ASTM D4027-98(2011)

(Test Method)Standard Test Method for Measuring Shear Properties of Structural Adhesives by the Modified-Rail Test

Standard Test Method for Measuring Shear Properties of Structural Adhesives by the Modified-Rail Test

SIGNIFICANCE AND USE

Structural design based on strength of materials principles or the theory of elasticity requires knowledge of the mechanical properties of the structural components, including adhesives. By the nature of their use, the most important adhesive properties are shear modulus and shear strength. A torsion test, such as described in Test Method E229, is theoretically the most accurate method for measuring adhesive shear properties. It is, however, impractical in many situations. For example, certain materials of construction are not readily adaptable to fabricating the thin-walled cylinders used as adherends in the torsion test. The modified-rail test does not have this disadvantage.

Two undesirable conditions occur in the modified-rail test specimens that do not occur in butt-joined cylinders; nonuniform shear-stress distribution along the joint, and the addition of some undefined combination of tension and compression stresses to the shear stress at a given location in the joint. The modified-rail shear tool minimizes but does not eliminate these undesirable effects.

Shear modulus, strength, and other properties are measured by the modified-rail method.

SCOPE

1.1 This test method describes equipment and procedures to measure the shear modulus and shear strength of adhesive layers between rigid adherends. The equipment may also be used for determining the adhesive's shear creep compliance, the effects of strain history such as cyclic loading upon shear properties, and a failure criteria for biaxial stress conditions such as shear plus tension and shear plus compression.

1.2 High-density wood shall be the preferred substrate. The practical upper limit on the shear modulus that can be measured is determined by the shear modulus of the adherends and by the strain measuring device. Thus, the practical limit of adhesive shear modulus that can be measured using high-density wood adherends is about 690 MPa (1 × 105 psi).

Note 1—Wood-base composites, metal, plastic, reinforced plastics, and other common construction materials may also be used for adherends.

1.3 The range of specimen dimensions that can be tested are: width 1.59 to 12.70 mm (0.0625 to 0.500 in.), length 102 to 203 mm (4 to 8 in.), and adherend thickness 13 to 25 mm (0.50 to 1.00 in.). The standard specimen dimensions shall be: width 3.18 mm (0.125 in.), length 203 mm (8 in.), and adherend thickness 19 mm (0.75 in.). Bondline thicknesses from 0.15 to 3.18 mm (0.006 to 0.125 in.) may be tested.

1.4 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D4027 −98 (Reapproved 2011)

Standard Test Method for

Measuring Shear Properties of Structural Adhesives by the

Modified-Rail Test

This standard is issued under the fixed designation D4027; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

2.1 ASTM Standards:

1.1 Thistestmethoddescribesequipmentandproceduresto

D905Test Method for Strength Properties of Adhesive

measure the shear modulus and shear strength of adhesive

Bonds in Shear by Compression Loading

layers between rigid adherends. The equipment may also be

D907Terminology of Adhesives

used for determining the adhesive’s shear creep compliance,

D4442Test Methods for Direct Moisture Content Measure-

the effects of strain history such as cyclic loading upon shear

ment of Wood and Wood-Based Materials

properties, and a failure criteria for biaxial stress conditions

E83Practice for Verification and Classification of Exten-

such as shear plus tension and shear plus compression.

someter Systems

1.2 High-density wood shall be the preferred substrate. The

E229Test Method for Shear Strength and Shear Modulus of

practical upper limit on the shear modulus that can be

Structural Adhesives (Withdrawn 2003)

measuredisdeterminedbytheshearmodulusoftheadherends

and by the strain measuring device.Thus, the practical limit of

3. Terminology

adhesive shear modulus that can be measured using high-

3.1 Definitions:

density wood adherends is about 690 MPa (1×10 psi).

3.1.1 Many terms in this test method are defined in Termi-

NOTE1—Wood-basecomposites,metal,plastic,reinforcedplastics,and

nology D907.

other common construction materials may also be used for adherends.

