ASTM G124-95(2003)

(Test Method)Standard Test Method for Determining the Combustion Behavior of Metallic Materials in Oxygen-Enriched Atmospheres

Standard Test Method for Determining the Combustion Behavior of Metallic Materials in Oxygen-Enriched Atmospheres

SIGNIFICANCE AND USE

This test method will allow comparisons of the combustion characteristics of various metallic materials. The combustion characteristics that can be evaluated include (1) threshold pressure and (2) average regression rate (apparent burn rate) of the sample.

SCOPE

1.1 This test method covers a test apparatus and technique to determine the minimum test gas pressure that supports self-sustained combustion (the threshold pressure) and the average regression rate (apparent burn rate) of a standardized sample of a metallic material that has been ignited using a strong promoter.

1.2 The data obtained from this test method are dependent on the precise test sample configuration and provide a basis for comparing the combustion behavior of materials. No criteria are implied for relating these data to the suitability of a material's use in any actual system. The application of data obtained from this test method is discussed in Guides G 88 and G 94.

1.3 Requirements for an apparatus suitable for this test method are given, as well as an example of such an apparatus. The example, however, is not required to be used.

1.4 This test method is for gaseous oxygen or any mixture of oxygen with diluents that will support combustion, at any pressure within the capabilities of the apparatus.

1.5 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific hazards statements are given in Section 9.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Please contact ASTM International (www.astm.org) for the latest information.

Designation:G124–95(Reapproved2003)

Standard Test Method for

Determining the Combustion Behavior of Metallic Materials

in Oxygen-Enriched Atmospheres

This standard is issued under the fixed designation G124; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

A

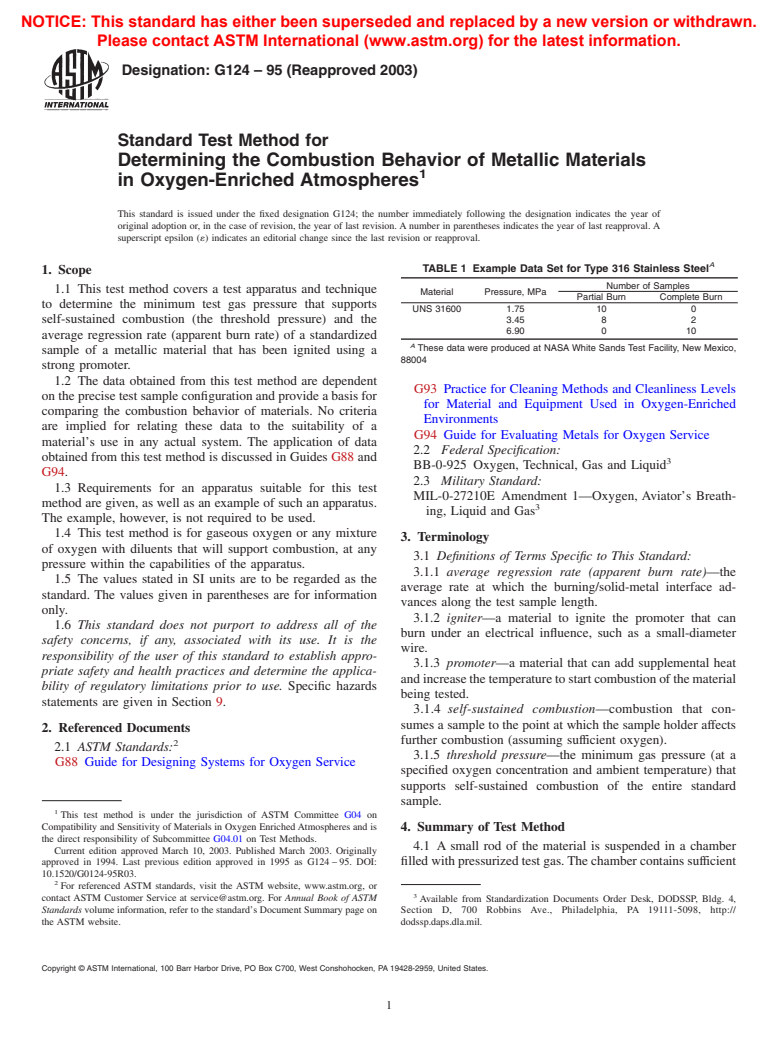

TABLE 1 Example Data Set for Type 316 Stainless Steel

1. Scope

Number of Samples

1.1 This test method covers a test apparatus and technique

Material Pressure, MPa

Partial Burn Complete Burn

to determine the minimum test gas pressure that supports

UNS 31600 1.75 10 0

self-sustained combustion (the threshold pressure) and the 3.45 8 2

6.90 0 10

average regression rate (apparent burn rate) of a standardized

A

These data were produced at NASA White Sands Test Facility, New Mexico,

sample of a metallic material that has been ignited using a

strong promoter.

