ASTM E2188-10

(Test Method)Standard Test Method for Insulating Glass Unit Performance

Standard Test Method for Insulating Glass Unit Performance

SIGNIFICANCE AND USE

This test method is intended to provide a means for testing the performance of the sealing system and construction of sealed insulating glass units.

Sealed insulating glass units tested in accordance with this method may be suitable for structurally glazed applications. However, factors such as sealant longevity when exposed to long term ultraviolet light and the structural properties of the sealant must be reviewed for these applications.

Sealed insulating glass units tested in accordance with this method are not intended for continuous exposure to high relative humidity conditions or long-term immersion in water.

SCOPE

1.1 This test method covers procedures for testing the performance of preassembled permanently sealed insulating glass units or insulating glass units with capillary tubes intentionally left open.

1.2 This test method is applicable only to sealed insulating glass units that are constructed with glass.

1.3 This test method is applicable to both double-glazed and triple-glazed insulating glass units. For triple-glazed insulating glass units where both of the outer lites are glass and the inner lite is either glass or a suspended film.

1.4 The unit construction used in this test method contains dimensions that are an essential component of the test. Different types of glass, different glass thicknesses, and different airspace sizes may affect the test results.

1.5 This test method is not applicable to sealed insulating glass units containing a spandrel glass coating due to testing limitations.

1.6 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E2188 − 10

Standard Test Method for

1

Insulating Glass Unit Performance

This standard is issued under the fixed designation E2188; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope E631Terminology of Building Constructions

E546Test Method for Frost/Dew Point of Sealed Insulating

1.1 This test method covers procedures for testing the

Glass Units

performance of preassembled permanently sealed insulating

E2190Specification for Insulating Glass Unit Performance

glass units or insulating glass units with capillary tubes

and Evaluation

intentionally left open.

1.2 This test method is applicable only to sealed insulating 3. Terminology

glass units that are constructed with glass.

3.1 Definition of Terms:

1.3 Thistestmethodisapplicabletobothdouble-glazedand 3.1.1 Fordefinitionsoftermsfoundinthisstandard,referto

Terminologies C162, C717, and E631.

triple-glazed insulating glass units. For triple-glazed insulating

glass units where both of the outer lites are glass and the inner

3.2 Definitions of Terms Specific to This Standard:

lite is either glass or a suspended film.

3.2.1 frost/dew point, n—the temperature at which water,

1.4 The unit construction used in this test method contains organic vapor, or other chemicals begin to appear on the

interior glass surface of a sealed insulating glass unit.

dimensions that are an essential component of the test. Differ-

ent types of glass, different glass thicknesses, and different

4. Significance and Use

airspace sizes may affect the test results.

4.1 This test method is intended to provide a means for

1.5 This test method is not applicable to sealed insulating

testing the performance of the sealing system and construction

glass units containing a spandrel glass coating due to testing

of sealed insulating glass units.

limitations.

4.1.1 Sealed insulating glass units tested in accordance with

1.6 The values stated in SI units are to be regarded as

this method may be suitable for structurally glazed applica-

standard. No other units of measurement are included in this

tions. However, factors such as sealant longevity when ex-

standard.

posedtolongtermultravioletlightandthestructuralproperties

1.7 This standard does not purport to address all of the of the sealant must be reviewed for these applications.

safety concerns, if any, associated with its use. It is the 4.1.2 Sealed insulating glass units tested in accordance with

responsibility of the user of this standard to establish appro- this method are not intended for continuous exposure to high

priate safety and health practices and determine the applica- relative humidity conditions or long-term immersion in water.

bility of regulatory limitations prior to use.

5. Test Specimens

2. Referenced Documents

5.1 Each test specimen shall measure 355 66mm by

2

505 66mm and shall be composed of two or three lites of

2.1 ASTM Standards:

clear, tinted or coated annealed, heat-strengthened, tempered,

C162Terminology of Glass and Glass Products

or laminated glass.

C717Terminology of Building Seals and Sealants

5.1.1 The double-glazed test samples shall be fabricated

C1036Specification for Flat Glass

with at least one lite of clear, uncoated glass.The triple-glazed

test samples shall be fabricated with at least one outer lite of

1

This test method is under the jurisdiction of ASTM Committee E06 on

clear, uncoated glass. The other outer lite shall be fabricated

Performance of Buildings and is the direct responsibility of Subcommittee E06.22

with a glass which allows easy viewing of the frost point.

on Durability Performance of Building Constructions.

5.1.2 The thickness of the glass lites shall be between

Current edition approved Nov. 1, 2010. Published February 2011. Originally

nominal 3.0 mm and a maximum of 6.0mm nominal.

approved in 2002. Last previous edition approved in 2002 as E2188–02. DOI:

10.1520/E2188-10.

