ASTM F681-82(1998)

(Practice)Standard Practice for Use of Branch Connections

Standard Practice for Use of Branch Connections

SCOPE

1.1 This practice lists commonly used types of branch connections for carbon steel, chromium-molybdenum steel pipe and copper-nickel alloy tubing. Branch to run size applications are given in Tables 1, 2, and 3. Other types of branch connections may be used provided they comply with the requirements of Title 46 CFR Subparts 56.07-10(f) and 56.70-15(g) of the USCG Regulations.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation: F 681 – 82 (Reapproved 1998)

Standard Practice for Use of

Branch Connections

This standard is issued under the fixed designation F 681; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope B31.1 Power Piping

2.3 Other Document:

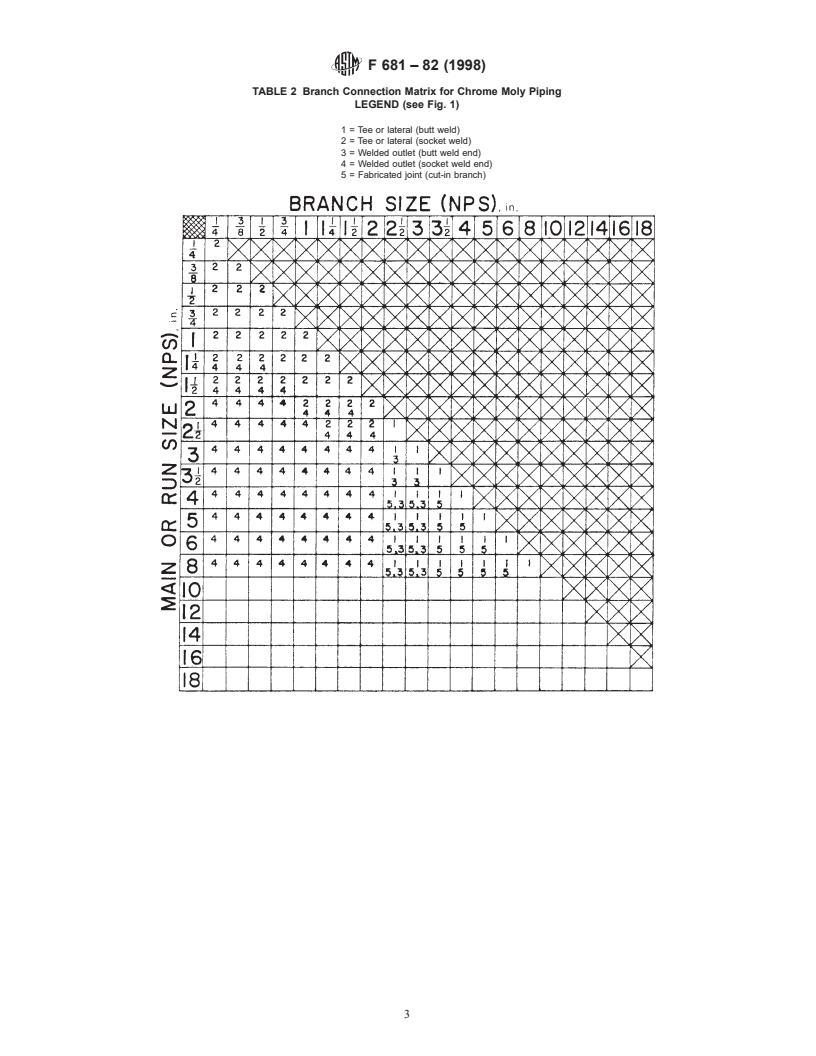

1.1 This practice lists commonly used types of branch

Title 46 Code of Federal Regulations (CFR) Shipping, Parts

connections for carbon steel, chromium-molybdenum steel

41 to 69

pipe and copper-nickel alloy tubing. Branch to run size

applications are given in Table 1, Table 2, and Table 3. Other

3. General Requirements

types of branch connections (Fig. 1) may be used provided they

3.1 Weld joint designs shall be in accordance with Specifi-

comply with the requirements of Title 46 CFR Subparts

cation F 722 and the limitations therein.

56.07-10(f) and 56.70-15(g) of the USCG Regulations.

3.2 Fabricated branch connections shall meet the reinforce-

2. Referenced Documents ment requirements of Section 104.3 of ANSI B31.1 as modified

by Title 46, CFR Subparts 56.07-10(f) and 56.70-15(g) of the

2.1 ASTM Standards:

USCG regulations.

F 722 Specification for Welded Joints for Shipboard Piping

3.3 Threaded fittings shall be subject to the limitations of

Systems

Title 46 CFR, Subpart 56.30-20 of the USCG Regulations.

