ASTM D848-09

(Test Method)Standard Test Method for Acid Wash Color of Industrial Aromatic Hydrocarbons

Standard Test Method for Acid Wash Color of Industrial Aromatic Hydrocarbons

SIGNIFICANCE AND USE

This test method is suitable for setting specifications on the materials referenced in 1.1. It may also be used as an internal quality control tool and in development or research work.

The color developed in the acid layer gives an indication of impurities which if sulfonated would cause the material to be discolored.

SCOPE

1.1 This test method covers the determination of the acid wash color of benzene, toluene, xylenes, refined solvent naphthas, and similar industrial aromatic hydrocarbons.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific hazard statements, see Sections 8 and 12.1.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D848 − 09

StandardTest Method for

1

Acid Wash Color of Industrial Aromatic Hydrocarbons

This standard is issued under the fixed designation D848; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope* 3. Terminology

3.1 SeeTerminology D4790 for definitions of terms used in

1.1 This test method covers the determination of the acid

this test method.

wash color of benzene, toluene, xylenes, refined solvent

naphthas, and similar industrial aromatic hydrocarbons.

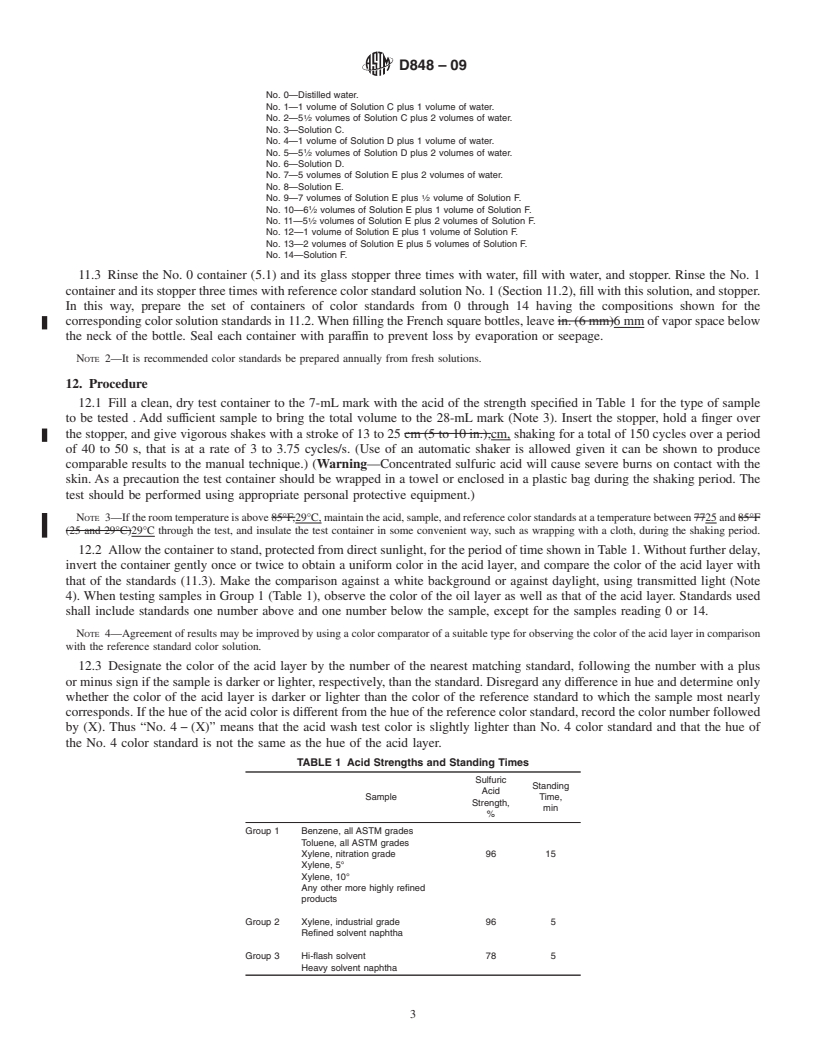

4. Summary of Test Method

1.2 The values stated in SI units are to be regarded as

4.1 Amixtureofthearomatichydrocarbonandsulfuricacid

standard. No other units of measurement are included in this

isvigorouslyshakenandthecoloroftheacidlayeriscompared

standard.

with that of color standards prepared from CoCl and FeCl .

2 3

1.3 This standard does not purport to address all of the

5. Significance and Use

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

5.1 This test method is suitable for setting specifications on

priate safety and health practices and determine the applica-

the materials referenced in 1.1. It may also be used as an

bility of regulatory limitations prior to use. For specific hazard

internal quality control tool and in development or research

statements, see Sections 8 and 12.1.

work.

5.2 Thecolordevelopedintheacidlayergivesanindication

2. Referenced Documents

of impurities which if sulfonated would cause the material to

2

2.1 ASTM Standards:

be discolored.

D1193Specification for Reagent Water

6. Apparatus

D3437Practice for Sampling and Handling Liquid Cyclic

Products

6.1 Containers for Color Standards—Clear and

D4790Terminology ofAromatic Hydrocarbons and Related

unblemished, clean, French square, flint-glass, flat-bottom,

Chemicals

glass-stoppered, 30-mL capacity bottles holding 31 to 33 mL

4

D6809Guide for Quality Control and Quality Assurance

when filled to the neck. The bottles shall be labeled with the

Procedures for Aromatic Hydrocarbons and Related Ma-

reference number of the color standard they contain (see 11.2).

terials

6.2 Test Containers—Containers exactly like those de-

3

2.2 Other Document:

scribed in 6.1 except that each French square bottle shall be

OSHA Regulations, 29 CFRparagraphs 1910.1000 and

marked by etching to show when the bottle contains the

1910.1200

volume of 7 and 28 mL, respectively. Colored crayons and

similar markers shall not be used for marking the bottles.