3.1.2 shear modulus, n—the ratio of shear stress to corre-

1.3 The range of specimen dimensions that can be tested

sponding shear strain below the proportional limit. (Compare

are: width 1.59 to 12.70 mm (0.0625 to 0.500 in.), length 102 secant modulus.)

to 203 mm (4 to 8 in.), and adherend thickness 13 to 25 mm

3.1.2.1 Discussion—The term shear modulus is generally

(0.50 to 1.00 in.). The standard specimen dimensions shall be:

reserved for materials that exhibit linear elastic behavior over

width 3.18 mm (0.125 in.), length 203 mm (8 in.), and

most of their stress-strain diagram. Many adhesives exhibit

adherend thickness 19 mm (0.75 in.). Bondline thicknesses

curvilinear or nonelastic behavior, or both, in which case some

from 0.15 to 3.18 mm (0.006 to 0.125 in.) may be tested.

other term, such as secant modulus, may be substituted.

3.1.3 shear strain, n—thetangentoftheangularchange,due

1.4 The values stated in SI units are to be regarded as the

to force between two lines originally perpendicular to each

standard. The values given in parentheses are for information

other through a point in the body.

only.

3.1.3.1 Discussion—Shear strain equals adherend slip/

1.5 This standard does not purport to address all of the

adhesive layer thickness.

safety concerns, if any, associated with its use. It is the

3.1.4 shear strength, n—in an adhesive joint, the maximum

responsibility of the user of this standard to establish appro-

average stress when a force is applied parallel to the joint.

priate safety and health practices and determine the applica-

3.1.4.1 Discussion—In most adhesive test methods, the

bility of regulatory limitations prior to use.

shearstrengthisactuallythemaximumaveragestressatfailure

ofthespecimen,notnecessarilythetruemaximumstressinthe

material.

This test method is under the jurisdiction of ASTM Committee D14 on

Adhesives and is the direct responsibility of Subcommittee D14.70 on Construction

Adhesives.

Current edition approved Jan. 1, 2011. Published January 2011. Originally For referenced ASTM standards, visit the ASTM website, www.astm.org, or

approved in 1981. Last previous edition approved in 2004 as D4027–98(2004). contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

DOI: 10.1520/D4027-98R11. Standards volume information, refer to the standard’s Document Summary page on

Kreuger, G. P., “Tests for the Shear Properties of Adhesives in Adherend- the ASTM website.

Adhesive Assemblies,” Unpublished report. Michigan Technological Institute, The last approved version of this historical standard is referenced on

Houghton, MI. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D4027−98 (2011)

FIG. 1Top, Side, and End Views of the Modified-Rail Shear Apparatus

3.2 Definitions of Terms Specific to This Standard: 3.2.7.1 Discussion—This term differs from that of the

3.2.1 load, n—the force applied to the specimen at any

stress-strain diagram in that load and slip are not divided by

given time. bond area and bond thickness (the constants that convert load

to stress and slip to strain). In actual practice, stress-strain

3.2.2 load-slip diagram, n—adiagraminwhichcorrespond-

information is generally collected in the form of a load-slip

ing values of load and slip are plotted against each other.

diagram for ease in plotting.

Values of load are usually plotted as ordinates and values of

slip as abscissas.

3.2.8 stress–strain diagram, n—a diagram in which corre-

3.2.3 normal stress, n—the stress component perpendicular

sponding values of stress and strain are plotted against each

to a plane on which the forces act, that is, perpendicular to the

other. Values of stress are usually plotted as ordinates (verti-

plane of the bondline.

cally) and values of strain as abscissas (horizontally).

3.2.4 proportional limit, n—the maximum stress that a

material is capable of sustaining without significant deviation 4. Summary of Test Method

from proportionality of stress to strain.

