ASTM F3459-21

(Specification)Standard Specification for Rigid Poly Vinyl Chloride (PVC) Exterior Profiles Used for Sound Walls

Standard Specification for Rigid Poly Vinyl Chloride (PVC) Exterior Profiles Used for Sound Walls

SCOPE

1.1 This specification establishes requirements for the material properties and physical properties, including dimensional tolerances, extrusion quality, and weatherability, of rigid poly (vinyl chloride) (PVC) exterior profiles used for sound walls. Methods for testing and for identifying exterior profile extrusions that comply with this specification are also provided. In addition, requirements for flexural capacity are given.

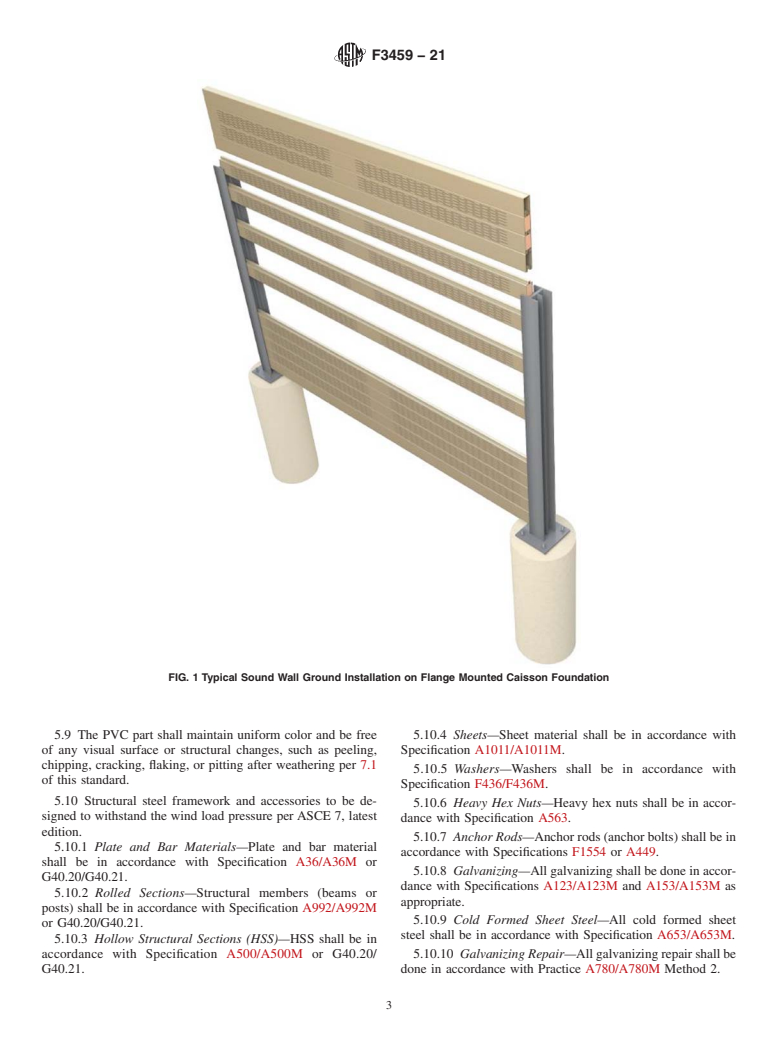

Note 1: Information with regard to application, assembly, and installation should be obtained from the manufacturer.

1.2 The material used in these exterior profiles is limited to rigid poly (vinyl chloride) (PVC) compounds in a single homogeneous extrusion or in a coextrusion of two or more PVC compounds in distinct layers.

