ASTM D4539-10

(Test Method)Standard Test Method for Filterability of Diesel Fuels by Low-Temperature Flow Test (LTFT)

Standard Test Method for Filterability of Diesel Fuels by Low-Temperature Flow Test (LTFT)

SIGNIFICANCE AND USE

The Low Temperature Flow Test results are indicative of the low temperature flow performance of the test fuel in some diesel vehicles (according to CRC Report No. 528). The test method is especially useful for the evaluation of fuels containing flow improver additives.

The test method can be used to supplement other measurements of diesel fuel low temperature behavior (in accordance with Test Methods D97, D2500, and D3117).

SCOPE

1.1 This test method covers estimating the filterability of diesel fuels in some automotive equipment at low temperatures.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 Warning—Mercury has been designated by EPA and many state agencies as a hazardous material that can cause central nervous system, kidney, and liver damage. Mercury, or its vapor, may be hazardous to health and corrosive to materials. Caution should be taken when handling mercury and mercury-containing products. See the applicable product Material Safety Data Sheet (MSDS) for details and EPA’s website (http://www.epa.gov/mercury/faq.htm) for additional information. Users should be aware that selling mercury or mercury-containing products, or both, in your state may be prohibited by state law.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific warning statements, see 1.3, 8.1, 8.2.1, 8.3, 8.5, and Annex A1.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D4539 − 10

Standard Test Method for

Filterability of Diesel Fuels by Low-Temperature Flow Test

1

(LTFT)

This standard is issued under the fixed designation D4539; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* D3117Test Method for Wax Appearance Point of Distillate

3

Fuels (Withdrawn 2010)

1.1 This test method covers estimating the filterability of

D3699Specification for Kerosine

diesel fuels in some automotive equipment at low tempera-

D4057Practice for Manual Sampling of Petroleum and

tures.

Petroleum Products

1.2 The values stated in SI units are to be regarded as

D4177Practice for Automatic Sampling of Petroleum and

standard. No other units of measurement are included in this

Petroleum Products

standard.

E1Specification for ASTM Liquid-in-Glass Thermometers

1.3 Warning—Mercury has been designated by EPA and 2.2 Coordinating Research Council, Inc.

CRC Report No. 528Diesel Fuel Low-Temperature Oper-

many state agencies as a hazardous material that can cause

4

central nervous system, kidney, and liver damage. Mercury, or ability Field Test

2.3 Canadian General Standards Board:

its vapor, may be hazardous to health and corrosive to

materials.Cautionshouldbetakenwhenhandlingmercuryand CAN/CGSB-3.0,No. 14.01-M86, Low Temperature Flow

5

Test (LTFT) for Diesel Fuels

mercury-containing products. See the applicable product Ma-

terial Safety Data Sheet (MSDS) for details and EPA’s website

NOTE 1—CAN/CGSB-3.0, No. 140.1-M86 is essentially equivalent to

(http://www.epa.gov/mercury/faq.htm) for additional informa-

Test Method D4539, but the differences in apparatus and procedures may

tion. Users should be aware that selling mercury or mercury-

or may not yield different results.

containingproducts,orboth,inyourstatemaybeprohibitedby

3. Summary of Test Method

state law.

3.1 The temperature of a series of test specimens of fuel is

1.4 This standard does not purport to address all of the

lowered at a prescribed cooling rate. Commencing at a desired

safety concerns, if any, associated with its use. It is the

test temperature and at each 1°C interval thereafter, a separate

responsibility of the user of this standard to establish appro-

specimen from the series is filtered through a 17-µm screen

priate safety and health practices and determine the applica-

until a minimum LTFT pass temperature is obtained. The

bility of regulatory limitations prior to use. For specific

minimum LTFT pass temperature is the lowest temperature,

warningstatements,see1.3,8.1,8.2.1,8.3,8.5,andAnnexA1.

expressedasamultipleof1°C,atwhichatestspecimencanbe

filtered in 60 s or less.

2. Referenced Documents

2

3.2 Alternatively, a single specimen may be cooled as

2.1 ASTM Standards:

described under 3.1 and tested at a specified temperature to

D97Test Method for Pour Point of Petroleum Products

determine whether it passes or fails at that temperature.

D975Specification for Diesel Fuel Oils

D1655Specification for Aviation Turbine Fuels

4. Significance and Use

D2500Test Method for Cloud Point of Petroleum Products

4.1 TheLowTemperatureFlowTestresultsareindicativeof

the low temperature flow performance of the test fuel in some

diesel vehicles (according to CRC Report No. 528). The test

1

This test method is under the jurisdiction of Committee D02 on Petroleum

method is especially useful for the evaluation of fuels contain-

Products, Liquid Fuels, and Lubricants and is the direct responsibility of Subcom-

mittee D02.07 on Flow Properties. ing flow improver additives.

