ASTM D2343-17(2023)

(Test Method)Standard Test Method for Tensile Properties of Glass Fiber Strands, Yarns, and Rovings Used in Reinforced Plastics

Standard Test Method for Tensile Properties of Glass Fiber Strands, Yarns, and Rovings Used in Reinforced Plastics

SIGNIFICANCE AND USE

5.1 Tensile properties determined by this test method are of value for identifying and characterizing materials for control and specification purposes as well as for providing data for research and development studies.

5.2 This test method is intended for use in testing resin-compatible sized glass fiber materials that have been designed specifically for use with certain generic types of plastics. The use of a resin system that is compatible with the reinforcement material under test produces results that are most representative of the actual strength that is available in the material when used as intended in an end item. Premature reinforcement failures occur if the elongation of the resin system is less than that of the reinforcement being tested. It is critical to select a resin system that does not lead to premature reinforcement failure. Use of compatible resin system and complete resin impregnation is recommended to avoid invalid failures and misleading results.

5.3 This test method is useful for testing pretreated specimens for which comparative results are desired. Gage length, gripping system, testing speed, and the resin impregnation ratio of the specimen affects the values obtained by this test method.

SCOPE

1.1 This test method covers the determination of the comparative tensile properties of glass fiber strands, yarns, and rovings in the form of impregnated rod test specimens when tested under defined conditions of pretreatment, temperature, humidity, and tension testing machine speed. This test method is applicable to continuous filament, glass fiber materials that have been coated with a resin compatible sizing. This method is intended for use in quality control and R & D, and is not intended to be used to develop composites design data.

Note 1: This method is technically equivalent to the short method described in ISO 9163.

Note 2: Prime consideration should be given to the use of a polymeric binder that produces specimens that yield the highest consistent values for the glass fiber material under test. Tensile properties vary with specimen preparation, resin impregnation system, and speed and environment of testing. Consider these factors where precise comparative results are desired.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D2343 − 17 (Reapproved 2023)

Standard Test Method for

Tensile Properties of Glass Fiber Strands, Yarns, and

Rovings Used in Reinforced Plastics

This standard is issued under the fixed designation D2343; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope 2. Referenced Documents

2.1 ASTM Standards:

1.1 This test method covers the determination of the com-

D618 Practice for Conditioning Plastics for Testing

parative tensile properties of glass fiber strands, yarns, and

D883 Terminology Relating to Plastics

rovings in the form of impregnated rod test specimens when

E4 Practices for Force Calibration and Verification of Test-

tested under defined conditions of pretreatment, temperature,

ing Machines

humidity, and tension testing machine speed. This test method

E6 Terminology Relating to Methods of Mechanical Testing

is applicable to continuous filament, glass fiber materials that

2.2 ISO Standard:

have been coated with a resin compatible sizing. This method

ISO 9163 Textile Glass—Rovings—Manufacture of Test

is intended for use in quality control and R & D, and is not

Specimens and Determination of Tensile Strength of

intended to be used to develop composites design data.

Impregnated Rovings

NOTE 1—This method is technically equivalent to the short method

described in ISO 9163. 3. Terminology

NOTE 2—Prime consideration should be given to the use of a polymeric

3.1 Definitions:

binder that produces specimens that yield the highest consistent values for

3.1.1 Definitions of terms and symbols relating to this test

the glass fiber material under test. Tensile properties vary with specimen

method appear in Terminologies E6 and D883.

preparation, resin impregnation system, and speed and environment of

testing. Consider these factors where precise comparative results are

4. Summary of Test Method

desired.

4.1 This test method consists of impregnating glass fiber

1.2 The values stated in SI units are to be regarded as the

strands, yarns, or rovings with a suitable polymeric binder

standard. The values given in parentheses are for information

material and loading the resulting test specimens to failure in a

only.

tension testing machine having a constant-rate-of crosshead

1.3 This standard does not purport to address all of the

movement. The cross sectional area is determined from skeins

safety concerns, if any, associated with its use. It is the

of glass fiber taken before and after each set of test specimens.

responsibility of the user of this standard to establish appro-

After impregnation and curing, the specimens shall either be

priate safety, health, and environmental practices and deter-

tabbed using glass fiber mat or cardboard and tested with

mine the applicability of regulatory limitations prior to use.

standard grips; or the ends shall be sanded with 240 grit

sandpaper or fine emery cloth and tested using rubber faced

1.4 This international standard was developed in accor-

grips.

dance with internationally recognized principles on standard-

ization established in the Decision on Principles for the

5. Significance and Use

Development of International Standards, Guides and Recom-

mendations issued by the World Trade Organization Technical 5.1 Tensile properties determined by this test method are of

Barriers to Trade (TBT) Committee. value for identifying and characterizing materials for control

and specification purposes as well as for providing data for

research and development studies.