1.2 The data obtained from this test method are dependent

G93 Practice for Cleaning Methods and Cleanliness Levels

ontheprecisetestsampleconfigurationandprovideabasisfor

for Material and Equipment Used in Oxygen-Enriched

comparing the combustion behavior of materials. No criteria

Environments

are implied for relating these data to the suitability of a

G94 Guide for Evaluating Metals for Oxygen Service

material’s use in any actual system. The application of data

2.2 Federal Specification:

obtained from this test method is discussed in Guides G88 and

BB-0-925 Oxygen, Technical, Gas and Liquid

G94.

2.3 Military Standard:

1.3 Requirements for an apparatus suitable for this test

MIL-0-27210E Amendment 1—Oxygen, Aviator’s Breath-

method are given, as well as an example of such an apparatus.

ing, Liquid and Gas

The example, however, is not required to be used.

1.4 This test method is for gaseous oxygen or any mixture

3. Terminology

of oxygen with diluents that will support combustion, at any

3.1 Definitions of Terms Specific to This Standard:

pressure within the capabilities of the apparatus.

3.1.1 average regression rate (apparent burn rate)—the

1.5 The values stated in SI units are to be regarded as the

average rate at which the burning/solid-metal interface ad-

standard. The values given in parentheses are for information

vances along the test sample length.

only.

3.1.2 igniter—a material to ignite the promoter that can

1.6 This standard does not purport to address all of the

burn under an electrical influence, such as a small-diameter

safety concerns, if any, associated with its use. It is the

wire.

responsibility of the user of this standard to establish appro-

3.1.3 promoter—a material that can add supplemental heat

priate safety and health practices and determine the applica-

andincreasethetemperaturetostartcombustionofthematerial

bility of regulatory limitations prior to use. Specific hazards

being tested.

statements are given in Section 9.

3.1.4 self-sustained combustion—combustion that con-

sumes a sample to the point at which the sample holder affects

2. Referenced Documents

further combustion (assuming sufficient oxygen).

2.1 ASTM Standards:

3.1.5 threshold pressure—the minimum gas pressure (at a

G88 Guide for Designing Systems for Oxygen Service

specified oxygen concentration and ambient temperature) that

supports self-sustained combustion of the entire standard

sample.

This test method is under the jurisdiction of ASTM Committee G04 on

Compatibility and Sensitivity of Materials in Oxygen EnrichedAtmospheres and is

4. Summary of Test Method

the direct responsibility of Subcommittee G04.01 on Test Methods.

4.1 A small rod of the material is suspended in a chamber

Current edition approved March 10, 2003. Published March 2003. Originally

approved in 1994. Last previous edition approved in 1995 as G124–95. DOI: filledwithpressurizedtestgas.Thechambercontainssufficient

10.1520/G0124-95R03.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Available from Standardization Documents Order Desk, DODSSP, Bldg. 4,

Standards volume information, refer to the standard’s Document Summary page on Section D, 700 Robbins Ave., Philadelphia, PA 19111-5098, http://

the ASTM website. dodssp.daps.dla.mil.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Please contact ASTM International (www.astm.org) for the latest information.

G124–95 (2003)

oxygen so that not more than 10% of the oxygen will be

consumedwhenthematerialcombustscompletely.Apromoter

(typically aluminum or magnesium) applied to the bottom of

the rod starts combustion of the material. The test pressure is

reduced and another rod is tested if combustion of the entire

rod occurs. This continues until self-sustained combustion of

theroddoesnotoccurforatleastfivetestsatonepressure.The

lowestpressureatwhichself-sustainedcombustionoccurredis

the threshold pressure for the material, and the difference

between it and the highest pressure level that produced only

incomplete combustion is the margin of potential error.Astute

initial estimates of the threshold can reduce the amount of

testing necessary to demonstrate the threshold to within the

required uncertainty.

