ASTM D5739-00

(Practice)Standard Practice for Oil Spill Source Identification by Gas Chromatography and Positive Ion Electron Impact Low Resolution Mass Spectrometry

Standard Practice for Oil Spill Source Identification by Gas Chromatography and Positive Ion Electron Impact Low Resolution Mass Spectrometry

SCOPE

1.1 This practice covers the use of gas chromatography and mass spectrometry to analyze and compare petroleum oil spills and suspected sources.

1.2 The probable source for a spill can be ascertained by the examination of certain unique compound classes that also demonstrate the most weathering stability. To a greater or lesser degree, certain chemical classes can be anticipated to chemically alter in proportion to the weathering exposure time and severity, and subsequent analytical changes can be predicted. This practice recommends various classes to be analyzed and also provides a guide to expected weathering-induced analytical changes.

1.3 This practice is applicable for moderately to severely degraded petroleum oils in the distillate range from diesel through Bunker C; it is also applicable for all crude oils with comparable distillation ranges. This practice may have limited applicability for some kerosenes, but it is not useful for gasolines.

1.4 The values stated in SI units are to be regarded as the standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 5739 – 00

Standard Practice for

Oil Spill Source Identification by Gas Chromatography and

Positive Ion Electron Impact Low Resolution Mass

Spectrometry

This standard is issued under the fixed designation D 5739; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope* D 3328 Test Methods for Comparison of Waterborne Petro-

leum Oils by Gas Chromatography

1.1 This practice covers the use of gas chromatography and

D 3414 Test Method for Comparison of Waterborne Petro-

mass spectrometry to analyze and compare petroleum oil spills

leum Oils by Infrared Spectroscopy

and suspected sources.

D 3415 Practice for Identification of Waterborne Oils

1.2 The probable source for a spill can be ascertained by the

D 3650 Test Method for Comparison of Waterborne Petro-

examination of certain unique compound classes that also

leum Oils by Fluorescence Analysis

demonstrate the most weathering stability. To a greater or

D 5037 Test Method for Comparison of Waterborne Petro-

lesser degree, certain chemical classes can be anticipated to

leum Oils by High Performance Liquid Chromatography

chemically alter in proportion to the weathering exposure time

E 355 Practice for Gas Chromatography Terms and Rela-

and severity, and subsequent analytical changes can be pre-

tionships

dicted. This practice recommends various classes to be ana-

lyzed and also provides a guide to expected weathering—

3. Summary of Practice

induced analytical changes.

3.1 The recommended chromatography column is a capil-

1.3 This practice is applicable for moderately to severely

lary directly interfaced to the mass spectrometer (either qua-

degraded petroleum oils in the distillate range from diesel

drupole or magnetic).

through Bunker C; it is also applicable for all crude oils with

3.2 The low-resolution mass spectrometer is operated in the

comparable distillation ranges. This practice may have limited

positive ion electron impact mode, 70 eV nominal.

applicability for some kerosenes, but it is not useful for

3.3 Mass spectral data are acquired, stored, and processed

gasolines.

with the aid of commercially available computer-based data

1.4 The values stated in SI units are to be regarded as the

systems.

standard.

1.5 This standard does not purport to address all of the

4. Significance and Use

safety concerns, if any, associated with its use. It is the

4.1 This practice is useful for assessing the source for an oil

responsibility of the user of this standard to establish appro-

spill. Other less complex analytical procedures (Test Methods

priate safety and health practices and determine the applica-

D 3328, D 3414, D 3650, and D 5037) may provide all of the

bility of regulatory limitations prior to use.

necessary information for ascertaining an oil spill source;

2. Referenced Documents however, the use of a more complex analytical strategy may be

necessaryincertaindifficultcases,particularlyforsignificantly

2.1 ASTM Standards:

2 weathered oils. This practice provides the user with a means to

D 1129 Terminology Relating to Water

this end.

D 3325 Practice for Preservation of Waterborne Oil

4.1.1 This practice presumes that a “screening” of possible

Samples

suspect sources has already occurred using less intensive

D 3326 Practices for Preparation of Samples for Identifica-

techniques. As a result, this practice focuses directly on the

tion of Waterborne Oils

generation of data using preselected targeted compound

classes. These targets are both petrogenic and pyrogenic and

can constitute both major and minor fractions of petroleum

This practice is under the jurisdiction of ASTM Committee D19 on Water and

oils; they were chosen in order to develop a practice that is

is the direct responsibility of Subcommittee D19.06 on Methods for Analysis for

universally applicable to petroleum oil identification in general

Organic Substances in Water.

