ASTM A275/A275M-18(2023)

(Practice)Standard Practice for Magnetic Particle Examination of Steel Forgings

Standard Practice for Magnetic Particle Examination of Steel Forgings

ABSTRACT

This test method covers the procedures for the standard practice of performing magnetic particle examination on steel forgings. The inspection medium shall consist of finely divided ferromagnetic particles, whose size, shape and magnetic properties, both individually and collectively, shall be taken into account. Forgings may be magnetized in the longitudinal or circular direction by employing the surge or continuous current flow methods. Magnetization may be applied by passing current through the piece or by inducing a magnetic field by means of a central conductor, such as a prod or yoke, or by coils. While the material is properly magnetized, the magnetic particles may be applied by either the dry method, wet method, or fluorescent method. The parts shall also be sufficiently demagnetized after inspection so that residual or leakage fields will not interfere with future operations to which the steel forgings shall be used for. Indications to be evaluated are grouped into three broad classes, namely: surface defects, which include laminar defects, forging laps and folds, flakes (thermal ruptures caused by entrapped hydrogen), heat-treating cracks, shrinkage cracks, grinding cracks, and etching or plating cracks; subsurface defects, which include stringers of nonmetallic inclusions, large nonmetallics, cracks in underbeads of welds, and forging bursts; and nonrelevant or false indications, which include magnetic writing, changes in section, edge of weld, and flow lines.

SIGNIFICANCE AND USE

4.1 For ferromagnetic materials, magnetic particle examination is widely specified for the detection of surface and near surface discontinuities such as cracks, laps, seams, and linearly oriented nonmetallic inclusions. Such examinations are included as mandatory requirements in some forging standards such as Specification A508/A508M.

4.2 Use of direct current or rectified alternating (full or half wave) current as the power source for magnetic particle examination allows detection of subsurface discontinuities.

SCOPE

1.1 This practice2 covers a procedure for magnetic particle examination of steel forgings. The procedure will produce consistent results upon which acceptance standards can be based. This practice does not contain acceptance standards or recommended quality levels.

1.2 Only direct current or rectified alternating (full or half wave) current shall be used as the electric power source for any of the magnetizing methods. Alternating current is not permitted because its capability to detect subsurface discontinuities is very limited and therefore unsuitable.

1.2.1 Portable battery powered electromagnetic yokes are outside the scope of this practice.

Note 1: Guide E709 may be utilized for magnetic particle examination in the field for machinery components originally manufactured from steel forgings.

1.3 The minimum requirements for magnetic particle examination shall conform to practice standards of Practice E1444/E1444M. If the requirements of this practice are in conflict with the requirements of Practice E1444/E1444M, the requirements of this practice shall prevail.

1.4 This practice and the applicable material specifications are expressed in both inch-pound units and SI units. However, unless the order specifies the applicable “M” specification designation [SI units], the material shall be furnished to inch-pound units.

1.5 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system are not necessarily exact equivalents; therefore, to ensure conformance with the standard, each system shall be used independently of the other, and values from the two systems shall not be combined.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices ...

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: A275/A275M − 18 (Reapproved 2023)

Standard Practice for

Magnetic Particle Examination of Steel Forgings

This standard is issued under the fixed designation A275/A275M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope 1.6 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

1.1 This practice covers a procedure for magnetic particle

responsibility of the user of this standard to establish appro-

examination of steel forgings. The procedure will produce

priate safety, health, and environmental practices and deter-

consistent results upon which acceptance standards can be

mine the applicability of regulatory limitations prior to use.

based. This practice does not contain acceptance standards or

1.7 This international standard was developed in accor-

recommended quality levels.

dance with internationally recognized principles on standard-

1.2 Only direct current or rectified alternating (full or half

ization established in the Decision on Principles for the

wave) current shall be used as the electric power source for any

Development of International Standards, Guides and Recom-

of the magnetizing methods. Alternating current is not permit-

mendations issued by the World Trade Organization Technical

ted because its capability to detect subsurface discontinuities is

Barriers to Trade (TBT) Committee.

very limited and therefore unsuitable.

2. Referenced Documents

1.2.1 Portable battery powered electromagnetic yokes are

outside the scope of this practice. 2.1 ASTM Standards:

A508/A508M Specification for Quenched and Tempered

NOTE 1—Guide E709 may be utilized for magnetic particle examination

Vacuum-Treated Carbon and Alloy Steel Forgings for

in the field for machinery components originally manufactured from steel

Pressure Vessels

forgings.

A788/A788M Specification for Steel Forgings, General Re-

1.3 The minimum requirements for magnetic particle ex-

quirements

amination shall conform to practice standards of Practice

E165/E165M Practice for Liquid Penetrant Testing for Gen-

E1444/E1444M. If the requirements of this practice are in

eral Industry

conflict with the requirements of Practice E1444/E1444M, the

E709 Guide for Magnetic Particle Testing

requirements of this practice shall prevail.

E1351 Practice for Production and Evaluation of Field

1.4 This practice and the applicable material specifications

Metallographic Replicas

are expressed in both inch-pound units and SI units. However,

E1444/E1444M Practice for Magnetic Particle Testing for

unless the order specifies the applicable “M” specification

Aerospace

designation [SI units], the material shall be furnished to

2.2 Other Document:

inch-pound units.

