ASTM F1791-00(2013)

(Specification)Standard Specification for Filters Used in Air or Nitrogen Systems

Standard Specification for Filters Used in Air or Nitrogen Systems

ABSTRACT

This specification covers the design, construction, test, and performance requirements for air or nitrogen system filters, referred to hereinafter as filters. These filters are intended to be installed in-line to protect equipment from particular contamination. Filter element type: type 1 - disposable, and type 2 - cleanable. Filter element bypass composition - composition A - with bypass, and composition B - without bypass. Filter element differential indicator style: style I - with differential pressure indicator, and style II - without differential pressure indicator. Visual examination, hydrostatic shell test, external leakage test, and bubble point test shall be performed to meet the requirements prescribed.

SCOPE

1.1 This specification covers the design, construction, test, and performance requirements for air or nitrogen system filters, referred to hereinafter as filters. These filters are intended to be installed in-line to protect equipment from particular contamination.

1.2 The values stated in this specification in inch-pounds units are to be regarded as the standard. The SI equivalent shown in parentheses are provided for information only.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F1791 −00 (Reapproved 2013) An American National Standard

Standard Specification for

1

Filters Used in Air or Nitrogen Systems

This standard is issued under the fixed designation F1791; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

5

1. Scope 2.4 Military Standards and Specifications:

MIL-STD-167-1 Mechanical Vibrations of Shipboard

1.1 This specification covers the design, construction, test,

Equipment (Type I—Environmental and Type II—

andperformancerequirementsforairornitrogensystemfilters,

Internally Excited)

referred to hereinafter as filters.These filters are intended to be

MIL-STD-740-1 Airborne Sound Measurements andAccep-

installed in-line to protect equipment from particular contami-

tance Criteria of Shipboard Equipment

nation.

MS16142 Boss, Gasket Seal Straight Thread Tube Fitting,

1.2 The values stated in this specification in inch-pounds

Standard Dimensions for

units are to be regarded as the standard. The SI equivalent

MIL-S-901 Shock Tests, H.I. (High-Impact); Shipboard

shown in parentheses are provided for information only.

Machinery, Equipment and Systems, Requirements for

1.3 This international standard was developed in accor-

MIL-F-1183 Fittings, Pipe, Cast Bronze, Silver-Brazing,

dance with internationally recognized principles on standard- General Specifications for

ization established in the Decision on Principles for the

2.5 Naval SEA Systems Command (NAVSEA)—Government

5

Development of International Standards, Guides and Recom-

Drawings:

mendations issued by the World Trade Organization Technical

NAVSEA 803-1385884 Unions, Fittings and Adapters Butt

Barriers to Trade (TBT) Committee.

and Socket Welding 6000 PSI, WOG, NPS

NAVSEA 803-1385943 Unions, Silver Brazing 3000 PSI,

2. Referenced Documents

WOG, NPS, for UT Inspection

2 NAVSEA 803-1385946 Unions, Bronze Silver Brazing,

2.1 ASTM Standards:

WOG for UT Inspection

F992 Specification for Valve Label Plates

3

2.2 American Society of Mechanical Engineers (ASME): 3. Terminology

B1.1 United Screw Threads (UN and UNR Thread Form)

3.1 Definitions:

B1.20.1 Pipe Threads, General Purpose (Inch)

3.1.1 absolute contaminant removal rating—the smallest

B16.11 Forged Steel Fittings, Socket-Welding and Threaded

size of contaminant as defined in ARP 901 that the filter will

B16.25 Buttwelding Ends

retain with 100 % efficiency by weight.

B16.34 Flanged, Threaded, and Welded End

3.1.2 bubble point—the pressure differential across a sub-

4

2.3 Society of Automotive Engineers (SAE):

merged filter element required to produce a visible and steady

ARP 901 Aerospace Recommended Practice—Bubble-Point

stream of air bubbles. Correlation between bubble point and

Test Method

contaminant removal capability provides an economical means

to test for contaminant removal capability on a production

basis.The bubble point indicates the maximum pore size of the

1

This specification is under the jurisdiction of ASTM Committee F25 on Ships filter media under static conditions.

and Marine Technology and is the direct responsibility of Subcommittee F25.11 on

3.1.3 bubble-tight—no visible leakage over a 3-min period

Machinery and Piping Systems.

usingeitherwatersubmersionortheapplicationofbubblefluid

Current edition approved May 1, 2013. Published May 2013. Originally

approved in 1997. Last previous edition approved in 2006 as F1791 – 00 (2006).

for detection.