Current edition approved June 10, 2000. Published September 2000. Originally

published as D 5739 – 95. Last previous edition D 5739 – 95.

Annual Book of ASTM Standards, Vol 11.01.

3 4

Annual Book of ASTM Standards, Vol 11.02. Annual Book of ASTM Standards, Vol 14.01.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D 5739 – 00

TABLE 1 Extracted Ion Chromatograms (EICs)

and is also easy to handle and apply. This practice can

accommodate light oils and cracked products (exclusive of Approximate Time

Compound Type Ion

Interval, min

gasoline) on the one hand, as well as residual oils on the other.

Naphthalenes C 156 18 to 23

4.1.2 This practice provides analytical characterizations of 2

C 170 20 to 25

petroleum oils for comparison purposes. Certain classes of

A

C 184 22 to 27

source-specific chemical compounds are targeted in this quali-

A

Dibenzothiophenes C 184 23 to 28

tative comparison; these target compounds are both unique 0

C 198 27 to 32

descriptors of an oil and chemically resistant to environmental

C 212 29 to 34

degradation. Spilled oil can be assessed in this way as being

C 226 31 to 35

similar or different from potential source samples by the direct

B

Phenanthrenes/ C 178 27 to 28

visual comparison of specific extracted ion chromatograms

anthracenes C 192 28 to 33

(EICs). In addition, other, more weathering-sensitive chemical

C 206 30 to 35

C 220 32 to 37

compound classes can also be examined in order to crudely 3

assess the degree of weathering undergone by an oil spill

Steranes 14a(H) 217 40 to 60

sample.

14b(H) 218 40 to 60

4.2 This practice simply provides a means of making

Triterpanes 191 40 to 60

qualitative comparisons between petroleum samples; quantita-

tion of the various chemical components is not addressed.

Alkanes 85 4 to 60

Alkanes 113 4 to 60

5. Apparatus

Alkanes and Acyclic 133 4to60

5.1 Gas Chromatograph Interfaced to a Mass Spectrometer,

isoprenoids

with a 70-eV electron impact ionization source. The system

shall include a computer for the control of data acquisition and

Benzonaphthothiophene 234 30 to 34

reduction.

Tri-aromatic steranes 231 39 to 45

5.2 Capillary Column, with a high-resolution, 30 m by

0.25-mmor0.32-mminsidediameter(0.25-µmd)(suchasJ&

f Norhopanes 177 33 to 47

W DB-5 or Supelco PTE-5), interfaced directly to the mass

Methylhopanes 205 41 to 46

spectrometer.

Pyrene/fluoranthene 202 24 to 32

6. Reagents and Materials

Methylpyrenes 216 30 to 32

6.1 Purity of Reagents—Only pesticide grade, nanograde,

or distilled in glass grade solvents will be used.

Fluorenes 166 16 to 21

6.2 Purity of Reference Compounds—All must be certified

Bicyclonaphthalenes 208 15 to 22

to be at least 95 % pure.

A

An authentic standard of dibenzothiophene can be chromatographed to

6.3 Septa—Only high-temperature, low-bleed (such as

ascertain its actual retention time.

TM

B

Thermogreen ) shall be used.

Phenanthrene is both pyrogenic and petrogenic. Consequently, m/e 178 may

demonstrateanincreaserelativetoitssourceinspillcasesinwhicharsonorother

6.4 Vials, glass, polytetrafluorethylene-lined screw cap,

combustion processes have occurred. This can result in a significant distortion in

10-mL capacity.

the C anthracene/phenanthrene distribution, which is, generally speaking,

6.5 Syringes,10µL.

counter to expected weathering processes.

6.6 Perfluorotributylamine, used for tuning the mass spec-

trometer.

7. Preparation of Instrumentation

6.7 Resolution Mixture—Pristane, phytane, n-heptadecane,

and n-octadecane in equal concentration in cyclohexane (50 to 7.1 Set an initial head pressure of between 5 and 20 psi

150 ng/µL). using helium as the carrier at 250°C (for either a 30-m by

6.8 Mass Discrimination Mixture—Naphthalene, fluoran- 0.25-mm inside diameter column or a 30-m by 0.32-mm inside

thene, and benzo (g, h, i) perylene in equal concentration in diameter column). Adjust a final head pressure (for either

cyclohexane (50 to 150 ng/µL). column) such that the linear velocity is in the range from 30 to