Recommended Practice No. SNT-TC-1A, Supplement

B-Magnetic Particle Method

1.5 The values stated in either SI units or inch-pound units

are to be regarded separately as standard. The values stated in

3. Terminology

each system are not necessarily exact equivalents; therefore, to

3.1 Definitions:

ensure conformance with the standard, each system shall be

3.1.1 indication—the visual magnetic particle buildup re-

used independently of the other, and values from the two

sulting from leakage fields in the magnetic field.

systems shall not be combined.

3.1.2 linear indication—an indication in which the length is

at least three times the width. The minimum length of

indications to be considered linear shall be ⁄16 in. [1.6 mm].

This practice is under the jurisdiction of ASTM Committee A01 on Steel,

Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee

A01.06 on Steel Forgings and Billets. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved March 1, 2023. Published March 2023. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1944. Last previous edition approved in 2018 as A275/A275M – 18. Standards volume information, refer to the standard’s Document Summary page on

DOI: 10.1520/A0275_A0275M-18R23. the ASTM website.

For ASME Boiler and Pressure Vessel Code applications see related Method Available from American Society for Nondestructive Testing (ASNT), P.O. Box

SA-275/SA-275M in Section II of that Code. 28518, 1711 Arlingate Ln., Columbus, OH 43228-0518, http://www.asnt.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

A275/A275M − 18 (2023)

3.1.3 magnetic flux—the product of the magnetic induction machined surface condition and final thermally treated condi-

and the area of a surface (or cross section) when the magnetic tion (including stress relief) or within 0.030 in. [0.8 mm] of the

induction is uniformly distributed and normal to the plane of final machined surface.

the surface. The concept that the magnetic field is flowing

along the lines of force suggests that these lines are therefore 8. Magnetizing Apparatus

“flux” lines, and they are called magnetic flux.

8.1 Rectified alternating (full or half wave) or direct-current

3.1.4 magnetic particle method of examination—a method

electric power sources may be used. When current is passed

for detecting discontinuities on or near the surface in suitably

through the part itself, the equipment shall consist of contact-

magnetized materials, which employs finely divided magnetic

ing or clamping elements with sufficient surface area and

particles that tend to congregate in regions of leakage fields.

clamping pressure to allow the required current to flow without

damaging (burning) the part being examined.

3.1.5 nonrelevant indications—indications produced by

leakage fields. However, the conditions causing them are

8.2 Portable electromagnetic (ac-dc) yokes may be used in

present by design or accident, or other features of the part

the dc mode as a magnetizing apparatus, provided the sensi-

having no relation to the damaging flaws being sought. The

tivity to detect crack-like defects is demonstrated to be at least

term signifies that such an indication has no relation to the

equivalent to that of the direct-magnetization method.

discontinuities that might constitute defects.

8.2.1 Portable battery powered electromagnetic yokes are

not included in the scope of this practice.

4. Significance and Use

4.1 For ferromagnetic materials, magnetic particle examina-

9. Magnetic Particles

tion is widely specified for the detection of surface and near

9.1 The inspection medium shall consist of finely divided

surface discontinuities such as cracks, laps, seams, and linearly

ferromagnetic particles, which may be suspended in a suitable

oriented nonmetallic inclusions. Such examinations are in-

liquid medium, or used in dry powder form.

cluded as mandatory requirements in some forging standards

9.2 The size and shape of the particles, and their magnetic

such as Specification A508/A508M.

properties, both individually and collectively, are important

4.2 Use of direct current or rectified alternating (full or half

(see Section 12).

wave) current as the power source for magnetic particle

examination allows detection of subsurface discontinuities.

10. Surface Preparation

5. Basis of Application

10.1 The sensitivity of the magnetic particle examination

will depend to a considerable extent upon the condition of the

5.1 When in accordance with the requirements of the

surface being tested. Defects may be satisfactorily revealed on

inquiry, contract, order, or specifications, forgings are fur-

shot-blasted or otherwise cleaned forged surfaces, or on

nished subject to magnetic particle examination, the manufac-

surfaces having small amounts of heat-treating scale without

turer and the purchaser shall be in agreement concerning the

any special surface preparation; however, loose scale must be

following:

removed. To reveal fine defects, the surfaces to be inspected

5.1.1 The locations on the forgings that are to be subjected

should be smooth machined to at least a 250 μin. [6.35 μm]

to magnetic particle examination.

finish where the definition for surface finish is as per Specifi-

5.1.2 The type, size, number, location, and orientation of

cation A788/A788M.

indications that are to be considered injurious.

5.1.3 The method of application of magnetic particles,

10.2 The surfaces shall be free of grease, oils, or other

demagnetization requirements and magnetic field strengths.

substances to which the particles may adhere.

5.2 In cases where large undercuts in the forgings are to be

10.3 Rough surfaces hamper the mobility of magnetic

taken by the purchaser, the manufacturer shall be given the

powders due to mechanical trapping, which in turn produces

privilege (when the design permits) of machining slots or

false indications. Such areas should be surface ground. If

grooves in the rough-machined forging to explore the internal

grinding is impractical, a paper tape overlay (as described in

conditions prior to shipping.

15.1.1.2) may eliminate the problem.

5.3 Acceptance standards.

11. Methods of Magnetization

6. Personnel Requirements

11.1 The forging may be magnetized either by passing

6.1 Personnel performing the magnetic particle examination

current through the piece or by inducing a magnetic field by

to this practice shall be qualified and certified in accordance

means of a central conductor or by coils.

with a written procedure conforming to Recommended Prac-

11.1.1 Continuous Method—In the continuous method, the

tice No. SNT-TC-1A or another national standard that is

inspection medium is applied to the surface under inspection

acceptable to both the purchaser and the supplier.

while the current is still flowing. The current source generates

high amperage current in pulses of up to 1 s duration. The

7. Stage of Inspection

duration of this flow shall allow at least three pulses of current

7.1 Unless otherwise specified by the purchaser, acceptance or in the case where machines supply continuous current flow

1 1

inspection shall be performed on a forging in the final a minimum shot of ⁄5 s to ⁄2 s duration should be applied.

