ASTM D2903-03

(Specification)Standard Specification for Crosslinked Chlorinated Polyolefin Heat-Shrinkable Tubing for Electrical Insulation

Standard Specification for Crosslinked Chlorinated Polyolefin Heat-Shrinkable Tubing for Electrical Insulation

ABSTRACT

This specification covers the manufacture, testing, and property requirements of two types of flexible crosslinked chlorinated polyolefin heat-shrinkable tubing used for electrical insulating purposes. It is supplied in an expanded form and will shrink to the specified diameter when heated. Type I tubing is used for normal operating temperatures, while Type II tubing is used for extended operating temperatures. The finished compound shall be free of foreign matter other than antioxidants, flame retardants, processing aids, crosslinking agents, pigments or other additives as appropriate. The final tubing shall be extruded, crosslinked and then expanded to the required dimensions. Specimens shall be sampled and tested accordingly for the following properties: corrosion by copper mirror and copper contact test; solvent resistance by immersion in Grade JP-4 fuel, lubricating oil, hydraulic fluid, sodium chloride solution, anti-icing fluid, and aviation gasoline; flammability (time of burning and burning distance); water absorption; and tensile strength, ultimate elongation, and weight increase.

SCOPE

1.1 This specification covers flexible crosslinked chlorinated polyolefin heat-shrinkable tubing used for electrical insulating purposes. It is supplied in an expanded form and will shrink to the specified diameter when heated.

Note 1—This standard does not have a similar or equivalent IEC standard.

1.2 The values stated in inch-pound units are to be regarded as the standard accept for temperature, which is stated in degrees Celsius. SI values in parentheses are for information only.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation: D2903 – 03

Standard Specification for

Crosslinked Chlorinated Polyolefin Heat-Shrinkable Tubing

1

for Electrical Insulation

This standard is issued under the fixed designation D2903; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope MIL-L-23699 Lubrication Oil, Aircraft, Turbine Engines,

Synthetic Base

1.1 This specification covers flexible crosslinked chlori-

MIL-A-8243 Anti-Icing and De-Icing Defrosting Fluid

nated polyolefin heat-shrinkable tubing used for electrical

MIL-G-5572 Fuel, Aviation, Grades 100 and 130

insulatingpurposes.Itissuppliedinanexpandedformandwill

2.3 Federal Standards:

shrink to the specified diameter when heated.

SS-S-550 Sodium Chloride, Technical, for Water Softening

NOTE 1—This standard does not have a similar or equivalent IEC 3

Units

standard.

3. Terminology

1.2 The values stated in inch-pound units are to be regarded

as the standard accept for temperature, which is stated in

3.1 Definitions:

degrees Celsius. SI values in parentheses are for information

3.1.1 For definitions pertaining to electrical insulation, refer

only.

to Terminology D1711.

3.1.2 For definitions pertaining to fire issues, refer to Ter-

2. Referenced Documents

minology E176.

2

2.1 ASTM Standards:

3.2 Definitions of Terms Specific to This Standard:

D412 Test Methods for Vulcanized Rubber and Thermo-

3.2.1 chlorinated polyolefin, n—a polymer or polymer

plastic Elastomers—Tension

blend based on chlorinated polyolefin(s), chlorinated olefin

D1711 Terminology Relating to Electrical Insulation

copolymer(s) or chlorinated polybutadiene polymer(s).

D2671 Test Methods for Heat-Shrinkable Tubing for Elec-

4. Classification

trical Use

D3636 Practice for Sampling and Judging Quality of Solid

4.1 Type I—Normal operating temperature.

Electrical Insulating Materials

4.2 Type II—Extended operating temperature.

E176 Terminology of Fire Standards

3

5. Ordering Information

2.2 Military Standards:

MIL-H-5606 Hydraulic Fluid Petroleum Base, Aircraft,

5.1 When ordering to this specification the purchaser must

Missile and Ordnance state the type, class, and size of the tubing required.