1 7. Reagents

This test method is under the jurisdiction of ASTM Committee D16 on

Aromatic Hydrocarbons and Related Chemicals and is the direct responsibility of

7.1 Purity of Reagents—Reagent grade chemicals shall be

Subcommittee D16.01 on Benzene, Toluene, Xylenes, Cyclohexane and Their

used in all tests. Unless otherwise indicated, it is intended that

Derivatives.

Current edition approved Dec. 1, 2009. Published January 2010. Originally all reagents shall conform to the specifications of the Commit-

approved in 1945. Last previous edition approved in 2003 as D848–03. DOI:

tee onAnalytical Reagents of theAmerican Chemical Society,

10.1520/D0848-09.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

4

Standards volume information, refer to the standard’s Document Summary page on The sole source of supply of the apparatus known to the committee at this time

the ASTM website. is Ramin USA Corporation, 39019 FM 149 Rd., Magnolia, TX 77354. If you are

3

AvailablefromU.S.GovernmentPrintingOfficeSuperintendentofDocuments, aware of alternative suppliers, please provide this information to ASTM Interna-

732 N. Capitol St., NW, Mail Stop: SDE, Washington, DC 20401, http:// tional Headquarters.Your comments will receive careful consideration at a meeting

1

www.access.gpo.gov. of the responsible technical committee, which you may attend.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D848 − 09

5

1

where such specifications are available. Other grades may be 11.1.3 Solution C—Mix 3 ⁄2 volumes of Solution A with

1

used provided it is first ascertained that the reagent is of 36 ⁄2 volumes of Solution B and dilute with 90 volumes of

sufficiently high purity to permit its use without lessening the water.

1

accuracy of

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:D848–03 Designation:D848–09

Standard Test Method for

1

Acid Wash Color of Industrial Aromatic Hydrocarbons

This standard is issued under the fixed designation D848; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope*

1.1 Thistestmethodcoversthedeterminationoftheacidwashcolorofbenzene,toluene,xylenes,refinedsolventnaphthas,and

similar industrial aromatic hydrocarbons.

1.2

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use. For specific hazard statements, see Sections 8 and 12.1.

2. Referenced Documents

2

2.1 ASTM Standards:

D1193 Specification for Reagent Water

D3437 Practice for Sampling and Handling Liquid Cyclic Products

D4790 Terminology of Aromatic Hydrocarbons and Related Chemicals Terminology of Aromatic Hydrocarbons and Related

Chemicals

D6809 Guide for Quality Control and Quality Assurance Procedures for Aromatic Hydrocarbons and Related Materials

2.2 Other Document:

3

OSHA Regulations. 29 CFR, paragraphs 1910.1000 and 1910.1200 Other Document:

OSHA Regulations, 29 CFR paragraphs 1910.1000 and 1910.1200

3. Terminology

3.1 See Terminology D4790 for definitions of terms used in this test method.

4. Summary of Test Method

4.1 Amixture of the aromatic hydrocarbon and sulfuric acid is vigorously shaken and the color of the acid layer is compared

with that of color standards prepared from CoCl and FeCl .

2 3

5. Significance and Use

5.1 This test method is suitable for setting specifications on the materials referenced in 1.1. It may also be used as an internal

quality control tool and in development or research work.

5.2 The color developed in the acid layer gives an indication of impurities which if sulfonated would cause the material to be

discolored.

6. Apparatus

6.1 Containers for Color Standards—Clear and unblemished, clean, French square, flint-glass, flat-bottom, glass-stoppered,

1

This test method is under the jurisdiction ofASTM Committee D16 onAromatic Hydrocarbons and Related Chemicals and is the direct responsibility of Subcommittee

D16.01 on Benzene, Toluene, Xylenes, Cyclohexane and Their Derivatives.

CurrenteditionapprovedJune10,2003.PublishedJuly2003.Originallyapprovedin1945.Lastpreviouseditionapprovedin2002asD848–02.DOI:10.1520/D0848-03.

Current edition approved Dec. 1, 2009. Published January 2010. Originally approved in 1945. Last previous edition approved in 2003 as D848–03. DOI:

10.1520/D0848-09.

2

ForreferencedASTMstandards,visittheASTMwebsite,www.astm.org,orcontactASTMCustomerServiceatservice@astm.org.For Annual Book of ASTM Standards

, Vol 11.01.volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Annual Book of ASTM Standards, Vol 06.04.

3

Available from U.S. Government Printing Office Superintendent of Documents, 732 N. Capitol St., NW, Mail Stop: SDE, Washington, DC 20401, http://

www.access.gpo.gov.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D848–09

4

1-oz30-mL capacity bottles holding 31 to 33 mL when filled to the neck. The bottles shall be labeled with the reference number

of the color standard they contain (see 11.2).

6.2 Test Containers—Containers exactly like those described in 6.1 except that each French square bottle shall be marked by

etching to show when the bottle contains the volume of 7 and 28 mL, respectively. Colored crayons and similar markers shall not

be used for marking the bottles.

7. Reagents

7.1 Purity of Reagents—Reagent grade chemicals shall be used in all tests. Unless otherwise indicated, it is intended that all

reagents shall conform to the specifications of the Committee on Analytical Reagents of the American Chemical Society, where

5

such specifications are available. Other grades may be used provi

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.