ASTM E546-14(2020)

(Test Method)Standard Test Method for Frost/Dew Point of Sealed Insulating Glass Units

Standard Test Method for Frost/Dew Point of Sealed Insulating Glass Units

SIGNIFICANCE AND USE

5.1 This test method and the apparatus described are intended primarily for sealed insulating glass units positioned horizontally. If the procedure is applied to such units in other than a horizontal position, the results may not be comparable to those obtained by this procedure.

Note 1: A similar method is Test Method E576.

SCOPE

1.1 This test method describes a laboratory procedure for determining the frost/dew point within the air space(s) of sealed insulating glass units, and establishes the criteria for determining whether that point is below or above a given or specified temperature.

1.2 This test method also describes the apparatus to be used for these determinations.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. For specific hazard statements, see 9.1.3.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: E546 − 14 (Reapproved 2020)

Standard Test Method for

Frost/Dew Point of Sealed Insulating Glass Units

This standard is issued under the fixed designation E546; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope E631Terminology of Building Constructions

1.1 This test method describes a laboratory procedure for

3. Terminology

determining the frost/dew point within the air space(s) of

sealed insulating glass units, and establishes the criteria for

3.1 Definitions—Fordefinitionsofgeneraltermsusedinthis

determining whether that point is below or above a given or

test method, refer to Terminology E631.

specified temperature.

3.2 Definitions of Terms Specific to This Standard:

1.2 This test method also describes the apparatus to be used

3.2.1 frost/dew point, n—the temperature at which water,

for these determinations.

organic vapor, or other chemicals begin to appear on the

1.3 The values stated in inch-pound units are to be regarded

interiorglasssurfaceofasealedinsulatingglassunitincontact

as standard. The values given in parentheses are mathematical

with the measuring surface of the frost/dew-point apparatus.

conversions to SI units that are provided for information only

3.2.2 frost state—the case where the frost/dew point of a

and are not considered standard.

sealed insulating glass unit is above the test temperature

1.4 This standard does not purport to address all of the

specified by the purchaser or user.

safety concerns, if any, associated with its use. It is the

3.2.3 no-frost state—the case where the frost/dew point of a

responsibility of the user of this standard to establish appro-

sealed insulating glass unit is below the temperature specified

priate safety, health, and environmental practices and deter-

by the purchaser or user.

mine the applicability of regulatory limitations prior to use.

For specific hazard statements, see 9.1.3.

4. Summary of Test Method

1.5 This international standard was developed in accor-

dance with internationally recognized principles on standard-

4.1 This test method is conducted by the use of a special

ization established in the Decision on Principles for the

apparatus, consisting basically of two chilled cylindrical metal

Development of International Standards, Guides and Recom-

blocks positioned one over the other and separated by a gap of

mendations issued by the World Trade Organization Technical

controllable distance. The upper block has an exposed flat

Barriers to Trade (TBT) Committee.

circular surface, 1 in. (25 mm) in diameter, and can be chilled

to far below the ice point by regulating the air-gap distance

2. Referenced Documents

between it and the lower metal block which is maintained at

2.1 ASTM Standards:

approximately−109°F (−78°C) by dry ice.The test specimen

C1036Specification for Flat Glass

is placed in contact with this chilled flat circular surface of the

E77Test Method for Inspection and Verification of Ther-

upper block for specified short periods of time, with the metal

mometers

surface at successively lower temperatures, to determine at

E576Test Method for Frost/Dew Point of Sealed Insulating

what temperature frost appears on the corresponding lower air

Glass Units in the Vertical Position

space glass surface.

5. Significance and Use

This test method is under the jurisdiction of ASTM Committee E06 on

Performance of Buildings and is the direct responsibility of Subcommittee E06.22

5.1 This test method and the apparatus described are in-

on Durability Performance of Building Constructions.

Current edition approved May 1, 2020. Published May 2020. Originally

tended primarily for sealed insulating glass units positioned

approved in 1975. Last previous edition approved in 2014 as E546–14. DOI:

horizontally. If the procedure is applied to such units in other

10.1520/E0546-14R20.

thanahorizontalposition,theresultsmaynotbecomparableto

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM those obtained by this procedure.

