ASTM D977-13

(Specification)Standard Specification for Emulsified Asphalt

Standard Specification for Emulsified Asphalt

ABSTRACT

This specification covers the requirements for thirteen grades of emulsified asphalt for use in pavement construction in the manner designated. The emulsified asphalts shall be homogeneous after thorough mixing and shall be tested within 14 days of delivery. Asphalts separated by freezing shall no longer be tested. Materials shall be appropriately sampled and tested, and shall conform accordingly to the following physical requirements: viscosity; storage stability; demulsibility; coating ability and water resistance; cement mixing; residue by distillation; oil distillate; ductility; solubility in trichloroethylene; and behavior during sieve, penetration, and float tests.

SCOPE

1.1 This specification covers thirteen grades of emulsified asphalt for use in pavement construction in the manner designated.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D977 −13

StandardSpecification for

1

Emulsified Asphalt

This standard is issued under the fixed designation D977; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope D7496 Test Method for Viscosity of Emulsified Asphalt by

Saybolt Furol Viscometer

1.1 This specification covers thirteen grades of emulsified

asphalt for use in pavement construction in the manner

3. Requirements

designated.

3.1 The emulsified asphalt shall be tested within 14 days of

1.2 The values stated in SI units are to be regarded as

delivery. The emulsified asphalt shall be homogeneous after

standard. No other units of measurement are included in this

thorough mixing provided separation has not been caused by

standard.

freezing. Emulsified asphalts separated by freezing shall not be

tested.

2. Referenced Documents

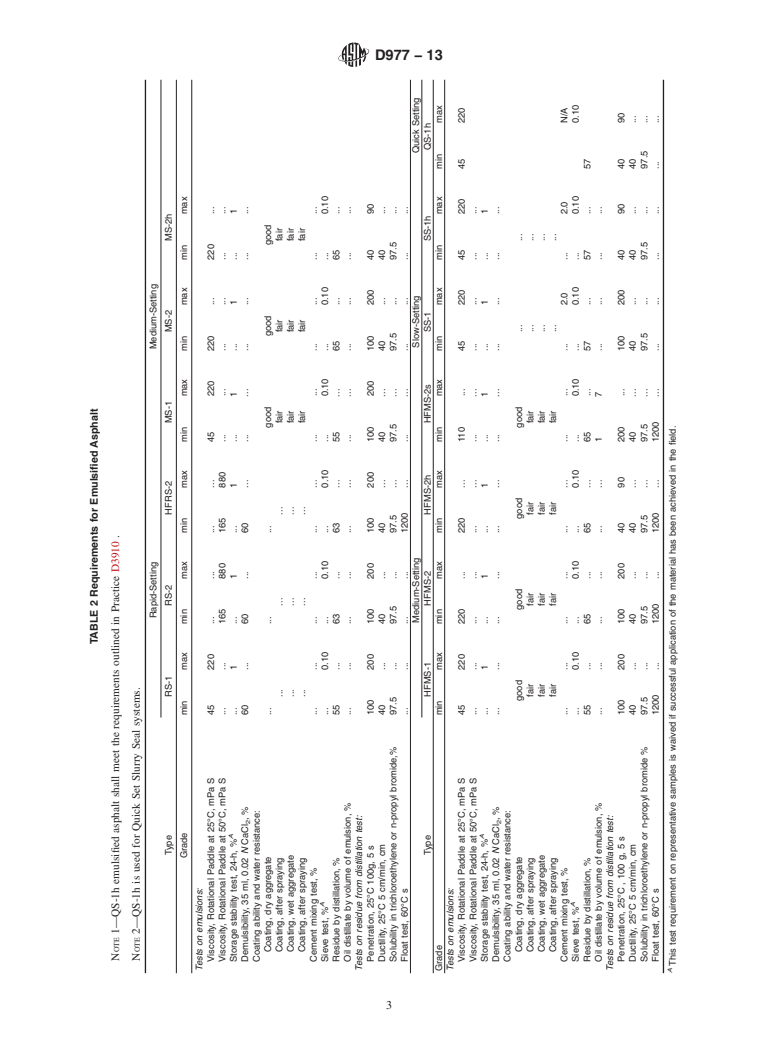

3.2 Emulsified asphalt shall conform to the requirements

2

2.1 ASTM Standards:

prescribed in Table 1 or Table 2. If no table is specified, default

D5 Test Method for Penetration of Bituminous Materials

is Table 1.

D113 Test Method for Ductility of Bituminous Materials

D139 Test Method for Float Test for Bituminous Materials

4. Sampling

D140 Practice for Sampling Bituminous Materials

4.1 Samples of emulsified asphalt shall be taken in accor-

D244 Test Methods and Practices for Emulsified Asphalts

dance with Practice D140.

D3910 Practices for Design, Testing, and Construction of

4.2 Samples shall be stored in clean, airtight sealed contain-

Slurry Seal

ers as specified in Practice D140 at a temperature of not less

D6930 Test Method for Settlement and Storage Stability of

than 4°C until tested.

