ASTM E576-88(1999)e1

(Test Method)Standard Test Method for Frost Point of Sealed Insulating Glass Units in the Vertical Position

Standard Test Method for Frost Point of Sealed Insulating Glass Units in the Vertical Position

SCOPE

1.1 This test method describes a field or laboratory procedure for determining the frost point within the air space(s) of sealed insulating glass units, and establishes the criteria for determining whether that point is below or above a given or specified temperature.

1.2 This test method also describes the apparatus to be used for these determinations.

1.3 This standard may involve hazardous materials, operations, and equipment. This standard does not purport to address all of the safety problems associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific hazard statements, see Notes 2 and 3.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

e1

Designation: E 576 – 88 (Reapproved 1999)

Standard Test Method for

Frost Point of Sealed Insulating Glass Units in the Vertical

Position

This standard is issued under the fixed designation E576; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

e NOTE—Keywords were added in October 1999.

1. Scope 3.2 frost state—the case where the frost point of a sealed

insulating glass unit is above the test temperature specified by

1.1 This test method describes a field or laboratory proce-

the purchaser or user.

dure for determining the frost point within the air space(s) of

3.3 no-froststate—thecasewherethefrostpointofasealed

sealed insulating glass units, and establishes the criteria for

insulating glass unit is below the temperature specified by the

determining whether that point is below or above a given or

purchaser or user.

specified temperature.

1.2 This test method also describes the apparatus to be used

4. Summary of Test Method

for these determinations.

4.1 This test method is conducted by the use of a special

1.3 This standard does not purport to address all of the

apparatus, consisting basically of two chilled cylindrical metal

safety concerns, if any, associated with its use. It is the

blocks positioned one over the other and separated by a gap of

responsibility of the user of this standard to establish appro-

controllable distance. The upper block has an exposed flat

priate safety and health practices and determine the applica-

circular surface, 25 mm (1 in.) in diameter, and can be chilled

bility of regulatory limitations prior to use. For specific hazard

to far below the ice point by regulating the air gap distance

statements, see Notes 2 and 3.

between it and the lower metal block which is maintained at

2. Referenced Documents approximately−78°C (−109°F) by dry ice. The test specimen

is placed in contact with this chilled flat circular surface of the

2.1 ASTM Standards:

2 upper block for specified short periods of time, with the metal

C1036 Specification for Flat Glass

surface at successively lower temperatures, to determine at

E77 Test Method for Inspection and Verification of Ther-

3 what temperature frost appears on the corresponding lower air

mometers

space glass surface.

E774 Specification for Sealed Insulating Glass Units

5. Significance and Use

3. Terminology

5.1 This test method is suitable for use under actual or

3.1 frost point—the temperature at which visible frost

simulated in-service conditions; that is, one side of the unit is

begins to deposit on the lower air space glass surface of a

exposed to room temperature, while the other side is exposed

sealed insulating glass unit in contact with the measuring

to natural or simulated weather conditions. Where the glazing

surface of the frost point apparatus.

conditions and the 24-h history are different or changed from

previous conditions, the frost point may not be comparable to

This test method is under the jurisdiction of the ASTM Committee E-6 on

a previous measurement.

Performance of Buildings and is the direct responsibility of Subcommittee E06.22

5.2 This test method is applicable for the uncoated or

on Durability Performance of Building Constructions.

unfilmed clear (transparent) glass pane of sealed insulating

CurrenteditionapprovedMarch25,1988.PublishedSeptember1988.Originally

published as E576–76. Last previous edition E576–79.

glassunits.Ifthisapparatusisusedwithcoatedorfilmedglass

Annual Book of ASTM Standards, Vol 15.02.

pane, the coating or film on the surface of glass pane may be

Annual Book of ASTM Standards, Vol 14.03.

4 damaged.