This test method is under the jurisdiction of ASTM Committee D20 on Plastics

and is the direct responsibility of Subcommittee D20.18 on Reinforced Thermoset-

ting Plastics. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Aug. 1, 2023. Published August 2023. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1965. Last previous edition approved in 2017 as D2343–17. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/D2343-17R23. the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D2343 − 17 (2023)

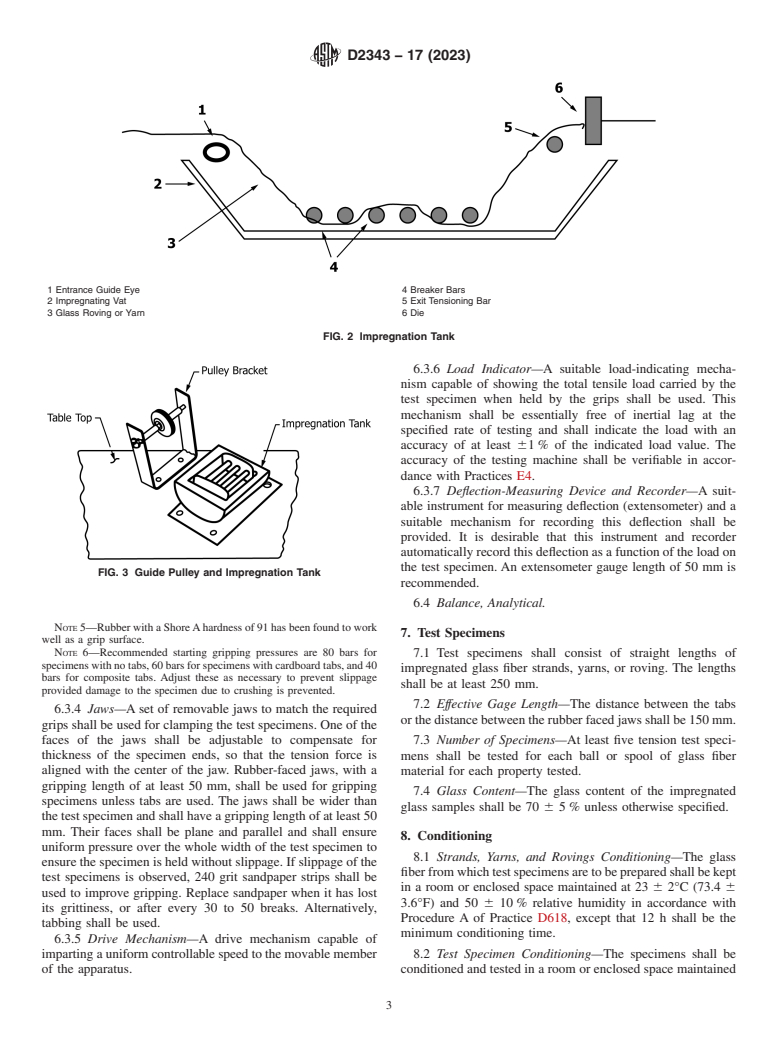

5.2 This test method is intended for use in testing resin- 6.1.3 Impregnation Tank, as illustrated in Fig. 2, consisting

compatible sized glass fiber materials that have been designed of a container and a static spreader bar assembly. The tank must

specifically for use with certain generic types of plastics. The have the capability of maintaining the required resin tempera-

use of a resin system that is compatible with the reinforcement ture within 65°C.

material under test produces results that are most representative

NOTE 3—Heating and temperature maintenance may be accomplished

of the actual strength that is available in the material when used

by use of a double walled vat, with heating fluid circulating between the

as intended in an end item. Premature reinforcement failures

walls, or by use of an external heating plate.

occur if the elongation of the resin system is less than that of

6.1.4 Die, as illustrated in Fig. 3, made of stainless steel,

the reinforcement being tested. It is critical to select a resin

which gives a defined circular cross-section to the impregnated

system that does not lead to premature reinforcement failure.

roving.