A275/A275M − 18 (2023)

11.1.2 Surge Method—In the surge method a high-

magnetizing force is applied and then reduced to a lower

continuous value, which is maintained during application of

the inspection medium.

11.2 At least two separate examinations shall be carried out

on each area. The second examination shall be with the lines of

magnetic flux approximately perpendicular to those used for

the first examination in that area. A different means of

magnetizing may be used for the second examination. Magne-

tizing in more than one direction cannot be accomplished

simultaneously.

NOTE 2—An exception to the above rule is overall sequential multi-

vector magnetization whereby several magnetizing circuits are provided

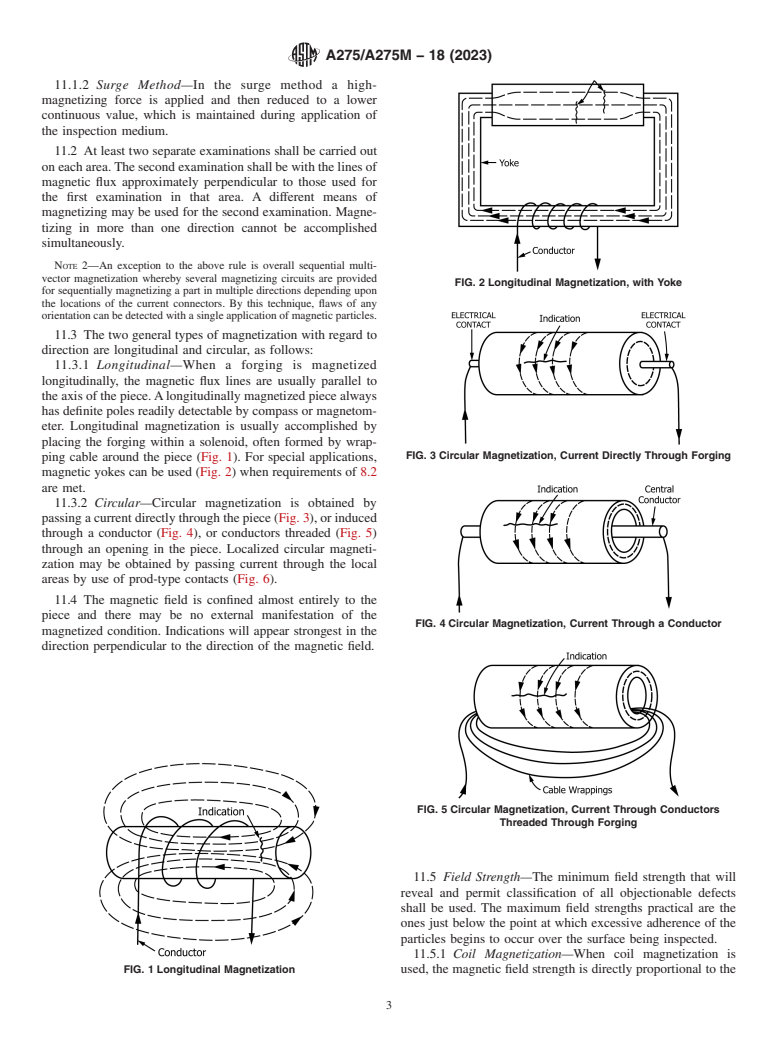

FIG. 2 Longitudinal Magnetization, with Yoke

for sequentially magnetizing a part in multiple directions depending upon

the locations of the current connectors. By this technique, flaws of any

orientation can be detected with a single application of magnetic particles.

11.3 The two general types of magnetization with regard to

direction are longitudinal and circular, as follows:

11.3.1 Longitudinal—When a forging is magnetized

longitudinally, the magnetic flux lines are usually parallel to

the axis of the piece. A longitudinally magnetized piece always

has definite poles readily detectable by compass or magnetom-

eter. Longitudinal magnetization is usually accomplished by

placing the forging within a solenoid, often formed by wrap-

FIG. 3 Circular Magnetization, Current Directly Through Forging

ping cable around the piece (Fig. 1). For special applications,

magnetic yokes can be used (Fig. 2) when requirements of 8.2

are met.

11.3.2 Circular—Circular magnetization is obtained by

passing a current directly through the piece (Fig. 3), or induced

through a conductor (Fig. 4), or conductors threaded (Fig. 5)

through an opening in the piece. Localized circular magneti-

zation may be obtained by passing current through the local

areas by use of prod-type contacts (Fig. 6).

11.4 The magnetic field is confined almost entirely to the

piece and there may be no external manifestation of the

FIG. 4 Circular Magnetization, Current Through a Conductor

magnetized condition. Indications will appear strongest in the

direction perpendicular to the direction of the magnetic field.

FIG. 5 Circular Magnetization, Current Through Conductors

Threaded Through Forging

11.5 Field Strength—The minimum field strength that will

reveal and permit classification of all objectionable defects

shall be used. The maximum field strengths practical are the

ones just below the point at which excessive adherence of the

particles begins to occur over the surface being inspected.

