ASTM D4030/D4030M-15

(Specification)Standard Specification for Glass Fiber Cord and Sewing Thread

Standard Specification for Glass Fiber Cord and Sewing Thread

ABSTRACT

This specification covers the requirements for continuous glass filament sewing thread and untreated and neoprene treated, continuous filament cord; intended to assist ultimate users by designing the types of these products that are typical in the industry. The fiber shall be electrical grade, free of any free alkali metal oxides, such as soda or potash, and foreign particle, dirt, and other impurities. The glass fiber cord or sewing thread shall be wound on tubes, spools, or cones and shall conform to the following requirements: filament diameter; yarn number; strand construction; twist direction; twist level; breaking strength; yarn diameter; twist balance; and ignition loss. The cord and the sewing thread shall also undergo visual examination to check for defects such as cut, spot or stain, and embedded foreign matter.

SCOPE

1.1 This specification covers the requirements for continuous glass filament sewing thread; and continuous filament cord, untreated and neoprene treated.

1.2 This specification is intended to assist ultimate users by designating the types of these products that are typical in the industry.

1.3 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in nonconformance with the standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D4030/D4030M − 15

Standard Specification for

1

Glass Fiber Cord and Sewing Thread

This standard is issued under the fixed designation D4030/D4030M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Terminology

1.1 This specification covers the requirements for continu- 3.1 For all terminology under the jurisdiction of Subcom-

ous glass filament sewing thread; and continuous filament cord, mittee D13.18 (cord, neoprene treated, sewing thread, twist

untreated and neoprene treated. balance, untreated), refer to Terminology D7018.

1.2 This specification is intended to assist ultimate users by 3.2 For definitions of other textile terms used in this

designating the types of these products that are typical in the specification, refer to Terminology D123.

industry.

4. Designation of Construction

1.3 The values stated in either SI units or inch-pound units

are to be regarded separately as standard. The values stated in 4.1 The yarn designations of fiber glass cords and sewing

threads are specified as directed in Specification D578 except

each system may not be exact equivalents; therefore, each

system shall be used independently of the other. Combining that for the cords either the letter “U” or the letter “N” is added

to the last segment of the designation.

values from the two systems may result in nonconformance

with the standard. 4.1.1 Cord designations may include a type number that

describes the relative diameter of the cords and treatment. The

1.4 This standard does not purport to address all of the

first character of this designation is a numeral from 1 to 10 that

safety concerns, if any, associated with its use. It is the

indicates the relative diameter of the cord to other cords, that is,

responsibility of the user of this standard to establish appro-

2 is larger than 1, 3 is larger than 2, etc. The second character

priate safety and health practices and determine the applica-

of this designation is the letter “U” or the letter “N”. The “U”

bility of regulatory limitations prior to use.

indicates that the cord is untreated, and the “N” indicates that

2. Referenced Documents the cord is neoprene treated. The type number for cord is

2

included in Tables 1 and 2 to show its relationship to

2.1 ASTM Standards:

designation.

D123 Terminology Relating to Textiles

4.1.2 Sewing thread construction includes a type number

D204 Test Methods for Sewing Threads

that describes a manufacturer’s code and the size. The second

D578 Specification for Glass Fiber Strands

character is a numeral and indicates the relative diameter of the

D1423 Test Method for Twist in Yarns by Direct-Counting

sewing threads, that is, 4 is larger than 2, 6 is larger than 4, etc.

D1776 Practice for Conditioning and Testing Textiles

This type number for sewing thread is included in Table 3 to

D4963 Test Method for Ignition Loss of Glass Strands and

show its relationship to designation.

Fabrics

D7018 Terminology Relating to Glass Fiber and Its Products

REQUIREMENTS

2.2 ANSI Standard:

ANSI/ASQC Z1.4 Sampling Procedures for Inspection by

5. Material

3

Attributes

5.1 The fiber shall be electrical grade, free of any free alkali

metal oxides, such as soda or potash, and foreign particles, dirt,

1

This specification is under the jurisdiction of ASTM Committee D13 on

and other impurities.

Textiles and is the direct responsibility of Subcommittee D13.18 on Glass Fiber and

its Products.

6. Designation

Current edition approved Feb. 1, 2015. Published April 2015. Originally

ε1

approved in 1981. Last previous edition approved in 2009 as D4030 – 09 . DOI:

6.1 The nominal designation of glass fibercords listed in

10.1520/D4030_D4030M-15.

2

Table 1 or Table 2 shall conform to the requirements of Table

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

1 or Table 2. The nominal designation of glass fiber sewing

Standards volume information, refer to the standard’s Document Summary page on

threads listed in Table 3 shall conform to the requirements of

the ASTM website.

