ASTM F1093-99(2023)

(Test Method)Standard Test Methods for Tensile Strength Characteristics of Oil Spill Response Boom

Standard Test Methods for Tensile Strength Characteristics of Oil Spill Response Boom

SIGNIFICANCE AND USE

5.1 Boom sections are frequently combined into assemblages hundreds of meters in length prior to towing through the water to a spill site. The friction of moving long boom assemblages through the water can impose high tensile stresses on boom segments near the tow vessel.

5.2 Tensile forces are also set up in a boom when it is being towed in a sweeping mode. The magnitude of this tensile force can be related to the immersed depth of the boom, the length of boom involved, the width of the bight formed by the two towing vessels, and the speed of movement.

Note 1: When the towing speed exceeds about 1 knot (0.5 m/s), substantial oil will be lost under the boom.

5.3 Knowledge of maximum and allowable working tensile stresses will help in the selection of boom for a given application and will permit specification of safe towing and anchoring conditions for any given boom.

SCOPE

1.1 These test methods cover static laboratory tests of the strength of oil spill response boom under tensile loading.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. For a specific hazard statement, see Section 7.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: F1093 − 99 (Reapproved 2023)

Standard Test Methods for

Tensile Strength Characteristics of Oil Spill Response

Boom

This standard is issued under the fixed designation F1093; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3.2.1 anchor point—a structural point on the end connector

or along the length of a boom section designed for the

1.1 These test methods cover static laboratory tests of the

attachment of anchor or mooring lines.

strength of oil spill response boom under tensile loading.

3.2.2 ballast—weight applied to the skirt to improve boom

1.2 The values stated in inch-pound units are to be regarded

performance.

as standard. The values given in parentheses are mathematical

3.2.3 boom section—the length of boom between two end

conversions to SI units that are provided for information only

connectors.

and are not considered standard.

3.2.4 boom segment—repetitive identical portion of the

1.3 This standard does not purport to address all of the

boom section.

safety concerns, if any, associated with its use. It is the

3.2.5 curtain-type boom—a boom consisting of a flexible

responsibility of the user of this standard to establish appro-

skirt supported by flotation. See Appendix X1.

priate safety, health, and environmental practices and deter-

mine the applicability of regulatory limitations prior to use.

3.2.6 end connector—a device permanently attached to the

For a specific hazard statement, see Section 7.

boom used for joining boom sections to one another or to other

1.4 This international standard was developed in accor-

accessory devices.

dance with internationally recognized principles on standard-

3.2.7 fence-type boom—a boom consisting of self-

ization established in the Decision on Principles for the

supporting or stiffened membrane supported by floatation. See

Development of International Standards, Guides and Recom-

Appendix X1.

mendations issued by the World Trade Organization Technical

3.2.8 float—that separable component of a boom that pro-

Barriers to Trade (TBT) Committee.

vides buoyancy.

3.2.9 freeboard—the vertical height of the boom above the

2. Referenced Documents

water line.

2.1 ASTM Standards:

3.2.10 hinge—location between boom segments at which

F818 Terminology Relating to Spill Response Booms and

the boom can be folded back 180° upon itself.

Barriers

3.2.11 skirt—the continuous portion of the boom below the

F962 Specification for Oil Spill Response Boom Connec-

floats.

tion: Z-Connector

3.2.12 tension member—any component which carries hori-

3. Terminology

zontal tension loads imposed on the boom.

3.1 The following definitions, quoted from Terminology

4. Summary of Test Method

F818, are used in these test methods.

4.1 A specimen of spill containment boom is tested by

3.2 Definitions:

subjecting the specimen to cyclic tests to 100 % of the

manufacturer’s rated tensile strength, and by applying tensile

loading which progressively deforms the specimen to the point

These test methods are under the jurisdiction of ASTM Committee F20 on

of failure. Similarly, a typical anchor point and towing device

Hazardous Substances and Oil Spill Response and are the direct responsibility of

are tested in an additional tensile test. For each phase of the

Subcommittee F20.11 on Control.

test, values of tensile load and deformation are observed and

Current edition approved May 1, 2023. Published May 2023. Originally

approved in 1991. Last previous edition approved in 2018 as F1093 – 99 (2018).

recorded, and modes of failure are described.

