ASTM D1125-95(1999)

(Test Method)Standard Test Methods for Electrical Conductivity and Resistivity of Water

Standard Test Methods for Electrical Conductivity and Resistivity of Water

SCOPE

1.1 These test methods cover the determination of the electrical conductivity and resistivity of water. The following test methods are included: Range Sections Test Method A-Field and Routine Laboratory 10 to 200 000 12 to 18 Measurement of Static (Non-Flowing) Samples

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation:D 1125–95 (Reapproved 1999)

Standard Test Methods for

Electrical Conductivity and Resistivity of Water

This standard is issued under the fixed designation D 1125; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope Exchange and Degassed Cation Conductivity

D5391 Test Method for Electrical Conductivity and Resis-

1.1 These test methods cover the determination of the

tivity of a Flowing High Purity Water Sample

electrical conductivity and resistivity of water. The following

E1 Specification for ASTM Thermometers

test methods are included:

Range Sections

3. Terminology

Test Method A—Field and Routine Laboratory 10 to 200 000 12 to 18

Measurement of Static (Non-Flowing) µS/cm

3.1 Definitions:

Samples

3.1.1 electrical conductivity—the reciprocal of the a-c re-

Test Method B—Continuous In-Line Measure 5 to 200 000 19 to 23

sistance in ohms measured between opposite faces of a

ment µ S/cm

centimetre cube of an aqueous solution at a specified tempera-

1.2 These test methods have been tested in reagent water. It

ture.

is the user’s responsibility to ensure the validity of these test

methods for waters of untested matrices. NOTE 1—The unit of electrical conductivity is siemens per centimetre.

(The previously used units of mhos/cm are numerically equivalent to

1.3 For measurements below the range of these test meth-

S/cm.) The actual resistance of the cell, R , is measured in ohms. The

x

ods, refer to Test Method D5391.

conductance, 1/R , is directly proportional to the cross-sectional area, A

x

1.4 This standard does not purport to address all of the

(in cm ), and inversely proportional to the length of the path, L (in cm):

safety concerns, if any, associated with its use. It is the

1/R 5 K·A/L

x

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica- The conductance measured between opposite faces of a

centimetre cube, K, is called conductivity. Conductivity values

bility of regulatory limitations prior to use.

are usually expressed in microsiemens/centimetre or in

2. Referenced Documents

siemens/centimetre at a specified temperature, normally 25°C.

3.1.2 electrical resistivity—the a-c resistance in ohms mea-

2.1 ASTM Standards:

D1066 Practice for Sampling Steam sured between opposite faces of a centimetre cube of an

aqueous solution at a specified temperature.

D1129 Terminology Relating to Water

D1192 Specification for Equipment for Sampling Water

NOTE 2—Theunitofelectricalresistivityisohm-centimetre.Theactual

and Steam in Closed Conduits

resistanceofthecell, R ,ismeasuredinohms,andisdirectlyproportional

x

D1193 Specification for Reagent Water

to the length of the path, L (in cm), and inversely proportional to the

D2186 Test Method for Deposit-Forming Impurities in

cross-sectional area, A (in cm ):

Steam

R 5 R·L/A

x

D2777 Practice for Determination of Precision and Bias of

The resistance measured between opposite faces of a centi-

Applicable Methods of Committee D-19 on Water

metre cube, R, is called resistivity. Resistivity values are

D3370 Practices for Sampling Water from Closed Con-

usually expressed in ohm·centimetre, or in megohm · centime-

duits

tre, at a specified temperature, normally 25°C.

D4519 Test Method for On-Line Determination of Anions

3.1.3 For definitions of other terms used in these methods,

and Carbon Dioxide in High Purity Water by Cation

refer to Terminology D1129.

3.2 Symbols:Symbols:

3.2.1 Symbols used in the equations in Sections 14 and 16

These test methods are under the jurisdiction of Committee D19 on Water and

are defined as follows:

−1

are the direct responsibility of Subcommittee D19.03 on Sampling of Water and

J =cell constant, cm ,

Water-Formed Deposits, Surveillance of Water, and Flow Measurement of Water.

Current edition approved Oct. 10, 1995. Published December 1995. Originally

published as D1125–50 T. Last previous edition D1125–91.

Annual Book of ASTM Standards, Vol 11.01.