Use of compatible resin system and complete resin impregna-

6.1.5 Winding Device and Frame, for collecting the impreg-

tion is recommended to avoid invalid failures and misleading

nated roving, which ensures that the fibers are kept under

results.

constant tension and places the strands onto the fixture in a

5.3 This test method is useful for testing pretreated speci-

manner, which allows separate specimens to be fabricated.

mens for which comparative results are desired. Gage length,

6.2 Template for Tabbing (Optional)—A template, as shown

gripping system, testing speed, and the resin impregnation ratio

in Fig. 4, shall be used to provide proper positioning of end

of the specimen affects the values obtained by this test method.

tabs.

6. Apparatus

6.3 Tension Testing Machine—A testing machine having a

6.1 Impregnation Apparatus—An example of an acceptable

constant-rate-of-crosshead movement and comprising essen-

impregnation apparatus for strands is shown in Fig. 1. Minor

tially the following shall be available:

modifications to the apparatus are acceptable providing con-

6.3.1 Stationary Member, with one grip.

sistent samples are produced. The apparatus shall consist

6.3.2 Movable Member, with a second grip.

essentially of the following:

6.3.3 Grips—Grips for holding the test specimen between

6.1.1 Free Wheeling Spindle (Optional)—A freely turning

the fixed and the movable member shall be of the self-aligning

spindle with a horizontal axis for holding the yarn spool or

type (that is, they shall be attached to the fixed and movable

roving ball. A spindle allows fiber to be pulled from a yarn

members in such a manner that they will move freely into

bobbin or the outside of a roving package. Alternately, inside

alignment as soon as any load is applied). The long axis of the

payout or drawing of the fiber from the interior of a roving

test specimens will then coincide with the direction of the

package or forming cake without the use of spindle is possible.

applied pull through the center line of the grip assembly.

6.1.2 Tension Regulating System capable of maintaining the

roving or yarn under tension between 0.2 newton and 20

NOTE 4—Air-actuated grips have been found advantageous and are

newton. recommended for use in this test method.

1 Die 5 Moving Support

2 Tensioning Bars 6 Impregnation Vat (temperature regulated)

3 Resin Level 7 Glass Input

4 Tensioning Device

FIG. 1 Typical Impregnation Equipment Configuration

D2343 − 17 (2023)

1 Entrance Guide Eye 4 Breaker Bars

2 Impregnating Vat 5 Exit Tensioning Bar

3 Glass Roving or Yarn 6 Die

FIG. 2 Impregnation Tank

6.3.6 Load Indicator—A suitable load-indicating mecha-

nism capable of showing the total tensile load carried by the

test specimen when held by the grips shall be used. This

mechanism shall be essentially free of inertial lag at the

specified rate of testing and shall indicate the load with an

accuracy of at least 61 % of the indicated load value. The

accuracy of the testing machine shall be verifiable in accor-

dance with Practices E4.

6.3.7 Deflection-Measuring Device and Recorder—A suit-

able instrument for measuring deflection (extensometer) and a

suitable mechanism for recording this deflection shall be

provided. It is desirable that this instrument and recorder

automatically record this deflection as a function of the load on

the test specimen. An extensometer gauge length of 50 mm is

FIG. 3 Guide Pulley and Impregnation Tank

recommended.

6.4 Balance, Analytical.

NOTE 5—Rubber with a Shore A hardness of 91 has been found to work

7. Test Specimens

well as a grip surface.

NOTE 6—Recommended starting gripping pressures are 80 bars for

7.1 Test specimens shall consist of straight lengths of

specimens with no tabs, 60 bars for specimens with cardboard tabs, and 40

impregnated glass fiber strands, yarns, or roving. The lengths

bars for composite tabs. Adjust these as necessary to prevent slippage

shall be at least 250 mm.

provided damage to the specimen due to crushing is prevented.

