ASTM B868-96

(Practice)Standard Practice for Contact Performance Classification of Electrical Connection Systems

Standard Practice for Contact Performance Classification of Electrical Connection Systems

SCOPE

1.1 This practice provides a uniform method of specifying performance requirements for (or reporting test results of) electrical contact and connection systems. Both conductor and connector system performance may be specified by this practice, separately or in combination.

1.2 This practice may be used for separable or permanent contacts employing metallic conductors and contacts.

1.3 This practice provides methods for both signal and power applications.

1.4 This practice does not specify the sample preparation or test sequences required for determining contact performance. It is the responsibility of the user of this practice to determine the applied test sequence(s) appropriate for the application.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or

withdrawn. Contact ASTM International (www.astm.org) for the latest information.

Designation: B 868 – 96 An American National Standard

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Standard Practice for

Contact Performance Classification of Electrical Connection

1

Systems

This standard is issued under the fixed designation B 868; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

4

1. Scope Aluminum-to-Copper Bare Overhead Conductors”

1.1 This practice provides a uniform method of specifying

3. Terminology

performance requirements for (or reporting test results of)

3.1 Terms used in this practice are defined in Terminology

electrical contact and connection systems. Both conductor and

B 542 except as noted in 3.2.

connector system performance may be specified by this prac-

3.2 Definitions of Terms Specific to This Standard:

tice, separately or in combination.

3.2.1 conductor, n—electrically conductive member carry-

1.2 This practice may be used for separable or permanent

ing current to a contact interface. Examples are wire and cable,

contacts employing metallic conductors and contacts.

busbar, and conductive paths on an etched printed circuit

1.3 This practice provides methods for both signal and

board.

power applications.

3.2.2 contact performance, n—contact interface behavior as

1.4 This practice does not specify the sample preparation or

indicated by initial electrical resistance and resistance change

test sequences required for determining contact performance. It

under the applied test conditions.

is the responsibility of the user of this practice to determine the

applied test sequence(s) appropriate for the application.

4. Summary of Practices

1.5 This standard does not purport to address all of the

4.1 The prescribed performance specification (or reporting)

safety concerns, if any, associated with its use. It is the

statement consists of three sections, as follows:

responsibility of the user of this standard to establish appro-

4.1.1 Performance Classification, in accordance with this

priate safety and health practices and determine the applica-

practice (Section 6).

bility of regulatory limitations prior to use.

4.1.2 Variability Index, determined by sample size and

distribution of resistance values measured at end of test, in

2. Referenced Documents

accordance with this practice (Section 7).

2.1 ASTM Standards:

4.1.3 Statement of test method employed to determine

B 539 Test Methods for Measuring Contact Resistance of

performance classification.

2

Electrical Connections (Static Contacts)

