ASTM F316-03

(Test Method)Standard Test Methods for Pore Size Characteristics of Membrane Filters by Bubble Point and Mean Flow Pore Test

Standard Test Methods for Pore Size Characteristics of Membrane Filters by Bubble Point and Mean Flow Pore Test

SCOPE

1.1 These test methods cover the determination of two of the pore size properties of membrane filters with maximum pore sizes from 0.1 to 15.0 m.

1.2 Test Method A presents a test method for measuring the maximum limiting pore diameter of nonfibrous membranes. The limiting diameter is the diameter of a circle having the same area as the smallest section of a given pore ().

1.3 Test Method B measures the relative abundance of a specified pore size in a membrane, defined in terms of the limiting diameter.

1.4 The analyst should be aware that adequate collaborative data for bias statements as required by Practice D 2777 is not provided. See the precision and bias section for details.

1.5 This standard may involve hazardous materials, operations, and equipment. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F316 – 03

Standard Test Methods for

Pore Size Characteristics of Membrane Filters by Bubble

Point and Mean Flow Pore Test

ThisstandardisissuedunderthefixeddesignationF316;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 These test methods cover the determination of two of

the pore size properties of membrane filters with maximum

pore sizes from 0.1 to 15.0 µm.

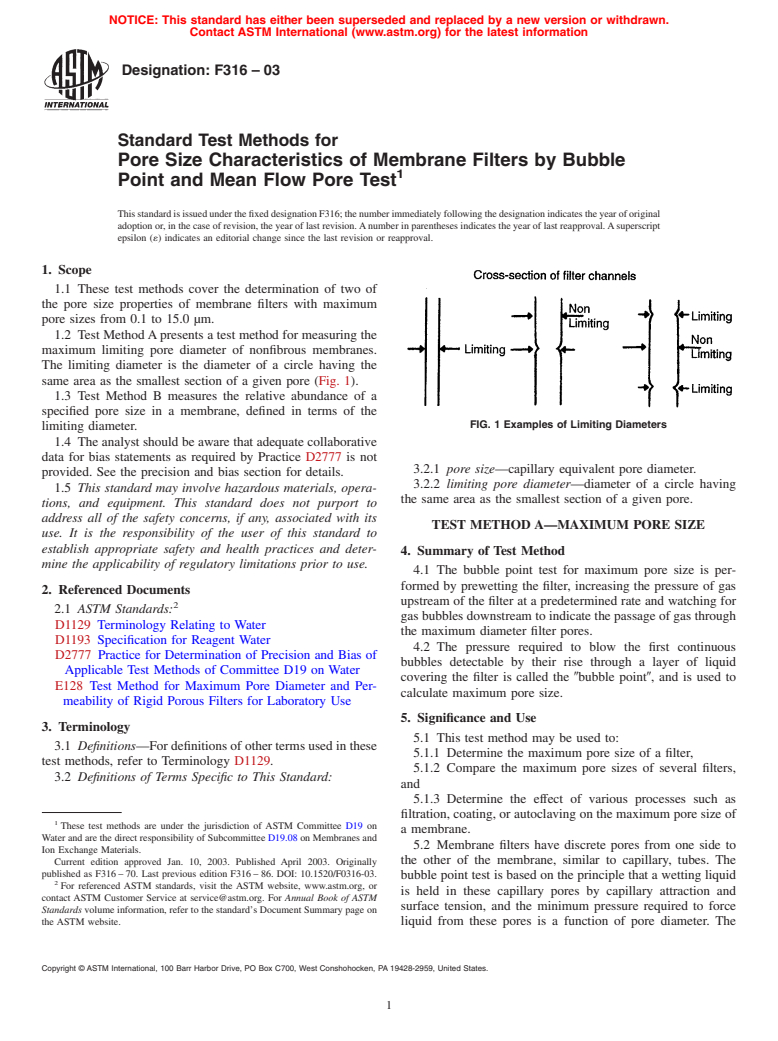

1.2 Test MethodApresents a test method for measuring the

maximum limiting pore diameter of nonfibrous membranes.

The limiting diameter is the diameter of a circle having the

same area as the smallest section of a given pore (Fig. 1).

1.3 Test Method B measures the relative abundance of a

specified pore size in a membrane, defined in terms of the

FIG. 1 Examples of Limiting Diameters

limiting diameter.

1.4 The analyst should be aware that adequate collaborative

data for bias statements as required by Practice D2777 is not

3.2.1 pore size—capillary equivalent pore diameter.

provided. See the precision and bias section for details.

3.2.2 limiting pore diameter—diameter of a circle having

1.5 This standard may involve hazardous materials, opera-

the same area as the smallest section of a given pore.

tions, and equipment. This standard does not purport to

address all of the safety concerns, if any, associated with its

TEST METHOD A—MAXIMUM PORE SIZE

use. It is the responsibility of the user of this standard to

establish appropriate safety and health practices and deter-

4. Summary of Test Method

mine the applicability of regulatory limitations prior to use.