Annual Book of ASTM Standards, Vol 04.11.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

e1

E 576 – 88 (1999)

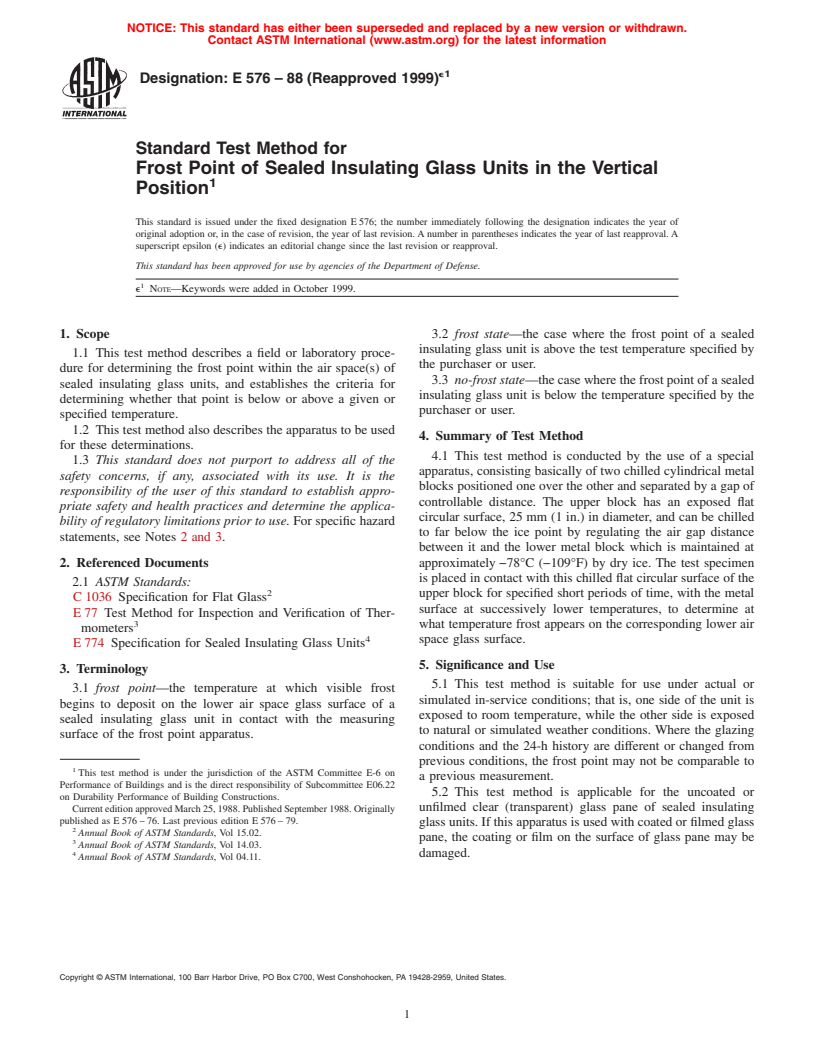

Parts List

Part No. Nomenclature Part No. Nomenclature

1 front metal block 12 supporting ring, bottom of

inner tube

2 rear metal block 13 control ring

3 top cover 14 cover lid, inner tube

4 supporting plate, front metal 15 elbow

block

5 spacer 16 tube, nylon

6 spring front metal block 17 main spring

7 supporting plate, top of 18 spacer

inner tube

8 outer tube 19 bearing

9 inner tube 20 bimetallic dial thermometer

10 disk, dry ice pushing 21 dial indicator

11 clamp, dial gage 22 heat source block

FIG. 1 Schematic Diagram of Frost Point Apparatus

5.3 This test method may require minor modifications to The two metal blocks are separated by a small air gap, the

keep the measuring surface of the frost point apparatus in distance of which can be regulated by the control ring. The

contact with the glass if the insulating glass unit is not in the exposedflatcircularsurfaceoftheupperblockis25mm(1in.)

true vertical position.

in diameter, has a ground or lapped finish, and when placed in

contact with the glass test specimen, forms the frost point

6. Apparatus

measuringsurface.Thelowerblockischilledbyadryicepack

6.1 Test Apparatus (see Fig. 1), consisting of upper and

kept in contact with it by the retainer spring assembly,

lowercylindricalmetalblocks,withathermocouple,bimetallic

maintaining it at a temperature near to that of sublimating dry

thermometer, or other suitable temperature sensors being

ice (−78°C (−109°F)). Because the solid metal blocks are

inserted in the upper block; a control ring; and an insulated

highlyconductive,thetemperatureofeachisvirtuallyuniform.

containment cylinder fitted with a retainer spring assembly.

