ASTM E2188-02

(Test Method)Standard Test Method for Insulating Glass Unit Performance

Standard Test Method for Insulating Glass Unit Performance

SCOPE

1.1 This test method covers procedures for testing the performance of preassembled permanently sealed insulating glass units or insulating glass units with capillary tubes intentionally left open.

1.2 This test method is applicable only to sealed insulating glass units that are constructed with glass.

1.3 The unit construction used in this test method contains dimensions that are an essential component of the test. Different types of glass, different glass thicknesses and different airspace sizes may affect the test results.

1.4 This test method is not applicable to sealed insulating glass units containing a spandrel glass coating due to testing limitations.

1.5 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation:E2188–02

Standard Test Method for

Insulating Glass Unit Performance

This standard is issued under the fixed designation E2188; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Terminology of Glass and Glass Products, C162 and Termi-

nology of Building Constructions, E631.

1.1 This test method covers procedures for testing the

3.2 Definitions of Terms Specific to This Standard:

performance of preassembled permanently sealed insulating

3.2.1 frost/dew point, n—the temperature at which water,

glass units or insulating glass units with capillary tubes

organic vapor, or other chemicals begin to appear on the

intentionally left open.

interior glass surface of a sealed insulating glass unit.

1.2 This test method is applicable only to sealed insulating

glass units that are constructed with glass.

4. Significance and Use

1.3 The unit construction used in this test method contains

4.1 This test method is intended to provide a means for

dimensions that are an essential component of the test. Differ-

testing the performance of the sealing system and construction

ent types of glass, different glass thicknesses and different

of sealed insulating glass units.

airspace sizes may affect the test results.

4.1.1 Sealed insulating glass units tested in accordance with

1.4 This test method is not applicable to sealed insulating

this method may be suitable for structurally glazed applica-

glass units containing a spandrel glass coating due to testing

tions. However, factors such as sealant longevity when ex-

limitations.

posedtolongtermultravioletlightandthestructuralproperties

1.5 The values stated in SI units are to be regarded as the

of the sealant must be reviewed for these applications.

standard. The values given in parentheses are for information

4.1.2 Sealed insulating glass units tested in accordance with

only.

this method are not intended for continuous exposure to high

1.6 This standard does not purport to address all of the

relative humidity conditions or long-term immersion in water.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

5. Test Specimens

priate safety and health practices and determine the applica-

5.1 Each test specimen shall measure 355 66mmby505

bility of regulatory limitations prior to use.

1 1

66mm(14 6 ⁄4 in. by 20 6 ⁄4 in.) and shall be composed

2. Referenced Documents of two or three lites of clear, tinted or coated annealed,

2 heat-strengthened, tempered or laminated glass.

2.1 ASTM Standards:

3 5.1.1 The double glazed test samples shall be fabricated

C1036 Specification for Flat Glass

with at least one lite of clear, uncoated glass. The triple glazed

E546 Test Method for Frost/Dew Point of Sealed Insulating

4 test samples shall be fabricated with at least one outer lite of

Glass Units

clear, uncoated glass. The other outer lite shall be fabricated

E2190 Specification for Insulating Glass Unit Performance

with a glass which allows easy viewing of the frost point.

and Evaluation

5.1.2 The thickness of the glass lite shall be between

1 1

3. Terminology nominal 3.0 mm ( ⁄8 in.) and a maximum of 6.0 mm ( ⁄4 in.)

nominal.

3.1 Definition of Terms:

5.1.3 Theairspacesforunitswitheithertwoorthreelitesof

3.1.1 FordefinitionsoftermsfoundinthisStandard,referto

1 1

glass shall be a minimum of 6.0 mm ( ⁄4 in.) 6 0.8 mm ( ⁄32

Standard Terminology of Building Seals and Sealants, C717,

in.).

5.1.4 Triple pane units where the intermediate airspace

This test method is under the jurisdiction of ASTM Committee E06 on

divider is a plastic film are acceptable.

Performance of Buildings and is the direct responsibility of Subcommittee E06.22

NOTE 1—Overall unit thickness has some limits. Testing laboratories

on Durability Performance of Building Constructions.

Current edition approved March 10, 2002. PublishedApril 2002. DOI: 10.1520/ are usually able to accommodate 30 mm overall thickness. If testing

E2188-02.

Annual Book of ASTM Standards, Vol 15.02.

Annual Book of ASTM Standards, Vol 04.11.