5. Significance and Use

5.1 Thistestmethodwillallowcomparisonsofthecombus-

tion characteristics of various metallic materials. The combus-

tion characteristics that can be evaluated include (1) threshold

pressureand(2)averageregressionrate(apparentburnrate)of

the sample.

6. Interferences

FIG. 1 Schematic of Typical System

6.1 Any internal materials that may bake out or vaporize

during the combustion process at test temperature/pressure

may interfere with the chemistry of the fire propagation.

6.2 The specific atmosphere in the test chamber can have a

severe effect. Therefore, alien air, argon, nitrogen, carbon

dioxide, moisture, and others can be important interfering

gases.

6.3 The test is conducted under stagnant conditions. A

flowing system or one that facilitates buoyant convective

currents may be a significantly more severe climate.

6.4 The specific temperature of the test sample prior to

ignition can have an important effect.

NOTE 1—The promoters discussed in this test method have produced

favorable results over a wide range of metal test specimens with the

degreeofprecisionsoughttodate.Asthethresholdisapproachedorwhen

interaction between promoter and metal occur promoter can thwart the

ignition process. Hence the prospect that future work may refine the

promoter and enable the measurement of lower thresholds than are

measurable today cannot be ruled out.

7. Apparatus

7.1 A schematic of a typical system is shown in Fig. 1.

Otherdesignsmayalsobeused,iftheyfulfilltherequirements

below.

7.2 Test Chamber—A cross-section of a typical stainless

steeltestchamberisshowninFig.2.Nomorethan10%ofthe

FIG. 2 Typical Stainless Steel Test Chamber Cross-Section

available oxygen should be consumed during a test.Appendix

X1 provides criteria for establishing the lowest test pressures

drops that result from oxygen consumption, but it will have a much

that meet this criterion for various vessel volumes. If the

smaller effect in preventing local buildup of diluents in the oxygen. Each

chambercannotbemadesufficientlylarge,anaccumulatorcan

of these influences will exhibit a progressively greater effect and conse-

beattachedthatcontainsmoretestgasifthechambercannotbe

quence in smaller vessels.

NOTE 3—The significance of ensuring an adequate oxygen inventory is

made sufficiently large; however, this is not as severe a test

to avoid the observation of apparently negative test results at conditions

environment as in the larger vessel.The test chamber shall not

that are above the threshold but for which extinguishment may, nonethe-

contribute any chemical interference to testing.

less, occur due to depletion of oxygen, consequential reduction of

NOTE 2—The addition of an accumulator can act as a snubber to pressure, or concentration of diluents. However, in any test in which

suppress pressure rises that occur due to temperature rises and pressure completecombustionofthespecimenoccurs,theresultisvalid,regardless

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Please contact ASTM International (www.astm.org) for the latest information.

G124–95 (2003)

of whether the test conditions met the minimum recommended require-

oxygen greater than 99.5% pure may affect the test results

ment for oxygen inventory.

significantly (1), and its use shall be noted on the data sheet.

7.3 Sample holder,capableofsecuringthesampleatthetop

NOTE 4—Some applications involve the use of oxygen mixed with

other gases, and data in the literature (1, 2) indicate that the rankings of

andsupportingitinaverticalposition.Thereshallbesufficient

materials can be different depending on the amount and kind of diluents

spacebeneaththesamplefortheigniterandanydropsofliquid

present. Although the basic apparatus and principle of this test are valid

material that may fall during the test.

when used with oxygen mixed with other gases, alterations to the test

7.4 Thermocouple, used to measure gas temperature in the

method may be necessary. At present, these alterations have not been

chamber. studied sufficiently for inclusion in this test method.

7.5 Pressure Transducer, used to measure gas pressure in

8.2 Promoter—The promoter shall consist of a sufficient

the chamber, accurate to within 61% of reading.

quantity of material to ignite the test specimens. Some ex-

amplesofpromotermaterialarealuminumandmagnesium(3).

7.6 Liner and Base Plate—A burn-resistant (for example,

No promoter may be necessary at all at times; the igniter wire

copper) liner and base plate in the test chamber serve as an

itself may provide sufficient energy to ignite the sample.

internal shield to protect the components from combustion

Nonmetallic promoters may be used; however, the combustion

products, molten slag, and so forth.

products of such promoters might contaminate the test media.

