ASTM D7199-06

(Practice)Standard Practice for Establishing Characteristic Values for Reinforced Glued Laminated Timber (Glulam) Beams Using Mechanics-Based Models

Standard Practice for Establishing Characteristic Values for Reinforced Glued Laminated Timber (Glulam) Beams Using Mechanics-Based Models

SCOPE

1.1 This practice covers mechanics-based requirements for calculating characteristic values for the strength and stiffness of reinforced structural glued laminated timbers (glulam) manufactured in accordance with applicable provisions of ANSI/AITC A190.1, subjected to quasi-static loadings. It addresses methods to obtain bending properties parallel to grain, about the x-x axis (Fbx and Ex) for horizontally-laminated reinforced glulam beams. Secondary properties such as bending about the y-y axis (Fby), shear parallel to grain (F vx and Fvy), tension parallel to grain (Ft), compression parallel to grain (Fc), and compression perpendicular to grain (Fc) are beyond the scope of this practice. Testing according to other applicable methods, such as Test Methods D 198, is required to establish these secondary properties. This practice also provides minimum test requirements to validate the mechanics-based model.

1.2 The practice also describes a minimum set of performance-based durability test requirements for reinforced glulams, as specified in Annex A1. Additional durability test requirements shall be considered in accordance with the specific end-use environment. Appendix X1 provides an example of a mechanics-based methodology that satisfies the requirements set forth in this standard.

1.3 Characteristic strength and elastic properties obtained using this standard may be used as a basis for developing design values. However, the proper safety, serviceability and adjustment factors including duration of load, to be used in design are outside the scope of this standard.

1.4 This practice does not cover unbonded reinforcement, prestressed reinforcement, nor shear reinforcement.

1.5 The values stated in SI units are to be regarded as standard. The mechanics based model may be developed using SI or in.-lb units.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 7199 – 06

Standard Practice for

Establishing Characteristic Values for Reinforced Glued

Laminated Timber (Glulam) Beams Using Mechanics-Based

Models

This standard is issued under the fixed designation D 7199; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 1.6 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

1.1 This practice covers mechanics-based requirements for

responsibility of the user of this standard to establish appro-

calculatingcharacteristicvaluesforthestrengthandstiffnessof

priate safety and health practices and determine the applica-

reinforced structural glued laminated timbers (glulam) manu-

bility of regulatory limitations prior to use.

factured in accordance with applicable provisions of ANSI/

AITC A190.1, subjected to quasi-static loadings. It addresses

2. Referenced Documents

methods to obtain bending properties parallel to grain, about

2.1 ASTM Standards:

the x-x axis (F and E ) for horizontally-laminated reinforced

bx x

D9 Terminology Relating to Wood and Wood-Based Prod-

glulam beams. Secondary properties such as bending about the

ucts

y-y axis (F ), shear parallel to grain (F and F ), tension

by vx vy

D 198 Test Methods of Static Tests of Lumber in Structural

parallel to grain (F), compression parallel to grain (F ), and

t c

Sizes

compressionperpendiculartograin(F')arebeyondthescope

c

D 905 Test Method for Strength Properties of Adhesive

of this practice. Testing according to other applicable methods,

Bonds in Shear by Compression Loading

such as Test Methods D 198, is required to establish these

D 1990 Practice for Establishing Allowable Properties for

secondaryproperties.Thispracticealsoprovidesminimumtest

Visually-Graded Dimension Lumber from In-Grade Tests

requirements to validate the mechanics-based model.

of Full-Size Specimens

1.2 The practice also describes a minimum set of

D 2559 Specification for Adhesives for Structural Lami-

performance-based durability test requirements for reinforced

nated Wood Products for Use Under Exterior (Wet Use)

glulams, as specified in Annex A1. Additional durability test

Exposure Conditions

requirements shall be considered in accordance with the

D 2915 Practice for Evaluating Allowable Properties for

specific end-use environment. Appendix X1 provides an ex-

Grades of Structural Lumber

ample of a mechanics-based methodology that satisfies the

D 3039/D 3039M Test Method for Tensile Properties of

requirements set forth in this standard.

