ASTM E576-08

(Test Method)Standard Test Method for Frost/Dew Point of Sealed Insulating Glass Units in the Vertical Position

Standard Test Method for Frost/Dew Point of Sealed Insulating Glass Units in the Vertical Position

SIGNIFICANCE AND USE

This test method is suitable for use under actual or simulated in-service conditions; that is, one side of the unit is exposed to room temperature, while the other side is exposed to natural or simulated weather conditions. Where the glazing conditions and the 24-h history are different or changed from previous conditions, the frost/dew point may not be comparable to a previous measurement.

This test method is applicable for the uncoated or unfilmed clear (transparent) glass pane of sealed insulating glass units. If this apparatus is used with coated or filmed glass pane, the coating or film on the surface of glass pane may be damaged.

This test method may require minor modifications to keep the measuring surface of the frost/dew-point apparatus in contact with the glass if the insulating glass unit is not in the true vertical position.

SCOPE

1.1 This test method describes a field or laboratory procedure for determining the frost/dew point within the air space(s) of sealed insulating glass units and establishes the criteria for determining whether that point is below or above a given or specified temperature.

1.2 This test method also describes the apparatus to be used for these determinations.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific hazard statements, see 9.1.3 and 9.3.7.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E576 − 08

Standard Test Method for

Frost/Dew Point of Sealed Insulating Glass Units in the

1

Vertical Position

This standard is issued under the fixed designation E576; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 3.2.1 frost state—the case where the frost/dew point of a

sealed insulating glass unit is above the test temperature

1.1 This test method describes a field or laboratory proce-

specified by the purchaser or user.

durefordeterminingthefrost/dewpointwithintheairspace(s)

of sealed insulating glass units and establishes the criteria for

3.2.2 frost/dew point—the temperature at which water, or-

determining whether that point is below or above a given or

ganic vapor, or other chemicals begin to appear on the interior

specified temperature.

glass surface of a sealed insulating glass unit in contact with

the measuring surface of the frost/dew-point apparatus.

1.2 This test method also describes the apparatus to be used

for these determinations.

3.2.3 no-frost state—the case where the frost/dew point of a

1.3 This standard does not purport to address all of the sealed insulating glass unit is below the temperature specified

safety concerns, if any, associated with its use. It is the by the purchaser or user.

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

4. Summary of Test Method

bility of regulatory limitations prior to use. For specific hazard

4.1 This test method is conducted by the use of a special

statements, see 9.1.3 and 9.3.7.

apparatus, consisting basically of two chilled cylindrical metal

blocks positioned one over the other and separated by a gap of

2. Referenced Documents

controllable distance. The upper block has an exposed flat

2

2.1 ASTM Standards:

circular surface, 25 mm (1 in.) in diameter, and can be chilled

C1036Specification for Flat Glass

to far below the ice point by regulating the air gap distance

E77Test Method for Inspection and Verification of Ther-

between it and the lower metal block which is maintained at

mometers

approximately −78°C (−109°F) by dry ice. The test specimen

E631Terminology of Building Constructions

is placed in contact with this chilled flat circular surface of the

E774Specification for the Classification of the Durability of

upper block for specified short periods of time, with the metal

3

Sealed Insulating Glass Units (Withdrawn 2006)

surface at successively lower temperatures, to determine at

what temperature frost appears on the corresponding lower air

3. Terminology

space glass surface.

3.1 Definitions—Fordefinitionsofgeneraltermsusedinthis

test method, refer to Terminology E631. 5. Significance and Use

3.2 Definitions of Terms Specific to This Standard:

5.1 This test method is suitable for use under actual or

simulated in-service conditions; that is, one side of the unit is

exposed to room temperature, while the other side is exposed

1

This test method is under the jurisdiction of ASTM Committee E06 on

to natural or simulated weather conditions. Where the glazing

Performance of Buildings and is the direct responsibility of Subcommittee E06.22

conditions and the 24-h history are different or changed from

on Durability Performance of Building Constructions.

previous conditions, the frost/dew point may not be compa-

Current edition approved April 1, 2008. Published May 2008. Originally

ε1

approved in 1976. Last previous edition approved in 1999 as E576–88(1999) . rable to a previous measurement.

DOI: 10.1520/E0576-08.

2

5.2 This test method is applicable for the uncoated or

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

unfilmed clear (transparent) glass pane of sealed insulating

Standards volume information, refer to the standard’s Document Summary page on

glassunits.Ifthisapparatusisusedwithcoatedorfilmedglass

the ASTM website.

3

pane, the coating or film on the surface of glass pane may be

The last approved version of this historical standard is referenced on

www.astm.org. damaged.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E576 − 08