DOI: 10.1520/F1791-00R13.

3.1.4 clean filter element pressure drop—the pressure drop

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM across the filter element when it is new or uncontaminated.

Standards volume information, refer to the standard’s Document Summary page on

3.1.5 cleanable filter element—a filter element that, after

the ASTM website.

3

being contaminated to its dirt-holding capacity (contaminated

Available from American Society of Mechanical Engineers (ASME), ASME

International Headquarters, Two Park Ave., New York, NY 10016-5990, http://

www.asme.org.

4 5

Available from SAE International (SAE), 400 Commonwealth Dr.,Warrendale, Available from DLA Document Services, Building 4/D, 700 Robbins Ave.,

PA 15096, http://www.sae.org. Philadelphia, PA 19111-5094, http://quicksearch.dla.mil.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

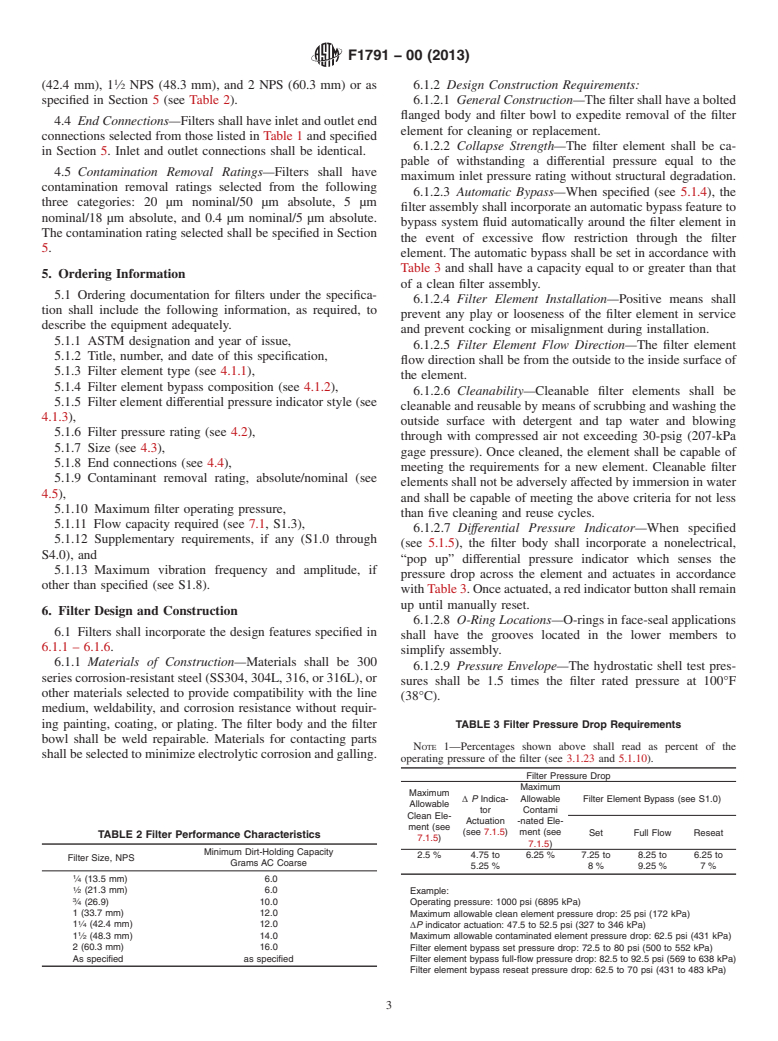

F1791−00 (2013)

filter element pressure drop), can be restored by cleaning to air-borne dust combined with the media during its

operational condition an

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.