Polymer Matrix Composite Materials

1.3 Characteristic strength and elastic properties obtained

D 3410/D 3410M Test Method for Compressive Properties

using this standard may be used as a basis for developing

of Polymer Matrix Composite Materials with Unsupported

design values. However, the proper safety, serviceability and

Gage Section by Shear Loading

adjustment factors including duration of load, to be used in

D 3737 Practice for Establishing Allowable Properties for

design are outside the scope of this standard.

Structural Glued Laminated Timber (Glulam)

1.4 This practice does not cover unbonded reinforcement,

D 4761 Test Methods for Mechanical Properties of Lumber

prestressed reinforcement, nor shear reinforcement.

and Wood-Base Structural Material

1.5 The values stated in SI units are to be regarded as

D 5124 Practice for Testing and Use of a Random Number

standard. The mechanics based model may be developed using

Generator in Lumber and Wood Products Simulation

SI or in.-lb units.

2.2 Other Standard:

1 2

This practice is under the jurisdiction of ASTM Committee D07 on Wood and For referenced ASTM standards, visit the ASTM website, www.astm.org, or

is the direct responsibility of Subcommittee D07.02 on Lumber and Engineered contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Wood Products. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved Nov. 1, 2006. Published December 2006. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D7199–06

ANSI/AITC A190.1 Structural Glued Laminated Timber 3.2.7 laminating effect—an apparent increase of lumber

lamination tensile strength because it is bonded to adjacent

3. Terminology

laminations within a glulam beam. This apparent increase may

be attributed to a redirection of stresses around knots and grain

3.1 Definitions—Standard definitions of wood terms are

deviations through adjacent laminations.

given inTerminologyD9 and standard definitions of structural

3.2.8 partial length reinforcement—reinforcement that is

glued laminated timber terms are given in Practice D 3737.

terminated within the length of the timber.

3.2 Definitions of Terms Specific to This Standard:

3.2.9 prestressed reinforcement—reinforcement that is pre-

3.2.1 bonded reinforcement—a reinforcing material that is

tensioned before being bonded or anchored to the beam. This

continuously attached to a glulam beam through adhesive

practice does not cover prestressed reinforcement.

bonding.

3.2.10 reinforcement—any material that is not a conven-

3.2.2 bumper lamination—a wood lamination continuously

tional lamstock whose mean longitudinal ultimate strength

bonded to the outer side of reinforcement.

exceeds 20 ksi for tension and compression, and whose mean

3.2.3 compression reinforcement—reinforcement placed on

tension and compression MOE exceeds 3000 ksi, when placed

the compression side of a flexural member.

into a glulam timber. Acceptable reinforcing materials include

3.2.4 conventional wood lamstock—solid sawn wood lami-

but are not restricted to: fiber-reinforced polymer (FRP) plates

nations with a net thickness of 2 in. or less, graded either

and bars, metallic plates and bars, FRP-reinforced laminated

visually or through mechanical means, finger-jointed and

veneer lumber (LVL), FRP-reinforced parallel strand lumber

face-bonded to form a glulam.

(PSL).

3.2.5 development length—the length of the bond line along

3.2.11 shear reinforcement—reinforcement intended to in-

the axis of the beam required to develop the design tensile

strength of the reinforcement. crease the shear strength of the beam. This standard does not

3.2.6 fiber-reinforcedpolymer(FRP)—anymaterialconsist- cover shear reinforcement.

ing of at least two distinct components: reinforcing fibers and 3.2.12 tension reinforcement—reinforcement placed on the

a binder matrix (a polymer). The reinforcing fibers are permit-

tension side of a flexural member.

ted to be either synthetic (for example, glass), metallic, or

3.2.13 unbonded reinforcement—a reinforcing material that

natural (for example, wood), and are permitted to be long and

is not continuously bonded to the beam. Examples include

continuously-oriented, or short and randomly oriented. The mechanically attached reinforcement and reinforcement that is

binder matrix is permitted to be either thermoplastic (for

attached only at the ends of the beams whether by adhesives or

example, polypropylene or nylon) or thermosetting (for ex- by mechanical fasteners, This practice does not cover un-

ample, epoxy or vinyl-ester).

bonded reinforcement.