2.2 ANSI Standard:

4. Keywords

4.1 branch connnections; carbon steel connections;

chromium-molybdenum steel pipe; copper-nickel alloy tubing

This practice is under the jurisdiction of ASTM Committee F25 on Ships and

Marine Technology and is the direct responsibility of Subcommittee F25.11 on

Machinery and Piping Systems. Available from American National Standards Institute (ANSI), 25 W. 43rd St.,

Current edition approved July 30, 1982. Published October 1982. Originally 4th Floor, New York, NY 10036.

published as F 681 – 80. Last previous edition F 681 – 80. Available from Standardization Documents Order Desk, Bldg. 4 Section D, 700

Annual Book of ASTM Standards, Vol 01.07. Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, We

...

This May Also Interest You

ABSTRACT

This specification covers the general requirements for nylon stuffing tubes and packing assemblies. Nylon stuffing tubes are intended for making electric cable penetrations in marine shipboard enclosures for electrical equipment. The following types are suitable for thin-wall enclosures up to a certain thickness and thick-wall enclosures, bulkheads, and decks of also of a certain thickness. Nylon stuffing tubes shall be classified into four types: Type 1 with straight, unified form thread, Type 2 with 90°, unified form thread, Type 3 with NPT, American standard pipe thread and Type 4 with Y, unified form thread. Materials used for the manufacture of these stuffing tubes and packing assemblies shall include polyamide or nylon and synthetic rubber or neoprene. The sizes and dimensions of stuffing tubes and packing assemblies are completely described. In order determine properties such as vibration resistance, ruggedness, and seal effectiveness of stuffing tubes, the following tests shall be performed: vibration test, mechanical abuse test, and level of effectiveness test. In terms of physical appearance, stuffing tubes shall be free from warp, cracks, chipped edges or surfaces, blisters, uneven surfaces, scratches, dents, and heat marks. They shall be free from fins, burrs, and unsightly finish caused by chipping, filing, or grinding without subsequent buffing or polishing. All molded nylon parts shall be cleaned thoroughly of annealing mediums. Packing assemblies shall be free of voids, pin holes, flash, or other imperfections, that may impair their serviceability.

SCOPE

1.1 This specification covers the general requirements for nylon stuffing tubes and packing assemblies. Nylon stuffing tubes are intended for making electric cable penetrations in marine shipboard enclosures for electrical equipment. The following types are suitable for both thin-wall enclosures up to 5 mm (3/16 in.) thick and thick-wall enclosures, bulkheads, and decks of 5 mm to 19 mm (3/16 in. to 3/4 in.) thick.

1.2 This specification does not cover metal stuffing tubes.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Technical specification6 pagesEnglish languagesale 15% off

ABSTRACT

This practice lists commonly used types of branch connections for carbon steel, chromium-molybdenum steel pipe and copper-nickel alloy tubing. The branch to run size applications are presented in details. The weld joint designs, fabricated branch connections and threaded fittings shall meet the requirements prescribed.

SCOPE

1.1 This practice lists commonly used types of branch connections for carbon steel, chromium-molybdenum steel pipe and copper-nickel alloy tubing. Branch to run size applications are given in Table 1, Table 2, and Table 3. Other types of branch connections (Fig. 1) may be used provided they comply with the requirements of Title 46 CFR Subparts 56.07-10(f) and 56.70-15(g) of the USCG Regulations.

FIG. 1 Illustrative Legend for Branch Connections

1.2 The values stated in inch-pound units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Standard5 pagesEnglish languagesale 15% off

ABSTRACT

This specification covers the requirements for electrical liquid level indicating equipment for shipboard low pressure and high pressure tanks containing freshwater, feed water, potable water, seawater, wastewater, diesel fuel, lubricating oil, contaminated oil, refrigerants, JP fuels, and various other fluids. Application includes compensating tanks in which the equipment must locate the interface. Each liquid level indicating equipment shall consists of one or more sensing devices; primary indicator panel assembly; and flexible interconnections, auxiliary indicator panel assembly, and portable indicator panel assembly, when needed or required. The level sensing techniques include: admittance and impedance, magnetic float, differential pressure, time domain reflectometry, capacitance, resistance tape, static pressure, radar, and ultrasonic sensing. The most common types of process media and the specified pressure range and display for liquid level indication are given. Materials for the sensing devices and wetted pans shall be selected for long-term compatibility with the process medium. Physical property requirements include: (1) enclosure, (2) liquid level indicating equipment mounting, (3) external configuration, (4) electrical connection, and (5) size and weight. Critical service life and performance requirements shall be specified in the acquisition requirements. The following performance characteristics and environmental exposures may or may not be important to the intended application: accuracy, response time, repeatability, hysteresis, insulation resistance, specific gravity, fluid conductivity, tank wall proximity, inclination, spike voltage, salt spray, vibration, shock enclosure, dc magnetic field, electromagnetic interference, immersion, and supply line voltage and frequency variation. Inspection requirements specified are classified as (1) first article test and (2) conformance test.