MIL-T-5624 Turbine Fuel, Aviation, Grades JP4 and JP5

6. Materials and Manufacture

MIL-L-7808 Lubrication Oil, Aircraft, Turbine Engine,

Synthetic Base 6.1 The compound used in the manufacture of this heat-

shrinkable tubing shall be based on chlorinated polyolefin as

defined in Section 3, Terminology. The finished compound

shall be free of foreign matter other than antioxidants, flame

1

This specification is under the jurisdiction of ASTM Committee D09 on

retardants, processing aids, crosslinking agents, pigments or

Electrical and Electronic Insulating Materials and is the direct responsibility of

Subcommittee D09.07 on Flexible and Rigid Insulating Materials.

other additives as appropriate.

Current edition approved March 10, 2003. Published April 2003. Originally

6.2 The tubing shall be extruded, crosslinked and then

approved in 1970. Last previous edition approved in 1998 as D2903 – 93 (1998).

expanded to the required dimensions.

DOI: 10.1520/D2903-03.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

7. Chemical Property Requirements Chemical Property

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

Requirements

the ASTM website.

3 7.1 Thematerialshallconformtothechemicalrequirements

Available from Naval Publications and Forms Center, 5801 Tabor Ave.,

Philadelphia, PA 19120. specified in Tables 1 and 2.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D2903 – 03

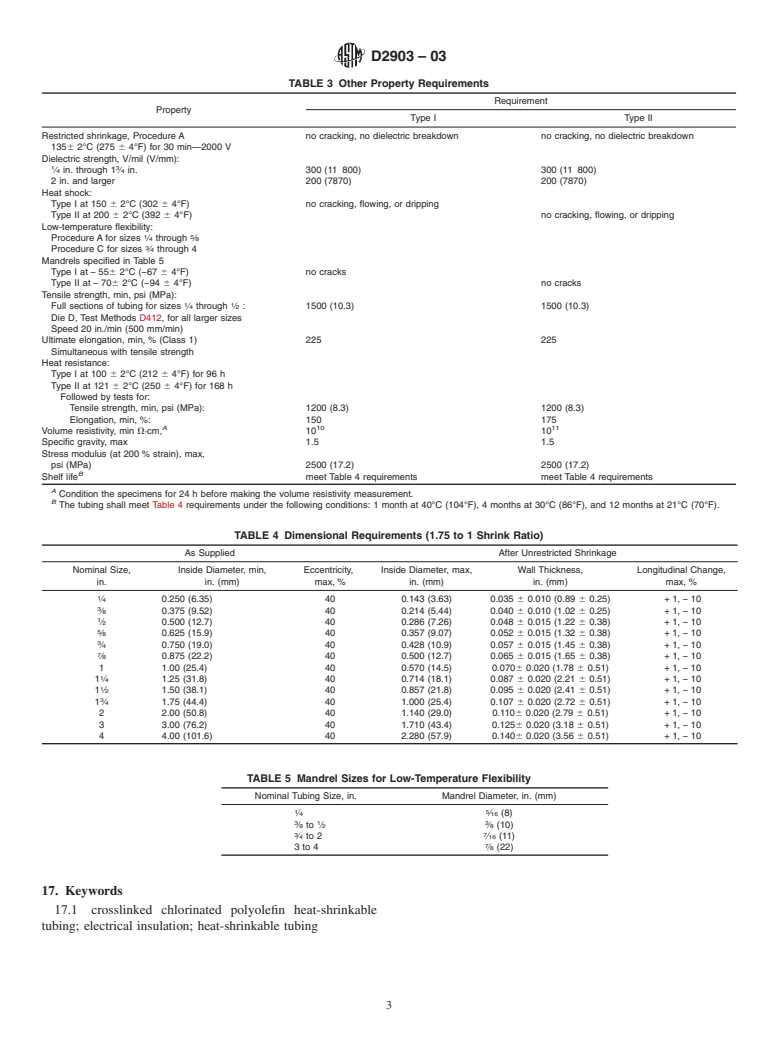

TABLE 1 Sampling Table for Lot Acceptance Tests

11. Sampling

Sampling Unit

11.1 A lot is defined as that material which is processed at

Require- Inspection

Property AQL of Sleeving, ft

ment Level

the same time and under essentially the same conditions in

(m)

accordance with this specification and submitted for inspection

Inside diameter as supplied Table 4 S-3 1.0 4 (1.2)

at one time.

