ASTM F2180-02(2011)e1

(Specification)Standard Specification for Metallic Implantable Strands and Cables

Standard Specification for Metallic Implantable Strands and Cables

ABSTRACT

This specification covers the materials, dimensional tolerances, constructions, and mechanical properties for standard metallic implantable strands and cables. Materials shall be manufactured using equivalent size wires in the cold-worked and stress-relieved or annealed condition. Standard strand constructions shall be 1×3, 1×7, and 1×19 strand. Cabling constructions shall be 7×7 and 7×19 cable. Mechanical requirements include ultimate tensile strength and minimum breaking force. Strand or cable shall have no welds or splices, free of imperfections, and shall conform to dimensions, surface finish, and tolerances indicated in this specification.

SCOPE

1.1 This specification covers the materials, dimensional tolerances, constructions, and mechanical properties for standard metallic implantable strands and cables.

1.2 This specification is intended to assist in the development of specific strand and cable specifications. It is particularly appropriate for high load bearing applications. It is not intended however, to address all of the possible variations in construction, material, or properties.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation:F2180 −02(Reapproved 2011)

Standard Specification for

Metallic Implantable Strands and Cables

This standard is issued under the fixed designation F2180; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

ε NOTE—Editorial changes were made throughout in January 2012.

1. Scope Surgical Implant Applications (UNS R30003 and UNS

R30008)

1.1 This specification covers the materials, dimensional

F1295 Specification for Wrought Titanium-6Aluminum-

tolerances, constructions, and mechanical properties for stan-

7Niobium Alloy for Surgical Implant Applications (UNS

dard metallic implantable strands and cables.

R56700)

1.2 This specification is intended to assist in the develop-

F1314Specification for Wrought Nitrogen Strengthened 22

ment of specific strand and cable specifications. It is particu-

Chromium–13 Nickel–5 Manganese–2.5 Molybdenum

larly appropriate for high load bearing applications. It is not

Stainless Steel Alloy Bar and Wire for Surgical Implants

intended however, to address all of the possible variations in

(UNS S20910)

construction, material, or properties.

F1341Specification for Unalloyed Titanium Wire UNS

1.3 The values stated in SI units are to be regarded as R50250, UNS R50400, UNS R50550, UNS R50700, for

Surgical Implant Applications (Withdrawn 2006)

standard. No other units of measurement are included in this

standard.

2.2 American Society for Quality (ASQ) Standard:

ASQC1Specification of General Requirements for a Qual-

2. Referenced Documents

ity Program

2.1 ASTM Standards:

2.3 Department of Defense Specifications:

E8Test Methods for Tension Testing of Metallic Materials

MIL-DTL-83420JWireRope,Flexible,ForAircraftControl

F86Practice for Surface Preparation and Marking of Metal-

MIL-DTL-83420/1BWire Rope, Flexible, Type 1, Compo-

lic Surgical Implants

sition A

F90 Specification for Wrought Cobalt-20Chromium-

MIL-DTL-83420/2BWire Rope, Flexible, Type 1, Compo-

15Tungsten-10NickelAlloy for Surgical ImplantApplica-

sition B

tions (UNS R30605)

F136 Specification for Wrought Titanium-6Aluminum-

3. Terminology

4VanadiumELI(ExtraLowInterstitial)AlloyforSurgical

3.1 Definitions:

Implant Applications (UNS R56401)

