ASTM D7857-16

(Test Method)Standard Test Method for Evaluating the Flexural Properties and Internal Bond Strength of Fire-Retarded Mat-Formed Wood Structural Composite Panels Exposed to Elevated Temperatures

Standard Test Method for Evaluating the Flexural Properties and Internal Bond Strength of Fire-Retarded Mat-Formed Wood Structural Composite Panels Exposed to Elevated Temperatures

SIGNIFICANCE AND USE

5.1 The properties evaluated by this test method are intended to provide comparative information on the effects of fire-retardant chemical formulations and environmental conditions on the flexural properties and IB strength of FRSC panels.

5.2 This practice uses a controlled elevated-temperature environment to produce temperature-induced losses in the mechanical properties of FRSC panels and untreated panels.

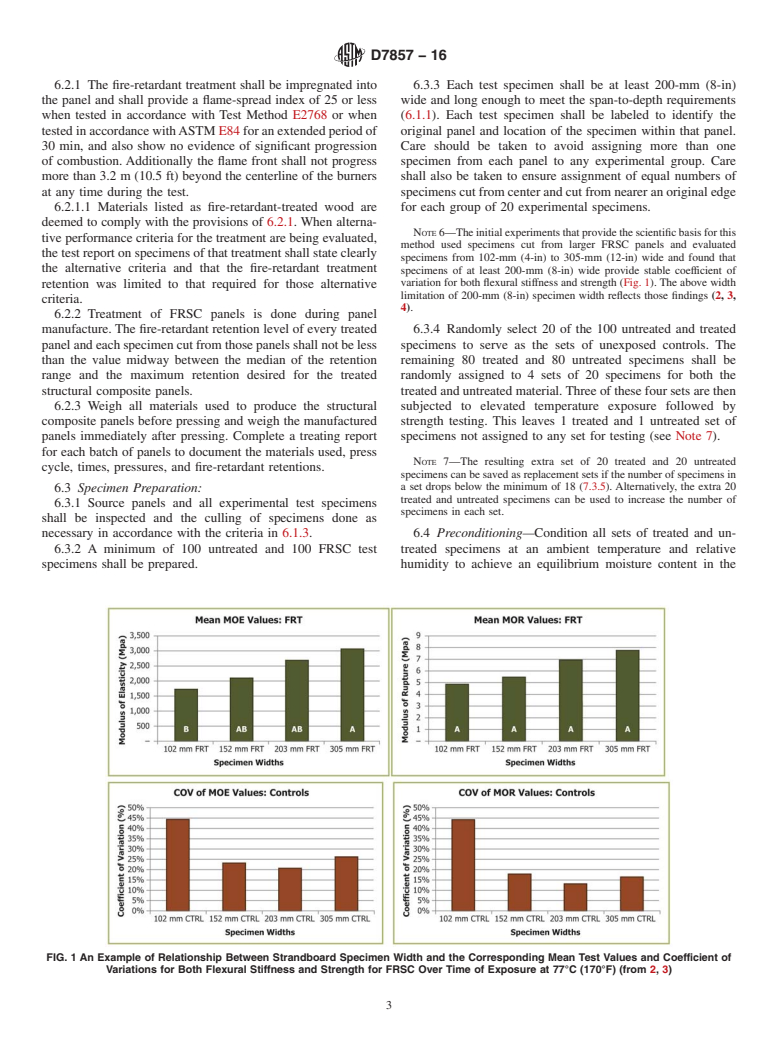

5.3 Prediction of performance in natural environments has not been directly correlated with the results of this test method.

5.4 The reproducibility of results in elevated-temperature exposure is highly dependent on the type of specimens tested and the evaluation criteria selected, as well as the control of the operating variables. In any testing program, sufficient replicates shall be included to establish the variability of the results. Variability is often observed when similar specimens are tested in different chambers even though the testing conditions are nominally similar and within the ranges specified in this test method.

SCOPE

1.1 This test method is designed as a laboratory screening test. It is intended to establish an understanding of the respective contributions of the many wood material, fire-retardant, resin and processing variables, and their interactions, upon the mechanical properties of fire-retarded mat-formed wood structural composite (FRSC) panels as they affect flexural and internal bond (IB) performance and as they are often affected later during exposure to high temperature and humidity. Once the critical material and processing variables have been identified through these small-specimen laboratory screening tests, additional testing and evaluation shall be required to determine the effect of the treatment on the panel structural properties and the effect of exposure to high temperature on the properties of commercially produced FRSC panels. In this test method, treated structural composite panels are exposed to a temperature of 77°C (170°F) and at least 50% relative humidity.

