ASTM D3656/D3656M-13(2021)

(Specification)Standard Specification for Insect Screening and Louver Cloth Woven fromVinyl-Coated Glass Yarns

Standard Specification for Insect Screening and Louver Cloth Woven from<brk/>Vinyl-Coated Glass Yarns

ABSTRACT

This specification covers the requirements for insect screening and louver cloth made from vinyl-coated glass yarns. Specifically covered here are: commercial standard vinyl-coated glass yarn insect screening designed and woven primarily for installation in or on any dwelling, patio, screening enclosure, building, or structure for the purpose of keeping out flies, mosquitoes, and most insects; and vinyl-coated glass yarn louver cloth used extensively in soffit and louver vents to keep out most large insects, birds, and airborne litter, while at the same time providing for adequate ventilation and air circulation. Products are produced in two basic classes (Classes 1 and 2) based on nominal thickness. Products shall be suitably tested and conform accordingly to specified requirements in tems of appearance, mesh, roll length, mass per unit area, flame resistance, fabric stability, bursting strength, stiffness index, and color stability to accelerated weathering.

SCOPE

1.1 This specification covers the requirements for vinyl-coated glass yarn insect screening and louver cloth.

1.2 This specification is intended to assist ultimate users by designating the sizes and types of these products that are generally available in the industry.

1.3 This specification shows the terminology and requirements for:

1.3.1 Commercial standard vinyl-coated glass yarn insect screening designed and woven primarily for installation in or on any dwelling, patio, screening enclosure, building, or structure for the purpose of keeping out flies, mosquitoes, and most insects.

1.3.2 Vinyl-coated glass yarn louver cloth used extensively in soffit and louver vents to keep out most large insects, birds, and airborne litter, while at the same time providing for adequate ventilation and air circulation.

1.4 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system are not necessarily exact equivalents; therefore, to ensure conformance with the standard, each system shall be used independently of the other, and values from the two systems shall not be combined.

1.5 The following precautionary caveat pertains only to the test methods portions, Sections 8 – 19, of this specification. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:D3656/D3656M −13 (Reapproved 2021)

Standard Specification for

Insect Screening and Louver Cloth Woven from

Vinyl-Coated Glass Yarns

This standard is issued under the fixed designation D3656/D3656M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope Development of International Standards, Guides and Recom-

mendations issued by the World Trade Organization Technical

1.1 This specification covers the requirements for vinyl-

Barriers to Trade (TBT) Committee.

coated glass yarn insect screening and louver cloth.

1.2 This specification is intended to assist ultimate users by

2. Referenced Documents

designating the sizes and types of these products that are

2.1 ASTM Standards:

generally available in the industry.

D123Terminology Relating to Textiles

1.3 This specification shows the terminology and require-

D1776/D1776MPractice for Conditioning and Testing Tex-

ments for:

tiles

1.3.1 Commercial standard vinyl-coated glass yarn insect

D3374/D3374MSpecification for Vinyl-Coated GlassYarns

screening designed and woven primarily for installation in or

D3773/D3773MTest Methods for Length of Woven Fabric

on any dwelling, patio, screening enclosure, building, or

D3774Test Method for Width of Textile Fabric

structure for the purpose of keeping out flies, mosquitoes, and

D3775TestMethodforEnd(Warp)andPick(Filling)Count

most insects.

of Woven Fabrics

1.3.2 Vinyl-coated glass yarn louver cloth used extensively

D3776/D3776MTest Methods for Mass Per Unit Area

in soffit and louver vents to keep out most large insects, birds,

and airborne litter, while at the same time providing for (Weight) of Fabric

adequate ventilation and air circulation. D3786/D3786MTest Method for Bursting Strength of Tex-

tileFabrics—DiaphragmBurstingStrengthTesterMethod

1.4 The values stated in either SI units or inch-pound units

D4028/D4028MSpecification for Solar Screening Woven

are to be regarded separately as standard. The values stated in

from Vinyl-Coated Fiber Glass Yarn

eachsystemarenotnecessarilyexactequivalents;therefore,to

D4372Specification for Flame-Resistant Materials Used in

ensure conformance with the standard, each system shall be

Camping Tentage (Withdrawn 2002)

used independently of the other, and values from the two

systems shall not be combined. D4912/D4912MTest Method for Fabric Stability of Vinyl-

Coated Glass Yarn Insect Screening and Louver Cloth

1.5 The following precautionary caveat pertains only to the

D4929Test Method for Determination of Organic Chloride

test methods portions, Sections8–19, of this specification.

