ASTM C496/C496M-04e1

(Test Method)Standard Test Method for Splitting Tensile Strength of Cylindrical Concrete Specimens

Standard Test Method for Splitting Tensile Strength of Cylindrical Concrete Specimens

SIGNIFICANCE AND USE

Splitting tensile strength is generally greater than direct tensile strength and lower than flexural strength (modulus of rupture).

Splitting tensile strength is used in the design of structural lightweight concrete members to evaluate the shear resistance provided by concrete and to determine the development length of reinforcement.

SCOPE

1.1 This test method covers the determination of the splitting tensile strength of cylindrical concrete specimens, such as molded cylinders and drilled cores.

1.2 The values stated in either inch-pound or SI units are to be regarded separately as standard. The SI units are shown in brackets. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in nonconformance with the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.4 The text of this standard references notes that provide explanatory material. These notes shall not be considered as requirements of the standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation:C496/C496M–04

Standard Test Method for

Splitting Tensile Strength of Cylindrical Concrete

1

Specimens

This standard is issued under the fixed designation C496/C496M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1

´ NOTE—Footnote 3 was reinserted editorially to correct a typo in December 2006.

1. Scope* C670 Practice for Preparing Precision and Bias Statements

for Test Methods for Construction Materials

1.1 This test method covers the determination of the split-

ting tensile strength of cylindrical concrete specimens, such as

3. Summary of Test Method

molded cylinders and drilled cores.

3.1 This test method consists of applying a diametral

1.2 The values stated in either inch-pound or SI units are to

compressive force along the length of a cylindrical concrete

be regarded separately as standard. The SI units are shown in

specimen at a rate that is within a prescribed range until failure

brackets. The values stated in each system may not be exact

occurs. This loading induces tensile stresses on the plane

equivalents;therefore,eachsystemshallbeusedindependently

containing the applied load and relatively high compressive

of the other. Combining values from the two systems may

stresses in the area immediately around the applied load.

result in nonconformance with the standard.

Tensile failure occurs rather than compressive failure because

1.3 This standard does not purport to address all of the

the areas of load application are in a state of triaxial compres-

safety concerns, if any, associated with its use. It is the

sion, thereby allowing them to withstand much higher com-

responsibility of the user of this standard to establish appro-

pressive stresses than would be indicated by a uniaxial com-

priate safety and health practices and determine the applica-

pressive strength test result.

bility of regulatory limitations prior to use.

3.2 Thin, plywood bearing strips are used to distribute the

1.4 The text of this standard references notes that provide

load applied along the length of the cylinder.

explanatory material. These notes shall not be considered as

3.3 Themaximumloadsustainedbythespecimenisdivided

requirements of the standard.

byappropriategeometricalfactorstoobtainthesplittingtensile

2. Referenced Documents strength.

2

2.1 ASTM Standards:

4. Significance and Use

C31/C31M Practice for Making and Curing Concrete Test

4.1 Splitting tensile strength is generally greater than direct

Specimens in the Field

tensile strength and lower than flexural strength (modulus of

C39/C39M Test Method for Compressive Strength of Cy-

rupture).

lindrical Concrete Specimens

4.2 Splitting tensile strength is used in the design of

C42/C42M Test Method for Obtaining and Testing Drilled

structural lightweight concrete members to evaluate the shear

Cores and Sawed Beams of Concrete

resistance provided by concrete and to determine the develop-

C192/C192M Practice for Making and Curing Concrete

ment length of reinforcement.

Test Specimens in the Laboratory

5. Apparatus

1

This test method is under the jurisdiction of ASTM Committee C09 on 5.1 Testing Machine—The testing machine shall conform to

Concrete and ConcreteAggregates and is the direct responsibility of Subcommittee

the requirements of Test Method C39/C39M and be of a type

C09.61 on Testing for Strength.

with sufficient capacity that will provide the rate of loading

Current edition approved Feb. 1, 2004. Published March 2004. Originally

prescribed in 7.5.

approved in 1962. Last previous edition approved in 1996 as C496 – 96. DOI:

10.1520/C0496_C0496M-04E01.

5.2 SupplementaryBearingBarorPlate—Ifthediameteror

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

the largest dimension of the upper bearing face or the lower

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

bearingblockislessthanthelengthofthecylindertobetested,

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. a supplementary bearing bar or plate of machined steel shall be