SCOPE

1.1 This specification covers the requirements for electrical liquid level indicating equipment for shipboard low pressure and high pressure tanks containing freshwater, feed water, potable water, seawater, wastewater, diesel fuel, lubricating oil, contaminated oil, refrigerants, JP fuels, and various other fluids. Application includes compensating tanks in which the equipment must locate the interface.

1.2 Each liquid level indicating equipment typically consists of the following components:

(a) One or more sensing devices;

(b) Flexible interconnections, if needed;

(c) Primary indicator panel assembly;

(d) Auxiliary indicator panel assembly, when required; and

(e) Portable indicator panel assembly, when required.

1.3 Special requirements for naval shipboard applications are included in the Supplementary Requirements section to this specification.

1.4 The values stated in SI units are to be regarded as standard. Inch-pound units are provided for information only and are not considered standard. Where information is to be specified, it shall be stated in SI units.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Technical specification14 pagesEnglish languagesale 15% off

ABSTRACT

This specification covers insulation monitoring devices for stripboard electrical systems. Materials covered by this specification include Type I (ac device) and Type II (dc device) electrical system insulation monitoring devices used in the detection of ohmic insulation faults to ground in either active ac ungrounded electrical systems with dc components (Type I) or dc ungrounded electrical systems (Type II). However, devices used in ac ungrounded systems without dc components are not included. The devices shall undergo conformance and routine tests to ensure that the device meets the requirements specified. Conformance tests shall included testing of response time, peak voltage, input impedance or resistance, built-in meters, and impulse voltage withstand capabilities, whereas routine tests shall include testing of response value, self-test function, built-in meters, and voltage.

SCOPE

1.1 This specification covers two (2) types of electrical system insulation monitoring devices.

1.1.1 Type I is an AC device intended as a permanently installed unit for use in the detection of ohmic insulation faults to ground in active AC ungrounded electrical systems up to 1000 VAC, having DC components up to 1500 VDC.

1.1.2 Type II is a DC device intended as a permanently installed unit for use in the detection of ohmic insulation faults to ground in DC ungrounded electrical systems up to 1500 VDC.

1.2 Limitations—This specification does not cover devices that are intended for operation in AC ungrounded systems without DC components.

1.3 The values stated in SI units are to be regarded as standard. The values given in parentheses after SI units are included for information only and are not considered standard.

1.4 The following precautionary caveat pertains only to the test methods portion, Section 7 of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Technical specification4 pagesEnglish languagesale 15% off

ABSTRACT

This specification covers the general requirements for nylon stuffing tubes and packing assemblies. Nylon stuffing tubes are intended for making electric cable penetrations in marine shipboard enclosures for electrical equipment. The following types are suitable for thin-wall enclosures up to a certain thickness and thick-wall enclosures, bulkheads, and decks of also of a certain thickness. Nylon stuffing tubes shall be classified into four types: Type 1 with straight, unified form thread, Type 2 with 90°, unified form thread, Type 3 with NPT, American standard pipe thread and Type 4 with Y, unified form thread. Materials used for the manufacture of these stuffing tubes and packing assemblies shall include polyamide or nylon and synthetic rubber or neoprene. The sizes and dimensions of stuffing tubes and packing assemblies are completely described. In order determine properties such as vibration resistance, ruggedness, and seal effectiveness of stuffing tubes, the following tests shall be performed: vibration test, mechanical abuse test, and level of effectiveness test. In terms of physical appearance, stuffing tubes shall be free from warp, cracks, chipped edges or surfaces, blisters, uneven surfaces, scratches, dents, and heat marks. They shall be free from fins, burrs, and unsightly finish caused by chipping, filing, or grinding without subsequent buffing or polishing. All molded nylon parts shall be cleaned thoroughly of annealing mediums. Packing assemblies shall be free of voids, pin holes, flash, or other imperfections, that may impair their serviceability.

SCOPE

1.1 This specification covers the general requirements for nylon stuffing tubes and packing assemblies. Nylon stuffing tubes are intended for making electric cable penetrations in marine shipboard enclosures for electrical equipment. The following types are suitable for both thin-wall enclosures up to 5 mm (3/16 in.) thick and thick-wall enclosures, bulkheads, and decks of 5 mm to 19 mm (3/16 in. to 3/4 in.) thick.