1.3 Units—The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:F3459 −21

Standard Specification for

Rigid Poly Vinyl Chloride (PVC) Exterior Profiles Used for

1

Sound Walls

This standard is issued under the fixed designation F3459; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope A123/A123MSpecification for Zinc (Hot-Dip Galvanized)

Coatings on Iron and Steel Products

1.1 This specification establishes requirements for the ma-

A153/A153MSpecification for Zinc Coating (Hot-Dip) on

terialpropertiesandphysicalproperties,includingdimensional

Iron and Steel Hardware

tolerances, extrusion quality, and weatherability, of rigid poly

A449Specification for Hex Cap Screws, Bolts and Studs,

(vinyl chloride) (PVC) exterior profiles used for sound walls.

Steel, Heat Treated, 120/105/90 ksi Minimum Tensile

Methods for testing and for identifying exterior profile extru-

Strength, General Use

sions that comply with this specification are also provided. In

A500/A500MSpecification for Cold-Formed Welded and

addition, requirements for flexural capacity are given.

Seamless Carbon Steel Structural Tubing in Rounds and

NOTE 1—Information with regard to application, assembly, and instal-

Shapes

lation should be obtained from the manufacturer.

A563Specification for Carbon and Alloy Steel Nuts

1.2 The material used in these exterior profiles is limited to

A653/A653MSpecification for Steel Sheet, Zinc-Coated

rigid poly (vinyl chloride) (PVC) compounds in a single

(Galvanized) or Zinc-Iron Alloy-Coated (Galvannealed)

homogeneous extrusion or in a coextrusion of two or more

by the Hot-Dip Process

PVC compounds in distinct layers.

A780/A780MPracticeforRepairofDamagedandUncoated

1.3 Units—The values stated in inch-pound units are to be

Areas of Hot-Dip Galvanized Coatings

regarded as standard. The values given in parentheses are

A992/A992MSpecification for Structural Steel Shapes

mathematical conversions to SI units that are provided for

A1011/A1011MSpecification for Steel, Sheet and Strip,

information only and are not considered standard.

Hot-Rolled, Carbon, Structural, High-Strength Low-

1.4 This standard does not purport to address all of the Alloy, High-Strength Low-Alloy with Improved

safety concerns, if any, associated with its use. It is the Formability, and Ultra-High Strength

responsibility of the user of this standard to establish appro-

D618Practice for Conditioning Plastics for Testing

priate safety, health, and environmental practices and deter-

D635Test Method for Rate of Burning and/or Extent and

mine the applicability of regulatory limitations prior to use.

Time of Burning of Plastics in a Horizontal Position

1.5 This international standard was developed in accor-

D696TestMethodforCoefficientofLinearThermalExpan-

dance with internationally recognized principles on standard-

sion of Plastics Between −30°C and 30°C with a Vitreous

ization established in the Decision on Principles for the

Silica Dilatometer

Development of International Standards, Guides and Recom-

D790Test Methods for Flexural Properties of Unreinforced

mendations issued by the World Trade Organization Technical

and Reinforced Plastics and Electrical Insulating Materi-

Barriers to Trade (TBT) Committee.

als

D883Terminology Relating to Plastics

2. Referenced Documents

D1042Test Method for Linear Dimensional Changes of

2

2.1 ASTM Standards:

Plastics Caused by Exposure to Heat and Moisture

A36/A36MSpecification for Carbon Structural Steel

D1600TerminologyforAbbreviatedTermsRelatingtoPlas-

tics

1

ThisspecificationisunderthejurisdictionofASTMCommitteeF14onFences

D2565Practice for Xenon-Arc Exposure of Plastics In-

and is the direct responsibility of Subcommittee F14.30 on Rigid Polymer Fence

tended for Outdoor Applications

Systems.

D4216Specification for Rigid Poly(Vinyl Chloride) (PVC)

Current edition approved Jan. 1, 2021. Published February 2021. DOI: 10.1520/

F3459-21.

and Related PVC and Chlorinated Poly(Vinyl Chloride)

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

(CPVC) Building Products Compounds

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

D4226Test Methods for Impact Resistance of Rigid Poly-

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. (Vinyl Chloride) (PVC) Building Products

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 --------------------

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.