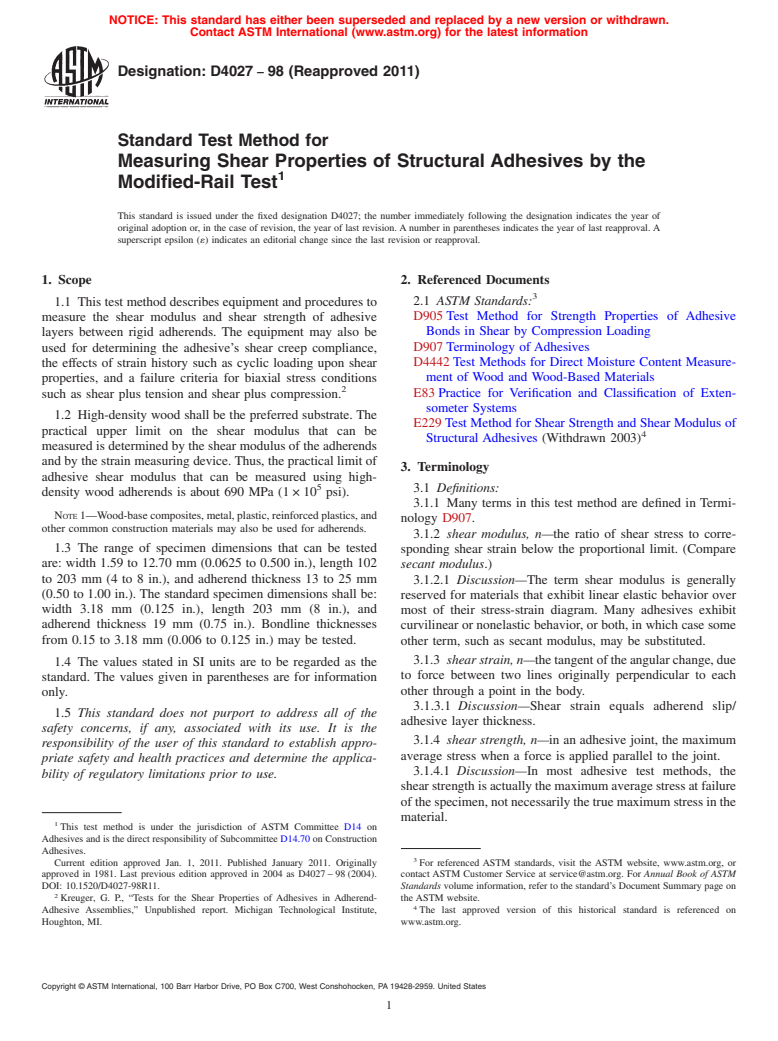

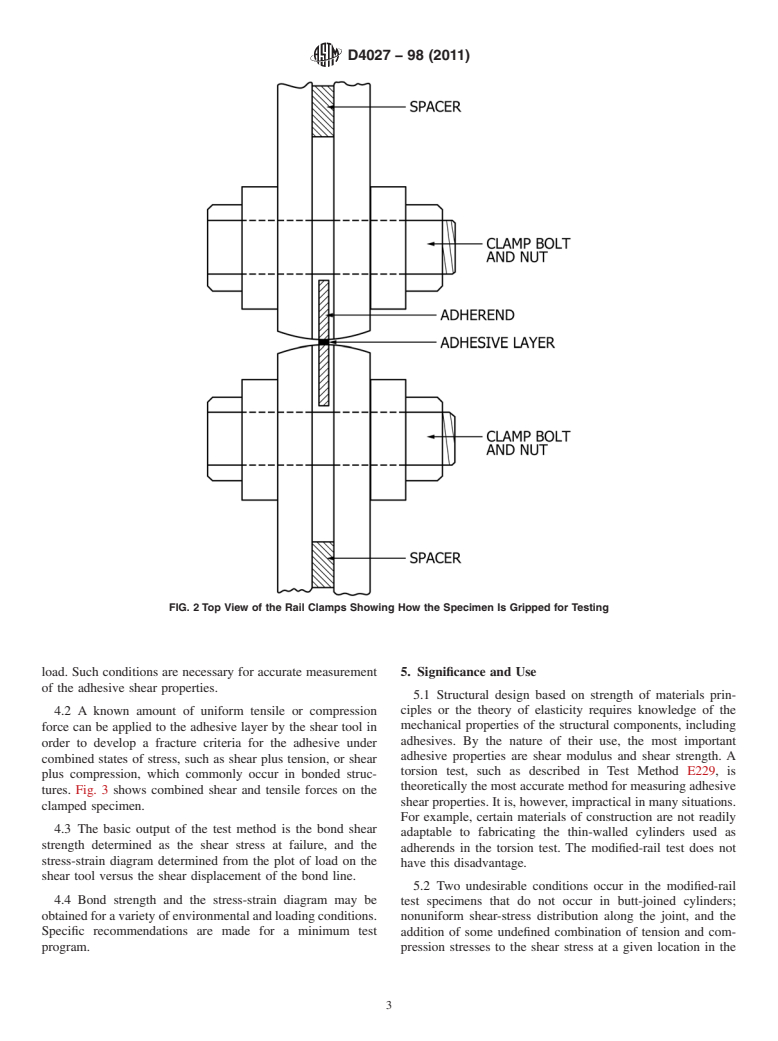

4.1 Shear force is applied to the adhesive through the

3.2.5 secant modulus, n—theslopeofthesecantdrawnfrom

adherends by a modified-rail shear tool such as shown in Fig.

the origin to any specified point on the stress-strain curve.