DOI: 10.1520/F1093-99R23.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

5. Significance and Use

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

5.1 Boom sections are frequently combined into assem-

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. blages hundreds of meters in length prior to towing through the

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F1093 − 99 (2023)

water to a spill site. The friction of moving long boom a precision equal or better than ⁄1000 th the distance between

assemblages through the water can impose high tensile stresses gage points (that is, 3 mm precision for 3 m gage point

on boom segments near the tow vessel. separation).

5.2 Tensile forces are also set up in a boom when it is being

6.7 Boom Specimens to be Tested—Equipment shall be

towed in a sweeping mode. The magnitude of this tensile force

arranged to apply tensile loading to a specimen consisting of at

can be related to the immersed depth of the boom, the length of

least two complete boom segments of standard length as

boom involved, the width of the bight formed by the two

supplied by the manufacturer. Boom segments of less than

towing vessels, and the speed of movement.

standard length may be used for this test provided that the

tension member length is proportional, the hinge area between

NOTE 1—When the towing speed exceeds about 1 knot (0.5 m/s),

them, the connector assemblies at each end, and the anchor

substantial oil will be lost under the boom.

point are fabricated identically to the manufacturer’s full size

5.3 Knowledge of maximum and allowable working tensile

standard boom section provided the total specimen is at least

stresses will help in the selection of boom for a given

10 ft (3 m) in length.

application and will permit specification of safe towing and

anchoring conditions for any given boom. 6.8 Alternative Apparatus—Because production lengths of

boom are normally longer than 15 ft and because undue stress

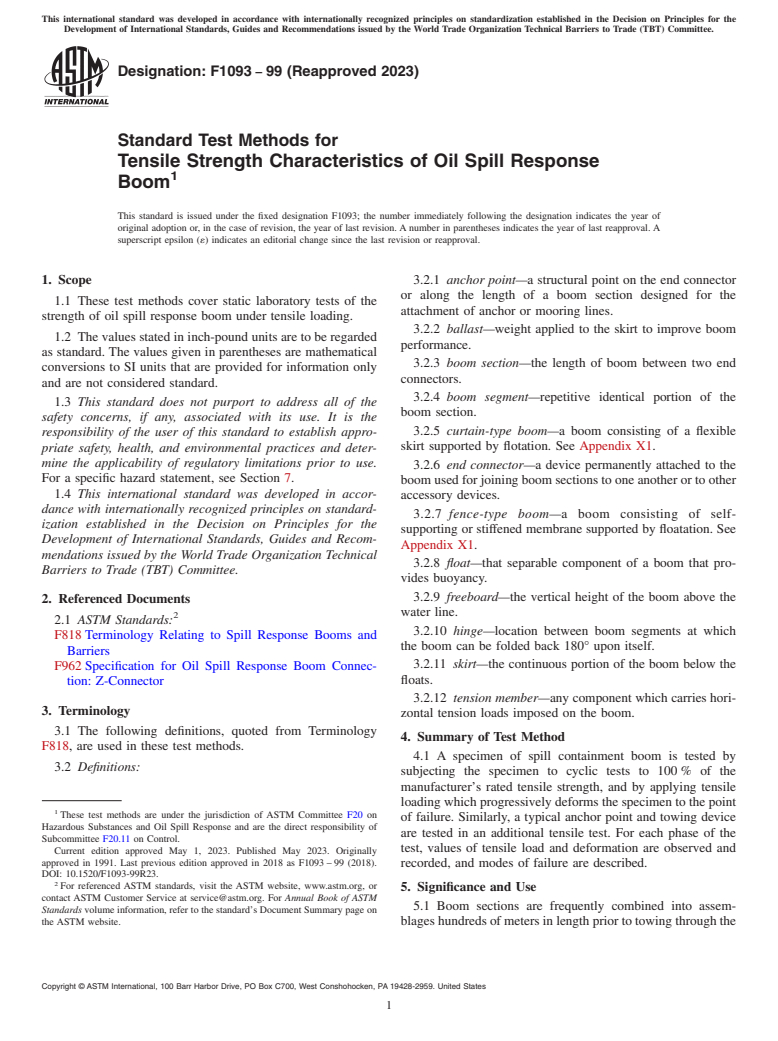

6. Apparatus due to gravity forces may be placed on such boom if tested

with the apparatus described above, the following described

6.1 Load Application Device—A suitable load application

apparatus may be substituted. Test apparatus which lays the

device, such as a hydraulic jack, shall be provided. The device

boom in a horizontal and continuously supported manner or

must be capable of applying loads somewhat in excess of the

one which provides support similar to that provided by the

predicted failure load on the boom.

