ASTM D6783-03

(Specification)Standard Specification for Polymer Concrete Pipe

Standard Specification for Polymer Concrete Pipe

SCOPE

1.1 This specification covers polymer concrete pipe, 6 in. (150 mm) through 144 in. (3 660 mm), intended for use in gravity-flow systems for conveying sanitary sewage, storm water, and industrial wastes.

Note 1—There is no similar or equivalent ISO standard.

1.2 Although this specification is suited primarily for pipe to be installed by direct burial and pipe jacking, it may be used to the extent applicable for other installations such as sliplining and rehabilitation of existing pipelines.

Note 2—Unlike reinforced thermosetting resin pipes, polymer concrete pipe is designed and installed using rigid pipe design theory and practices.

1.3 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 The following safety hazards caveat pertains only to the test methods portion, Section 8, of this specification. This standard may involve hazardous materials, operations, and equipment. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory requirements prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation: D 6783 – 03

Standard Specification for

1

Polymer Concrete Pipe

This standard is issued under the fixed designation D 6783; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

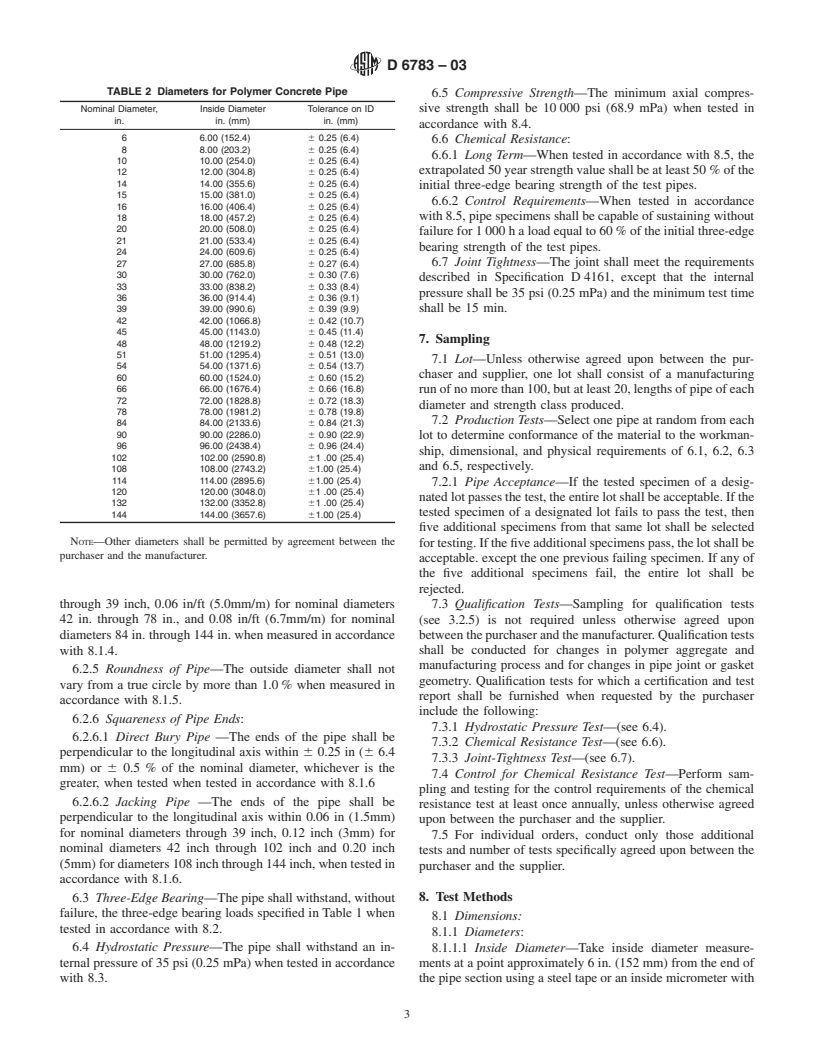

1. Scope C 579 Test Method for Compressive Strength of Chemical-

Resistant Mortars, Grouts, Monolithic Surfacings and

1.1 This specification covers polymer concrete pipe, 6 in.

4

Polymer Concretes

(150 mm) through 144 in. (3 660 mm), intended for use in

D 648 Test Method for Deflection Temperature of Plastics

gravity-flow systems for conveying sanitary sewage, storm

5

Under Flexural Load in the Edgewise Position

water, and industrial wastes.

