ASTM D8194-18e1

(Practice)Standard Practice for Evaluation of Suitability of 37 mm Filter Monitors and 47 mm Filters Used to Determine Particulate Contaminant in Aviation Turbine Fuels

Standard Practice for Evaluation of Suitability of 37 mm Filter Monitors and 47 mm Filters Used to Determine Particulate Contaminant in Aviation Turbine Fuels

SIGNIFICANCE AND USE

5.1 This practice provides criteria for products used to measure particulate matter present in a sample of aviation turbine fuel. The objective is to verify that filters, support pads, and field monitors fall within the acceptable ranges that are established by this practice.

SCOPE

1.1 This practice determines suitability of products used for measuring particulate contamination in aviation turbine fuel when using Test Methods D5452 and D2276.

1.2 There are two major parts of this practice. The first is for evaluation of the cellulose acetate butyrate field monitors that are used in combination with the filters and the filter support pads. The second part is for evaluation of the filter when used with an appropriate cellulose acetate butyrate field monitor.

1.3 Units—The values stated in SI units are to be regarded as the standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

´1

Designation:D8194 −18

Standard Practice for

Evaluation of Suitability of 37mm Filter Monitors and

47mm Filters Used to Determine Particulate Contaminant in

1

Aviation Turbine Fuels

This standard is issued under the fixed designation D8194; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1

ε NOTE—Subsection 9.1.2 was corrected editorially in August 2020.

1. Scope D1193 Specification for Reagent Water

D1319 Test Method for Hydrocarbon Types in Liquid Petro-

1.1 This practice determines suitability of products used for

leum Products by Fluorescent Indicator Adsorption

measuring particulate contamination in aviation turbine fuel

D1655 Specification for Aviation Turbine Fuels

when using Test Methods D5452 and D2276.

D2276 Test Method for Particulate Contaminant inAviation

1.2 Therearetwomajorpartsofthispractice.Thefirstisfor

Fuel by Line Sampling

evaluation of the cellulose acetate butyrate field monitors that

D2624 Test Methods for Electrical Conductivity ofAviation

are used in combination with the filters and the filter support

and Distillate Fuels

pads. The second part is for evaluation of the filter when used

D3948 TestMethodforDeterminingWaterSeparationChar-

with an appropriate cellulose acetate butyrate field monitor.

acteristicsofAviationTurbineFuelsbyPortableSeparom-

1.3 Units—The values stated in SI units are to be regarded

eter

as the standard. No other units of measurement are included in D4171 Specification for Fuel System Icing Inhibitors

this standard.

D5452 Test Method for Particulate Contamination in Avia-

tion Fuels by Laboratory Filtration

1.4 This standard does not purport to address all of the

F316 Test Methods for Pore Size Characteristics of Mem-

safety concerns, if any, associated with its use. It is the

brane Filters by Bubble Point and Mean Flow Pore Test

responsibility of the user of this standard to establish appro-

priate safety, health, and environmental practices and deter-

2.2 Federal Standard:

mine the applicability of regulatory limitations prior to use.

MIL-DTL-85470 Inhibitor, Icing, Fuel System, High Flash

4

1.5 This international standard was developed in accor-

NATO Code Number S-1745

dance with internationally recognized principles on standard-

ization established in the Decision on Principles for the

3. Terminology

Development of International Standards, Guides and Recom-

3.1 Definitions:

mendations issued by the World Trade Organization Technical

3.1.1 cellulose acetate butyrate, n—thermoplastic that is

Barriers to Trade (TBT) Committee.

known to be adequate for manufacture of field monitors and

2. Referenced Documents chemically compatible for use with aviation fuel.

2

2.1 ASTM Standards:

3.1.2 field monitor, n—two-part device (inlet plus outlet)

D362 SpecificationforIndustrialGradeToluene(Withdrawn

used to hold a filter securely.

3

1989)

3.1.2.1 Discussion—In this practice, all field monitors are

manufactured from cellulose acetate butyrate polymer.

1

This practice is under the jurisdiction ofASTM Committee D02 on Petroleum

3.1.3 filter, n—thin, porous membrane used to separate

Products, Liquid Fuels, and Lubricants and is the direct responsibility of Subcom-

particulate contamination from a liquid.

mittee D02.J0.05 on Fuel Cleanliness.