Inside diameter after unre- Table 4 S-3 1.0 4 (1.2)

stricted shrinkage

11.2 Inspect a quantity of the end item selected at random

Wall thickness after shrinkage Table 4 S-3 1.0 4 (1.2)

from each lot in accordance with Practice D3636 and Table 1.

Longitudinal change Table 4 S-2 1.0 4 (1.2)

Straight length size, min 16.1 herein S-3 1.0 single straight

length 12. Tests and Retests

Workmanship 10.1 herein I 4.0 4 (1.2)

12.1 If

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

An American National Standard

Designation:D2903–93(Reapproved 1998) Designation: D 2903 – 03

Standard Specification for

Crosslinked Chlorinated Polyolefin Heat-Shrinkable Tubing

1

for Electrical Insulation

This standard is issued under the fixed designation D 2903; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This specification covers flexible crosslinked chlorinated polyolefin heat-shrinkable tubing used for electrical insulating

purposes. It is supplied in an expanded form and will shrink to the specified diameter when heated.

NOTE 1—This standard does not have a similar or equivalent IEC standard.

1.2 The values stated in inch-pound units are to be regarded as the standard accept for temperature, which is stated in degrees

Celsius. SI values in parentheses are for information only.

2. Referenced Documents

2.1 ASTM Standards:

2

D 412 Test Methods for Vulcanized Rubber and Thermoplastic Rubbers and Thermoplastic Elastomers—Tension

3

D 1711 Terminology Relating to Electrical Insulation

4

D 2671 Test Methods for Heat-Shrinkable Tubing for Electrical Use

4

D 3636Practice for Sampling and Judging Quality of Solid Electrical Insulating Materials Practice for Sampling and Judging

4

Quality of Solid Electrical Insulating Materials

5

E 176 Terminology of Fire Standards

6

2.2 Military Standards:

MIL-H-5606 Hydraulic Fluid Petroleum Base, Aircraft, Missile and Ordnance

MIL-T-5624 Turbine Fuel, Aviation, Grades JP4 and JP5

MIL-L-7808 Lubrication Oil, Aircraft, Turbine Engine, Synthetic Base

MIL-L-23699 Lubrication Oil, Aircraft, Turbine Engines, Synthetic Base

MIL-A-8243 Anti-Icing and De-Icing Defrosting Fluid

MIL-G-5572 Fuel, Aviation, Grades 100 and 130

2.3 Federal Standard: Federal Standards:

6

SS-S-550 Sodium Chloride, Technical, for Water Softening Units

3. Terminology

3.1 Definitions: For definitions of terms used in this standard, refer to Terminology D1711

3.1.1 For definitions pertaining to electrical insulation, refer to Terminology D 1711.

3.1.2 For definitions pertaining to fire issues, refer to Terminology E 176.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 chlorinated polyolefin, n—apolymerorpolymerblendbasedonchlorinatedpolyolefin(s),chlorinatedolefincopolymer(s)

or chlorinated polybutadiene polymer(s).

4. Classification

4.1 Type I—Normal operating temperature.

1

ThisspecificationisunderthejurisdictionofASTMCommitteeD-9D09onElectricalandElectronicInsulatingMaterialsandisthedirectresponsibilityofSubcommittee

D09.07 on Flexible and Rigid Insulating Materials.

Current edition approved Oct. 15, 1993.March 10, 2003. Published December 1993.April 2003. Originally published as D2903–70T.approved in 1970. Last previous

edition approved in 1998 as D 2903 – 893 (1998).

2

Annual Book of ASTM Standards, Vol 09.01.

3

Annual Book of ASTM Standards, Vol 10.01.

4

Annual Book of ASTM Standards, Vol 10.02.