Useofthecontrolringadjuststheairgapdistancebetweenthe

two blocks to give the desired thermal resistance across the air

5 gap. The circular measuring surface of the upper block is thus

Available from Dennis Industries, 20032 Waynegarden Court, Germantown,

MD 20874. readily adjusted to the desired temperature while in contact

e1

E 576 – 88 (1999)

with the test specimen. The circular measuring surface diam- 6.3 Glass Thickness Gage (see Fig. 3).

eter specified is suitable for frost point measurement of glass

7. Test Unit

up to 6.0 mm ( ⁄4 in.) thick.

7.1 The sealed insulating glass unit to be tested should have

6.1.1 UpperandLowerBlocks,aluminumalloythatmaybe

anodized,conformingtothedimensionsshowninFig.1.Other a clear glass pane (see 5.2) in contact with the measuring side

of the test apparatus and shall be positioned vertically.

parts of the apparatus may be fabricated from any appropriate

materials.

8. Conditioning

6.1.2 Calibrated Temperature-Measuring Device, such as a

8.1 Condition the unit to be tested at room temperature on

thermocouple, thermistor, or bimetallic thermometer, having a

bothunitsidesbyexposingtoatemperatureof24 63°C(756

suitable range graduated in 1°C (2°F) or smaller units, and an

5°F) for not less than 24 h prior to the testing.

accuracy of 60.5°C (61°F) over the full scale. A suggested

8.2 Condition the unit to be tested under simulated in-

calibration of the bimetallic thermometer is described in

service conditions by exposing to temperatures within 63°C

Appendix X1.