4 5

This test specification is under development by ASTM Committee E06 on Theconstructionofthetestunitsisoptionalandshallbedeterminedbythetest

Performance of Buildings and is the direct responsibility of Subcommittee E06. 22 specifier. When testing to Specification E2190, the required unit construction is

on Durability Performance of Building Constructions. specified in that document.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

E2188–02

thicker units, contact the testing laboratory prior to manufacturing to

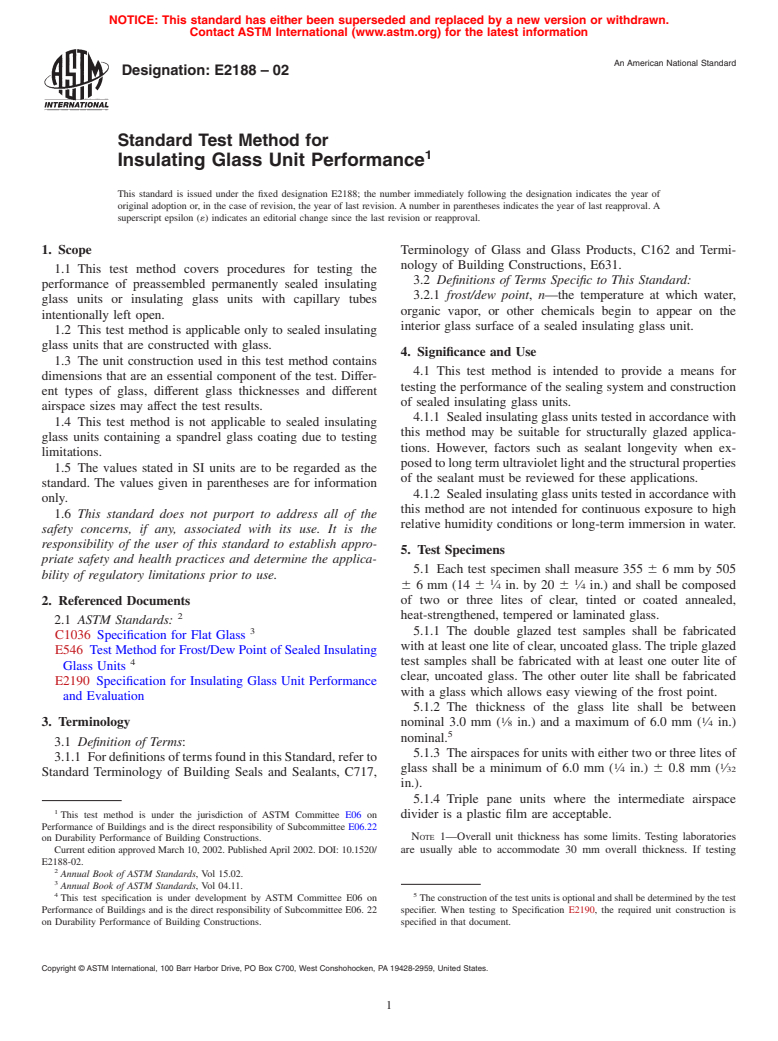

6.1.1 Weather Cycle Test Apparatus —The weather cycle

ascertain their capabilities for testing thicker units.

test apparatus shall be essentially that shown in Figs. 2 and 3

to provide the required test conditions indicated in Section 8.

5.2 The thickness tolerance of the glass shall conform to

Modifications to this test apparatus are acceptable providing

Specification C1036.

that the required test conditions are met.

5.3 Eachspecimenshallbepermanentlyandlegiblymarked

6.1.1.1 Ultraviolet Light Source:

with the designation of the manufacturer, the date of fabrica-

tion(monthorquarterandyear)andorientationintendedinthe

NOTE 2—Warning:Ultraviolet light sources used in this test method

field (for units constructed with coated glass). are harmful, especially to the eyes.Appropriate protective measures must

be observed.

5.4 At least twelve specimens of identical component ma-

terials and construction shall be submitted.