5

Available from Naval Publications and Forms Center, 5801 Tabor Ave., Philadelphia, PA 19120.

5

Annual Book of ASTM Standards, Vol 04.07.

6

Available from Naval Publications and Forms Center, 5801 Tabor Ave., Philadelphia, PA 19120.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D2903–03

4.2 Type II—Extended operating temperature.

5. Ordering Information

5.1 When ordering to this specification the purchaser must state the type, class, and size of the tubing required.

6. Materials and Manufacture

6.1 The compound used in the manufacture of this heat-shrinkable tubing shall be based on chlorinated polyolefin as defined

in Section 3, Terminology. The finished compound shall be free of foreign matter other than antioxidants, flame retardants,

processing aids, crosslinking agents, pigments or other additives as appropriate.

6.2 The tubing shall be extruded, crosslinked and then expanded to the required dimensions.

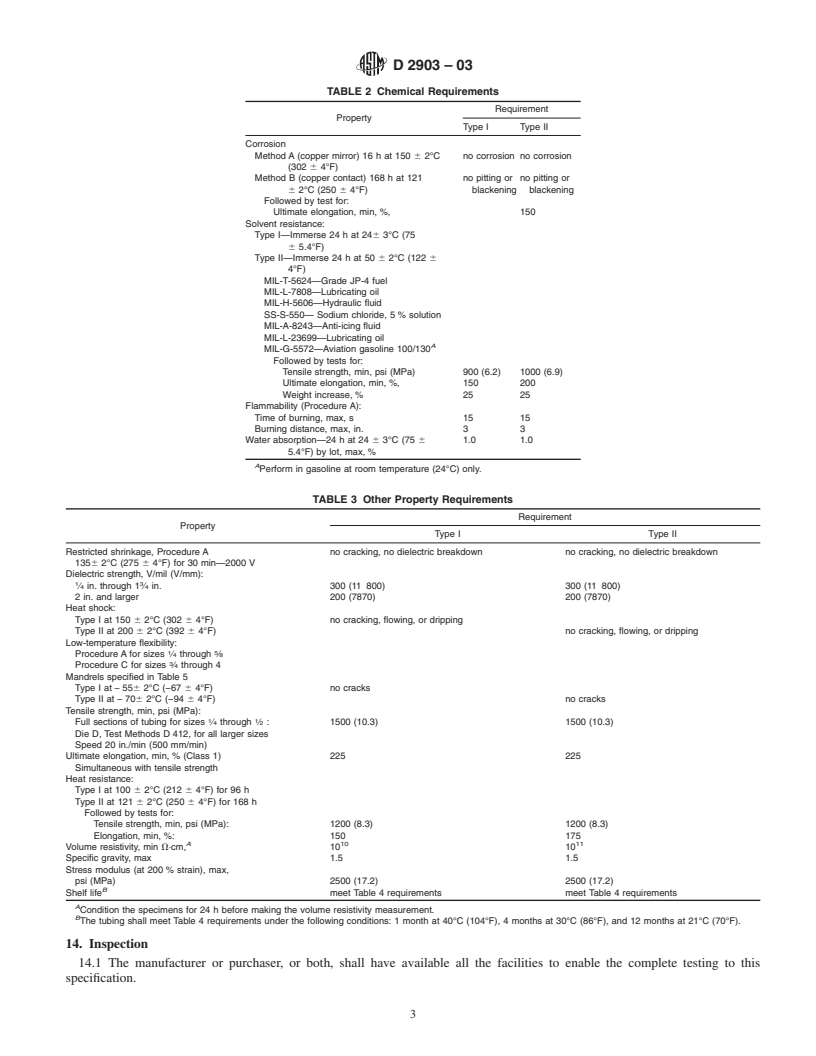

7. Chemical Property Requirements Chemical Property Requirements

7.1 The material shall conform to the chemical requirements specified in Tables 1 and 2.

7.2 Every lot of material manufactured requires testing for flammability, but the other chemical property requirements may be

tested less frequently or with a frequency agreed upon by the purchaser and seller.

8. Other Property Requirements

8.1 T

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.