4.1 The bubble point test for maximum pore size is per-

formed by prewetting the filter, increasing the pressure of gas

2. Referenced Documents

upstream of the filter at a predetermined rate and watching for

2.1 ASTM Standards:

gas bubbles downstream to indicate the passage of gas through

D1129 Terminology Relating to Water

the maximum diameter filter pores.

D1193 Specification for Reagent Water

4.2 The pressure required to blow the first continuous

D2777 Practice for Determination of Precision and Bias of

bubbles detectable by their rise through a layer of liquid

Applicable Test Methods of Committee D19 on Water

covering the filter is called the 9bubble point9, and is used to

E128 Test Method for Maximum Pore Diameter and Per-

calculate maximum pore size.

meability of Rigid Porous Filters for Laboratory Use

5. Significance and Use

3. Terminology

5.1 This test method may be used to:

3.1 Definitions—For definitions of other terms used in these

5.1.1 Determine the maximum pore size of a filter,

test methods, refer to Terminology D1129.

5.1.2 Compare the maximum pore sizes of several filters,

3.2 Definitions of Terms Specific to This Standard:

and

5.1.3 Determine the effect of various processes such as

filtration, coating, or autoclaving on the maximum pore size of

These test methods are under the jurisdiction of ASTM Committee D19 on

a membrane.

Water and are the direct responsibility of Subcommittee D19.08 on Membranes and

5.2 Membrane filters have discrete pores from one side to

Ion Exchange Materials.

the other of the membrane, similar to capillary, tubes. The

Current edition approved Jan. 10, 2003. Published April 2003. Originally

published as F316 – 70. Last previous edition F316 – 86. DOI: 10.1520/F0316-03.

bubble point test is based on the principle that a wetting liquid

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

is held in these capillary pores by capillary attraction and

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

surface tension, and the minimum pressure required to force

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. liquid from these pores is a function of pore diameter. The

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F316 – 03

pressureatwhichasteadystreamofbubblesappearsinthistest where such specifications are available. Other grades may be

is the bubble point pressure.The bubble point test is significant used provided it is first ascertained that the reagent is of

not only for indicating maximum pore size, but may also sufficient high purity to permit its use without lessening the

indicate a damaged membrane, ineffective seals, or a system accuracy of the determination.

leak. 7.2 Water, conforming to Specification D1193, Type IV or

higher purity.

5.3 The results of this test method should not be used as the

7.3 Denatured Alcohol.

sole factor to describe the limiting size for retention of

7.4 Petroleum Distillate, with surface tension of 30

particulate contaminants from fluids. The effective pore size

dynes/cm at 25°C.

calculated from this test method is based on the premise of

7.5 Mineral Oil, such as USP liquid petrolatum heavy, with

capillary pores having circular cross sections, and does not

surface tension of 34.7 dynes/cm at 25°C.

refertoactualparticlesizeretention.SeeTestMethodE128for

7.6 1,1.2-trichloro-l,2,2-trifluoroethane (Freon TFt), avail-

additional information.

able from commercial chemical supply houses.

7.7 Clean Gas Pressure Source, with regulation (filtered air

6. Apparatus

or nitrogen).

6.1 Filter Holder,asshowninFig.2,consistingofabaseA,

NOTE 2—Table 1 lists the nominal surface tension of these liquids at

a locking ring B, O-ring seal C, support disk D, and gas inlet

25°C. Table 2 lists the simplified maximum pore size formulas based on

E. The support disk shall be 2-ply construction, consisting of a

these values, where the liquid completely wets the membrane.

100 by 100 mesh or finer screen and a perforated metal plate

for rigidity. The diameter of the test filter may be either 25 or

8. Procedure

47 mm, as appropriate to the holder being used for the test.