5

D 883 Terminology Relating to Plastics

NOTE 1—There is no similar or equivalent ISO standard.

D 1600 Terminology for Abbreviated Terms Relating to

5

1.2 Althoughthisspecificationissuitedprimarilyforpipeto Plastics

be installed by direct burial and pipe jacking, it may be used to D 2584 Test Method for Ignition Loss of Cured Reinforced

6

the extent applicable for other installations such as sliplining Resins

and rehabilitation of existing pipelines. D 3567 Practice for Determining Dimensions of “Fiber-

glass” (Glass-Fiber-Reinforced-Thermosetting-Resin)

NOTE 2—Unlike reinforced thermosetting resin pipes, polymer con-

7

Pipe and Fittings

crete pipe is designed and installed using rigid pipe design theory and

D 3681 Test Method for Chemical Resistance of “Fiber-

practices.

glass” (Glass-Fiber-Reinforced-Thermosetting-Resin)

1.3 The values stated in inch-pound units are to be regarded

7

Pipe in a Deflected Condition

as the standard. The values given in parentheses are for

6

D 3892 Practice for Packaging/Packing of Plastics

information only.

D 4161 Specification for “Fiberglass” (Glass-Fiber-

1.4 The following safety hazards caveat pertains only to the

Reinforced-Thermosetting-Resin) Pipe Joints Using Flex-

test methods portion, Section 8, of this specification. This

7

ible Elastomeric Seals

standard may involve hazardous materials, operations, and

7

F 412 Terminology Relating to Plastic Piping Systems

equipment. This standard does not purport to address all of the

F 477 Specification for Elastomeric Seals (Gaskets) for

safety concerns, if any, associated with its use. It is the

7

Joining Plastic Pipe

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

3. Terminology

bility of regulatory requirements prior to use.

3.1 Definitions—Unless otherwise indicated, definitions are

in accordance with Terminologies C 125, D 883, and F 412,

2. Referenced Documents

and abbreviations are in accordance withTerminology D 1600.

2.1 ASTM Standards:

3.2 Definitions of Terms Specific to This Standard:

2

A 276 Specification for Stainless Steel Bars and Shapes

3.2.1 aggregate, n—a granular material, such as sand,

3

C 33 Specification for Concrete Aggregates

gravel, or crushed stone, in accordance with to the require-

C 117 Test Method for Materials Finer than 75 µm (No.

ments of Specification C 33 except that the requirements for

4

200) Sieve in Mineral Aggregates by Washing

gradation shall not apply.

C 125 Terminology Relating to Concrete and Concrete

3.2.2 pipe jacking, n—a system of directly installing pipes

4

Aggregates

behind a shield machine by hydraulic jacking from a drive

C 136 Test Method for Sieve Analysis of Fine and Coarse

shaft, such that the pipes form a continuous string in the

4

Aggregates

ground.

3.2.3 polymer concrete, n—a composite material that con-

sists essentially of a thermosetting resin within which are

1

This specification is under the jurisdiction of ASTM Committee D20 on

embedded particles or fragments of aggregate.

Plastics and is the direct responsibility of Subcommittee D20.23 on Reinforced

Plastic Piping Systems and Chemical Equipment.

Current edition approved July 10, 2003. Published August 2003. Originally

approved in 2002. Last previous edition approved in 2002 as D6783–02.

2 5

Annual Book of ASTM Standards, Vol 01.03. Annual Book of ASTM Standards, Vol 08.01.

3 6

Annual Book of ASTM Standards, Vol 04.02. Annual Book of ASTM Standards, Vol 08.02.

4 7

Annual Book of ASTM Standards, Vol 04.05. Annual Book of ASTM Standards, Vol 08.04.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D6783–03

3.2.4 polymer concrete pipe, n—tubular product containing

aggregate, embedded in or surrounded by cured thermosetting

resin, which may also contain granular or platelet fil

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.