7.7 Sight Glass, capable of withstanding the maximum test

NOTE 5—In selecting the promoter material, the possibility of a

pressure anticipated. If video or film recording of the burning

chemical reaction between the test material and the promoter should be

event contained in the test chamber is desired, the sight glass

considered.Also,forcertainmetals,thechemicalenergyreleasedfromthe

shall transmit compatible light.

combustion of promoter might be insufficient to ignite the metal. Other

7.8 Igniter Power Supply, electrically isolated and capable

ignition sources, for example, electrical or laser, may be used in such

cases.

ofprovidingadequatecurrenttoinitiatetheigniterwirewithin

a few seconds of the application of power.

8.3 Igniter Wire—The igniter wire shall be made of a

7.9 Test Cell, (a room to house the test chamber), con- material capable of igniting the promoter. Some examples of

structedofnoncombustiblematerial(suchasconcreteormetal) the igniter wire material are nickel/chromium or aluminum/

withsufficientstrengthtoprovideprotectionfromexplosionor palladium.

fire hazards. A continuous ventilation system shall circulate

9. Hazards

freshairinthetestcell.Thecellshallprovideafacilitythatcan

9.1 High-Pressure Oxygen System—Warning: There are

be maintained at a high level of good housekeeping. The test

hazards involving the use of a high-pressure oxygen system.

cellshallbecleanedperiodicallytoavoidcontaminationofthe

The following guidelines will reduce the dangers:

sample and equipment.

9.1.1 Personnel should be isolated from the test system

7.10 Piping System, which purges, pressurizes, and vents

whenitispressurized.Preferably,personnelshouldbeshielded

thetestchamber.Thepipingsystemshallbedesignedtopermit

by both physical protection (for example, the test cell) and

remotetestchamberpurge,pressurization,andventingwithout

distance.

unsafeexposureofpersonnel.Thechambershallbepurgedand

9.1.2 The test system itself should be isolated to prevent

pressurizedthroughonelineandventedthroughaseparateline

danger to people not involved in the test.

to minimize the chances of contaminant migrating into the

9.1.3 The test system should incorporate equipment able to

pressurization line, which might influence subsequent tests. A

handle the maximum operating pressure safely, including an

typical piping system for this test is shown in Fig. 1.

appropriate safety-factor.

7.11 ControlArea,whichwillisolatetestpersonnelfromthe

9.1.4 The system should be kept clean to prevent uninten-

test cell during tests. This control area shall be provided with

tional ignition.

the necessary control and instrumentation features to perform

9.1.5 The test system should be double-isolated from the

test chamber purge, pressurization and venting operations, and

test gas supply system.

monitoring of the test chamber instrumentation during the test.

9.1.6 Remote readout devices should be provided so per-

sonnel do not have to approach the test system to obtain

7.12 DataAcquisition System (Optional),capableofrecord-

ing,storing,andaccessingthepressureandtemperaturedataat operating data.

9.2 Oxygen—Warning: Oxygen enrichment accelerates

arateoftensamples/s(minimum).Itshallalsoincludeavideo

combustionvigorously.Careshouldbetakenatalltimeswhen

recording device that displays the “real-time” burn phenom-

workingwithoxygen.CGAPamphletsG-4.0 (4)andG-4.1 (5)

enon. The video recording can be used for regression rate

and Practice G93 provide further details.

determination.

9.3 Metal Oxides—Warning: Toxic metal and oxide dusts

may be produced when using this test method.These dusts are

8. Reagents and Materials

8.1 Gaseous Oxygen—Oxygen purity equal to or greater

Theboldfacenumbersinparenthesesrefertothelistofreferencesattheendof

than that of practical systems is preferred, especially when

this test method.

testing alloys containing aluminum, magnesium, zirconium,

The trade name for aluminum-palladium wire is Pyrofuze. It is a registered

etc.(thatis,metalsbelievedtoburnatleastinpartinthevapor

trademark of the Pyrofuze Corp., 121 S. Columbus Ave., Mt. Vernon, NY 10553,

phase). An analysis of the test oxidant is required. The use of and is available from them.

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Please contact ASTM International (w

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.