11.5.1 Coil Magnetization—When coil magnetization is

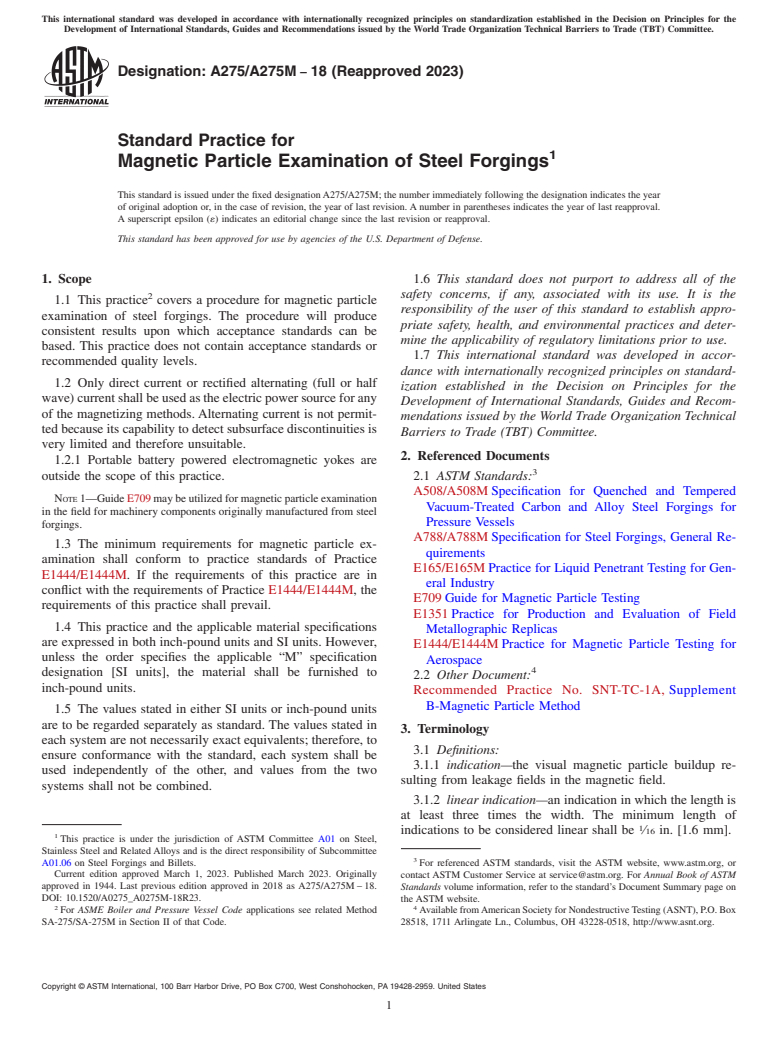

FIG. 1 Longitudinal Magnetization used, the magnetic field strength is directly proportional to the

A275/A275M − 18 (2023)

ampere-turns. A field indicator (see 11.5.6) shall be used to

demonstrate the presence of an adequate field strength over the

area to be inspected.

11.5.1.2 Circular Magnetization (Fig. 5)—For circular mag-

netization with through coils, use the current with amperage as

specified in 11.5.2 divided by the number of turns in the coil.

11.5.2 Direct Magnetization—When current is passed di-

rectly through the part to be examined, the current shall be

FIG. 6 Circular Magnetization with “Prod” Type Contact

between 100 A per inch and 900 A per inch [4 A per millimetre

Electrodes

and 35 A per millimetre] of diameter or cross section (per inch

or millimetre of greatest width in a plane at right angles to

current flow). For hollow parts this would be wall thickness

when cables are clamped to the wall. Suggested current for

diameters or sections up to 5 in. [125 mm] are 600 A per inch

to 900 A per inch [25 A per millimetre to 35 A per millimetre];

for diameters or sections between 5 in. and 10 in. [125 mm to

250 mm], 400 A per inch to 600 A per inch [15 A per

millimetre to 25 A per millimetre]; and 100 A per inch to 400 A

per inch [4 A per millimetre to 15 A per millimetre] for outside

diameters or sections over 10 in. [250 mm]. If i

...

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: A275/A275M − 18 (Reapproved 2023)

Standard Practice for

Magnetic Particle Examination of Steel Forgings

This standard is issued under the fixed designation A275/A275M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope 1.6 This standard does not purport to address all of the

2 safety concerns, if any, associated with its use. It is the

1.1 This practice covers a procedure for magnetic particle

responsibility of the user of this standard to establish appro-

examination of steel forgings. The procedure will produce

priate safety, health, and environmental practices and deter-

consistent results upon which acceptance standards can be

mine the applicability of regulatory limitations prior to use.

based. This practice does not contain acceptance standards or

1.7 This international standard was developed in accor-

recommended quality levels.

dance with internationally recognized principles on standard-

1.2 Only direct current or rectified alternating (full or half

ization established in the Decision on Principles for the

wave) current shall be used as the electric power source for any

Development of International Standards, Guides and Recom-

of the magnetizing methods. Alternating current is not permit-

mendations issued by the World Trade Organization Technical

ted because its capability to detect subsurface discontinuities is

Barriers to Trade (TBT) Committee.

very limited and therefore unsuitable.

2. Referenced Documents

1.2.1 Portable battery powered electromagnetic yokes are

outside the scope of this practice.

2.1 ASTM Standards:

A508/A508M Specification for Quenched and Tempered

NOTE 1—Guide E709 may be utilized for magnetic particle examination

Vacuum-Treated Carbon and Alloy Steel Forgings for

in the field for machinery components originally manufactured from steel

Pressure Vessels

forgings.