3 Table 3. The nominal designations of other lass fibercords or

Available from American National Standards Institute (ANSI), 25 W. 43rd St.,

4th Floor, New York, NY 10036, http://www.ansi.org. sewing threads shall be agreed upon between the purchaser and

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

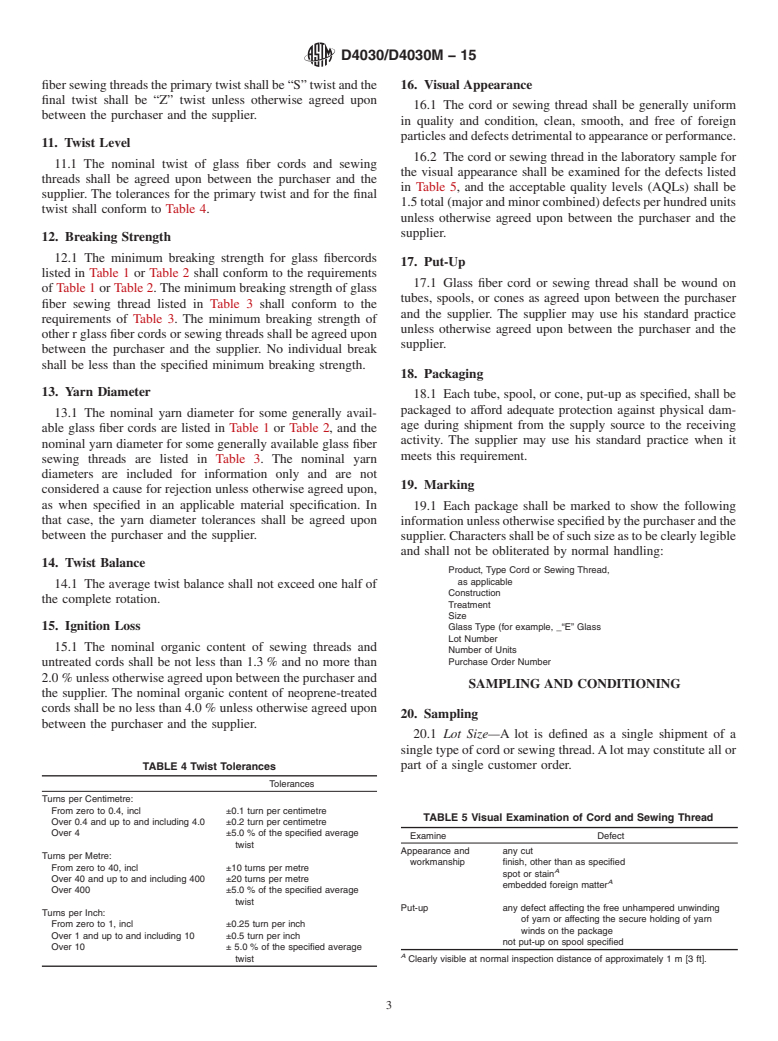

D4030/D4030M − 15

TABLE 1 Physical Properties of

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation: D4030/D4030M − 09 D4030/D4030M − 15

Standard Specification for

1

Glass Fiber Cord and Sewing Thread

This standard is issued under the fixed designation D4030/D4030M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1

ε NOTE—The inch-pound units were put in brackets editorially in September 2010.

1. Scope

1.1 This specification covers the requirements for continuous glass filament sewing thread; and continuous filament cord,

untreated and neoprene treated.

1.2 This specification is intended to assist ultimate users by designating the types of these products that are typical in the

industry.

1.3 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each

system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the

two systems may result in nonconformance with the standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D123 Terminology Relating to Textiles

D204 Test Methods for Sewing Threads

D578 Specification for Glass Fiber Strands

D1423 Test Method for Twist in Yarns by Direct-Counting

D1776 Practice for Conditioning and Testing Textiles

D4963 Test Method for Ignition Loss of Glass Strands and Fabrics

D7018 Terminology Relating to Glass Fiber and Its Products

2.2 ANSI Standard:

3

ANSI/ASQC Z1.4 Sampling Procedures for Inspection by Attributes

3. Terminology

3.1 For all terminology under the jurisdiction of Subcommittee D13.18 (cord, neoprene treated, sewing thread, twist balance,

untreated), refer to Terminology D7018.

3.2 For definitions of other textile terms used in this specification, refer to Terminology D123.

4. Designation of Construction

4.1 The yarn designations of fiber glass cords and sewing threads are specified as directed in Specification D578 except that for

the cords either the letter “U” or the letter “N” is added to the last segment of the designation.