1.Theadherendsarefirmlyclampedbetweentwopairsofrigid

3.2.5.1 Discussion—Modulus is expressed in force per unit

rails as shown in Fig. 2. One pair is fixed and the other is

area (megapascals, pounds-force per square inch, etc.).

movable. The rigid rails limit undesired adherend deformation

3.2.6 shear stress, n—thestresscomponenttangentialtothe

during testing. The pair of movable rails is fixed to two

plane on which the forces act, that is, in the plane of the

counter-moment pivot arms. These arms restrict the attached

bondline.

rails (and clamped adherend) to collinear motion with respect

3.2.7 slip, n—the relative collinear displacement of the to the fixed rails (and clamped adherend). The results of using

thissheartoolarenearlyuniformstressandstraindistributions

adherends on either side of the adhesive layer in the direction

of the applied load. and the reduction of normal stress in the adhesive layer under

D4027−98 (2011)

FIG. 2Top View of the Rail Clamps Showing How the Specimen Is Gripped for Testing

load. Such conditions are necessary for accurate measurement 5. Significance and Use

of the adhesive shear properties.

5.1 Structural design based on strength of materials prin-

ciples or the theory of elasticity requires knowledge of the

4.2 A known amount of uniform tensile or compression

mechanical properties of the structural components, including

force can be applied to the adhesive layer by the shear tool in

adhesives. By the nature of their use, the most important

order to develop a fracture criteria for the adhesive under

adhesive properties are shear modulus and shear strength. A

combined states of stress, such as shear plus tension, or shear

torsion test, such as described in Test Method E229,is

plus compression, which commonly occur in bonded struc-

theoretically the most accurate method for measuring adhesive

tures. Fig. 3 shows combined shear and tensile forces on the

shearproperties.Itis,however,impracticalinmanysituations.

clamped specimen.

For example, certain materials of construction are not readily

4.3 The basic output of the test method is the bond shear

adaptable to fabricating the thin-walled cylinders used as

strength determined as the shear stress at failure, and the

adherends in the torsion test. The modified-rail test does not

stress-strain diagram determined from the plot of load on the

have this disadvantage.

shear tool versus the shear displacement of the bond line.

5.2 Two undesirable conditions occur in the modified-rail

4.4 Bond strength and the stress-strain diagram may be

test specimens that do not occur in butt-joined cylinders;

obtainedforavarietyofenvironmentalandloadingconditions. nonuniform shear-stress distribution along the joint, and the

Specific recommendations are made for a minimum test addition of some undefined combination of tension and com-

program. pression stresses to the shear stress at a given location in the

D4027−98 (2011)

NOTE 1—During a shear only test the horizontal arrows (tension forces) would be absent.

FIG. 3Side View of the Rail Clamps Showing the Forces On the Clamps (Specimen) During Combined Shear and Tension Loading

joint. The modified-rail shear tool minimizes but does not minimum vertical space of 508 mm (20 in.) and horizontal

eliminate these undesirable effects.

space of 305 mm (12 in.) is required to install the shear tool in

the testing machine.

5.3 Shear modulus, strength, and other properties are mea-

sured by the modified-rail method. 6.1.2 The testing machine shall have a device capable of

readingtheloadtothenearest4.5 60.9N(1.0 60.2lbf).This

6. Apparatus

readout device should preferably be an electronic load cell to

6.1 Universal Testing Machine:

facilitate simultaneous recording of load with the adhesive

6.1.1 The universal testing machine shall have a minimum

deformation.

load capacity of 8900 N (2000 lbf), and a range of crosshead

6.2 Modified-Rail Shear Tool:

speedfrom0.317to10.16mm/min(0.0125to0.40in./min).A

D4027−98 (2011)

FIG. 4Detail Drawings of Modified-Rail Shear Apparatus

6.2.1 Ashear tool suitable for this test method is illustrated 7.2 Hard maple shall be the standard material for specimen

in Fig. 1, Fig. 2, Fig. 4, Fig. 5, and Fig. 6. adherends. Other species may be selected at the option of the

6.2.2 The shear tool is fitted with a threaded bolt (Adjuster, adhesive manufacturer or by the party requesting these tests.