3.3 Symbols:

Arm = moment arm, distance between compression and

tension force couple applied to beam cross-section

Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

b = beam width

4th Floor, New York, NY 10036.

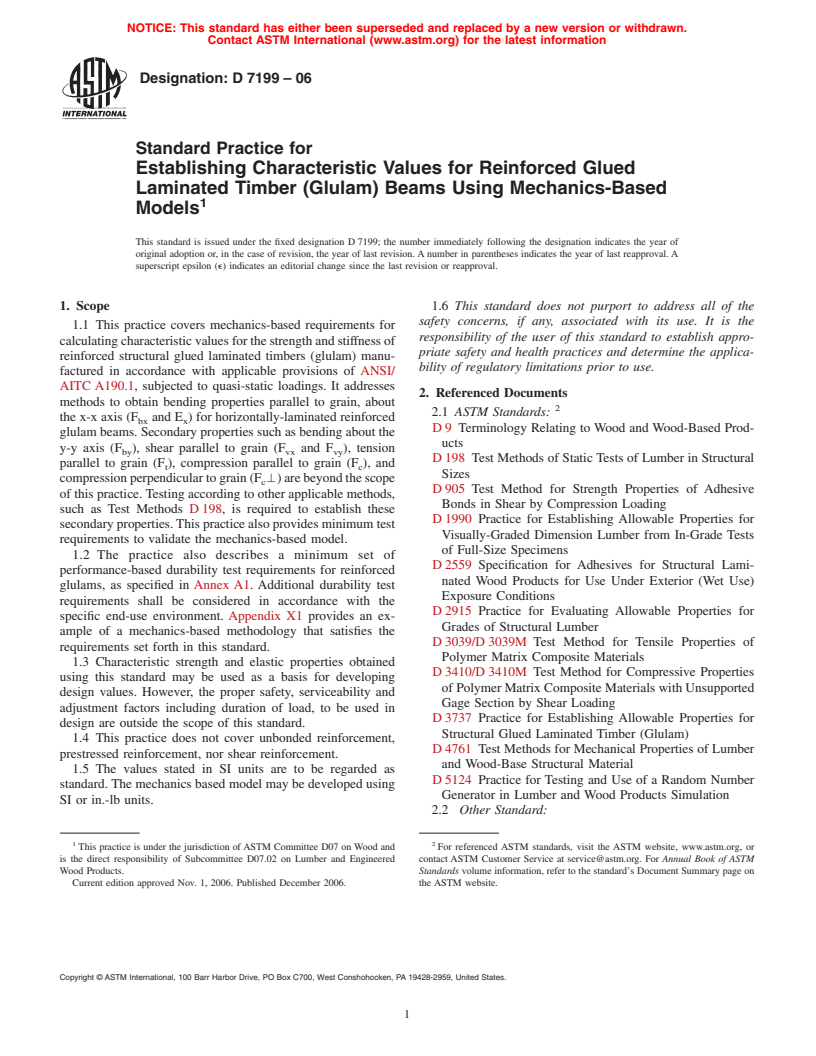

FIG. 1 Typical Stress-Strain Relationship for Wood Lamstock, with Bilinear Approximation