3 4

Annual Book of ASTM Standards, Vol 11.02. Annual Book of ASTM Standards, Vol 14.03.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D 1125–95 (1999)

A

TABLE 1 Electrical Conductivity Values Assigned to the Potassium Chloride in the Reference Solution

Approximate Electrical

Reference Tempera-

Normality of Method of Preparation Conductivity,

Solution ture, °C

Solution µS/cm

A 1 74.2460 g of KCl weighed in air per 1 L of 0 65 176

solution at 20°C 18 97 838

25 111 342

B 0.1 7.4365 g of KCl weighed in air per 1 L of 0 7 138

solution at 20°C 18 11 167

25 12 856

C 0.01 0.7440 g of KCl weighed in air per 1 L of 0 773.6

solution at 20°C 18 1 220.5

25 1 408.8

B

D 0.001 Dilute 100 mL of Solution C to 1 L at 20°C 0 77.69

B

18 127.54

25 146.93

A

Excluding the conductivity of the water used to prepare the solutions. (See 7.2 and Section 14.) These tabulated conductivity values are in international units. When

using measuring instruments calibrated in absolute units, multiply the tabular values by 0.999505.

B

From Glasstone (13).

K =conductivity at 25°C, µS/cm, 5.2 Undissolved or slowly precipitating materials in the

K =measured conductance, S, samplecanformacoatingontheelectrodesoftheconductivity

x

K =conductivity of the KCl in the reference solution at the

cell that may cause erroneous readings. For example, biofoul-

temperature of measurement (Table 1), µS/cm,

ing of the cell or a build-up of filming amines may cause poor

K =conductivity of the water used to prepare the reference

cell response. In most cases these problems can be eliminated

solution, at the same temperature of measurement, µS/cm,

by washing the cells with appropriate solvents.

Q =temperature correction factor (see Section 11),

5.3 If an unshielded cell is used to measure the resistivity/

R =resistivity at 25°C, ohm · cm,

conductivity of high resistivity water there is a possibility of

R =measured resistance, ohm.

x

electrical pickup causing erroneous reading. For this reason it

is recommended that conductivity cells for this application be

4. Significance and Use

of coaxial shielded type or equivalent, and that the cables and

4.1 These test methods are applicable for such purposes as

instrument also be shielded.

impurity detection and, in some cases, the quantitative mea-

surement of ionic constituents dissolved in waters. These

6. Apparatus

include dissolved electrolytes in natural and treated waters,

6.1 Measuring Circuit—The instrument may be a manually

suchasboilerwater,boilerfeedwater,coolingwater,andsaline

operated wheatstone bridge or the equivalent, or a direct

and brackish water.

reading analog or digital meter. Instruments shall energize the

4.1.1 Their concentration may range from trace levels in

conductivitycellwithalternatingcurrentand,togetherwiththe

pure waters (1) to significant levels in condensed steam (see

cell and any extension leadwire, shall be designed to reduce

Test Methods D2186 and D4519, and Ref (2)), or pure salt

errors from the following sources:

solutions.

6.1.1 In highly conductive solutions—Uncompensated elec-

4.1.2 Where the principal interest in the use of conductivity

trode polarization due to excessive current density at the

methods is to determine steam purity, see Ref (3). These test

electrode surfaces can cause negative conductivity errors.

methods may also be used for checking the correctness of

Insufficient series capacitance at the electrode/solution inter-

water analyses (4).

face can allow charging effects to distort the a-c measurement

5. Interferences and cause errors if not compensated. Leadwire resistance can

add significantly to the measured resistance.

5.1 Exposure of a sample to the atmosphere may cause

6.1.2 In low conductivity solutions—Excessive parallel ca-

changes in conductivity/resistivity, due to loss or gain of

pacitance in the cell and extension leadwire can shunt the

dissolvedgases.Thisisextremelyimportantinthecaseofvery

measurement and cause positive conductivity errors. Tempera-

pure waters with low concentrations of dissolved ionized

ture compensation errors can be significant below 5 µS/cm if

materials. The carbon dioxide, normally present in the air, can

variable coefficient algorithms are not employed as described

drasticallyincreasetheconductivityofpurewatersbyapproxi-

in Test Method D5391.

mately 1 µS/cm. Contact with air should be avoided by using

flow-through or in-line cell where feasible. Chemically pure

6.1.3 These sources of error are minimized by an appropri-

inert gases, such as nitrogen or helium, may be used to blanket

ate combination of a-c drive voltage, wave shape, frequency,

the surface of samples.