1.2 This specification does not cover metal stuffing tubes.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Technical specification6 pagesEnglish languagesale 15% off

ABSTRACT

This practice lists commonly used types of branch connections for carbon steel, chromium-molybdenum steel pipe and copper-nickel alloy tubing. The branch to run size applications are presented in details. The weld joint designs, fabricated branch connections and threaded fittings shall meet the requirements prescribed.

SCOPE

1.1 This practice lists commonly used types of branch connections for carbon steel, chromium-molybdenum steel pipe and copper-nickel alloy tubing. Branch to run size applications are given in Table 1, Table 2, and Table 3. Other types of branch connections (Fig. 1) may be used provided they comply with the requirements of Title 46 CFR Subparts 56.07-10(f) and 56.70-15(g) of the USCG Regulations.

FIG. 1 Illustrative Legend for Branch Connections

1.2 The values stated in inch-pound units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Standard5 pagesEnglish languagesale 15% off

ABSTRACT

This specification covers the requirements for electrical liquid level indicating equipment for shipboard low pressure and high pressure tanks containing freshwater, feed water, potable water, seawater, wastewater, diesel fuel, lubricating oil, contaminated oil, refrigerants, JP fuels, and various other fluids. Application includes compensating tanks in which the equipment must locate the interface. Each liquid level indicating equipment shall consists of one or more sensing devices; primary indicator panel assembly; and flexible interconnections, auxiliary indicator panel assembly, and portable indicator panel assembly, when needed or required. The level sensing techniques include: admittance and impedance, magnetic float, differential pressure, time domain reflectometry, capacitance, resistance tape, static pressure, radar, and ultrasonic sensing. The most common types of process media and the specified pressure range and display for liquid level indication are given. Materials for the sensing devices and wetted pans shall be selected for long-term compatibility with the process medium. Physical property requirements include: (1) enclosure, (2) liquid level indicating equipment mounting, (3) external configuration, (4) electrical connection, and (5) size and weight. Critical service life and performance requirements shall be specified in the acquisition requirements. The following performance characteristics and environmental exposures may or may not be important to the intended application: accuracy, response time, repeatability, hysteresis, insulation resistance, specific gravity, fluid conductivity, tank wall proximity, inclination, spike voltage, salt spray, vibration, shock enclosure, dc magnetic field, electromagnetic interference, immersion, and supply line voltage and frequency variation. Inspection requirements specified are classified as (1) first article test and (2) conformance test.

SCOPE

1.1 This specification covers the requirements for electrical liquid level indicating equipment for shipboard low pressure and high pressure tanks containing freshwater, feed water, potable water, seawater, wastewater, diesel fuel, lubricating oil, contaminated oil, refrigerants, JP fuels, and various other fluids. Application includes compensating tanks in which the equipment must locate the interface.

1.2 Each liquid level indicating equipment typically consists of the following components:

(a) One or more sensing devices;

(b) Flexible interconnections, if needed;

(c) Primary indicator panel assembly;

(d) Auxiliary indicator panel assembly, when required; and

(e) Portable indicator panel assembly, when required.

1.3 Special requirements for naval shipboard applications are included in the Supplementary Requirements section to this specification.

1.4 The values stated in SI units are to be regarded as standard. Inch-pound units are provided for information only and are not considered standard. Where information is to be specified, it shall be stated in SI units.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Technical specification14 pagesEnglish languagesale 15% off

ABSTRACT

This specification covers insulation monitoring devices for stripboard electrical systems. Materials covered by this specification include Type I (ac device) and Type II (dc device) electrical system insulation monitoring devices used in the detection of ohmic insulation faults to ground in either active ac ungrounded electrical systems with dc components (Type I) or dc ungrounded electrical systems (Type II). However, devices used in ac ungrounded systems without dc components are not included. The devices shall undergo conformance and routine tests to ensure that the device meets the requirements specified. Conformance tests shall included testing of response time, peak voltage, input impedance or resistance, built-in meters, and impulse voltage withstand capabilities, whereas routine tests shall include testing of response value, self-test function, built-in meters, and voltage.

SCOPE

1.1 This specification covers two (2) types of electrical system insulation monitoring devices.

1.1.1 Type I is an AC device intended as a permanently installed unit for use in the detection of ohmic insulation faults to ground in active AC ungrounded electrical systems up to 1000 VAC, having DC components up to 1500 VDC.