Current edition approved Dec. 1, 2018. Published February 2019. DOI: 10.1520/

3.1.4 plugs, n—small plastic parts designed to block inlets

D8194-18E01.

and outlets of field monitors.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

3 4

The last approved version of this historical standard is referenced on Available from DLA Document Services, Bldg. 4/D, 700 Robbins Ave.,

www.astm.org. Philadelphia, PA 19111-5094, http://quicksearch.dla.miL.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

´1

D8194−18

A

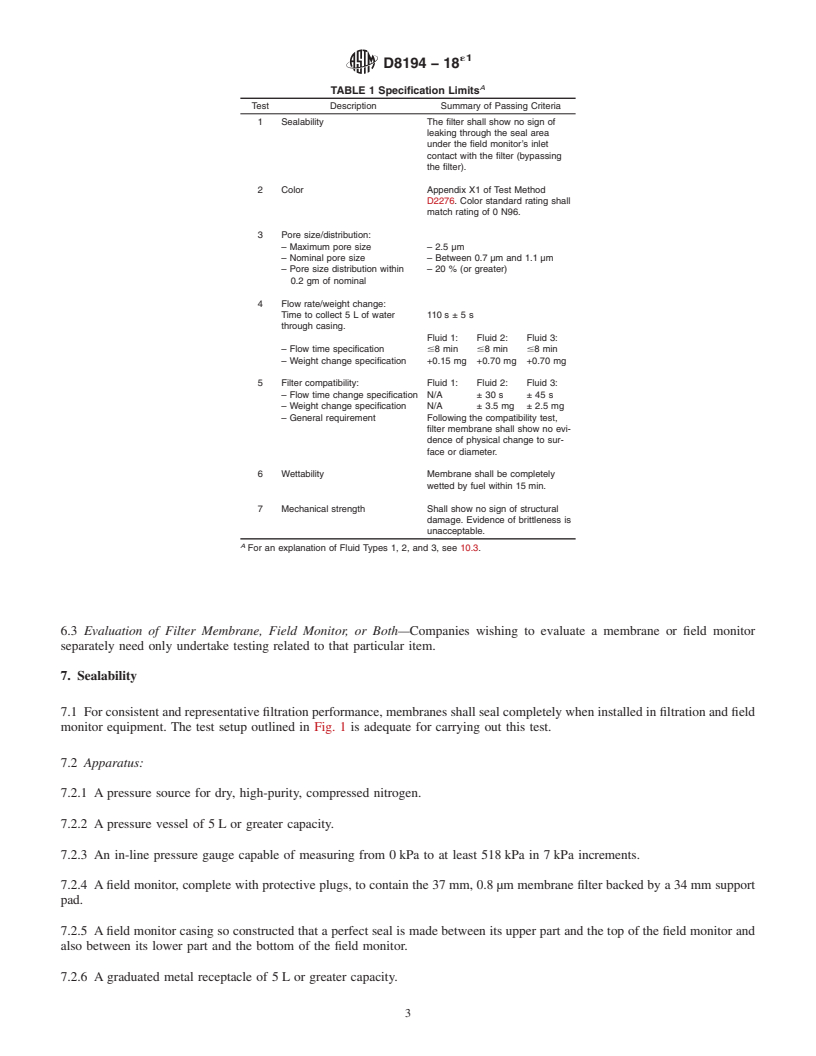

TABLE 1 Specification Limits

4. Summary of Practice

Test Description Summary of Passing Criteria

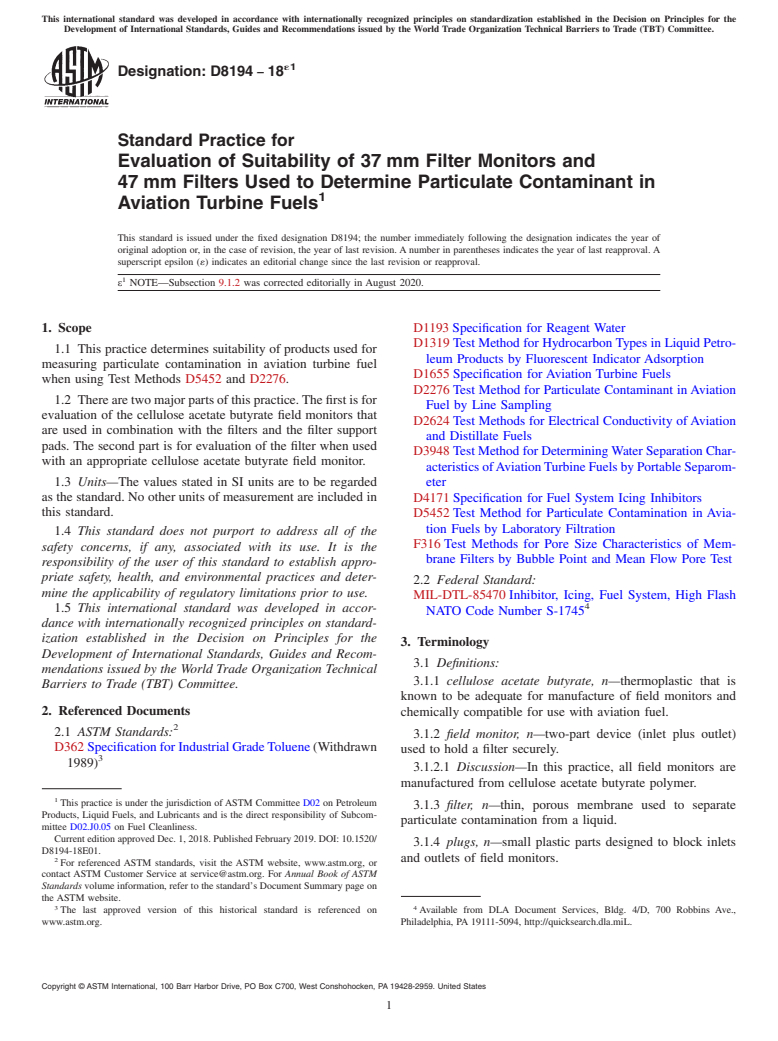

4.1 Water with blue dye dispersion is passed through a

1 Sealability The filter shall show no sign of

membrane filter in a field monitor to evaluate the field monitor

leaking through the seal area

for leaks bypassing the filter. under the field monitor’s inlet

contact with the filter (b

...

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation: D8194 − 18

Standard Practice for

Evaluation of Suitability of 37 mm Filter Monitors and

47 mm Filters Used to Determine Particulate Contaminant in

1

Aviation Turbine Fuels

This standard is issued under the fixed designation D8194; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1

ε NOTE—Subsection 9.1.2 was corrected editorially in August 2020.

1. Scope D1193 Specification for Reagent Water

D1319 Test Method for Hydrocarbon Types in Liquid Petro-

1.1 This practice determines suitability of products used for

leum Products by Fluorescent Indicator Adsorption

measuring particulate contamination in aviation turbine fuel

D1655 Specification for Aviation Turbine Fuels

when using Test Methods D5452 and D2276.

D2276 Test Method for Particulate Contaminant in Aviation

1.2 There are two major parts of this practice. The first is for

Fuel by Line Sampling

evaluation of the cellulose acetate butyrate field monitors that