water (that is, a split table supporting the boom in an upright

6.2 Tensiometer—A tensiometer shall be selected which will

manner) will be satisfactory.

encompass the range of values from no load up to the

maximum boom tensile load which might reasonably be

7. Hazards

expected prior to failure of the boom.

7.1 Failure of a loaded containment boom can release a

6.3 End Supports—The test bed provided shall have end

substantial amount of energy. During testing, personnel and

supports of sufficient strength and rigidity to resist significant

equipment shall be positioned and protected so that sudden

deformation under the maximum loads expected during testing.

failure of the test specimen is unlikely to cause injury or

6.4 Towing Devices and Connectors—At least one of the

damage.

manufacturer’s standard tow bridles or towing devices shall be

used at the leading end of the boom specimen (where the load

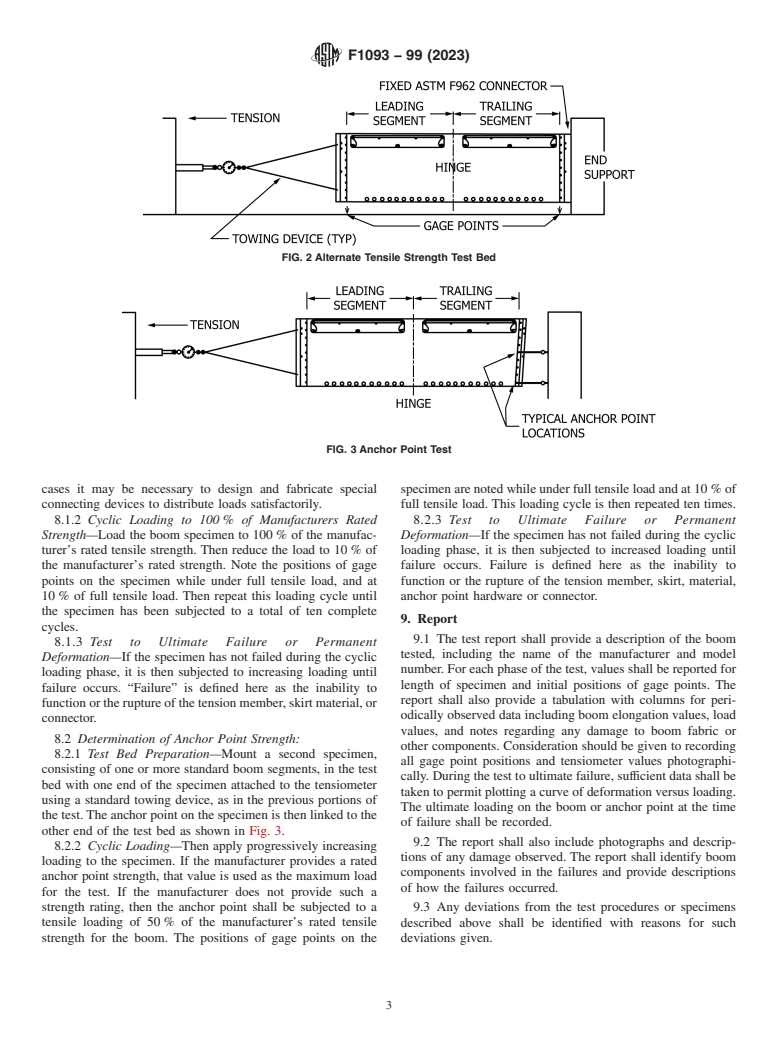

8. Procedure

is applied). A similar tow bridle or towing device shall be used

8.1 Determination of Boom Tensile Strength:

at the trailing end if the test apparatus is long enough.

8.1.1 Test Bed Preparation—Prepare a test bed with two end

However, if it is not, the connector at the trailing end of the

supports separated with sufficient cleara

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.