This test method covers a procedure for determining the

3. Summary of Practice

resistance of resilient floor covering to color change from

exposure to light over a specified period of time.

3.1 Specimens are exposed continuously at a controlled

1.2 This standard does not purport to address all of the temperature and humidity to a properly filtered xenon-arc

safety concerns, if any, associated with its use. It is the

radiant-energy source. The filters selected are to simulate

responsibility of the user of this standard to establish appro- indoor exposure conditions behind window glass. See Practice

priate safety, health, and environmental practices and deter-

D4459.

mine the applicability of regulatory limitations prior to use.

3.2 To ensure uniform exposure, periodic specimen reposi-

1.3 This international standard was developed in accor-

tioning is a good practice to reduce the variability in exposure

dance with internationally recognized principles on standard-

stresses experienced during the test interval.

ization established in the Decision on Principles for the

Development of International Standards, Guides and Recom-

NOTE 1—See Practice G151 for guidance on repositioning of speci-

mendations issued by the World Trade Organization Technical

mens.

Barriers to Trade (TBT) Committee.

3.3 The effect of radiation (actinic and thermal) on the

specimen shall be the color difference between the specimen

2. Referenced Documents

before and after exposure.

2

2.1 ASTM Standards:

D2244 Practice for Calculation of Color Tolerances and

4. Significance and Use

Color Differences from Instrumentally Measured Color

Coordinates 4.1 Resilient floor covering is made by fusing polymer

materials under heat or pressure, or both, in various manufac-

D4459 Practice for Xenon-Arc Exposure of Plastics In-

tended for Indoor Applications turing and decorating processes. The polymer material may be

E177 Practice for Use of the Terms Precision and Bias in compounded with plasticizers, stabilizers, fillers, and other

ASTM Test Methods ingredients for processability and product performance char-

E691 Practice for Conducting an Interlaboratory Study to acteristics. The formulation of the compound can be varied

Determine the Precision of a Test Method

considerably depending on the desired performance character-

G151 Practice for Exposing Nonmetallic Materials inAccel- istics and methods of processing.

erated Test Devices that Use Laboratory Light Sources

4.2 Light stability, which is resistance to discoloration from

G155 Practice for Operating XenonArc LightApparatus for

light, is a basic requirement for functional use.

Exposure of Non-Metallic Materials

G177 Tables for Reference Solar Ultraviolet Spectral Distri-

4.3 This test method provides a means of measuring the

amount of color change in flooring products when subjected to

acceleratedlightexposureoveraperiodoftime(functionaluse

1

ThistestmethodisunderthejurisdictionofASTMCommitteeF06onResilient

of the flooring product).

Floor Coverings and is the direct responsibility of Subcommittee F06.20 on Test

Methods.

4.4 This test method specifies that a sample is measured by

Current edition approved April 1, 2021. Published April 2021. Originally

a spectrophotometer and expressed in ∆E* units before and

approved in 1995. Last previous edition approved in 2015 as F1515 – 15. DOI:

after accelerated light exposure.

10.1520/F1515–21.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

NOTE 2—It is the intent that this test method be used for testing light

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on stability performance properties to be referenced in resilient flooring

the ASTM website. specifications.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F1515 − 21