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. NOTE 1—A similar method is Test Method E576.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E546 − 14 (2020)

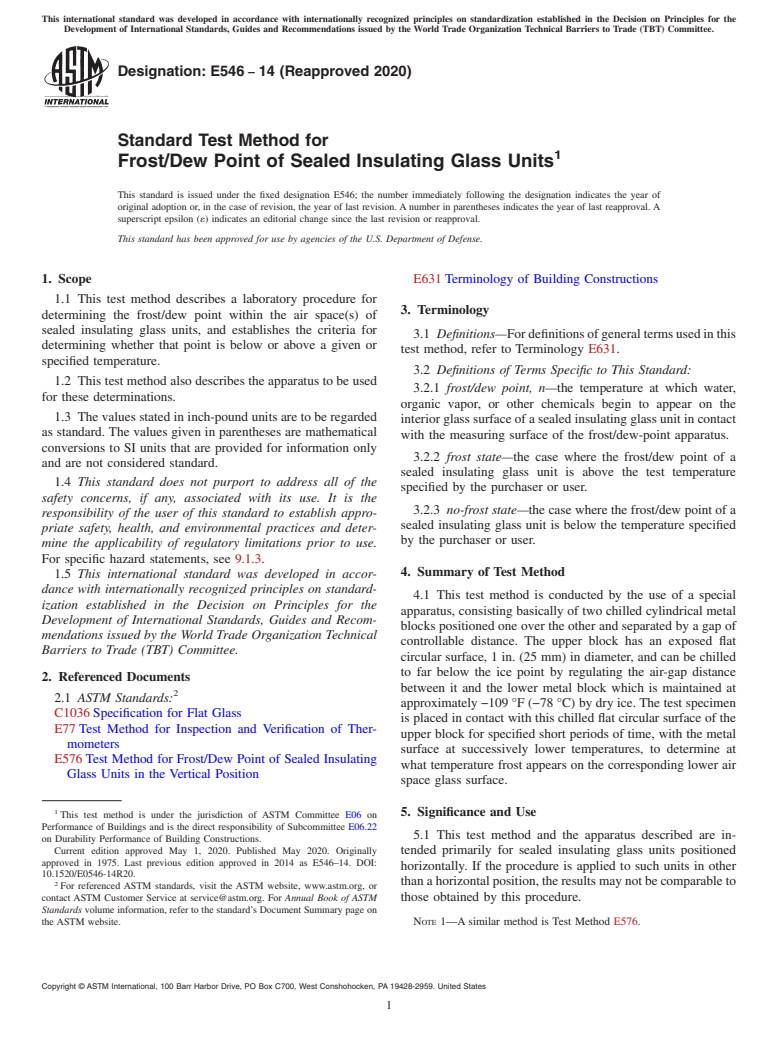

Parts List

Part No. Nomenclature Part No. Nomenclature

1 upper metal block 12 supporting ring, bottom of inner tube

2 lower metal block 13 control ring

3 top cover 14 cover lid, inner tube

4 supporting plate, upper metal block 15 elbow

5 spacer 16 tube, nylon

6 spring, upper metal block 17 main spring

7 supporting plate, top of inner tube 18 spacer

8 outer tube 19 bearing

9 inner tube 20 bimetallic dial thermometer

10 disk, dry ice pushing 21 dial indicator

11 clamp, dial gage 22 heat source block

FIG. 1 Schematic Diagram of Frost/Dew-Point Apparatus

6. Apparatus inserted in the upper block; a control ring; and an insulated

containment cylinder fitted with a retainer spring assembly.

6.1 Test Apparatus (see Fig. 1), consisting of upper and

The two metal blocks are separated by a small air gap, the

lower cylindrical metal blocks with a thermocouple, bimetallic

distance of which can be regulated by the control ring. The

thermometer, or other suitable temperature sensors being

exposedflatcircularsurfaceoftheupperblockis1in.(25mm)

indiameter;hasagroundorlappedfinish;and,whenplacedin

The sole source of supply of the apparatus known to the committee at this time

contact with the glass test specimen, forms the frost/dew point

is Dennis Industries, 20032 Waynegarden Court, Germantown, MD 20874, http://

www.dennisind.com. If you are aware of alternative suppliers, please provide this

measuringsurface.Thelowerblockischilledbyadryicepack

information to ASTM International Headquarters. Your comments will receive

kept in contact with it by the retainer spring assembly,

careful consideration at a meeting of the responsible technical committee, which

maintaining it at a temperature near to that of sublimating dry

you may attend.

E546 − 14 (2020)

ice (−109°F (−78°C)). Because the solid metal blocks are upside down on a soft cloth, opening the cover lid, taking out

highlyconductive,thetemperatureofeachisvirtuallyuniform. the retainer spring assembly, and repeating steps 9.1.3 and

Useofthecontrolringadjuststheairgapdistancebetweenthe 9.1.4.

two blocks to give the desired thermal resistance across the air

9.3 Determination of Frost State and No-Frost State:

gap. The circular measuring surface of the upper block is thus

9.3.1 Charge the frost/dew point apparatus with dry ice as

readily adjusted to the desired temperature while in contact

described in 9.1 or 9.2.

with the test specimen. The circular measuring surface diam-

9.3.2 Clean both exterior surfaces of the specimen.

eter specified is suitable for frost/dew point measurement of

9.3.3 Due to the changes in the cold plate design the use of

glass up to ⁄4 in. (6.0 mm) thick.

the aluminized polyester film is no longer a requirement.

6.1.1 Upper and Lower Metal Blocks, aluminum alloy that

However it is still recommended in order to ensure a pristine

may be anodized, conforming to the dimensions shown in Fig.

viewing surface.