6.9 Reference oil, possibly a crude oil, used for generation 40 cm/s.

oftheextractedionchromatograms(EICs)listedinTable1and 7.2 Mass Spectrometric Tuning:

validat of system performance for oil sample comparison 7.2.1 Tune the mass spectrometer to the following perfluo-

purposes. (See for representative EICs produced using the rotributylamine (PFTBA) specification, addressing both mass

conditions stated in section 8.) scale calibration and peak-to-peak ratios:

D 5739 – 00

8.2 Sample Preparation—Weigh 100 to 200 mg of oil into

(m/e 69 at 100 % of base peak)

A B

(m/e 219 at 35 to 40 % of base peak)

a screw-cap glass vial, and add 10 mLcyclohexane. Sonication

C

(m/e 502 at 1 to 2 % of base peak)

may be necessary, as well as centrifugation, to remove particu-

A

The sensitivity for almost all of the ions monitored (Table 1) can be improved

lates if the sample does not dissolve completely.

somewhat by adjusting this percentage to between 60 and 65; however, the

8.3 Instrumental Parameters:

resulting mass spectra may be distorted significantly so that MS computer search

routines for the identification of unknowns by comparison to conventionally 8.3.1 Gas Chromatograph—Use the following parameters:

acquired mass spectral libraries may be impaired significantly.

1-µL splitless injection for 45 s; an initial column temperature

B

Adjust the entrance lens voltage.

of 55°C for 2 min; a temperature ramp at 6°C/min to 270°C; a

C

Adjust the ion focus voltage.

temperature ramp of 3°C/min to 300°C; a final column

7.2.2 Retune every 12 h of mass spectrometer operation.

temperature of 300°C for 17 min; an injection temperature of

7.3 Resolution Check—Under the instrumental conditions

290°C; and a mass spectrometer (MS) interface temperature of

listed (7.1), pristane and phytane usually display 80 % or

300°C. A total run time of approximately 65 min will be

greater resolution from C and C , respectively. If the

17 18 achieved using these parameters.

resolution is less than 50 %, take corrective action such as

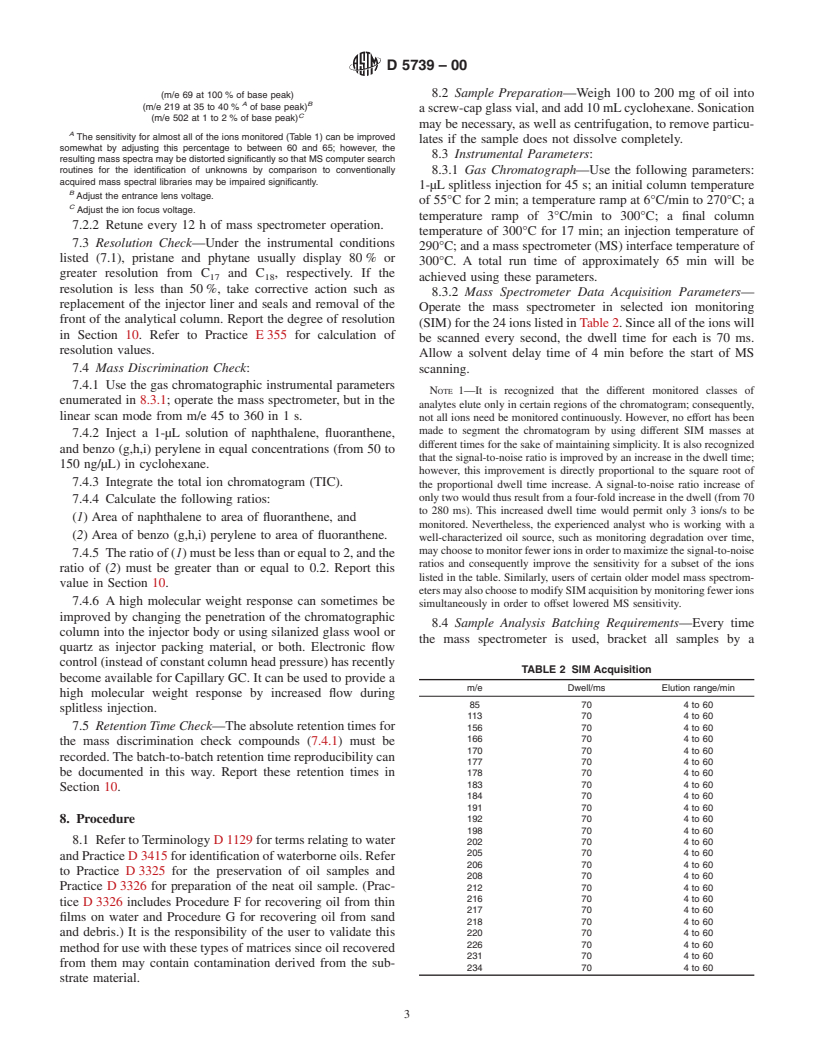

8.3.2 Mass Spectrometer Data Acquisition Parameters—

replacement of the injector liner and seals and removal of the

Operate the mass spectrometer in selected ion monitoring

front of the analytical column. Report the degree of resolution

(SIM)forthe24ionslistedinTable2.Sincealloftheionswill

in Section 10. Refer to Practice E 355 for calculation of

be scanned every second, the dwell time for each is 70 ms.

resolution values.