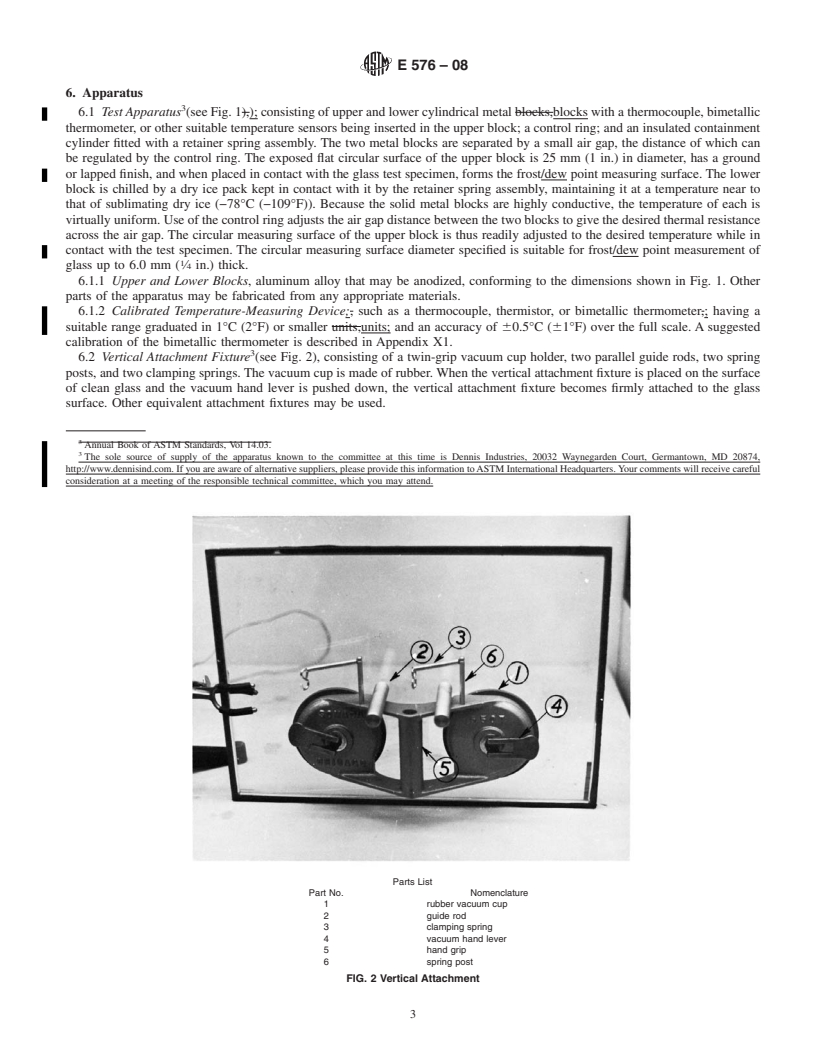

Parts List

Part No. Nomenclature Part No. Nomenclature

1 front metal block 12 supporting ring, bottom of

inner tube

2 rear metal block 13 control ring

3 top cover 14 cover lid, inner tube

4 supporting plate, front metal 15 elbow

b

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

e1

Designation:E576–88(Reapproved 1999) Designation: E 576 – 08

Standard Test Method for

Frost/Dew Point of Sealed Insulating Glass Units in the

1

Vertical Position

This standard is issued under the fixed designation E576; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1

e NOTE—Keywords were added in October 1999.

1. Scope

1.1 This test method describes a field or laboratory procedure for determining the frost/dew point within the air space(s) of

sealed insulating glass units,units and establishes the criteria for determining whether that point is below or above a given or

specified temperature.

1.2 This test method also describes the apparatus to be used for these determinations.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use. For specific hazard statements, see Notes 29.1.3 and 9.3.7.

2. Referenced Documents

2

2.1 ASTM Standards:

C1036 Specification for Flat Glass

E77 Test Method for Inspection and Verification of Thermometers

E631 Terminology of Building Constructions

E774Specification for Sealed Insulating Glass Units Specification for the Classification of the Durability of Sealed Insulating

Glass Units

3. Terminology

3.1 frost point—the temperature at which visible frost begins to deposit on the lower air space glass surface of a sealed

insulating glass unit in contact with the measuring surface of the frost point apparatus. Definitions—For definitions of general

terms used in this test method, refer to Terminology E631.

3.2 frost state—the case where the frost point of a sealed insulating glass unit is above the test temperature specified by the

purchaser or user.

3.3no-frost state—the case where the frost point of a sealed insulating glass unit is below the temperature specified by the

purchaser or user. Definitions of Terms Specific to This Standard:

3.2.1 frost state—the case where the frost/dew point of a sealed insulating glass unit is above the test temperature specified by

the purchaser or user.

3.2.2 frost/dew point—the temperature at which water, organic vapor, or other chemicals begin to appear on the interior glass

surface of a sealed insulating glass unit in contact with the measuring surface of the frost/dew-point apparatus.

3.2.3 no-frost state—the case where the frost/dew point of a sealed insulating glass unit is below the temperature specified by

the purchaser or user.

4. Summary of Test Method

4.1 This test method is conducted by the use of a special apparatus, consisting basically of two chilled cylindrical metal blocks

positionedoneovertheotherandseparatedbyagapofcontrollabledistance.Theupperblockhasanexposedflatcircularsurface,

1

This test method is under the jurisdiction of the ASTM Committee E-6E06 on Performance of Buildings and is the direct responsibility of Subcommittee E06.22 on

Durability Performance of Building Constructions.

Current edition approved March 25, 1988.April 1, 2008. Published September 1988.May 2008. Originally published as E576–76.approved in 1976. Last previous edition

e1

approved in 1999 as E576–788(1999) .

2

ForreferencedASTMstandards,visittheASTMwebsite,www.astm.org,orcontactASTMCustomerServiceatservice@astm.org.ForAnnualBookofASTMStandards

, Vol 15.02.volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

E576–08

25 mm (1 in.) in diameter, and can be chilled to far below the ice point by regulating the air gap distance between it and the lower

metal block which is maintained at approximately −78°C (−109°F) by dry ice. The test specimen is placed in contact with this

chilled flat circular surface of the upper block for specified short periods of time, with the metal surface at successively lower

temperatures, to determine at what temperature frost appears on the corresponding lower air space glass surface.

5. Significance and Use

5.1 This test method is suitable for use unde

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.