phase correction, wave sampling technique and temperature

compensationdesignedinbytheinstrumentmanufacturer.The

instrument manufacturer’s recommendations shall be followed

5 in selecting the proper cell constant, leadwire size, and length

Theboldfacenumbersinparenthesesrefertothelistofreferencesattheendof

these test methods. and maintenance of the electrode surface condition for the

D 1125–95 (1999)

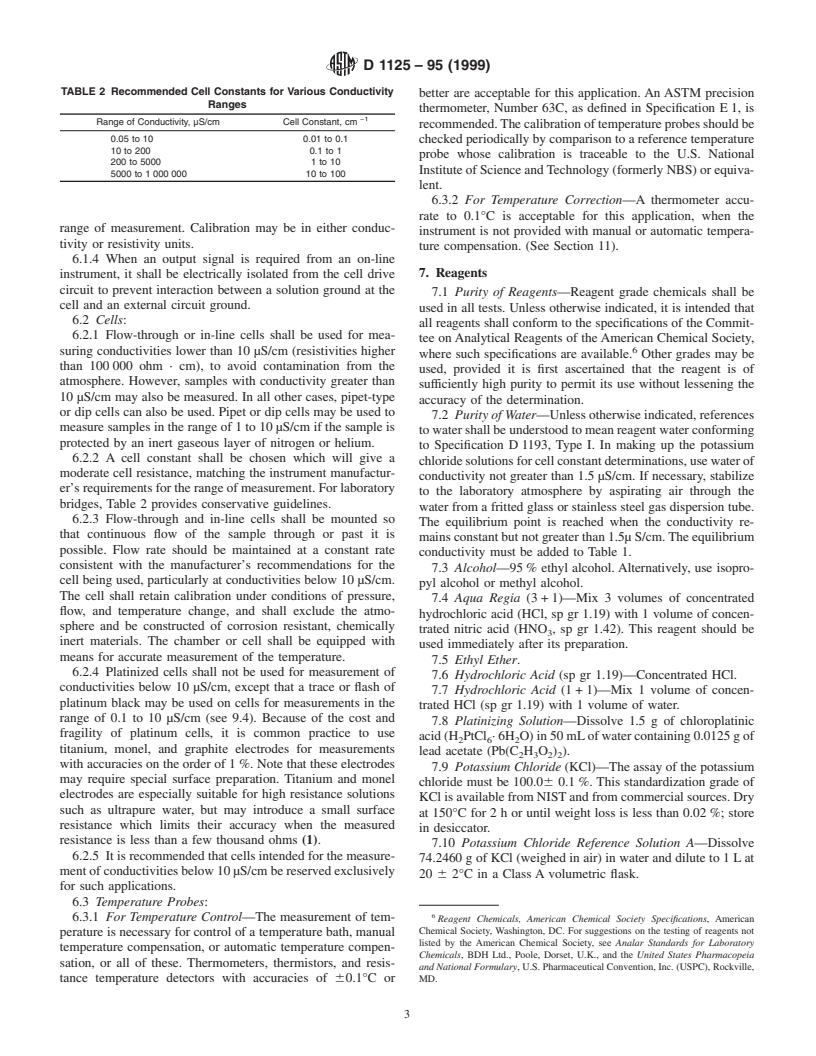

TABLE 2 Recommended Cell Constants for Various Conductivity

better are acceptable for this application. An ASTM precision

Ranges

thermometer, Number 63C, as defined in Specification E1, is

−1

Range of Conductivity, µS/cm Cell Constant, cm

recommended.Thecalibrationoftemperatureprobesshouldbe

0.05 to 10 0.01 to 0.1

checkedperiodicallybycomparisontoareferencetemperature

10 to 200 0.1 to 1

probe whose calibration is traceable to the U.S. National

200 to 5000 1 to 10

InstituteofScienceandTechnology(formerlyNBS)orequiva-

5000 to 1 000 000 10 to 100

lent.

6.3.2 For Temperature Correction—A thermometer accu-

rate to 0.1°C is acceptable for this application, when the

range of measurement. Calibration may be in either conduc-

instrument is not provided with manual or automatic tempera-

tivity or resistivity units.

ture compensation. (See Section 11).