(65°F)ofthedesiredsimulatedconditionsfornotlessthan24

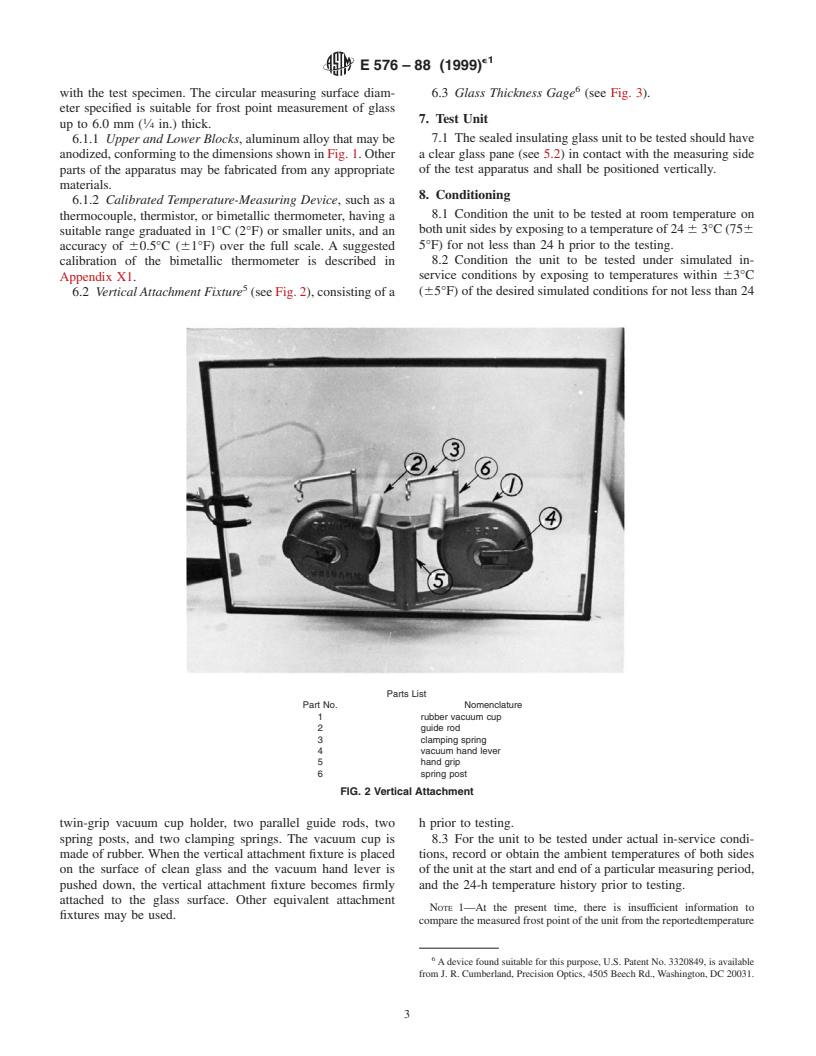

6.2 VerticalAttachmentFixture (seeFig.2),consistingofa

Parts List

Part No. Nomenclature

1 rubber vacuum cup

2 guide rod

3 clamping spring

4 vacuum hand lever

5 hand grip

6 spring post

FIG. 2 Vertical Attachment

twin-grip vacuum cup holder, two parallel guide rods, two h prior to testing.

spring posts, and two clamping springs. The vacuum cup is 8.3 For the unit to be tested under actual in-service condi-

made of rubber. When the vertical attachment fixture is placed tions, record or obtain the ambient temperatures of both sides

on the surface of clean glass and the vacuum hand lever is oftheunitatthestartandendofaparticularmeasuringperiod,

pushed down, the vertical attachment fixture becomes firmly and the 24-h temperature history prior to testing.

attached to the glass surface. Other equivalent attachment

NOTE 1—At the present time, there is insufficient information to

fixtures may be used.

comparethemeasuredfrostpointoftheunitfromthereportedtemperature

Adevice found suitable for this purpose, U.S. Patent No. 3320849, is available

from J. R. Cumberland, Precision Optics, 4505 Beech Rd.,Washington, DC 20031.

e1

E 576 – 88 (1999)

(a) Gage (b) Gage in Use

FIG. 3 Glass Thickness Gage

history to that implied in-service level of the unit. However, the tempera-

9.3.2.4 Read the minimum thickness of the glass above.

turehistorywillprovideavaluablebasisforevaluatingthein-servicelevel

9.3.3 Placethefrost-pointapparatusontopoftheguiderods

and life of the unit in the future.

of the vertical attachment fixture, facing the measuring surface

ofthefrost-pointapparatustowardtherubbervacuumcup,and

9. Procedure

slidebothguidefinsofthefrost-pointapparatusinbetweenthe

9.1 Preparation of Frost-Point Apparatus:

guide rods from the rear end.

9.1.1 Disassemble the apparatus by removing the dry ice

9.3.4 Hook each clamping spring to the hooks of the

container and retainer spring assembly. Carefully clean the

frost-point apparatus.

measuringsurfacewithasoftclothorpaper.Donotscratchthe

9.3.5 Clean the exterior glass surface where the frost-point

measuring surface.Wipe and clean the apparatus thoroughly if

apparatus and the vertical attachment fixtures are to be placed.

any moisture has condensed on the surfaces and walls.

Measure the frost point within an area at least 250 mm (10 in.)

9.1.2 Assemble the dry ice container and turn the control

away from the spacer or at the center of the unit. Examine the

ring so that the air gap distance between front and rear metal

interiorairspaceglasssurfaceintheregionwheredeworfrost

blocksisabout13mm(0.5in.).Inverttheapparatusontoasoft

is to be deposited, to be aware of any dirt or other foreign

cloth, or a suitable mounting bracket.

particles that might be mistaken for frost. However, a small

9.1.3 Spray alcohol or acetone (Warning—See Note 2)on

foreign particle on the interior air space glass surface may be

the fin of the dry ice container to ensure good contact with the

helpful in focusing on the surface where the frost is to be

dry ice. Compactly charge the container with the crushed or

deposited.Avoidtheareawheresunlightstrikesdirectlyonthe

pulverized dry ice up to the “full” mark. Compress the dry ice

unit or shade it from direct sunlight.

with the spring assembly and lock the cover lid.