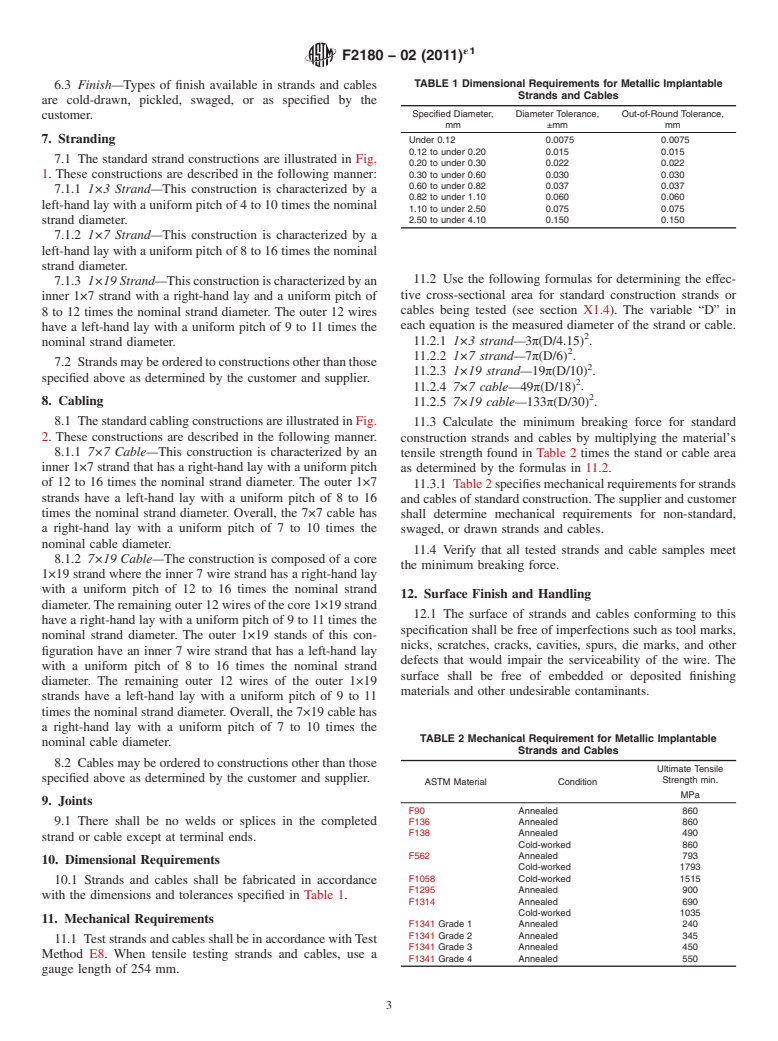

3.1.1 cable,n—agroupofstrandshelicallytwistedtogether.

F138 Specification for Wrought 18Chromium-14Nickel-

2.5MolybdenumStainlessSteelBarandWireforSurgical 3.1.2 diameter, n—the distance between opposing points

Implants (UNS S31673)

across the circle circumscribing either the strand or cable as

F562 Specification for Wrought 35Cobalt-35Nickel- illustrated in Figs. 1 and 2 (see MIL-DTL-83420J, MIL-DTL-

20Chromium-10Molybdenum Alloy for Surgical Implant

83420/1B and MIL-DTL-83420/2B).

Applications (UNS R30035)

3.1.3 lay(ortwist),n—thehelicalformtakenbythewiresin

F1058Specification for Wrought 40Cobalt-20Chromium-

a strand and by the strands in a cable (see MIL-DTL-83420J).

16Iron-15Nickel-7Molybdenum Alloy Wire and Strip for

3.1.3.1 Discussion—In a “Right Lay” situation, the wires of

the strand (or the strands in a cable) are oriented in the same

direction as the thread on a right-hand screw.

This specification is under the jurisdiction of ASTM Committee F04 on

Medical and Surgical Materials and Devicesand is the direct responsibility of

Subcommittee F04.21 on Osteosynthesis.

Current edition approved Oct. 1, 2011. Published October 2011. Originally

ε2

approved in 2002. Last previous edition approved in 2007 as F2180–02 (2007) . The last approved version of this historical standard is referenced on

DOI: 10.1520/F2180-02R11E01. www.astm.org.

2 4

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Available from American Society for Quality (ASQ), 600 N. Plankinton Ave.,

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Milwaukee, WI 53203, http://www.asq.org.

Standards volume information, refer to the standard’s Document Summary page on Available from DODSSP, Building 4, Section D, 700 Robbins Ave.,

the ASTM website. Philadelphia, PA 19111–5098.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

F2180−02 (2011)