Current edition approved Oct. 1, 2010. Published November 2010. Originally

approved in 1985. Last previous edition approved in 2009 as D4539–09. DOI:

3

10.1520/D4539-10. The last approved version of this historical standard is referenced on

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or www.astm.org.

4

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Available from Coordinating Research Council, Inc., 219 Perimeter Center

Standards volume information, refer to the standard’s Document Summary page on Parkway, Atlanta, GA 30346.

5

the ASTM website. Available from CGSB Sales Centre, Ottawa, Canada K1A 1G6.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D4539 − 10

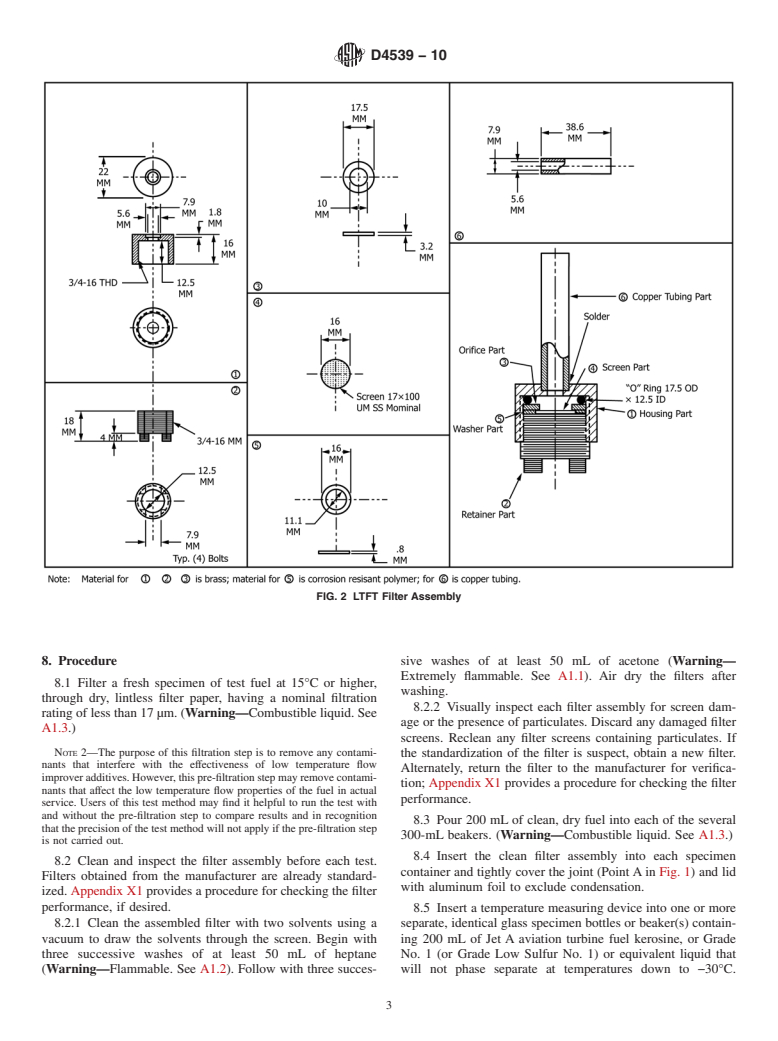

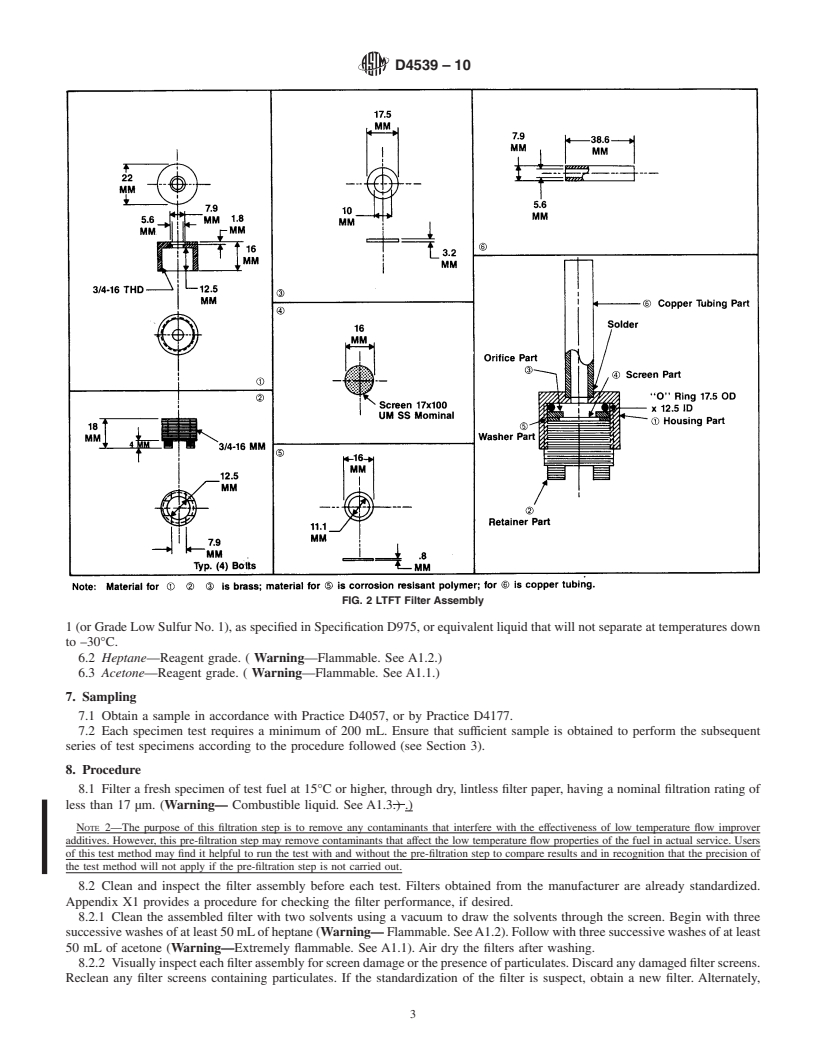

FIG. 1 LTFT Sample Filtration Assembly

4.2 The test method can be used to supplement other of any single temperature point along the prescribed ramp

measurements of diesel fuel

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately,ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:D4539–09 Designation: D4539 – 10

Standard Test Method for

Filterability of Diesel Fuels by Low-Temperature Flow Test

1

(LTFT)

This standard is issued under the fixed designation D4539; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This test method covers estimating the filterability of diesel fuels in some automotive equipment at low temperatures.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 Warning—Mercury has been designated by EPA and many state agencies as a hazardous material that can cause central

nervous system, kidney, and liver damage. Mercury, or its vapor, may be hazardous to health and corrosive to materials. Caution

should be taken when handling mercury and mercury-containing products. See the applicable product Material Safety Data Sheet

(MSDS) for details and EPA’s website (http://www.epa.gov/mercury/faq.htm) for additional information. Users should be aware

that selling mercury or mercury-containing products, or both, in your state may be prohibited by state law.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use. For specific warning statements, see 1.3, 8.1, 8.2.1, 8.3, 8.5, and Annex A1.

2. Referenced Documents

2

2.1 ASTM Standards:

D97 Test Method for Pour Point of Petroleum Products

D975 Specification for Diesel Fuel Oils

D1655 Specification for Aviation Turbine Fuels

D2500 Test Method for Cloud Point of Petroleum Products