5.1.3 Theairspacesforunitswitheithertwoorthreelitesof

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

glass shall be a minimum of 6.0 60.8mm.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

5.1.4 When testing to Specification E2190 the specimen

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. construction shall be as defined in that document.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

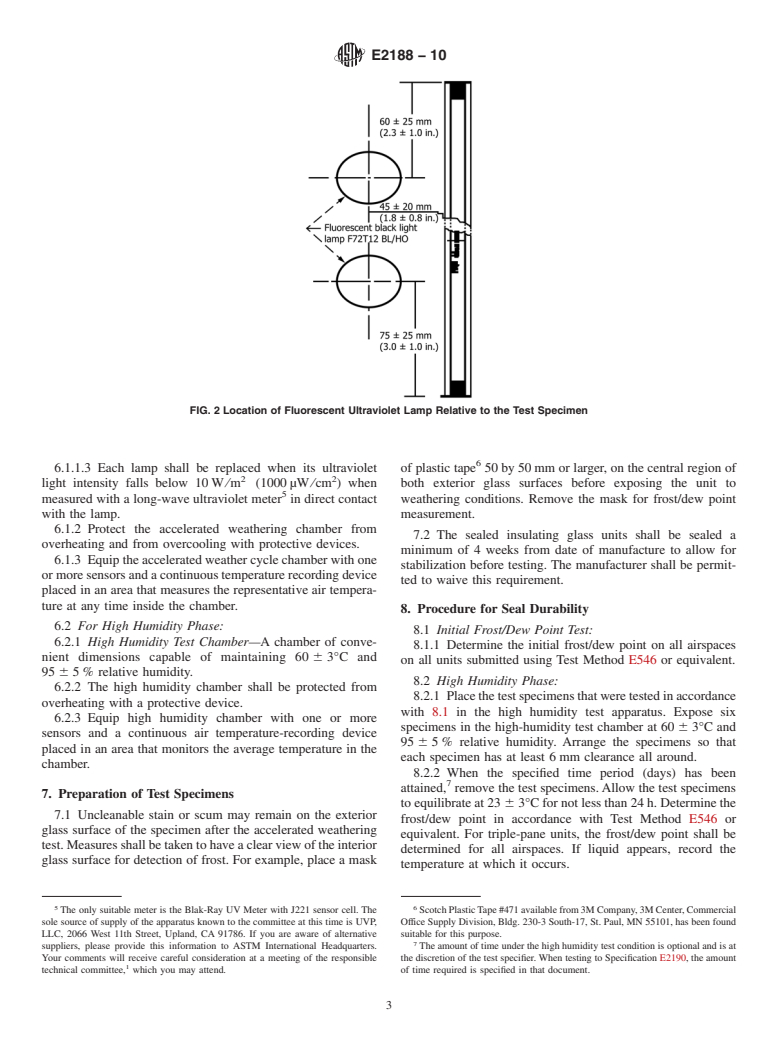

E2188 − 10

5.1.5 Triple-pane units where the intermediate airspace 5.8 Test specimens representing

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

An American National Standard

Designation:E2188–02 Designation:E2188–10

Standard Test Method for

1

Insulating Glass Unit Performance

This standard is issued under the fixed designation E2188; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers procedures for testing the performance of preassembled permanently sealed insulating glass units

or insulating glass units with capillary tubes intentionally left open.

1.2 This test method is applicable only to sealed insulating glass units that are constructed with glass.

1.3Theunitconstructionusedinthistestmethodcontainsdimensionsthatareanessentialcomponentofthetest.Differenttypes

of glass, different glass thicknesses and different airspace sizes may affect the test results.

1.4Thistestmethodisnotapplicabletosealedinsulatingglassunitscontainingaspandrelglasscoatingduetotestinglimitations.

1.5The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.6

1.3 This test method is applicable to both double-glazed and triple-glazed insulating glass units. For triple-glazed insulating

glass units where both of the outer lites are glass and the inner lite is either glass or a suspended film.

1.4 The unit construction used in this test method contains dimensions that are an essential component of the test. Different

types of glass, different glass thicknesses, and different airspace sizes may affect the test results.

1.5 This test method is not applicable to sealed insulating glass units containing a spandrel glass coating due to testing

limitations.

1.6 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

C162 Terminology of Glass and Glass Products

C717 Terminology of Building Seals and Sealants

C1036 Specification for Flat Glass

E631 Terminology of Building Constructions

E546 Test Method for Frost/Dew Point of Sealed Insulating Glass Units

E2190 Specification for Insulating Glass Unit Performance and Evaluation

3. Terminology

3.1 Definition of Terms:

3.1.1For definitions of terms found in this Standard, refer to Standard Terminology of Building Seals and Sealants, C717,

Terminology of Glass and Glass Products, C162 and Terminology of Building Constructions, E631.

3.1.1 For definitions of terms found in this standard, refer to Terminologies C162, C717, and E631.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 frost/dew point, n—thetemperatureatwhichwater,organicvapor,orotherchemicalsbegintoappearontheinteriorglass

surface of a sealed insulating glass unit.

1

This test method is under the jurisdiction ofASTM Committee E06 on Performance of Buildings and is the direct responsibility of Subcommittee E06.22 on Durability

Performance of Building Constructions.

Current edition approved March 10, 2002. Published April 2002. DOI: 10.1520/E2188-02.

Current edition approved Nov. 1, 2010. Published February 2011. Originally approved in 2002. Last previous edition approved in 2002 as E2188–02. DOI:

10.1520/E2188-10.

2

ForreferencedASTMstandards,visittheASTMwebsite,www.astm.org,orcontactASTMCustomerServiceatservice@astm.org.For Annual Book of ASTM Standards

, Vol 15.02.volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

E2188–10

4. Significance and Use

4.1 Thistestmethodisintendedtoprovideameansfortestingtheperformanceofthesealingsystemandconstructionofsealed

insulating glass units.

4.1.1 Sealed insulating glass units tested in accordance with this method may be suitable for structurally glazed applications.

However, factors such as sealant longevity when exposed to long term ultraviolet light and the structural properties of the sealant

must be reviewed for these applications.

4.1.2 Sealed insulating glass

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.