8.1 Wet the test membrane completely by floating it on a

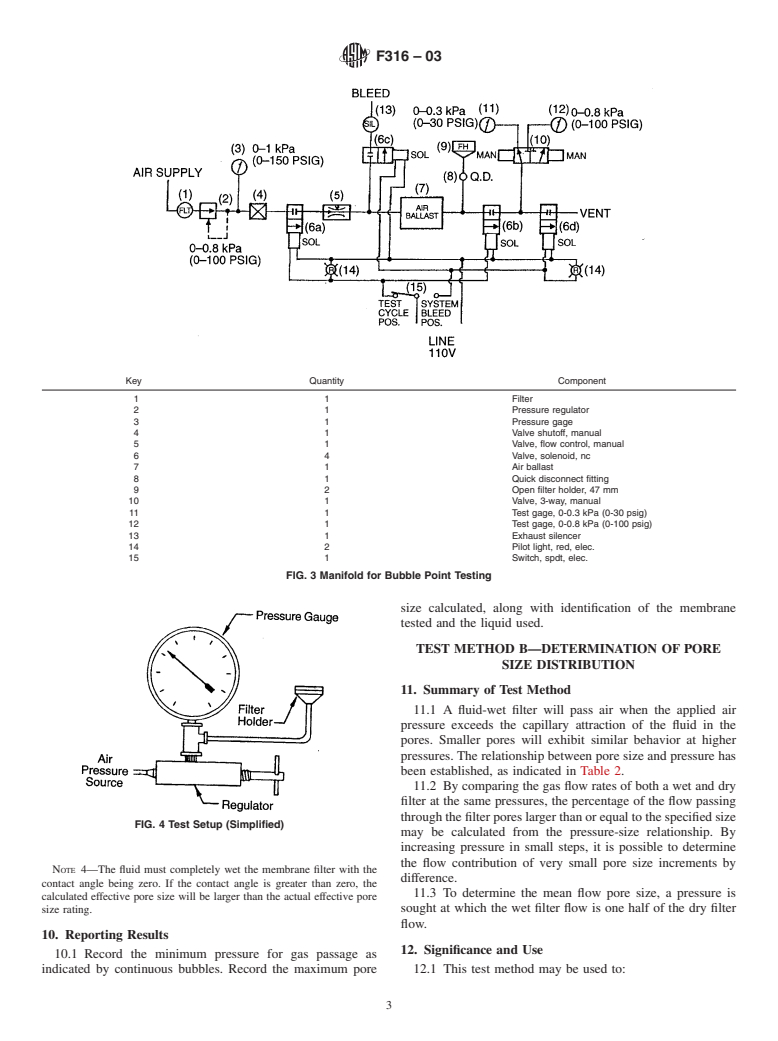

6.2 Manifold,asshowninFig.3,amicrometricflowcontrol

pool of the liquid. Use a vacuum chamber to assist in wetting

valve capable of providing a linear rise in pressure and a gas

the filter, if needed.

ballast of at least 16 000-cm capacity.

8.2 Place the wet membrane in the filter holder.

8.3 Close the filter holder and apply slight gas pressure to

NOTE 1—For less accurate determinations, the simplified apparatus

shown in Fig. 4 may be used. eliminate possible liquid back flow.

8.4 Cover the perforated metal plate with 2 to 3 mm of test

6.3 Pressure Gages (and mercury manometer if required),

liquid.

covering the range of pressures needed for the pore sizes under

8.5 Increase the gas pressure slowly. Record the lowest

investigation (see Table 1).

pressure at which a steady stream of bubbles rises from the

6.4 Metal Punch, used to cut a suitable size filter from the

central area of the liquid reservoir.

test sheet to fit the test filter holder.

NOTE 3—Faultysealingmaycauseerroneousbubblingfromthesealing

edge of the liquid reservoir. Be sure to record the bubble point pressure

7. Reagents

with bubbles from the central area of the reservoir (see Fig. 5).

7.1 Purity of Reagents—Reagent grade chemicals shall be

9. Calculation

used in all tests. Unless otherwise indicated, it is intended that

all reagents shall conform to the specifications of the Commit-

9.1 If the test liquid is known to wet the membrane

tee on Analytical Reagents of the American Chemical Society

completely, calculate the maximum pore size from the follow-

ing equation:

d 5 Cg/p (1)

where:

d = limiting diameter, µm,

g = surface tension, mN/m, (dynes/cm),

p = pressure, Pa or cm Hg, and

C = constant, 2860 when p is in Pa, 2.15 when p is in cm

Hg, and 0.415 when p is in psi units.

Reagent Chemicals, American Chemical Society Specifications, American

Chemical Society, Washington, DC. For Suggestions on the testing of reagents not

listed by the American Chemical Society, see Annual Standards for Laboratory

Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia

and National Formulary, U.S. Pharmacopeial Convention, Inc. (USPC), Rockville,

FIG. 2 Filter Holder MD.

F316 – 03

Key Quantity Component

1 1 Filter

2 1 Pressure regulator

3 1 Pressure gage

4 1 Valve shutoff, manual

5 1 Valve, flow control, manual

6 4 Valve, solenoid, nc

7 1 Air ballast

8 1 Quick disconnect fitting

9 2 Open filter holder, 47 mm

10 1 Valve, 3-way, manual

11 1 Test gage, 0-0.3 kPa (0-30 psig)

12 1 Test gage, 0-0.8 kPa (0-100 psig)

13 1 Exhaust silencer

14 2 Pilot light, red, elec.

15 1 Switch, spdt, elec.

FIG. 3 Manifold for Bubble Point Testing

size calculated, along with identification of the membrane

tested and the liquid used.

TEST METHOD B—DETERMINATION OF PORE

SIZE DISTRIBUTION

11. Summary of Test Method

11.1 A fluid-wet filter will pass air when the applied air

pressure exceeds the capillary attraction of the fluid in the

pores. Smaller pores will exhibit similar behavior at higher

pressures. The relationship between pore size and pressure has

been established, as indicated in Table 2.

11.2 By comparing the gas flow rates of both a wet and dry

filter at the same pressures, the percentage of the flow passing

through the filter pores larger than or equal to the specified size

FIG. 4 Test Setup (Simplified)

may be calculated from the pressure-size relationship. By

increasing pressure in small s

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.