6.1.4 When an output signal is required from an on-line

7. Reagents

instrument, it shall be electrically isolated from the cell drive

circuit to prevent interaction between a solution ground at the

7.1 Purity of Reagents—Reagent grade chemicals shall be

cell and an external circuit ground.

used in all tests. Unless otherwise indicated, it is intended that

6.2 Cells:

all reagents shall conform to the specifications of the Commit-

6.2.1 Flow-through or in-line cells shall be used for mea-

tee onAnalytical Reagents of theAmerican Chemical Society,

suring conductivities lower than 10 µS/cm (resistivities higher

where such specifications are available. Other grades may be

than 100000 ohm · cm), to avoid contamination from the

used, provided it is first ascertained that the reagent is of

atmosphere. However, samples with conductivity greater than

sufficiently high purity to permit its use without lessening the

10 µS/cm may also be measured. In all other cases, pipet-type

accuracy of the determination.

or dip cells can also be used. Pipet or dip cells may be used to

7.2 Purity of Water—Unlessotherwiseindicated,references

measure samples in the range of 1 to 10 µS/cm if the sample is

towatershallbeunderstoodtomeanreagentwaterconforming

protected by an inert gaseous layer of nitrogen or helium.

to Specification D1193, Type I. In making up the potassium

6.2.2 A cell constant shall be chosen which will give a

chloridesolutionsforcellconstantdeterminations,usewaterof

moderate cell resistance, matching the instrument manufactur-

conductivity not greater than 1.5 µS/cm. If necessary, stabilize

er’srequirementsfortherangeofmeasurement.Forlaboratory

to the laboratory atmosphere by aspirating air through the

bridges, Table 2 provides conservative guidelines.

water from a fritted glass or stainless steel gas dispersion tube.

6.2.3 Flow-through and in-line cells shall be mounted so

The equilibrium point is reached when the conductivity re-

that continuous flow of the sample through or past it is

mainsconstantbutnotgreaterthan1.5µS/cm.Theequilibrium

possible. Flow rate should be maintained at a constant rate

conductivity must be added to Table 1.

consistent with the manufacturer’s recommendations for the

7.3 Alcohol—95% ethyl alcohol.Alternatively, use isopro-

cell being used, particularly at conductivities below 10 µS/cm.

pyl alcohol or methyl alcohol.

The cell shall retain calibration under conditions of pressure,

7.4 Aqua Regia (3+1)—Mix 3 volumes of concentrated

flow, and temperature change, and shall exclude the atmo-

hydrochloric acid (HCl, sp gr 1.19) with 1 volume of concen-

sphere and be constructed of corrosion resistant, chemically

trated nitric acid (HNO , sp gr 1.42). This reagent should be

inert materials. The chamber or cell shall be equipped with

used immediately after its preparation.

means for accurate measurement of the temperature.

7.5 Ethyl Ether.

6.2.4 Platinized cells shall not be used for measurement of

7.6 Hydrochloric Acid (sp gr 1.19)—Concentrated HCl.

conductivities below 10 µS/cm, except that a trace or flash of

7.7 Hydrochloric Acid (1+1)—Mix 1 volume of concen-

platinum black may be used on cells for measurements in the

trated HCl (sp gr 1.19) with 1 volume of water.

range of 0.1 to 10 µS/cm (see 9.4). Because of the cost and

7.8 Platinizing Solution—Dissolve 1.5 g of chloroplatinic

fragility of platinum cells, it is common practice to use

acid(H PtCl ·6H O)in50mLofwatercontaining0.0125gof

2 6 2

titanium, monel, and graphite electrodes for measurements

lead acetate (Pb(C H O ) ).

2 3 2 2

with accuracies on the order of 1%. Note that these electrodes

7.9 Potassium Chloride (KCl)—The assay of the potassium

may require special surface preparation. Titanium and monel

chloride must be 100.06 0.1%. This standardization grade of

electrodes are especially suitable for high resistance solutions

KClisavailablefromNISTandfromcommercialsources.Dry

such as ultrapure water, but may introduce a small surface

at 150°C for 2 h or until weight loss is less than 0.02%; store

resistance which limits their accuracy when the measured

in desiccator.

resistance is less than a few thousand ohms (1).

7.10 Potassium Chloride Reference Solution A—Dissolve

6.2.5 Itisrecommendedthatcellsintendedforthemeasure-

74.2460 g of KCl (weighed in air) in water and dilute to 1 Lat

mentofconductivitiesbelow10µS/cmbereservedexclusively

20 6 2°C in a Class A volumetric flask

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.