A788/A788M Specification for Steel Forgings, General Re-

1.3 The minimum requirements for magnetic particle ex-

quirements

amination shall conform to practice standards of Practice

E165/E165M Practice for Liquid Penetrant Testing for Gen-

E1444/E1444M. If the requirements of this practice are in

eral Industry

conflict with the requirements of Practice E1444/E1444M, the

E709 Guide for Magnetic Particle Testing

requirements of this practice shall prevail.

E1351 Practice for Production and Evaluation of Field

1.4 This practice and the applicable material specifications

Metallographic Replicas

are expressed in both inch-pound units and SI units. However,

E1444/E1444M Practice for Magnetic Particle Testing for

unless the order specifies the applicable “M” specification

Aerospace

designation [SI units], the material shall be furnished to

2.2 Other Document:

inch-pound units.

Recommended Practice No. SNT-TC-1A, Supplement

B-Magnetic Particle Method

1.5 The values stated in either SI units or inch-pound units

are to be regarded separately as standard. The values stated in

3. Terminology

each system are not necessarily exact equivalents; therefore, to

3.1 Definitions:

ensure conformance with the standard, each system shall be

3.1.1 indication—the visual magnetic particle buildup re-

used independently of the other, and values from the two

sulting from leakage fields in the magnetic field.

systems shall not be combined.

3.1.2 linear indication—an indication in which the length is

at least three times the width. The minimum length of

indications to be considered linear shall be ⁄16 in. [1.6 mm].

This practice is under the jurisdiction of ASTM Committee A01 on Steel,

Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee

A01.06 on Steel Forgings and Billets. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved March 1, 2023. Published March 2023. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1944. Last previous edition approved in 2018 as A275/A275M – 18. Standards volume information, refer to the standard’s Document Summary page on

DOI: 10.1520/A0275_A0275M-18R23. the ASTM website.

2 4

For ASME Boiler and Pressure Vessel Code applications see related Method Available from American Society for Nondestructive Testing (ASNT), P.O. Box

SA-275/SA-275M in Section II of that Code. 28518, 1711 Arlingate Ln., Columbus, OH 43228-0518, http://www.asnt.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

A275/A275M − 18 (2023)

3.1.3 magnetic flux—the product of the magnetic induction machined surface condition and final thermally treated condi-

and the area of a surface (or cross section) when the magnetic tion (including stress relief) or within 0.030 in. [0.8 mm] of the

induction is uniformly distributed and normal to the plane of final machined surface.

the surface. The concept that the magnetic field is flowing

along the lines of force suggests that these lines are therefore 8. Magnetizing Apparatus

“flux” lines, and they are called magnetic flux.

8.1 Rectified alternating (full or half wave) or direct-current

3.1.4 magnetic particle method of examination—a method

electric power sources may be used. When current is passed

for detecting discontinuities on or near the surface in suitably

through the part itself, the equipment shall consist of contact-

magnetized materials, which employs finely divided magnetic

ing or clamping elements with sufficient surface area and

particles that tend to congregate in regions of leakage fields.

clamping pressure to allow the required current to flow without

damaging (burning) the part being examined.

3.1.5 nonrelevant indications—indications produced by

leakage fields. However, the conditions causing them are

8.2 Portable electromagnetic (ac-dc) yokes may be used in

present by design or accident, or other features of the part

the dc mode as a magnetizing apparatus, provided the sensi-

having no relation to the damaging flaws being sought. The

tivity to detect crack-like defects is demonstrated to be at least

term signifies that such an indication has no relation to the

equivalent to that of the direct-magnetization method.

discontinuities that might constitute defects.

8.2.1 Portable battery powered electromagnetic yokes are

not included in the scope of this practice.

4. Significance and Use

4.1 For ferromagnetic materials, magnetic particle examina-

9. Magnetic Particles

tion is widely specified for the detection of surface and near

9.1 The inspection medium shall consist of finely divided

surface discontinuities such as cracks, laps, seams, and linearly

ferromagnetic particles, which may be suspended in a suitable

oriented nonmetallic inclusions. Such examinations are in-

liquid medium, or used in dry powder form.

cluded as mandatory requirements in some forging standards

9.2 The size and shape of the particles, and their magnetic

such as Specification A508/A508M.

properties, both individually and collectively, are important

4.2 Use of direct current or rectified alternating (full or half

(see Section 12).

wave) current as the power source for magnetic particle

examination allows detection of subsurface discontinuities.

10. Surface Preparation

5. Basis of Application

10.1 The sensitivity of the magnetic particle examination

will depend to a considerable extent upon the condition of the

5.1 When in accordance with the requirements of the

surface being tested. Defects may be satisfactorily revealed on

inquiry, contract, order, or specifications, forgings are fur-

shot-blasted or otherwise cleaned forged surfaces, or on

nished subject to magnetic particle examination, the manufac-

surfaces having small amounts of heat-treating scale without

turer and the purchaser shall be in agreement concerning the

any special surface preparation; however, loose scale must be

following:

removed. To reveal fine defects, the surfaces to be inspected

5.1.1 The locations on the forgings that are to be subjected

should be smooth machined to at least a 250 µin. [6.35 µm]

to magnetic particle examination.

finish where the definition for surface finish is as per Specifi-

5.1.2 The type, size, number, location, and orientation of

cation A788/A788M.

indications that are to be considered injurious.