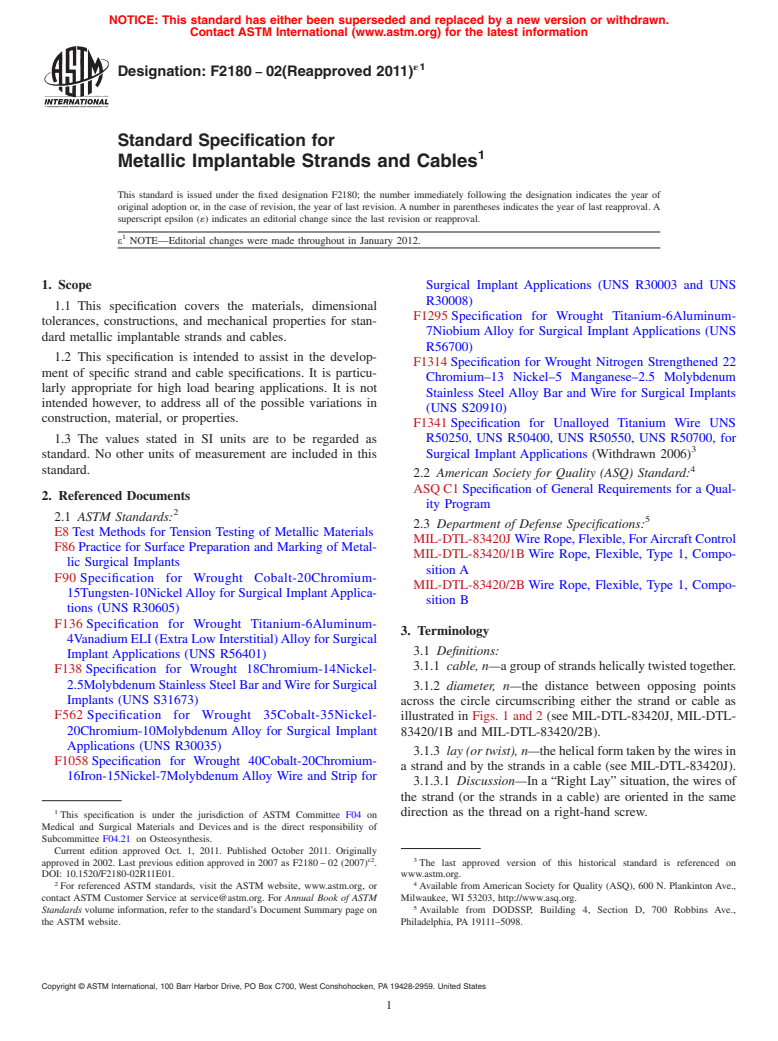

FIG. 1Standard Stranding Constructions

FIG. 2Standard Cabling Constructions

3.1.4 length of lay (or pitch), n—the distance parallel to the 5. Ordering Information

axis of the strand (or cable) in which a wire (or strand) makes

5.1 Inquiries and orders under this specification shall in-

one complete turn about the axis.

clude the following information:

3.1.5 M×N, n—the construction designation for strands and

5.1.1 Quantity (weight, length, or number of pieces),

cables. In this construction designation M represents the

5.1.2 ASTM designation,

number of strands in the cable and N represents the number of

5.1.3 Material (ASTM designation),

wires in each strand.

5.1.4 Condition,

3.1.5.1 Discussion— Some examples of strand construc-

5.1.5 Construction,

tionsare1×7and1×3.Similarexamplesofcableconstructions

5.1.6 Applicable dimensions (including diameter, length(s)

are 7×7 and 7×19.

of lay, and length),

3.1.6 strand, n—a group of wires helically twisted together.

5.1.7 Mechanical properties (including breaking force),

3.1.7 wire, n—an individual element (typically a cylindrical

5.1.8 Special requirements, and

rod) making up a strand.

5.1.9 Special tests.

4. General Requirements

6. Materials and Manufacture

4.1 In addition to the requirements of this specification, all

6.1 Wires—Implantable strands and cables shall be manu-

requirements of the current editions of Specifications F90,

factured using equivalent size wires.

F136, F138, F562, F1058, F1295, F1314, and F1341 shall

apply.

6.2 Condition—Implantable strands and cables shall be

4.2 In cases of conflict between this specification and those supplied in the cold-worked, cold-worked and stress-relieved,

listed in 2.1, this specification shall take precedence. or annealed condition.

´1

F2180−02 (2011)

TABLE 1 Dimensional Requirements for Metallic Implantable

6.3 Finish—Types of finish available in strands and cables

Strands and Cables

are cold-drawn, pickled, swaged, or as specified by the

Specified Diameter, Diameter Tolerance, Out-of-Round Tolerance,

customer.

mm ±mm mm

7. Stranding Under 0.12 0.0075 0.0075

0.12 to under 0.20 0.015 0.015

7.1 The standard strand constructions are illustrated in Fig.

0.20 to under 0.30 0.022 0.022

1. These constructions are described in the following manner: 0.30 to under 0.60 0.030 0.030

0.60 to under 0.82 0.037 0.037

7.1.1 1×3 Strand—This construction is characterized by a

0.82 to under 1.10 0.060 0.060

left-hand lay with a uniform pitch of 4 to 10 times the nominal

1.10 to under 2.50 0.075 0.075

2.50 to under 4.10 0.150 0.150

strand diameter.

7.1.2 1×7 Strand—This construction is characterized by a

left-hand lay with a uniform pitch of 8 to 16 times the nominal

strand diameter.

11.2 Use the following formulas for determining the effec-

7.1.3 1×19Strand—Thisconstructionischaracterizedbyan

tive cross-sectional area for standard construction strands or

inner 1×7 strand with a right-hand lay and a uniform pitch of

cables being tested (see section X1.4). The variable “D” in

8 to 12 times the nominal strand diameter. The oute

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.