Emulsified Asphalts

D6933 Test Method for Oversized Particles in Emulsified

5. Test Methods

Asphalts (Sieve Test)

D6935 Test Method for Determining Cement Mixing of 5.1 The properties of the emulsified asphalts given in Table

Emulsified Asphalt 1 or Table 2 shall be determined in accordance with the

D6936 Test Method for Determining Demulsibility of Emul- following ASTM test methods:

sified Asphalt 5.1.1 Viscosity—Test Method D7496.

D6997 Test Method for Distillation of Emulsified Asphalt 5.1.2 Storage Stability—Test Method D6930.

D7226 Test Method for Determining the Viscosity of Emul- 5.1.3 Demulsibility—Test Method D6936.

sified Asphalts Using a Rotational Paddle Viscometer 5.1.4 Coating Ability and Water Resistance—Test Methods

D7553 Test Method for Solubility of Asphalt Materials in D244.

5.1.5 Cement Mixing—Test Method D6935.

N-Propyl Bromide

D2042 Test Method for Solubility of Asphalt Materials in 5.1.6 Sieve Test—Test Method D6933.

5.1.7 Distillation—Test Method D6997.

Trichloroethylene

5.1.8 Tests on Residue from Distillation—Test Methods

D244.

1

This specification is under the jurisdiction of ASTM Committee D04 on Road 5.1.8.1 Penetration—Test Method D5

and Paving Materials and is the direct responsibility of Subcommittee D04.41 on

5.1.8.2 Ductility—Test Method D113

Emulsified Asphalt Specifications.

5.1.8.3 Solubility—Test Method D2042 or D7553

CurrenteditionapprovedJune1,2013.PublishedJuly2013.Originallyapproved

5.1.8.4 Float Test—Test Method D139

in 1948. Last previous edition approved in 2012 as D977-12b. DOI: 10.1520/

D0977-13.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or 6. Keywords

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

6.1 emulsion; emulsified asphalt; high float; medium set-

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. ting; rapid setting; slow setting

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D977−13

2

TABLE 1 Requirements for Emulsified Asphalt

NOTE 1—QS-1h emulsified asphalt shall meet the requirements outlined in Practice D3910 .

NOTE 2—QS-1h is used for Quick Set Slurry Seal systems.

Rapid-Setting Medium-Setting

Type RS-1 RS-2 HFRS-2 MS-1 MS-2 MS-2h

Grade min max min max min max min max min max min max

Tests on emulsions:

Viscosity, Saybolt Furol at 25°C SFS 20 100 . . . . 20 100 100 . 100 .

Viscosity, Saybolt Furol at 50°C SFS . . 75 400 75 400 . . . . . .

A

Storage stability test, 24-h, % . 1 . 1 . 1 . 1 . 1 . 1

Demulsibility, 35 ml, 0.02 N CaCl , % 60 . 60 . 60 . . . . . . .

2

Coating ability and water resistance:

Coating, dry aggregate . . . good good good

Coating, after spraying . . . fair fair fair

Coating, wet aggre

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D977 − 12b D977 − 13

Standard Specification for

1

Emulsified Asphalt

This standard is issued under the fixed designation D977; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope

1.1 This specification covers thirteen grades of emulsified asphalt for use in pavement construction in the manner designated.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

2. Referenced Documents

2

2.1 ASTM Standards:

D5 Test Method for Penetration of Bituminous Materials

D113 Test Method for Ductility of Bituminous Materials

D139 Test Method for Float Test for Bituminous Materials

D140 Practice for Sampling Bituminous Materials

D244 Test Methods and Practices for Emulsified Asphalts

D3910 Practices for Design, Testing, and Construction of Slurry Seal

D6930 Test Method for Settlement and Storage Stability of Emulsified Asphalts

D6933 Test Method for Oversized Particles in Emulsified Asphalts (Sieve Test)

D6935 Test Method for Determining Cement Mixing of Emulsified Asphalt

D6936 Test Method for Determining Demulsibility of Emulsified Asphalt

D6997 Test Method for Distillation of Emulsified Asphalt

D7226 Test Method for Determining the Viscosity of Emulsified Asphalts Using a Rotational Paddle Viscometer

D7553 Test Method for Solubility of Asphalt Materials in N-Propyl Bromide

D2042 Test Method for Solubility of Asphalt Materials in Trichloroethylene

D7496 Test Method for Viscosity of Emulsified Asphalt by Saybolt Furol Viscometer

3. Requirements

3.1 The emulsified asphalt shall be tested within 14 days of delivery. The emulsified asphalt shall be homogeneous after

thorough mixing provided separation has not been caused by freezing. Emulsified asphalts separated by freezing shall not be tested.