5.1.3 The method of application of magnetic particles,

10.2 The surfaces shall be free of grease, oils, or other

demagnetization requirements and magnetic field strengths.

substances to which the particles may adhere.

5.2 In cases where large undercuts in the forgings are to be

10.3 Rough surfaces hamper the mobility of magnetic

taken by the purchaser, the manufacturer shall be given the

powders due to mechanical trapping, which in turn produces

privilege (when the design permits) of machining slots or

false indications. Such areas should be surface ground. If

grooves in the rough-machined forging to explore the internal

grinding is impractical, a paper tape overlay (as described in

conditions prior to shipping.

15.1.1.2) may eliminate the problem.

5.3 Acceptance standards.

11. Methods of Magnetization

6. Personnel Requirements

11.1 The forging may be magnetized either by passing

6.1 Personnel performing the magnetic particle examination

current through the piece or by inducing a magnetic field by

to this practice shall be qualified and certified in accordance

means of a central conductor or by coils.

with a written procedure conforming to Recommended Prac-

11.1.1 Continuous Method—In the continuous method, the

tice No. SNT-TC-1A or another national standard that is

inspection medium is applied to the surface under inspection

acceptable to both the purchaser and the supplier.

while the current is still flowing. The current source generates

high amperage current in pulses of up to 1 s duration. The

7. Stage of Inspection

duration of this flow shall allow at least three pulses of current

7.1 Unless otherwise specified by the purchaser, acceptance or in the case where machines supply continuous current flow

1 1

inspection shall be performed on a forging in the final a minimum shot of ⁄5 s to ⁄2 s duration should be applied.

A275/A275M − 18 (2023)

11.1.2 Surge Method—In the surge method a high-

magnetizing force is applied and then reduced to a lower

continuous value, which is maintained during application of

the inspection medium.

11.2 At least two separate examinations shall be carried out

on each area. The second examination shall be with the lines of

magnetic flux approximately perpendicular to those used for

the first examination in that area. A different means of

magnetizing may be used for the second examination. Magne-

tizing in more than one direction cannot be accomplished

simultaneously.

NOTE 2—An exception to the above rule is overall sequential multi-

vector magnetization whereby several magnetizing circuits are provided

FIG. 2 Longitudinal Magnetization, with Yoke

for sequentially magnetizing a part in multiple directions depending upon

the locations of the current connectors. By this technique, flaws of any

orientation can be detected with a single application of magnetic particles.

11.3 The two general types of magnetization with regard to

direction are longitudinal and circular, as follows:

11.3.1 Longitudinal—When a forging is magnetized

longitudinally, the magnetic flux lines are usually parallel to

the axis of the piece. A longitudinally magnetized piece always

has definite poles readily detectable by compass or magnetom-

eter. Longitudinal magnetization is usually accomplished by

placing the forging within a solenoid, often formed by wrap-

FIG. 3 Circular Magnetization, Current Directly Through Forging

ping cable around the piece (Fig. 1). For special applications,

magnetic yokes can be used (Fig. 2) when requirements of 8.2

are met.

11.3.2 Circular—Circular magnetization is obtained by

passing a current directly through the piece (Fig. 3), or induced

through a conductor (Fig. 4), or conductors threaded (Fig. 5)

through an opening in the piece. Localized circular magneti-

zation may be obtained by passing current through the local

areas by use of prod-type contacts (Fig. 6).

11.4 The magnetic field is confined almost entirely to the

piece and there may be no external manifestation of the

FIG. 4 Circular Magnetization, Current Through a Conductor

magnetized condition. Indications will appear strongest in the

direction perpendicular to the direction of the magnetic field.

FIG. 5 Circular Magnetization, Current Through Conductors

Threaded Through Forging

11.5 Field Strength—The minimum field strength that will

reveal and permit classification of all objectionable defects

shall be used. The maximum field strengths practical are the

ones just below the point at which excessive adherence of the

particles begins to occur over the surface being inspected.

11.5.1 Coil Magnetization—When coil magnetization is

FIG. 1 Longitudinal Magnetization used, the magnetic field strength is directly proportional to the

A275/A275M − 18 (2023)

ampere-turns. A field indicator (see 11.5.6) shall be used to

demonstrate the presence of an adequate field strength over the

area to be inspected.

11.5.1.2 Circular Magnetization (Fig. 5)—For circular mag-

netization with through coils, use the current with amperage as

specified in 11.5.2 divided by the number of turns in the coil.

11.5.2 Direct Magnetization—When current is passed di-

rectly through the part to be examined, the current shall be

FIG. 6 Circular Magnetization with “Prod” Type Contact

between 100 A per inch and 900 A per inch [4 A per millimetre

Electrodes

and 35 A per millimetre] of diameter or cross section (per inch

or millimetre of greatest width in a plane at right angles to

current flow). For hollow parts this would be wall thickness

when cables are clamped to the wall. Suggested current for

diameters or sections up to 5 in. [125 mm] are 600 A per inch

to 900 A per inch [25 A per millimetre to 35 A per millimetre];

for diameters or sections between 5 in. and 10 in. [125 mm to

250 mm], 400 A per inch to 600 A per inch [15 A per

millimetre to 25 A per millimetre]; and 100 A per inch to 400 A

per inch [4 A per millimetre to 15 A per millimetre] for outside

diameters or sections over 10 in. [250 mm]. If it is not practical

to obtain these current levels for diameters over 10 in.