Allow a solvent delay time of 4 min before the start of MS

7.4 Mass Discrimination Check:

scanning.

7.4.1 Use the gas chromatographic instrumental parameters

NOTE 1—It is recognized that the different monitored classes of

enumerated in 8.3.1; operate the mass spectrometer, but in the

analytes elute only in certain regions of the chromatogram; consequently,

linear scan mode from m/e 45 to 360 in 1 s.

not all ions need be monitored continuously. However, no effort has been

made to segment the chromatogram by using different SIM masses at

7.4.2 Inject a 1-µL solution of naphthalene, fluoranthene,

different times for the sake of maintaining simplicity. It is also recognized

and benzo (g,h,i) perylene in equal concentrations (from 50 to

that the signal-to-noise ratio is improved by an increase in the dwell time;

150 ng/µL) in cyclohexane.

however, this improvement is directly proportional to the square root of

7.4.3 Integrate the total ion chromatogram (TIC).

the proportional dwell time increase. A signal-to-noise ratio increase of

only two would thus result from a four-fold increase in the dwell (from 70

7.4.4 Calculate the following ratios:

to 280 ms). This increased dwell time would permit only 3 ions/s to be

(1) Area of naphthalene to area of fluoranthene, and

monitored. Nevertheless, the experienced analyst who is working with a

(2) Area of benzo (g,h,i) perylene to area of fluoranthene.

well-characterized oil source, such as monitoring degradation over time,

maychoosetomonitorfewerionsinordertomaximizethesignal-to-noise

7.4.5 Theratioof(1)mustbelessthanorequalto2,andthe

ratios and consequently improve the sensitivity for a subset of the ions

ratio of (2) must be greater than or equal to 0.2. Report this

listed in the table. Similarly, users of certain older model mass spectrom-

value in Section 10.

etersmayalsochoosetomodifySIMacquisitionbymonitoringfewerions

7.4.6 A high molecular weight response can sometimes be

simultaneously in order to offset lowered MS sensitivity.

improved by changing the penetration of the chromatographic

8.4 Sample Analysis Batching Requirements—Every time

column into the injector body or using silanized glass wool or

the mass spectrometer is used, bracket all samples by a

quartz as injector packing material, or both. Electronic flow

control (instead of constant column head pressure) has recently

TABLE 2 SIM Acquisition

become available for Capillary GC. It can be used to provide a

m/e Dwell/ms Elution range/min

high molecular weight response by increased flow during

85 70 4 to 60

splitless injection.

113 70 4 to 60

7.5 Retention Time Check—The absolute retention times for

156 70 4 to 60

166 70 4 to 60

the mass discrimination check compounds (7.4.1) must be

170 70 4 to 60

recorded.The batch-to-batch retention time reproducibility can

177 70 4 to 60

be documented in this way. Report these retention times in 178 70 4 to 60

183 70 4 to 60

Section 10.

184 70 4 to 60

191 70 4 to 60

8. Procedure 192 70 4 to 60

198 70 4 to 60

8.1 Refer toTerminology D 1129 for terms relating to water 202 70 4 to 60

205 70 4 to 60

andPracticeD 3415foridentificationofwaterborneoils.Refer

206 70 4 to 60

to Practice D 3325 for the preservation of oil samples and

208 70 4 to 60

Practice D 3326 for preparation of the neat oil sample. (Prac- 212 70 4 to 60

216 70 4 to 60

tice D 3326 includes Procedure F for recovering oil from thin

217 70 4 to 60

films on water and Procedure G for recovering oil from sand

218 70 4 to 60

and debris.) It is the responsibility of the user to validate this 220 70 4 to 60

226 70 4 to 60

method for use with these types of matrices since oil recovered

231 70 4 to 60

from them may contain contamination derived from the sub-

234 70 4 to 60

strate material.

D 5739 – 00

duplicate analysis, and specifically prepare an oil sample in Dibenzothiophene and anthracene/phenanthrene are therefore

duplicate (8.2). Also, the first and last samples to be analyzed inherently more

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.