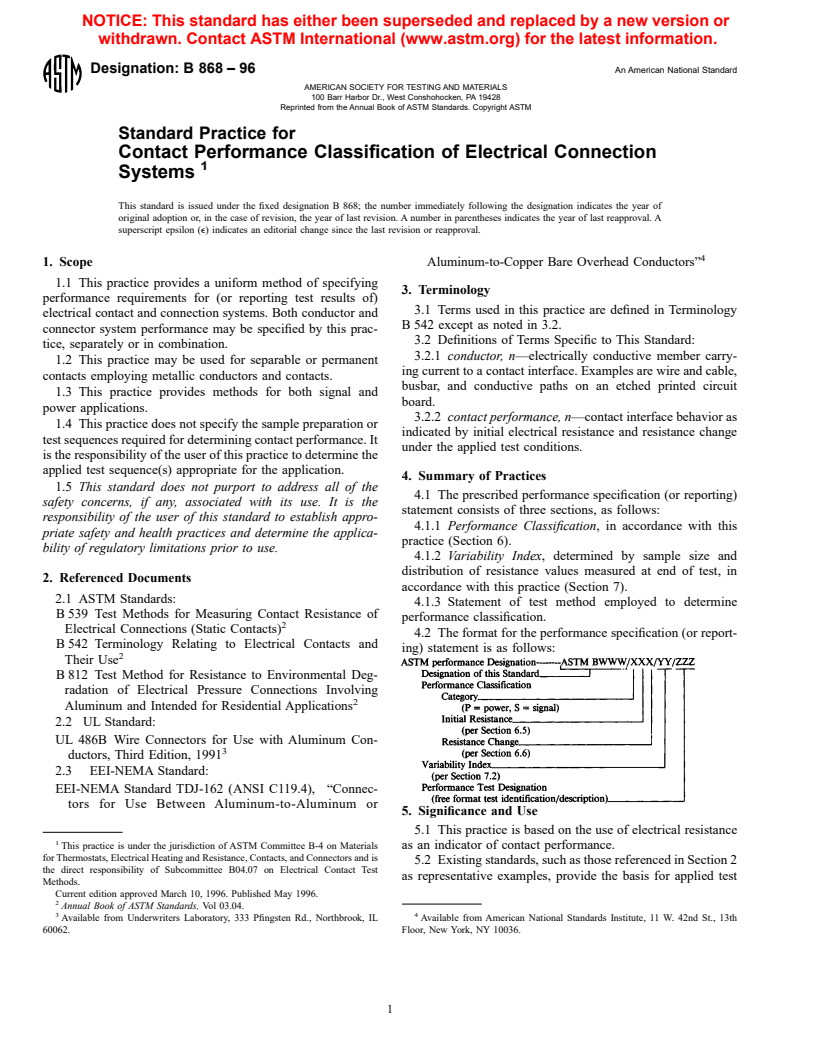

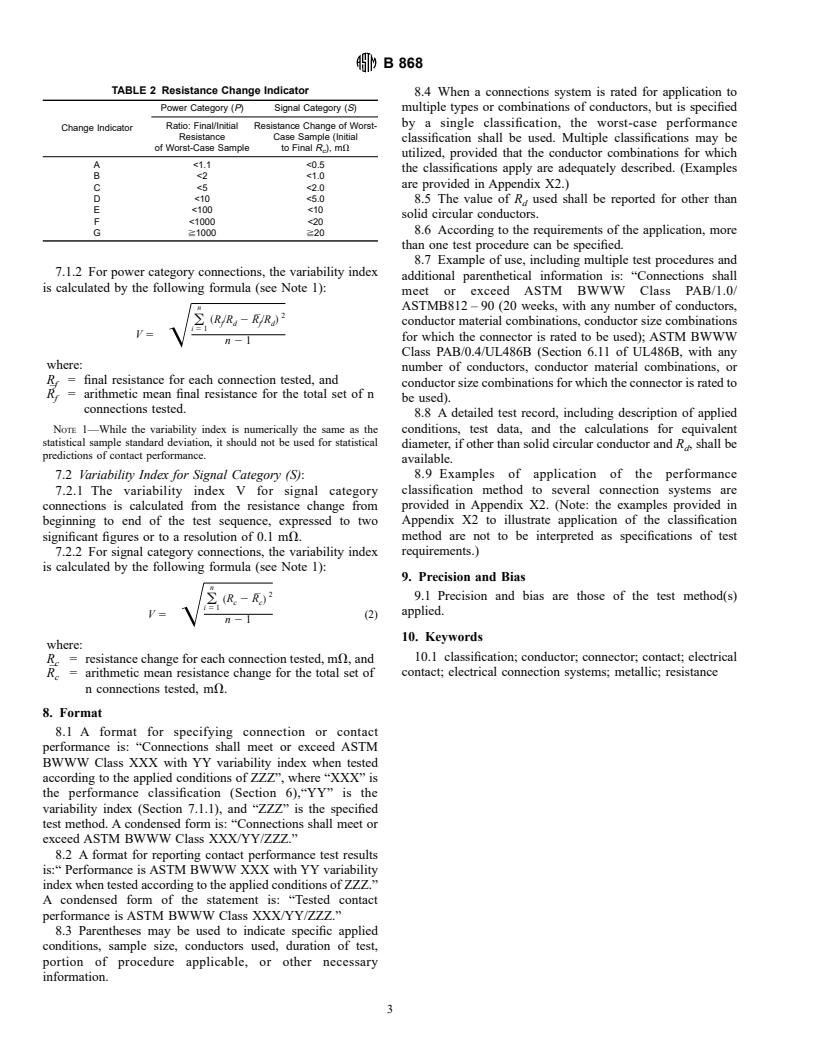

4.2 The format for the performance specification (or report-

B 542 Terminology Relating to Electrical Contacts and

ing) statement is as follows:

2

Their Use

B 812 Test Method for Resistance to Environmental Deg-

radation of Electrical Pressure Connections Involving

2

Aluminum and Intended for Residential Applications

2.2 UL Standard:

UL 486B Wire Connectors for Use with Aluminum Con-

3

ductors, Third Edition, 1991

2.3 EEI-NEMA Standard:

EEI-NEMA Standard TDJ-162 (ANSI C119.4), “Connec-

tors for Use Between Aluminum-to-Aluminum or

5. Significance and Use

5.1 This practice is based on the use of electrical resistance

1

This practice is under the jurisdiction of ASTM Committee B-4 on Materials as an indicator of contact performance.

for Thermostats, Electrical Heating and Resistance, Contacts, and Connectors and is

5.2 Existing standards, such as those referenced in Section 2

the direct responsibility of Subcommittee B04.07 on Electrical Contact Test

as representative examples, provide the basis for applied test

Methods.

Current edition approved March 10, 1996. Published May 1996.

2

Annual Book of ASTM Standards, Vol 03.04.

3 4

Available from Underwriters Laboratory, 333 Pfingsten Rd., Northbrook, IL Available from American National Standards Institute, 11 W. 42nd St., 13th

60062. Floor, New York, NY 10036.

1

---------------------- Page: 1 ----------------------

B 868

conditions. Modifications in procedure or sample size, or both, time as contact performance in accordance with 6.2.5, and the

of existing standards may have to be made to provide for conductor is solid with circular cross section, potential drop

resistance measurement and to meet variability index require- measurements may be used without conversion for the purpose

ments that a user may specify. of determining contact performance. (See example, Appendix

5.3 This practice accommodates the use of multiple test X2.)

methods, as may be required to assure satisfactory performance 6.3 Contact resistance shall be measured in accordan

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.