1. Other parts of the apparatus may be fabricated from any

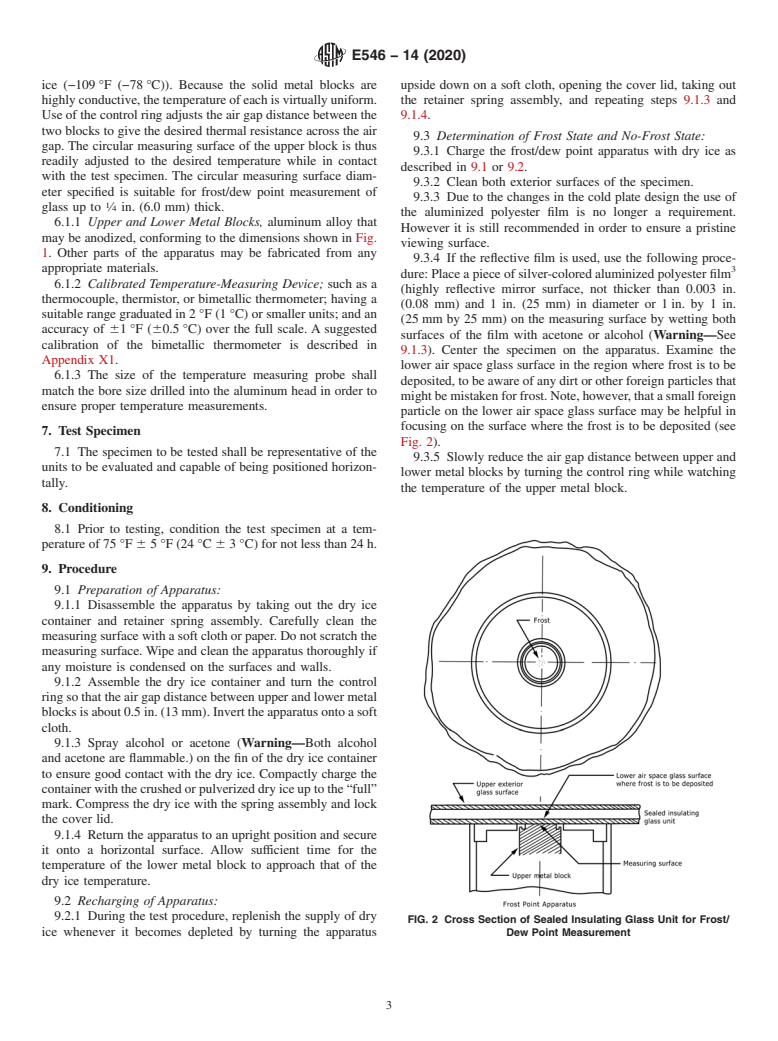

9.3.4 If the reflective film is used, use the following proce-

appropriate materials. 3

dure:Placeapieceofsilver-coloredaluminizedpolyesterfilm

6.1.2 Calibrated Temperature-Measuring Device; such as a

(highly reflective mirror surface, not thicker than 0.003 in.

thermocouple, thermistor, or bimetallic thermometer; having a

(0.08 mm) and 1 in. (25 mm) in diameter or 1in. by 1 in.

suitablerangegraduatedin2°F(1°C)orsmallerunits;andan

(25mm by 25 mm) on the measuring surface by wetting both

accuracy of 61°F(60.5°C) over the full scale. A suggested

surfaces of the film with acetone or alcohol (Warning—See

calibration of the bimetallic thermometer is described in

9.1.3). Center the specimen on the apparatus. Examine the

Appendix X1.

lower air space glass surface in the region where frost is to be

6.1.3 The size of the temperature measuring probe shall

deposited,tobeawareofanydirtorotherforeignparticlesthat

match the bore size drilled into the aluminum head in order to

mightbemistakenforfrost.Note,however,thatasmallforeign

ensure proper temperature measurements.

particle on the lower air space glass surface may be helpful in

focusing on the surface where the frost is to be deposited (see

7. Test Specimen

Fig. 2).

7.1 The specimen to be tested shall be representative of the

9.3.5 Slowly reduce the air gap distance between upper and

units to be evaluated and capable of being positioned horizon-

lower metal blocks by turning the control ring while watching

tally.

the temperature of the upper metal block.

8. Conditioning

8.1 Prior to testing, condition the test specimen at a tem-

peratureof75°F 65°F(24°C 63°C)fornotlessthan24h.

9. Procedure

9.1 Preparation of Apparatus:

9.1.1 Disassemble the apparatus by taking out the dry ice

container and retainer spring assembly. Carefully clean the

measuringsurfacewithasoftclothorpaper.Donotscratchthe

measuring surface.Wipe and clean the apparatus thoroughly if

any moisture is condensed on the surfaces and walls.

9.1.2 Assemble the dry ice container and t

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.