D3117 Test Method for Wax Appearance Point of Distillate Fuels

D3699 Specification for Kerosine

D4057 Practice for Manual Sampling of Petroleum and Petroleum Products

D4177 Practice for Automatic Sampling of Petroleum and Petroleum Products

E1 Specification for ASTM Liquid-in-Glass Thermometers

2.2 Coordinating Research Council, Inc.

3

CRC Report No. 528 Diesel Fuel Low-Temperature Operability Field Test

2.3 Canadian General Standards Board:

4

CAN/CGSB-3.0, No. 14.01-M86, Low Temperature Flow Test (LTFT) for Diesel Fuels

NOTE 1—CAN/CGSB-3.0,No.140.1-M86isessentiallyequivalenttoTestMethodD4539,butthedifferencesinapparatusandproceduresmayormay

not yield different results.

3. Summary of Test Method

3.1 The temperature of a series of test specimens of fuel is lowered at a prescribed cooling rate. Commencing at a desired test

temperature and at each 1°C interval thereafter, a separate specimen from the series is filtered through a 17-µm screen until a

minimum LTFT pass temperature is obtained. The minimum LTFT pass temperature is the lowest temperature, expressed as a

multiple of 1°C, at which a test specimen can be filtered in 60 s or less.

1

This test method is under the jurisdiction of Committee D02 on Petroleum Products and Lubricants and is the direct responsibility of Subcommittee D02.07 on Flow

Properties.

´1

Current edition approved April 15, 2009. Published May 2009. Originally approved in 1985. Last previous edition approved in 2003 as D4539–03 . DOI:

10.1520/D4539-09.

Current edition approved Oct. 1, 2010. Published November 2010. Originally approved in 1985. Last previous edition approved in 2009 as D4539–09. DOI:

10.1520/D4539-10.

2

ForreferencedASTMstandards,visittheASTMwebsite,www.astm.org,orcontactASTMCustomerServiceatservice@astm.org.ForAnnualBookofASTMStandards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from Coordinating Research Council, Inc., 219 Perimeter Center Parkway, Atlanta, GA 30346.

4

Available from CGSB Sales Centre, Ottawa, Canada K1A 1G6.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D4539 – 10

3.2 Alternatively, a single specimen may be cooled as described under 3.1 and tested at a specified temperature to determine

whether it passes or fails at that temperature.

4. Significance and Use

4.1 The Low Temperature Flow Test results are indicative of the low temperature flow performance of

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.