D2624 Test Methods for Electrical Conductivity of Aviation

are used in combination with the filters and the filter support

and Distillate Fuels

pads. The second part is for evaluation of the filter when used

D3948 Test Method for Determining Water Separation Char-

with an appropriate cellulose acetate butyrate field monitor.

acteristics of Aviation Turbine Fuels by Portable Separom-

1.3 Units—The values stated in SI units are to be regarded eter

as the standard. No other units of measurement are included in

D4171 Specification for Fuel System Icing Inhibitors

this standard. D5452 Test Method for Particulate Contamination in Avia-

tion Fuels by Laboratory Filtration

1.4 This standard does not purport to address all of the

F316 Test Methods for Pore Size Characteristics of Mem-

safety concerns, if any, associated with its use. It is the

brane Filters by Bubble Point and Mean Flow Pore Test

responsibility of the user of this standard to establish appro-

priate safety, health, and environmental practices and deter-

2.2 Federal Standard:

mine the applicability of regulatory limitations prior to use.

MIL-DTL-85470 Inhibitor, Icing, Fuel System, High Flash

4

1.5 This international standard was developed in accor-

NATO Code Number S-1745

dance with internationally recognized principles on standard-

ization established in the Decision on Principles for the

3. Terminology

Development of International Standards, Guides and Recom-

3.1 Definitions:

mendations issued by the World Trade Organization Technical

3.1.1 cellulose acetate butyrate, n—thermoplastic that is

Barriers to Trade (TBT) Committee.

known to be adequate for manufacture of field monitors and

2. Referenced Documents

chemically compatible for use with aviation fuel.

2

2.1 ASTM Standards:

3.1.2 field monitor, n—two-part device (inlet plus outlet)

D362 Specification for Industrial Grade Toluene (Withdrawn

used to hold a filter securely.