[250 mm], the prese

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: A275/A275M − 18 A275/A275M − 18 (Reapproved 2023)

Standard Practice for

Magnetic Particle Examination of Steel Forgings

This standard is issued under the fixed designation A275/A275M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope*Scope

1.1 This practice covers a procedure for magnetic particle examination of steel forgings. The procedure will produce consistent

results upon which acceptance standards can be based. This practice does not contain acceptance standards or recommended

quality levels.

1.2 Only direct current or rectified alternating (full or half wave) current shall be used as the electric power source for any of the

magnetizing methods. Alternating current is not permitted because its capability to detect subsurface discontinuities is very limited

and therefore unsuitable.

1.2.1 Portable battery powered electromagnetic yokes are outside the scope of this practice.

NOTE 1—Guide E709 may be utilized for magnetic particle examination in the field for machinery components originally manufactured from steel

forgings.

1.3 The minimum requirements for magnetic particle examination shall conform to practice standards of Practice E1444/E1444M.

If the requirements of this practice are in conflict with the requirements of Practice E1444/E1444M, the requirements of this

practice shall prevail.

1.4 This practice and the applicable material specifications are expressed in both inch-pound units and SI units. However, unless

the order specifies the applicable “M” specification designation [SI units], the material shall be furnished to inch-pound units.

1.5 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each

system may not beare not necessarily exact equivalents; therefore, to ensure conformance with the standard, each system shall be

used independently of the other. Combiningother, and values from the two systems may result in non-conformance with the

standard.shall not be combined.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of

regulatory limitations prior to use.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

This practice is under the jurisdiction of ASTM Committee A01 on Steel, Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee A01.06

on Steel Forgings and Billets.

Current edition approved May 1, 2018March 1, 2023. Published May 2018March 2023. Originally approved in 1944. Last previous edition approved in 20152018 as

A275/A275M – 15.A275/A275M – 18. DOI: 10.1520/A0275_A0275M-18.10.1520/A0275_A0275M-18R23.

For ASME Boiler and Pressure Vessel Code applications see related Method SA-275/SA-275M in Section II of that Code.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

A275/A275M − 18 (2023)

2. Referenced Documents

2.1 ASTM Standards:

A508/A508M Specification for Quenched and Tempered Vacuum-Treated Carbon and Alloy Steel Forgings for Pressure Vessels

A788/A788M Specification for Steel Forgings, General Requirements

E165/E165M Practice for Liquid Penetrant Testing for General Industry

E709 Guide for Magnetic Particle Testing

E1351 Practice for Production and Evaluation of Field Metallographic Replicas

E1444/E1444M Practice for Magnetic Particle Testing for Aerospace

2.2 Other Document:

Recommended Practice No. SNT-TC-1A, Supplement B-Magnetic Particle Method

3. Terminology

3.1 Definitions:

3.1.1 indication—the visual magnetic particle buildup resulting from leakage fields in the magnetic field.

3.1.2 linear indication—an indication in which the length is at least three times the width. The minimum length of indications to

be considered linear shall be ⁄16 in. [1.6 mm].

3.1.3 magnetic flux—the product of the magnetic induction and the area of a surface (or cross section) when the magnetic induction

is uniformly distributed and normal to the plane of the surface. The concept that the magnetic field is flowing along the lines of

force suggests that these lines are therefore “flux” lines, and they are called magnetic flux.

3.1.4 magnetic particle method of examination—a method for detecting discontinuities on or near the surface in suitably

magnetized materials, which employs finely divided magnetic particles that tend to congregate in regions of leakage fields.

3.1.5 nonrelevant indications—indications produced by leakage fields. However, the conditions causing them are present by

design or accident, or other features of the part having no relation to the damaging flaws being sought. The term signifies that such

an indication has no relation to the discontinuities that might constitute defects.

4. Significance and Use

4.1 For ferromagnetic materials, magnetic particle examination is widely specified for the detection of surface and near surface

discontinuities such as cracks, laps, seams, and linearly oriented nonmetallic inclusions. Such examinations are included as

mandatory requirements in some forging standards such as Specification A508/A508M.

4.2 Use of direct current or rectified alternating (full or half wave) current as the power source for magnetic particle examination

allows detection of subsurface discontinuities.

5. Basis of Application

5.1 When in accordance with the requirements of the inquiry, contract, order, or specifications, forgings are furnished subject to

magnetic particle examination, the manufacturer and the purchaser shall be in agreement concerning the following:

5.1.1 The locations on the forgings that are to be subjected to magnetic particle examination.

5.1.2 The type, size, number, location, and orientation of indications that are to be considered injurious.

5.1.3 The method of application of magnetic particles, demagnetization requirements and magnetic field strengths.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’sstandard’s Document Summary page on the ASTM website.

Available from American Society for Nondestructive Testing (ASNT), P.O. Box 28518, 1711 Arlingate Ln., Columbus, OH 43228-0518, http://www.asnt.org.

A275/A275M − 18 (2023)

5.2 In cases where large undercuts in the forgings are to be taken by the purchaser, the manufacturer shall be given the privilege

(when the design permits) of machining slots or grooves in the rough-machined forging to explore the internal conditions prior to

shipping.

5.3 Acceptance standards.

6. Personnel Requirements

6.1 Personnel performing the magnetic particle examination to this practice shall be qualified and certified in accordance with a

written procedure conforming to Recommended Practice No. SNT-TC-1A or another national standard that is acceptable to both

the purchaser and the supplier.

7. Stage of Inspection

7.1 Unless otherwise specified by the purchaser, acceptance inspection shall be performed on a forging in the final machined

surface condition and final thermally treated condition (including stress relief) or within 0.030 in. [0.8 mm] of the final machined

surface.