7.2 Effective Gage Length—The distance between the tabs

6.3.4 Jaws—A set of removable jaws to match the required

or the distance between the rubber faced jaws shall be 150 mm.

grips shall be used for clamping the test specimens. One of the

faces of the jaws shall be adjustable to compensate for 7.3 Number of Specimens—At least five tension test speci-

thickness of the specimen ends, so that the tension force is

mens shall be tested for each ball or spool of glass fiber

aligned with the center of the jaw. Rubber-faced jaws, with a material for each property tested.

gripping length of at least 50 mm, shall be used for gripping

7.4 Glass Content—The glass content of the impregnated

specimens unless tabs are used. The jaws shall be wider than

glass samples shall be 70 6 5 % unless otherwise specified.

the test specimen and shall have a gripping length of at least 50

mm. Their faces shall be plane and parallel and shall ensure

8. Conditioning

uniform pressure over the whole width of the test specimen to

8.1 Strands, Yarns, and Rovings Conditioning—The glass

ensure the specimen is held without slippage. If slippage of the

fiber from which test specimens are to be prepared shall be kept

test specimens is observed, 240 grit sandpaper strips shall be

in a room or enclosed space maintained at 23 6 2°C (73.4 6

used to improve gripping. Replace sandpaper when it has lost

3.6°F) and 50 6 10 % relative humidity in accordance with

its grittiness, or after every 30 to 50 breaks. Alternatively,

Procedure A of Practice D618, except that 12 h shall be the

tabbing shall be used.

minimum conditioning time.

6.3.5 Drive Mechanism—A drive mechanism capable of

imparting a uniform controllable speed to the movable member 8.2 Test Specimen Conditioning—The specimens shall be

of the apparatus. conditioned and tested in a room or enclosed space maintained

D2343 − 17 (2023)

1 Notches for locations for impregnated rods 4 Dimension depending on number of specimens

2 Position for strip of cardboard or mat 5 Thickness of cardboard or mat

3 Border 6 Stops

FIG. 4 Tabbing Template

at atmospheric conditions of 23 6 2°C (73.4 6 3.6°F) and 50 10.5 Select a stripper die of the proper diameter by using the

6 10 % relative humidity in accordance with Procedure A of chart or calculations in 12.3.

Practice D618, except that 16 h shall be the minimum

10.6 Thread the glass fiber material through the impregnat-

conditioning time.

ing apparatus in an “under, over, under” path through the static

spreader bars. Firmly attach the end of the glass fiber to the

9. Speed of Testing

winding fixture with heat-resistant masking tape. Drape the

9.1 Speed of testing shall be the relative rate of motion of

material on the winding fixture. Rotate the fixture either

the grips or test fixtures during test.

manually or at a motorized rate not exceeding 8 m/min (26

9.2 The standard speed of testing is 10 mm/min for tensile ft/min).

strength and 5 mm/min for apparent modulus of elasticity

10.6.1 Maintain a resin-to-glass weight ratio of 70 % for the

unless otherwise specified.

preparation of the test specimens (see Note 7).

NOTE 7—The choice of die and the tex of the fiber will determine the

10. Impregnation Procedure

glass content and is also influenced by viscosity of the resin used. Use the

10.1 Set up the impregnating apparatus in accordance with

calculations in 12.2 to determine the die size to be used. If the calculated

die size does not yield the needed glass-weight ratio, then adjustment of

Fig. 1.

the die diameter will be needed.

10.2 Cover the ends of the winding fixture using 0.025 mm

10.6.2 After the required number of specimens are wound,

(0.001 in.) nominal thickness, heat-resistant plastic film, alu-

hold the winding tension on the material and use heat-resistant

minum foil, or equivalent parting film.

masking tape to attach the material to the winding fixture. Cut

10.3 Prepare a sufficient quantity of resin system suitable

the material after attachment has been made.

for impregnating the material under test. Pour the impregnating

mixture into the tank so that the level is about 10 mm (0.39 in.)

NOTE 8—Optionally, a flat tongue depressor or metal spatula may be

used to flatten the end 100 mm (3.9 in.) of the glass strands. This flattening

above the static breaker bars (see Fig. 2).

of the gripped portion of the strands allows better clamping of the

10.4 Immediately prior to threading the material through the

specimens while minimizing crushing in the grip jaws.

impregnation apparatus, cut a 1000 6 1-mm (40 6 0.04-in.)

10.6.3 Place the loaded winding fixture in a horizontal

skein of the material under test. Repeat the procedure imme-

position in an air-circulating oven at a temperature and for a

diately after winding one set of specimens. Plac

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.