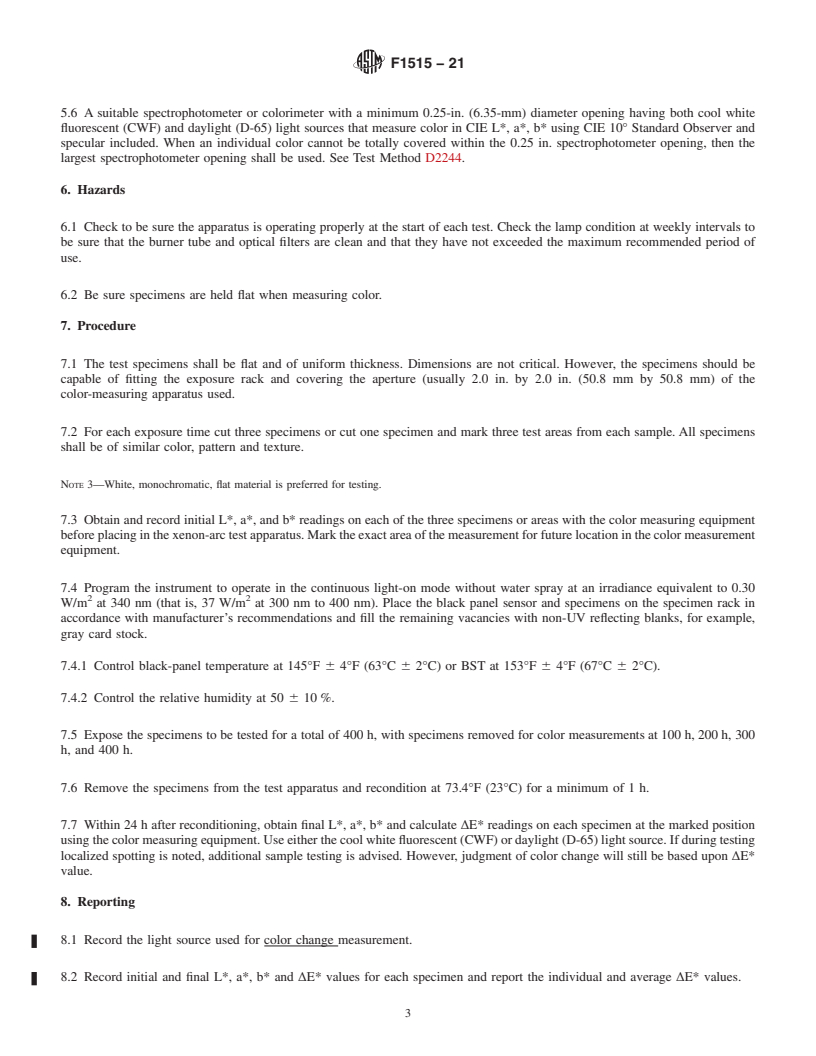

5. Apparatus should be capable of fitting the exposure rack and covering the

aperture (usually 2.0 in. by 2.0 in. (50.8 mm by 50.8 mm) of

5.1 The apparatus em

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: F1515 − 15 F1515 − 21

Standard Test Method for

Measuring Light Stability of Resilient Flooring by Color

1

Change

This standard is issued under the fixed designation F1515; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers a procedure for determining the resistance of resilient floor covering to color change from exposure

to light over a specified period of time.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of

regulatory limitations prior to use.

1.3 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

D2244 Practice for Calculation of Color Tolerances and Color Differences from Instrumentally Measured Color Coordinates

D4459 Practice for Xenon-Arc Exposure of Plastics Intended for Indoor Applications

E177 Practice for Use of the Terms Precision and Bias in ASTM Test Methods

E691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

G151 Practice for Exposing Nonmetallic Materials in Accelerated Test Devices that Use Laboratory Light Sources

G155 Practice for Operating Xenon Arc Light Apparatus for Exposure of Non-Metallic Materials

G177 Tables for Reference Solar Ultraviolet Spectral Distributions: Hemispherical on 37° Tilted Surface

3. Summary of Practice

3.1 Specimens are exposed continuously at a controlled temperature and humidity to a properly filtered xenon-arc radiant-energy

source. The filters selected are to simulate indoor exposure conditions behind window glass. See Practice D4459.

3.2 To ensure uniform exposure, periodic specimen repositioning is a good practice to reduce the variability in exposure stresses

experienced during the test interval.

NOTE 1—See Practice G151 for guidance on repositioning of specimens.

1

This test method is under the jurisdiction of ASTM Committee F06 on Resilient Floor Coverings and is the direct responsibility of Subcommittee F06.20 on Test Methods.

Current edition approved Dec. 15, 2015April 1, 2021. Published January 2016April 2021. Originally approved in 1995. Last previous edition approved in 20082015 as

F1515 – 03 (2008).F1515 – 15. DOI: 10.1520/F1515–15.10.1520/F1515–21.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F1515 − 21

3.3 The effect of radiation (actinic and thermal) on the specimen shall be the color difference between the specimen before and

after exposure.

4. Significance and Use

4.1 Resilient floor covering is made by fusing polymer materials under heat or pressure, or both, in various manufacturing and

decorating processes. The polymer material may be compounded with plasticizers, stabilizers, fillers, and other ingredients for

processability and product performance characteristics. The formulation of the compound can be varied considerably depending

on the desired performance characteristics and methods of processing.

4.2 Light stability, which is resistance to discoloration from light, is a basic requirement for functional use.

4.3 This test method provides a means of measuring the amount of color change in flooring products when subjected to accelerated

light exposure over a period of time (functional use of the flooring product).

4.4 This test method specifies that a sample is measured by a spectrophotometer and expressed in ΔE* units before and after

accelerated light exposure.

NOTE 2—It is the intent that this test method be used for testing light stability performance properties to be reference

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.