D7199–06

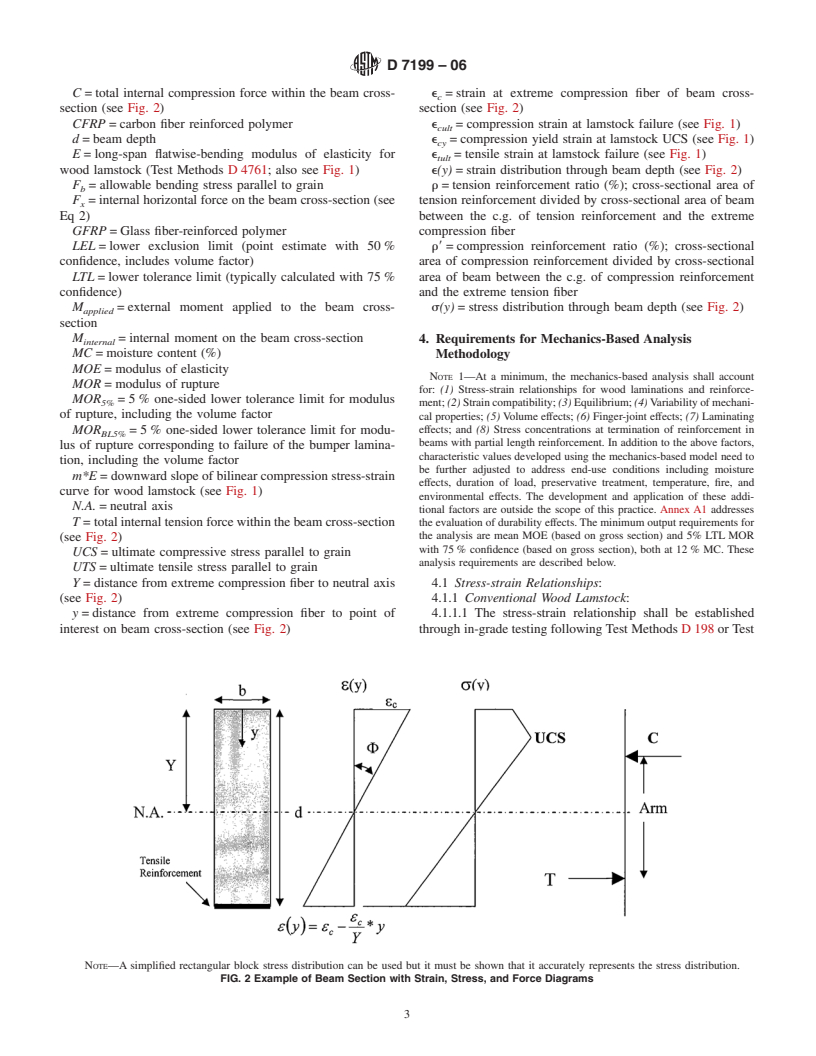

C = total internal compression force within the beam cross- e = strain at extreme compression fiber of beam cross-

c

section (see Fig. 2) section (see Fig. 2)

CFRP = carbon fiber reinforced polymer e = compression strain at lamstock failure (see Fig. 1)

cult

d = beam depth e = compression yield strain at lamstock UCS (see Fig. 1)

cy

E = long-span flatwise-bending modulus of elasticity for e = tensile strain at lamstock failure (see Fig. 1)

tult

wood lamstock (Test Methods D 4761; also see Fig. 1) e(y) = strain distribution through beam depth (see Fig. 2)

F = allowable bending stress parallel to grain r = tension reinforcement ratio (%); cross-sectional area of

b

F = internal horizontal force on the beam cross-section (see tension reinforcement divided by cross-sectional area of beam

x

Eq 2) between the c.g. of tension reinforcement and the extreme

GFRP = Glass fiber-reinforced polymer compression fiber

LEL = lower exclusion limit (point estimate with 50 % r8 = compression reinforcement ratio (%); cross-sectional

confidence, includes volume factor) area of compression reinforcement divided by cross-sectional

LTL = lower tolerance limit (typically calculated with 75 % area of beam between the c.g. of compression reinforcement

confidence) and the extreme tension fiber

M = external moment applied to the beam cross- s(y) = stress distribution through beam depth (see Fig. 2)

applied

section

M = internal moment on the beam cross-section 4. Requirements for Mechanics-BasedAnalysis

internal

MC = moisture content (%)

Methodology

MOE = modulus of elasticity

NOTE 1—At a minimum, the mechanics-based analysis shall account

MOR = modulus of rupture

for: (1) Stress-strain relationships for wood laminations and reinforce-

MOR = 5 % one-sided lower tolerance limit for modulus

5% ment;(2)Straincompatibility;(3)Equilibrium;(4)Variabilityofmechani-

of rupture, including the volume factor

cal properties; (5) Volume effects; (6) Finger-joint effects; (7) Laminating

effects; and (8) Stress concentrations at termination of reinforcement in

MOR = 5 % one-sided lower tolerance limit for modu-

BL5%

beams with partial length reinforcement. In addition to the above factors,

lus of rupture corresponding to failure of the bumper lamina-

characteristic values developed using the mechanics-based model need to

tion, including the volume factor

be further adjusted to address end-use conditions including moisture

m*E = downward slope of bilinear compression stress-strain

effects, duration of load, preservative treatment, temperature, fire, and

curve for wood lamstock (see Fig. 1)