1.2 The purpose of the preliminary laboratory-based test method is to compare the flexural properties and IB strength of FRSC panels relative to untreated structural composite panels with otherwise identical manufacturing parameters. The results of tests conducted in accordance with this test method provide a reference point for estimating strength temperature relationships for preliminary purposes. They establish a starting point for subsequent full-scale testing of commercially produced FRSC panels.

1.3 This test method does not cover testing and evaluation requirements necessary for product certification and qualification or the establishment of design value adjustment factors for FRSC panels.

Note 1: One potentially confounding limitation of this preliminary screening test method is that it may be conducted with laboratory panels that may not necessarily represent commercial quality panels. A final qualification program should likely be conducted using commercial quality panels and the scope of the review should include evaluation of the effects of the treatment and elevated temperature exposure on all relevant mechanical properties of the commercially produced panel.

1.4 This test method is not intended for use with structural plywood.

1.5 The values stated in SI units are to be regarded as standard. The values given in parentheses are mathematical conversions to inch-pound units that are provided for information only and are not considered standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D7857 − 16

Standard Test Method for

Evaluating the Flexural Properties and Internal Bond

Strength of Fire-Retarded Mat-Formed Wood Structural

1

Composite Panels Exposed to Elevated Temperatures

This standard is issued under the fixed designation D7857; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

qualitypanelsandthescopeofthereviewshouldincludeevaluationofthe

1. Scope

effects of the treatment and elevated temperature exposure on all relevant

1.1 This test method is designed as a laboratory screening

mechanical properties of the commercially produced panel.

test. It is intended to establish an understanding of the

1.4 This test method is not intended for use with structural

respective contributions of the many wood material, fire-

plywood.

retardant, resin and processing variables, and their interactions,

1.5 The values stated in SI units are to be regarded as

upon the mechanical properties of fire-retarded mat-formed

standard. The values given in parentheses are mathematical

wood structural composite (FRSC) panels as they affect

conversions to inch-pound units that are provided for informa-

flexural and internal bond (IB) performance and as they are

tion only and are not considered standard.

often affected later during exposure to high temperature and

humidity. Once the critical material and processing variables

1.6 This standard does not purport to address all of the

have been identified through these small-specimen laboratory

safety concerns, if any, associated with its use. It is the

screening tests, additional testing and evaluation shall be

responsibility of the user of this standard to establish appro-

required to determine the effect of the treatment on the panel

priate safety and health practices and determine the applica-

structural properties and the effect of exposure to high tem-

bility of regulatory limitations prior to use.

perature on the properties of commercially produced FRSC

2. Referenced Documents

panels. In this test method, treated structural composite panels

2

are exposed to a temperature of 77°C (170°F) and at least 50%

2.1 ASTM Standards:

relative humidity.

D9 Terminology Relating to Wood and Wood-Based Prod-

ucts

1.2 The purpose of the preliminary laboratory-based test

D198 Test Methods of Static Tests of Lumber in Structural

method is to compare the flexural properties and IB strength of

Sizes

FRSC panels relative to untreated structural composite panels

D1037 Test Methods for Evaluating Properties of Wood-

with otherwise identical manufacturing parameters.The results

Base Fiber and Particle Panel Materials

of tests conducted in accordance with this test method provide

D1165 Nomenclature of Commercial Hardwoods and Soft-

a reference point for estimating strength temperature relation-

woods

ships for preliminary purposes. They establish a starting point

D2395 TestMethodsforDensityandSpecificGravity(Rela-

for subsequent full-scale testing of commercially produced

tive Density) of Wood and Wood-Based Materials

FRSC panels.

D2915 Practice for Sampling and Data-Analysis for Struc-

1.3 This test method does not cover testing and evaluation

tural Wood and Wood-Based Products

requirements necessary for product certification and qualifica-

D3043 Test Methods for Structural Panels in Flexure

tion or the establishment of design value adjustment factors for

D5516 TestMethodforEvaluatingtheFlexuralPropertiesof

FRSC panels.

Fire-Retardant Treated Softwood Plywood Exposed to

NOTE 1—One potentially confounding limitation of this preliminary

Elevated Temperatures

screening test method is that it may be conducted with laboratory panels

D6305 Practice for Calculating Bending Strength Design

that may not necessarily represent commercial quality panels. A final

qualification program should likely be conducted using commercial

Adjustment Factors for Fire-Retardant-Treated Plywood

Roof Sheathing

1

This test method is under the jurisdiction of ASTM Committee D07 on Wood

2

and is the direct responsibility of Subcommittee D07.07 on Fire Performance of For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Wood. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Current edition approved March 1, 2016. Published April 2016. DOI: 10.1520/ Standards volume information, refer to the standard’s Document Summary page on

D7857-16. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.