8. Magnetizing Apparatus

8.1 Rectified alternating (full or half wave) or direct-current electric power sources may be used. When current is passed through

the part itself, the equipment shall consist of contacting or clamping elements with sufficient surface area and clamping pressure

to allow the required current to flow without damaging (burning) the part being examined.

8.2 Portable electromagnetic (ac-dc) yokes may be used in the dc mode as a magnetizing apparatus, provided the sensitivity to

detect crack-like defects is demonstrated to be at least equivalent to that of the direct-magnetization method.

8.2.1 Portable battery powered electromagnetic yokes are not included in the scope of this practice.

9. Magnetic Particles

9.1 The inspection medium shall consist of finely divided ferromagnetic particles, which may be suspended in a suitable liquid

medium, or used in dry powder form.

9.2 The size and shape of the particles, and their magnetic properties, both individually and collectively, are important (see Section

12).

10. Surface Preparation

10.1 The sensitivity of the magnetic particle examination will depend to a considerable extent upon the condition of the surface

being tested. Defects may be satisfactorily revealed on shot-blasted or otherwise cleaned forged surfaces, or on surfaces having

small amounts of heat-treating scale without any special surface preparation; however, loose scale must be removed. To reveal fine

defects, the surfaces to be inspected should be smooth machined to at least a 250-μin. [6.35-μm]250 μin. [6.35 μm] finish where

the definition for surface finish is as per Specification A788/A788M.

10.2 The surfaces shall be free of grease, oils, or other substances to which the particles may adhere.

10.3 Rough surfaces hamper the mobility of magnetic powders due to mechanical trapping, which in turn produces false

indications. Such areas should be surface ground. If grinding is impractical, a paper tape overlay (as described in 15.1.1.2) may

eliminate the problem.

11. Methods of Magnetization

11.1 The forging may be magnetized either by passing current through the piece or by inducing a magnetic field by means of a

central conductor or by coils.

A275/A275M − 18 (2023)

11.1.1 Continuous Method—In the continuous method, the inspection medium is applied to the surface under inspection while the

current is still flowing. The current source generates high amperage current in pulses of up to 1-s1 s duration. The duration of this

flow shall allow at least three pulses of current or in the case where machines supply continuous current flow a minimum shot of

1 1

⁄5 s to ⁄2-s s duration should be applied.

11.1.2 Surge Method—In the surge method a high-magnetizing force is applied and then reduced to a lower continuous value,

which is maintained during application of the inspection medium.

11.2 At least two separate examinations shall be carried out on each area. The second examination shall be with the lines of

magnetic flux approximately perpendicular to those used for the first examination in that area. A different means of magnetizing

may be used for the second examination. Magnetizing in more than one direction cannot be accomplished simultaneously.

NOTE 2—An exception to the above rule is overall sequential multivector magnetization whereby several magnetizing circuits are provided for

sequentially magnetizing a part in multiple directions depending upon the locations of the current connectors. By this technique, flaws of any orientation

can be detected with a single application of magnetic particles.

11.3 The two general types of magnetization with regard to direction are longitudinal and circular, as follows:

11.3.1 Longitudinal—When a forging is magnetized longitudinally, the magnetic flux lines are usually parallel to the axis of the

piece. A longitudinally magnetized piece always has definite poles readily detectable by compass or magnetometer. Longitudinal

magnetization is usually accomplished by placing the forging within a solenoid, often formed by wrapping cable around the piece

(Fig. 1). For special applications, magnetic yokes can be used (Fig. 2) when requirements of 8.2 are met.

11.3.2 Circular—Circular magnetization is obtained by passing a current directly through the piece (Fig. 3), or induced through

a conductor (Fig. 4), or conductors threaded (Fig. 5) through an opening in the piece. Localized circular magentizationmagneti-

zation may be obtained by passing current through the local areas by use of prod-type contacts (Fig. 6).

11.4 The magnetic field is confined almost entirely to the piece and there may be no external manifestation of the magnetized

condition. Indications will appear strongest in the direction perpendicular to the direction of the magnetic field.

FIG. 1 Longitudinal Magnetization

A275/A275M − 18 (2023)

FIG. 2 Longitudinal Magnetization, with Yoke

FIG. 3 Circular Magnetization, Current Directly Through Forging

FIG. 4 Circular Magnetization, Current Through a Conductor

FIG. 5 Circular Magnetization, Current Through Conductors Threaded Through Forging

11.5 Field Strength—The minimum field strength that will reveal and permit classification of all objectionable defects shall be

used. The maximum field strengths practical are the ones just below the point at which excessive adherence of the particles begins

to occur over the surface being inspected.

11.5.1 Coil Magnetization—When coil magnetization is used, the magnetic field strength is directly proportional to the current

(ampere-turns if a coil or solenoid is used) and inversely proportional to the thickness of the section being inspected.

A275/A275M − 18 (2023)

FIG. 6 Circular Magnetization with “Prod” Type Contact

Electrodes

11.5.1.1 Longitudinal Magnetization—For encircling coils (Fig. 1), the turns of the coil shall be kept closely together. The field

strength decreases as distance from the coil increases and long parts must be magnetized in sections. If the area to be inspected

extends beyond 6 in. [150 mm] on either side of the coils, the adequacy of the field shall be demonstrated by the use of field

indicators (see 11.5.6).

(1) Small Forgings—Magnetizing force shall be 35 00035 000 ampere-turns divided by the sum of 2 plus the “length over

dia

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.