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

´1

C496/C496M–04

used. The surfaces of the bar or plate shall be machined to 7. Procedure

within 6 0.001 in. [0.025 mm] of planeness, as measured on

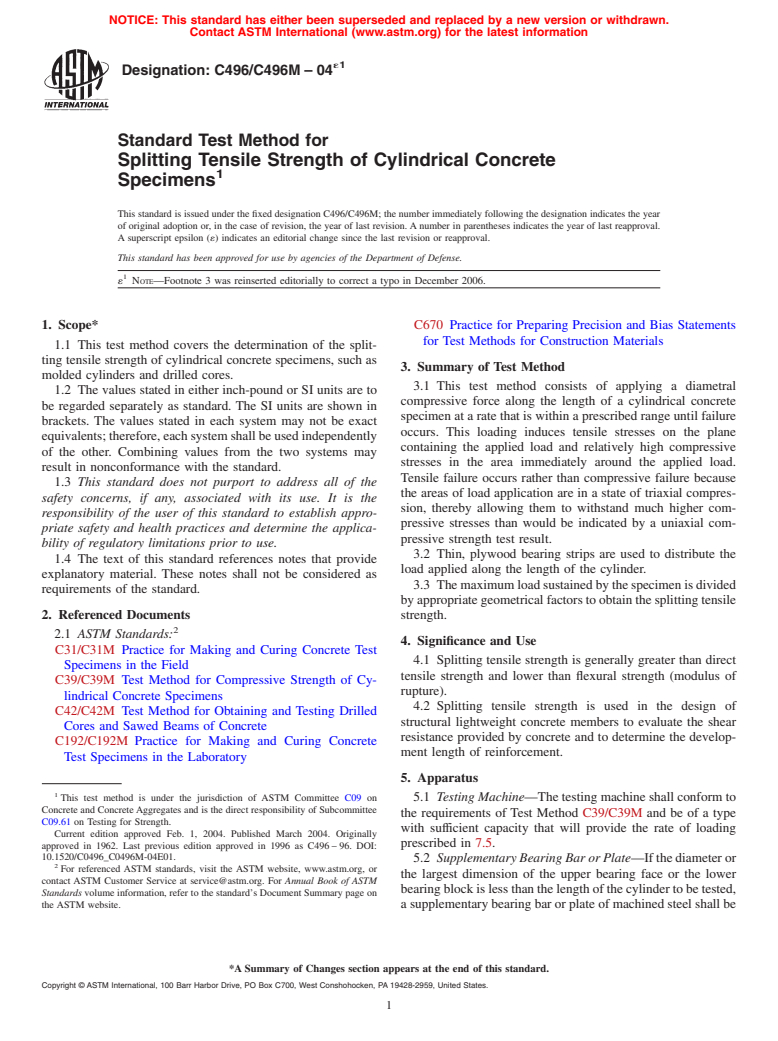

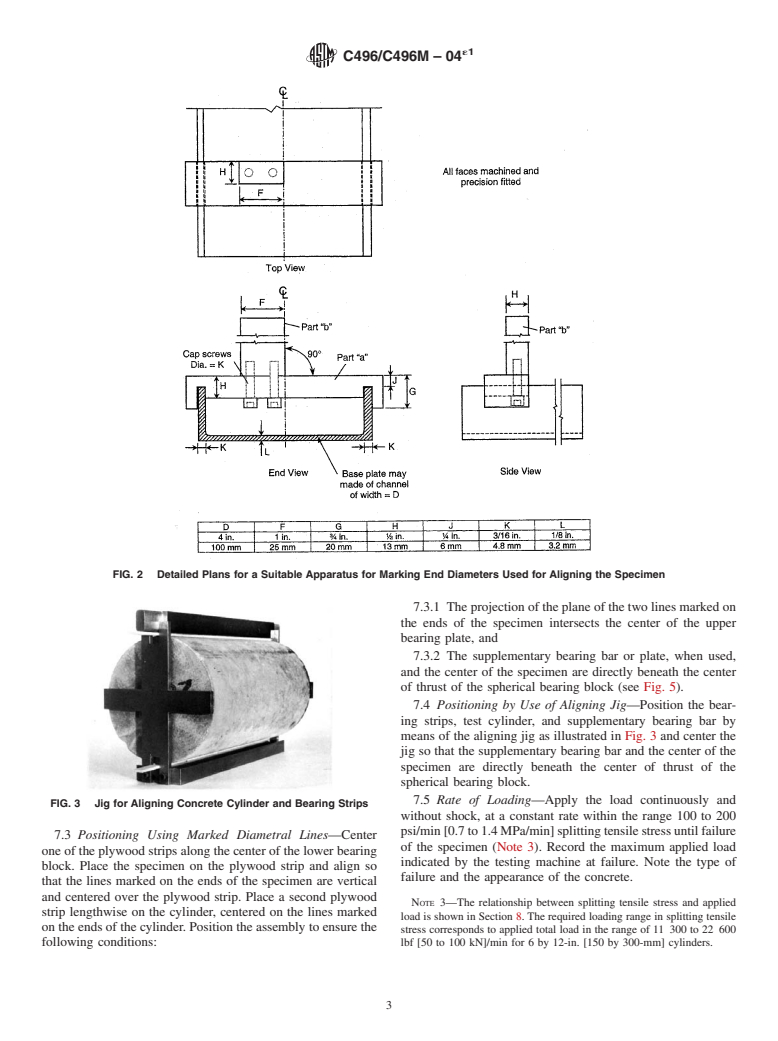

7.1 Marking—Draw diametral lines on each end of the

any li

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.