Fig. 1 ) to apply normal force for combined stress studies.The 7.2.1 Generally a high-density wood such as hard maple,

magnitudeofthenormalforceisconstantfromtheoutsetofthe yellow birch, Douglas-fir, or southern pine are desirable to

test.Thebolthasastraingagebondedtoitthat,withasuitable minimize wood deformation effects on the measured adhesive

readout device and calibration, can be used to set the desired deformation. The specific gravity of the lumber selected shall

normal force. equal or exceed average specific gravity for the species as

given in Table4-2 of the Wood Handbook. For hard maple,

6.3 Slip or Strain Gage—Since the shear strain of adhesive

the average is 0.63. A method of selecting maple lumber of

layers will normally be very small, anASTM ClassAor Class

satisfactoryspecificgravityisdescribedintheappendixtoTest

B-1extensometerasdescribedinPracticeE83shallbeused.A

Method D905.

mechanical-electrical transducer such as the linear variable

7.2.2 A uniform textured wood such as maple or birch is

differential transducer (LVDT) can be used to measure the

desirable to minimize wood density variation effects on the

shear slip indirectly by attachment of the LVDT to the

adhesive layer. Coarse-textured woods such as Douglas-fir,

specimen clamps. Or miniature electrical resistance strain

hemlock, or southern pine are acceptable however.

gages can be used to measure the shear strain by direct

7.2.3 The wood shall be nominal 25.4 mm (1 in.) flat-sawn

attachment to the adhesive joint.

lumber presenting a flat grain (tangential surface) for bonding.

7.2.4 The lumber shall be straight-grained and free of

7. Materials

defects including knots, cracks, abrupt grain deviations, decay,

7.1 The adhesives used shall be selected by the adhesive

and any unusual discolorations within the bond area.

manufacturer or by the party requesting these tests.

5 6

Complete detail drawings of the modified-rail shear apparatus are available U.S. Forest Products Laboratory. Wood Handbook: Wood as an Engineering

from the Forest Products Laboratory, Forest Service, U.S. Department of Material, USDA Agricultural Handbook 72, revised. U.S. Government. Printing

Agriculture, Madison, WI 53705. Office, Washington, DC 20402, 1974.

D4027−98 (2011)

FIG. 5Schematic Diagram Showing Use of the Modified-Rail Shear Apparatus With a Universal Test Machine to Apply Load

FIG. 6Schematic Diagram Showing Use of the Modified-Rail Shear Apparatus With an Integral Hydraulic Cylinder to Apply Load

8. Sampling 9.1.2.1 Bondline thickness may be varied when this test

method is used to measure the effects of bondline thickness

8.1 When testing adhesives that form highly variable bond-

upon strength and shear modulus.

lines such as the solvent dispersed construction adhesives,

9.1.2.2 Bondline thickness shall never be greater than the

prepare at least three billets for each test condition. Individual

adhesive manufacturer’s stated maximum thickness.

specimens cut from the billets shall be drawn at random for

9.1.3 The maximum range of bondline thickness that is

assignment to a given test condition.

acceptableforuseinthistestmethodis0.15to3.18mm(0.006

8.2 Eight specimens shall be tested at every set of condi-

to 0.125 in.).

tions.

9.2 Specimen Preparation:

9. Test Specimen

9.2.1 Cut the lumber into pieces measuring nominal 25 by

9.1 Specimen Dimensions: 64 by 305 mm (1 by 2.5 by 12 in.) with the grain in the long

9.1.1 The standard specimen dimensions are shown in Fig. direction. Lightly surface both faces of each piece. Condition

7. The thickness of the specimen may range from 1.59 to 12.7 these pieces to an equilibrium moisture content between 7 and

mm (0.06 to 0.50 in.) at the discretion of the party requesting 10% (ovendry basis) or to the moisture content specified by

the tests. the adhesive manufacturer. Determine moisture content at

9.1.2 The recommended bondline thickness shall be 0.79 equilibrium from extra pieces of lumber in accordance wi

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.