4.1.1 Cord designations may include a type number that describes the relative diameter of the cords and treatment. The first

character of this designation is a numeral from 1 to 10 that indicates the relative diameter of the cord to other cords, that is, 2 is

larger than 1, 3 is larger than 2, etc. The second character of this designation is the letter “U” or the letter “N”. The “U” indicates

1

This specification is under the jurisdiction of ASTM Committee D13 on Textiles and is the direct responsibility of Subcommittee D13.18 on Glass Fiber and its Products.

Current edition approved July 1, 2009Feb. 1, 2015. Published August 2009April 2015. Originally approved in 1981. Last previous edition approved in 20042009 as

ε1

D4030 – 04.D4030 – 09 . DOI: 10.1520/D4030_D4030M-09E01.10.1520/D4030_D4030M-15.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from American National Standards Institute (ANSI), 25 W. 43rd St., 4th Floor, New York, NY 10036, http://www.ansi.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

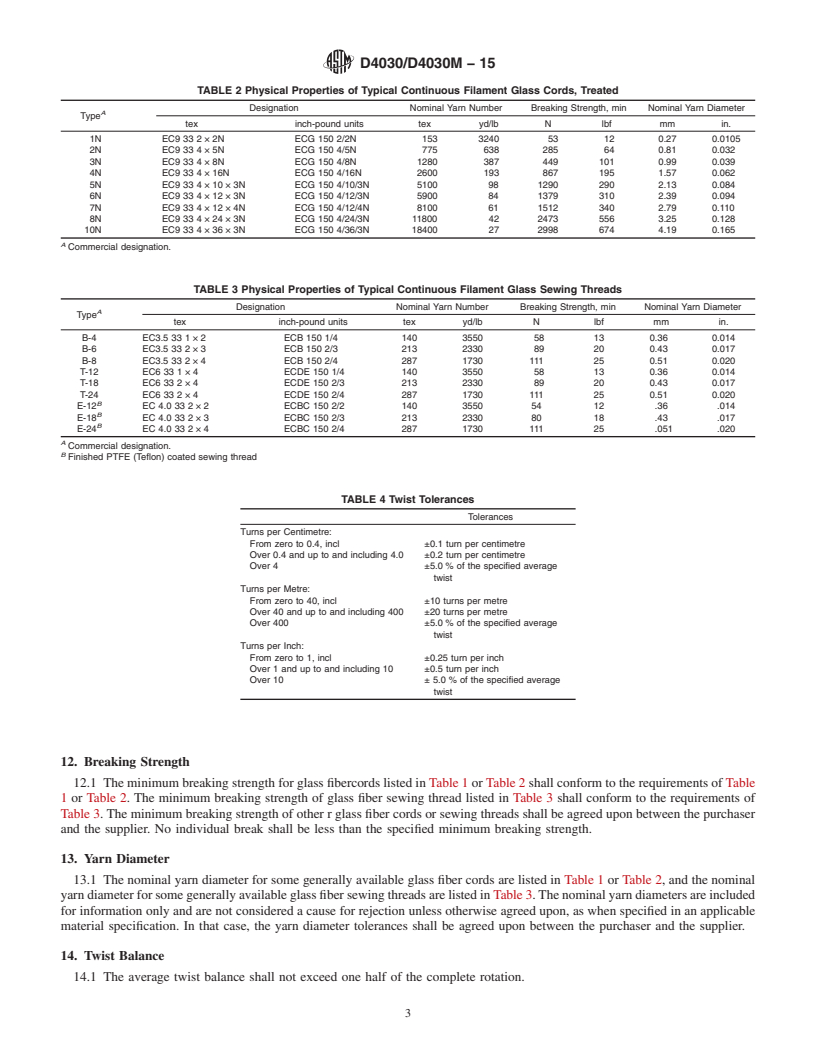

D4030/D4030M − 15

that the cord is untreated, and the “N” indicates that the cord is neoprene treated. The type number for cord is included in Tables

1 and 2 to show its relationship to designation.

4.1.2 Sewing thread construction includes a type number that describes a manufacturer’s code and the size. The second

character is a numeral and indicates the relative diameter of the sewing threads, that is, 4 is larger than 2, 6 is larger than 4, etc.

This type number for sewing thread is included in Table 3 to show its relationship to designation.

REQUIREMENTS

5. Material

5.1 The fiber shall be electrical grade, free of any free alkali metal oxides, such as soda or potash, and foreign particles, dirt,

and other i

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.