environmental effects. The development and application of these addi-

N.A. = neutral axis

tional factors are outside the scope of this practice. Annex A1 addresses

T = total internal tension force within the beam cross-section the evaluation of durability effects. The minimum output requirements for

the analysis are mean MOE (based on gross section) and 5% LTL MOR

(see Fig. 2)

with 75 % confidence (based on gross section), both at 12 % MC. These

UCS = ultimate compressive stress parallel to grain

analysis requirements are described below.

UTS = ultimate tensile stress parallel to grain

Y = distance from extreme compression fiber to neutral axis 4.1 Stress-strain Relationships:

(see Fig. 2) 4.1.1 Conventional Wood Lamstock:

y = distance from extreme compression fiber to point of

4.1.1.1 The stress-strain relationship shall be established

interest on beam cross-section (see Fig. 2) through in-grade testing following Test Methods D 198 or Test

NOTE—A simplified rectangular block stress distribution can be used but it must be shown that it accurately represents the stress distribution.

FIG. 2 Example of Beam Section with Strain, Stress, and Force Diagrams

D7199–06

Methods D 4761, or other established relationships as long as flatwise-bending modulus of elasticity (E). One example of

the resulting model meets the criteria established in Section 5. how this may be achieved is provided in Appendix X1.

Test lamstock shall be sampled in sufficient quantity from

4.4.2 These correlation values are obtained from test data.

enough sources to insure that the test results are representative

Test lamstock shall be sampled in sufficient quantity, from

of the lamstock population that will be used in the fabrication

enough sources to insure that the test results are representative

of the beams. Follow-up testing shall be performed annually in

of the lamstock population that will be used in the fabrication

order to track changes in lamstock properties over time, so that

of the beams. Follow-up testing shall be performed annually in

the layup designs may be adjusted accordingly.

order to track changes in lamstock properties over time, so that

4.1.1.2 The stress-strain relationship shall be linear in ten-

the layup designs may be adjusted accordingly.

sion. The stress-strain relationship shall be nonlinear in com-

4.5 Volume Effects:

pression if compression is the governing failure mode. In this

4.5.1 The model shall properly account for changes in beam

case, a bilinear approximation is acceptable, and shall be used

strength properties as affected by beam size. In conventional

throughoutthisstandard(seeFig.1).Inthebilinearmodelboth

glulam, this is achieved by using a volume factor C , which

v

tension and compression MOE shall be permitted to be

wasderivedfromlaboratorytestdata.Withadequatereinforce-

approximated by using the long-span flatwise-bending MOE

ment, glulams can achieve a reduction or even elimination of

obtained using Test Methods D 4761.In Fig. 1, m*E is the

volume effects. The model shall properly account for this

downwardslopeofthecompressionstress-straincurve,defined

phenomenon. One possible approach to address the volume

as the best-fit downward line through the point (UCS, e )on

cy

effect is described in Appendix X1.

thecompressionstress-straincurve.Thedownwardbest-fitline

4.6 Finger-Joint Effects:

shall be permitted to be terminated at the point where the

4.6.1 Finger joints affect the mechanical properties of lam-

ultimate compressive strain e is approximately 1 %.

cu

stockusedinglulams.Themodelshallaccountfortheseeffects

4.1.2 Reinforcement:

on both the mean and variability of the beam mechanical

4.1.2.1 The stress-strain relationship shall be established

properties. One example of how this may be achieved is

through material-level testing in accordance with Test Method

provided in Appendix X1.

D 3039/D 3039M and D 3410/D 3410M.

4.7 Laminating Effects:

4.1.2.2 Nonlinearities in the stress-strain relationship shall

be included in the analysis, if present.

4.7.1 The laminating effects may be predicted by the model

4.1.2.3 Acceptable stress-strain models for unidirectional or else developed outside the model (and applied in the model)

E-glass FRP (GFRP), Aramid, or Carbon FRP (CFRP) in using an em

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.