1.1.2 Type II is a DC device intended as a permanently installed unit for use in the detection of ohmic insulation faults to ground in DC ungrounded electrical systems up to 1500 VDC.

1.2 Limitations—This specification does not cover devices that are intended for operation in AC ungrounded systems without DC components.

1.3 The values stated in SI units are to be regarded as standard. The values given in parentheses after SI units are included for information only and are not considered standard.

1.4 The following precautionary caveat pertains only to the test methods portion, Section 7 of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Technical specification4 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

4.1 This practice is useful as a screening basis for acceptance or rejection of transparencies during manufacturing so that units with identifiable flaws will not be carried to final inspection for rejection at that time.

4.2 This practice may also be employed as a go-no go technique for acceptance or rejection of the finished product.

4.3 This practice is simple, inexpensive, and effective. Flaws identified by this practice, as with other optical methods, are limited to those that produce temperature gradients when electrically powered. Any other type of flaw, such as minor scratches parallel to the direction of electrical flow, are not detectable.

SCOPE

1.1 This practice covers a standard procedure for detecting flaws in the conductive coating (heater element) by the observation of polarized light patterns.

1.2 This practice applies to coatings on surfaces of monolithic transparencies as well as to coatings imbedded in laminated structures.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. For specific precautionary statements, see Section 6.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Standard4 pagesEnglish languagesale 15% off

ABSTRACT

This specification covers grades of fuel oil intended for use in various types of fuel-oil-burning equipment under various climatic and operating conditions. These grades include the following: Grades No. 1 S5000, No. 1 S500, No. 2 S5000, and No. 2 S500 for use in domestic and small industrial burners; Grades No. 1 S5000 and No. 1 S500 adapted to vaporizing type burners or where storage conditions require low pour point fuel; Grades No. 4 (Light) and No. 4 (Heavy) for use in commercial/industrial burners; and Grades No. 5 (Light), No. 5 (Heavy), and No. 6 for use in industrial burners. Preheating is usually required for handling and proper atomization. The grades of fuel oil shall be homogeneous hydrocarbon oils, free from inorganic acid, and free from excessive amounts of solid or fibrous foreign matter. Grades containing residual components shall remain uniform in normal storage and not separate by gravity into light and heavy oil components outside the viscosity limits for the grade. The grades of fuel oil shall conform to the limiting requirements prescribed for: (1) flash point, (2) water and sediment, (3) physical distillation or simulated distillation, (4) kinematic viscosity, (5) Ramsbottom carbon residue, (6) ash, (7) sulfur, (8) copper strip corrosion, (9) density, and (10) pour point. The test methods for determining conformance to the specified properties are given.

SCOPE

1.1 This specification (see Note 1) covers grades of fuel oil intended for use in various types of fuel-oil-burning equipment under various climatic and operating conditions. These grades are described as follows:

1.1.1 Grades No. 1 S5000, No. 1 S500, No. 1 S15, No. 2 S5000, No. 2 S500, and No. 2 S15 are middle distillate fuels for use in domestic and small industrial burners. Grades No. 1 S5000, No. 1 S500, and No. 1 S15 are particularly adapted to vaporizing type burners or where storage conditions require low pour point fuel.

1.1.2 Grades B6–B20 S5000, B6–B20 S500, and B6–B20 S15 are middle distillate fuel/biodiesel blends for use in domestic and small industrial burners.

1.1.3 Grades No. 4 (Light) and No. 4 are heavy distillate fuels or middle distillate/residual fuel blends used in commercial/industrial burners equipped for this viscosity range.

1.1.4 Grades No. 5 (Light), No. 5 (Heavy), and No. 6 are residual fuels of increasing viscosity and boiling range, used in industrial burners. Preheating is usually required for handling and proper atomization.

Note 1: For information on the significance of the terminology and test methods used in this specification, see Appendix X1.

Note 2: A more detailed description of the grades of fuel oils is given in X1.3.

1.2 This specification is for the use of purchasing agencies in formulating specifications to be included in contracts for purchases of fuel oils and for the guidance of consumers of fuel oils in the selection of the grades most suitable for their needs.

1.3 Nothing in this specification shall preclude observance of federal, state, or local regulations which can be more restrictive.

1.4 The values stated in SI units are to be regarded as standard.

1.4.1 Non-SI units are provided in Table 1 and Table 2 and in 7.1.2.1/7.1.2.2 because these are common units used in the industry.

Note 3: The generation and dissipation of static electricity can create problems in the handling of distillate burner fuel oils. For more information on the subject, see Guide D4865.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Technical specification13 pagesEnglish languagesale 15% off

- Technical specification13 pagesEnglish languagesale 15% off

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.