9.3.6 Release both vacuum hand levers of the vertical

NOTE 2—Warning:Both alcohol and acetone are flammable.

attachment fixture.

9.1.4 Turn the apparatus to an upright position. Allow 9.3.7 Clean the surfaces of the rubber vacuum cups, and the

sufficient time for the temperature of the rear metal block to

measuring surface and front surface of the frost-point appara-

approach near that of the dry ice temperature. tus. If there are any water vapor or frost deposits on the

9.2 Recharging of Frost Point Apparatus—During the test

measuring surface of the frost-point apparatus, clean the

procedure,replenishthesupplyofdryicewheneveritbecomes measuring surface by wetting with alcohol (Warning—See

depleted by inverting the apparatus onto a soft cloth, opening

Note3).Ifthemeasuringsurfaceisheavilyscratched,thefront

the cover lid, taking out the retainer spring assembly, and metal block should be replaced or repaired. If the dew or frost

repeating steps 9.1.3 and 9.1.4. deposit can be checked from the other side of the unit as

9.3 Determination of Frost State or No-Frost State: described in 9.3.15, a piece of silver-colored aluminized

9.3.1 Charge the frost-point apparatus with dry ice as polyester film (with a highly reflective surface, not thicker

described in 9.1 or 9.2. than 0.08 mm (0.003 in.), and 25 mm (1 in.) in diameter, or 25

9.3.2 Measure the thickness of glass in the measuring side by 25 mm (1 by 1 in.) can be placed on the measuring surface

as follows: by wetting both surfaces with alcohol.

9.3.2.1 Place the long side of the glass thickness gage (see

NOTE 3—Warning:Alcohol is flammable.

Fig. 3) against the glass pane at a 45° angle.

9.3.2.2 Observe the reflection in the glass. 9.3.8 To provide better thermal contact, wet the measuring

9.3.2.3 Note where the long line superimposes the short surface of the frost point apparatus and exterior glass surface

line. where it is to be contacted with alcohol (see Note 3).

e1

E 576 – 88 (1999)

9.3.9 Hold the hand grip of the vertical attachment fixture adjustment of the control ring. Temperature fluctuation should

with one hand in a level position. Contact the measuring not exceed 61°C (62°F).

surface against the wetted glass surface and push the vertical

9.3.14 Maintain the stabilized temperature for a minimum

attachment so that both rubber vacuum cups touch flatly time duration as follows:

against the glass surface (see Fig. 4).

Glass Thickness Designation, Stabilized Temperature—Duration,

mm (in.) minimum, min

9.3.10 Slowly flip the vacuum hand levers to a locking

2.5 ( ⁄32)3

position so that the vertical attachment fixture is held firmly

3.0 ( ⁄8)3

against the glass surface of the unit. If a vacuum cup does not

5.0 ( ⁄16)4

6.0 ( ⁄4)5

hold the vacuum properly, release the vacuum hand lever and

flip it again while applying a little more force. Make sure that

NOTE 5—See Specification C1036.

the measuring surface and front surface of the frost-point

9.3.15 If the other side of the unit is accessible, clean the

apparatus are flush with the glass surface. If it is not flush with

exterior glass surface and examine the interior air space glass

the glass surface, adjust it by either increasing the tension of

surface in contact with the measuring surface. Illuminate the

the clamping springs or adjusting the guide rod. If needed,

interior air space glass surface with a flashlight for better

shim the guide rod.

detectionoffrostdeposit,ifneeded.Iftheothersideoftheunit

NOTE 4—Warning:Take care that the vertical attachment fixture does

is not accessible, unhook the clamping spring and slide out the

not fall off during the measurement.

frost point apparatus far enough to examine the interior air

9.3.11 Wipe off the excessive alcohol running down the

space glass surface. Then, quickly examine the interior air

glass surface from the measuring surface before it reaches the space glass surface for frost deposit. If the frost forms or water

glazing materials. vapor condenses on the exterior glass surface where the

9.3.12 Slowlyreducetheairgapd

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.