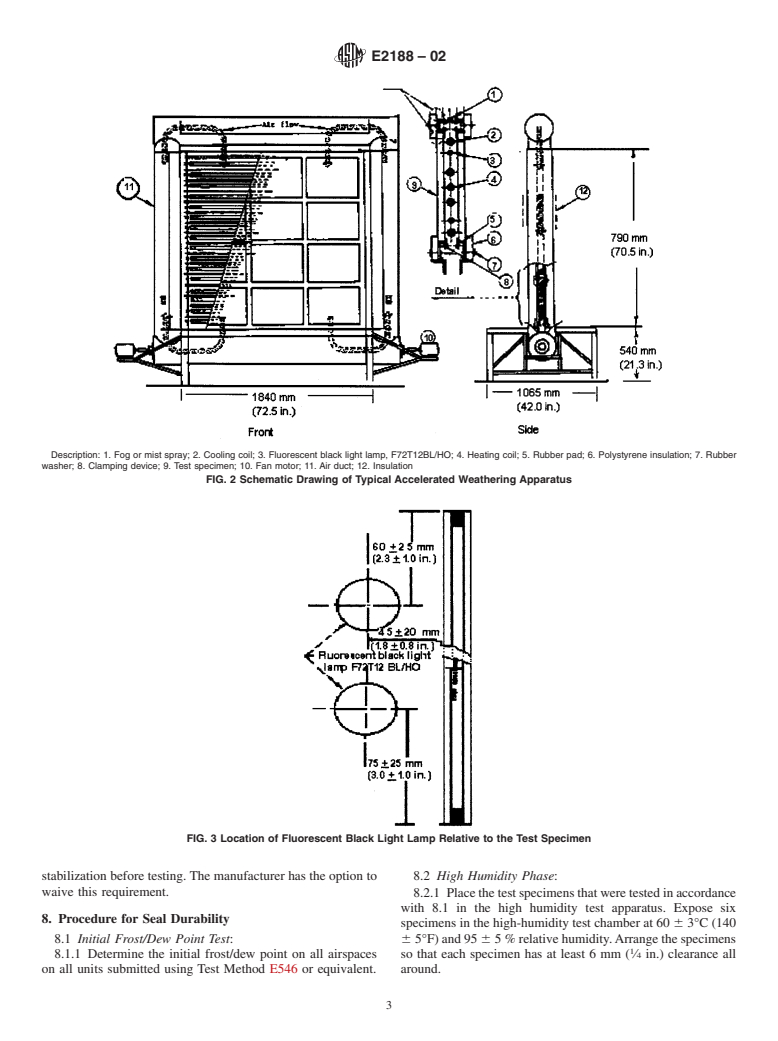

6.1.1.2 The source shall consist of two fluorescent black

5.5 Duringallstagesofexposureandstorage,theunitsshall

light lamps, Type F72T12BL/HO (Note 3), for each test

beheldinaverticalpositionwithequalsupporttoallpanesand

specimen located as shown in Fig. 2.

no compression loading.

NOTE 3—Rated average life at 3 h per start: 12000 h. Rated average

5.6 Selection of units for testing shall be made at random

life at 12 h per start: 18000 h. Useful length: 1625 mm (64 in.). Wattage:

exceptforunitsdamagedintransit.Damagedunitsshallnotbe

85 W. Relative black light energy output is 190% that of F40BL lamp.

tested.

UVA 340 nanometers.

5.7 Test samples representing units that will be gas filled

6.1.1.3 Each lamp must be replaced when its ultraviolet

shall be fabricated using the same hole sealing and gas filling

2 2

light intensity falls below 10 W/m (1000 µW/cm ) when

techniques as those used for manufacturing. For example, if a

measured with a long-wave ultraviolet meter in direct contact

gas-filling plug is used in manufacturing then it must be used

with the lamp.

in the test units. The samples do not need to be filled with gas

6.1.2 Protect the accelerated weathering chamber from

providing that the gas is classified as inert. Test samples

overheating and from overcooling with protective devices.

representing products that are normally filled with an inert gas

6.1.3 Equiptheacceleratedweathercyclechamberwithone

in production, may be submitted air filled for this testing as

ormoresensorsandacontinuoustemperaturerecordingdevice

longastheyhavebeenmanufacturedwiththesametechniques

placed in an area that monitors the average temperature at any

as used in production.

time inside the chamber.

5.8 Test samples representing units that include tubes in-

6.2 For High Humidity Phase:

tended to be left open shall be fabricated with one tube. These

6.2.1 High Humidity Test Chamber—A chamber of conve-

tubes shall be left open during testing. Test samples represent-

nient dimensions capable of maintaining 60 6 3°C (140 6

ing units that include tubes intended to be closed off after

5°F) and 95 6 5% relative humidity.

shippingshallbefabricatedwithonetube.Thesetubesshallbe

6.2.2 The high humidity chamber shall be protected from

closed at the exterior end prior to testing.

overheating with a protective device.

5.9 Test samples representing units that include muntins

6.2.3 Equip high humidity chamber with one or more

shall be fabricated with muntins dividing the sample into nine

sensors and a continuous temperature-recording device placed

equal areas (3 by 3). See Fig. 1.

in an area that monitors the average temperature in the

chamb

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.