3

1989)

3.1.2.1 Discussion—In this practice, all field monitors are

manufactured from cellulose acetate butyrate polymer.

1

This practice is under the jurisdiction of ASTM Committee D02 on Petroleum

3.1.3 filter, n—thin, porous membrane used to separate

Products, Liquid Fuels, and Lubricants and is the direct responsibility of Subcom-

particulate contamination from a liquid.

mittee D02.J0.05 on Fuel Cleanliness.

Current edition approved Dec. 1, 2018. Published February 2019. DOI: 10.1520/

3.1.4 plugs, n—small plastic parts designed to block inlets

D8194-18E01.

2 and outlets of field monitors.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

3 4

The last approved version of this historical standard is referenced on Available from DLA Document Services, Bldg. 4/D, 700 Robbins Ave.,

www.astm.org. Philadelphia, PA 19111-5094, http://quicksearch.dla.miL.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

´1

D8194 − 18

A

TABLE 1 Specification Limits

4. Summary of Practice

Test Description Summary of Passing Criteria

4.1 Water with blue dye dispersion is passed through a

1 Sealability The filter shall show no sign of

membrane filter in a field monitor to evaluate the field monitor

leaking through the seal area

for leaks bypassing the filter. under the field monitor’s inlet

contact with the filter (bypassing

4.2 Membrane filters are evaluated for color per Appendix

the filter).

X1 of Test Me

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation: D8194 − 18 D8194 − 18

Standard Practice for

Evaluation of Suitability of 37 mm Filter Monitors and

47 mm Filters Used to Determine Particulate Contaminant in

1

Aviation Turbine Fuels

This standard is issued under the fixed designation D8194; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1

ε NOTE—Subsection 9.1.2 was corrected editorially in August 2020.

1. Scope

1.1 This practice determines suitability of products used for measuring particulate contamination in aviation turbine fuel when

using Test Methods D5452 and D2276.

1.2 There are two major parts of this practice. The first is for evaluation of the cellulose acetate butyrate field monitors that are

used in combination with the filters and the filter support pads. The second part is for evaluation of the filter when used with an

appropriate cellulose acetate butyrate field monitor.

1.3 Units—The values stated in SI units are to be regarded as the standard. No other units of measurement are included in this

standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of

regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

3

D362 Specification for Industrial Grade Toluene (Withdrawn 1989)

D1193 Specification for Reagent Water

D1319 Test Method for Hydrocarbon Types in Liquid Petroleum Products by Fluorescent Indicator Adsorption

D1655 Specification for Aviation Turbine Fuels

D2276 Test Method for Particulate Contaminant in Aviation Fuel by Line Sampling

D2624 Test Methods for Electrical Conductivity of Aviation and Distillate Fuels

D3948 Test Method for Determining Water Separation Characteristics of Aviation Turbine Fuels by Portable Separometer

1

This practice is under the jurisdiction of ASTM Committee D02 on Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of Subcommittee

D02.J0.05 on Fuel Cleanliness.

Current edition approved Dec. 1, 2018. Published February 2019. DOI: 10.1520/D8194-18.10.1520/D8194-18E01.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

The last approved version of this historical standard is referenced on www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

´1

D8194 − 18

D4171 Specification for Fuel System Icing Inhibitors

D5452 Test Method for Particulate Contamination in Aviation Fuels by Laboratory Filtration

F316 Test Methods for Pore Size Characteristics of Membrane Filters by Bubble Point and Mean Flow Pore Test

2.2 Federal Standard:

4

MIL-DTL-85470 Inhibitor, Icing, Fuel System, High Flash NATO Code Number S-1745

3. Terminology

3.1 Definitions:

3.1.1 cellulose acetate butyrate, n—thermoplastic that is known to be adequate for manufacture of field monitors and chemically

compatible for use with aviation fuel.

3.1.2 field monitor, n—two-part device (inlet plus outlet) used to hold a filter securely.

3.1.2.1 Discussion—

In this practice, all field monitors are manufactured from cellulose acetate butyrate polymer.

3.1.3 filter, n—thin, porous membrane used to separate particulate contamination from a liquid.

3.1.4 plugs, n—small plastic parts designed to block inlets and outlets of field monitors.

4. Summary of Practice

4.1 Water with blue dye dispersion is passed through a membrane filter in a field monitor to evaluate the field monitor for leaks

bypassing the filter.

4.2 Membrane filters are evaluated for color per Appendix X1 of Test Method D2276.

4.3 Maximum and mean flow rate pore sizes of membrane filters are determined, as well a

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.