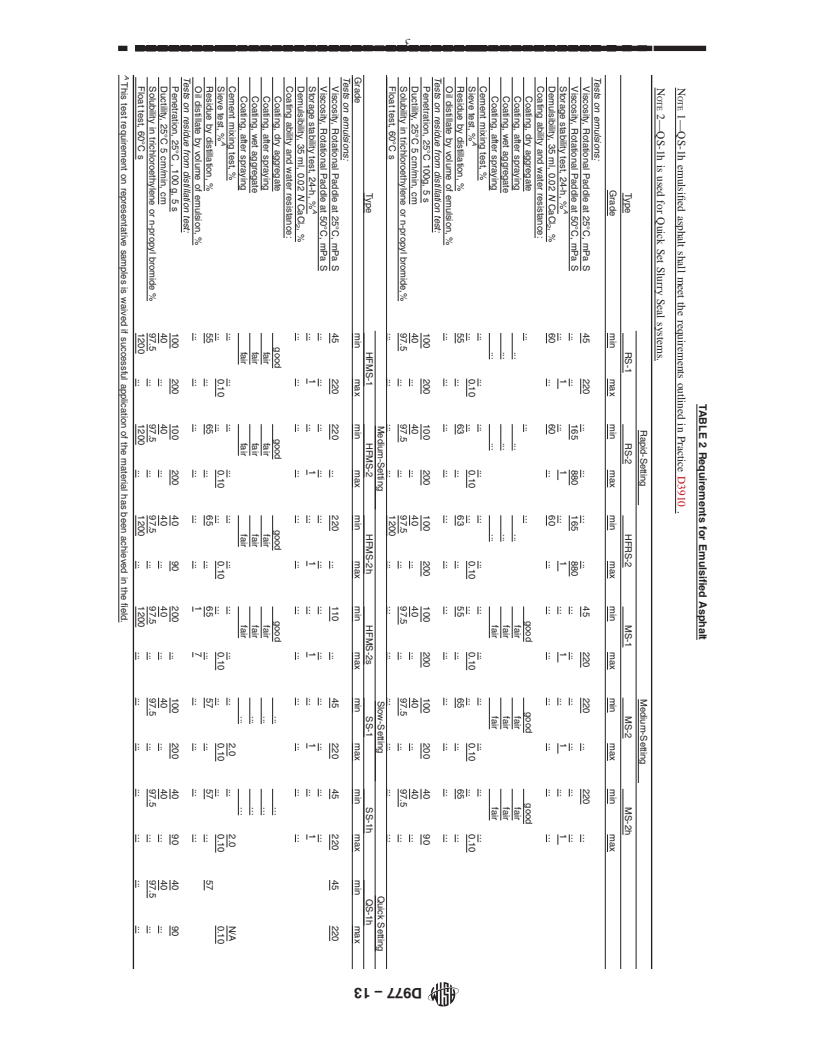

3.2 Emulsified asphalt shall conform to the requirements prescribed in Table 1 or Table 2. If no table is specified, default is Table

1.

4. Sampling

4.1 Samples of emulsified asphalt shall be taken in accordance with Practice D140.

4.2 Samples shall be stored in clean, airtight sealed containers as specified in Practice D140 at a temperature of not less than

4°C until tested.

5. Test Methods

5.1 The properties of the emulsified asphalts given in Table 1 or Table 2 shall be determined in accordance with the following

ASTM test methods:

1

This specification is under the jurisdiction of ASTM Committee D04 on Road and Paving Materials and is the direct responsibility of Subcommittee D04.41 on Emulsified

Asphalt Specifications.

Current edition approved Dec. 1, 2012June 1, 2013. Published December 2012July 2013. Originally approved in 1948. Last previous edition approved in 2012 as

D977-12a.-12b. DOI: 10.1520/D0977-12b.10.1520/D0977-13.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D977 − 13

2

TABLE 1 Requirements for Emulsified Asphalt

NOTE 1—QS-1h emulsions emulsified asphalt shall meet the requirements outlined in PracticesPractice D3910 .

NOTE 2—QS-1h is used for Quick Set Slurry Seal systems.

Rapid-Setting Medium-Setting

Type RS-1 RS-2 HFRS-2 MS-1 MS-2 MS-2h

Grade min max min max min max min max min max min max

Tests on emulsions:

Viscosity, Saybolt Furol at 25°C SFS 20 100 . . . . 20 100 100 . 100 .

Viscosity, Saybolt Furol at 50°C SFS . . 75 400 75 400 . . . . . .

A

Storage stability test, 24-h, % . 1 . 1 . 1 . 1 . 1 . 1

Demulsibility, 35 ml, 0.02 N CaCl , % 60 . 60 . 60 . . . . . . .

2

Coating ability and water resistance:

Coating, dry aggregate . . . good good good

Coating, after spraying . . . fair fair fair

Coating, wet aggregate . . . fair fair fair

Coating, after spraying . . . fair fair fair

Cement mixing test, % . . . . . . . . . . . .

A

Sieve test, % . 0.10 . 0.10 . 0.10 . 0.10 . 0.10 . 0.10

Residue by distillat

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.