Content in Crude Oil

This standard does not purport to address all of the safety

D7018/D7018MTerminology Relating to Glass Fiber and

concerns, if any, associated with its use. It is the responsibility

Its Products (Withdrawn 2021)

of the user of this standard to establish appropriate safety,

health, and environmental practices and determine the appli-

2.2 AATCC Standard:

cability of regulatory limitations prior to use.

Evaluation Procedure 1,Gray Scale for Color Change

1.6 This international standard was developed in accor-

dance with internationally recognized principles on standard-

ization established in the Decision on Principles for the

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

This specification is under the jurisdiction of ASTM Committee D13 on the ASTM website.

TextilesandisthedirectresponsibilityofSubcommitteeD13.18onGlassFiberand The last approved version of this historical standard is referenced on

its Products. www.astm.org.

CurrenteditionapprovedJuly1,2021.PublishedJuly2021.Originallyapproved Available from American Association of Textile Chemists and Colorists

in 1978. Last previous edition approved in 2013 as D3656/D3656M–13. DOI: (AATCC), P.O. Box 12215, Research Triangle Park, NC 27709-2215, http://

10.1520/D3656_D3656M-13R21. www.aatcc.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D3656/D3656M−13 (2021)

TABLE 1 Generally Available Mesh, Widths, and Colors

Standard Construction

Standard Widths

Nominal Yarn Diameter,

Product Class Warp by Fill Mesh/25.4 Colors

µm [in.]

mm in.

mm [Mesh/1 in.]

Insect screening 1 292 [0.011] 18 × 16 610, 762, 813, 914, 24, 30, 32, 36, 42, 48, gray, charcoal

1067, 1219, 1524, 60, 72, 84

1829, 2134

2 330 [0.013] 18 × 14 914, 1219, 1524, 1829, 36, 48, 60, 72, 84, 96, gray, charcoal

2134, 2438, 2743 108

2 330 [0.013] 18 × 14 914, 1219, 1829, 2134 36, 48, 72, 84 aqua

2 330 [0.013] 20 × 20 914, 1219, 1524, 1829, 36, 48, 60, 72, 84 gray, charcoal

Louver cloth 2 330 [0.013] Less than 12 × 12 152, 203, 305, 610, 6, 8, 12, 24, 36, 48 gray, charcoal

914, 1219

2.3 ANSI/ASQC Standards: 4.2.1 For vinyl-coated glass yarn insect screening not listed

ANSI/ASQC Z1.4Sampling Procedures for Inspection by in Table 1, the mesh, width, and colors shall be agreed upon

Attributes between the purchaser and supplier.

ANSI/ASQC Z1.9Sampling Procedures and Tables for In-

5. Sampling and Test Specimens

spection Variables for Percent Nonconforming

5.1 Sampling—On a continual basis, samples are selected

2.4 Federal Standards:

randomly from each mesh and tested to insure compliance,

CCC-D-950Specification, Dyeing and After Treating Pro-

unless otherwise agreed upon between the purchaser and the

cesses for Cotton Cloths

supplier.

Test Method Standard No. 191a,Textile Test Methods,

Method5872EffectofHighTemperatureonClothBlock-

5.2 Test Specimens—For insect screening or louver cloth

ing

appearance, width, and length testing, a roll shall serve as the

Standard595ACHG Not 1, Color Volume 1

test specimen. For other properties, take the test specimen(s)

2.5 IFAI (Industrial Fabrics Association International) from the roll. No specimen shall be taken closer than 25 mm

CPAI-84Specification for Flame-Resistant Materials Used

[1in.] from the edge or 0.9 m [1 yd] from the end of the roll.

in Camping Tentage

REQUIREMENTS

3. Terminology

3.1 For all terminology relating to D13.18, Glass Fiber and

6. General Requirements

Its Products, refer to Terminology D7018/D7018M.

6.1 Material:

3.1.1 The following terms are relevant to this standard:

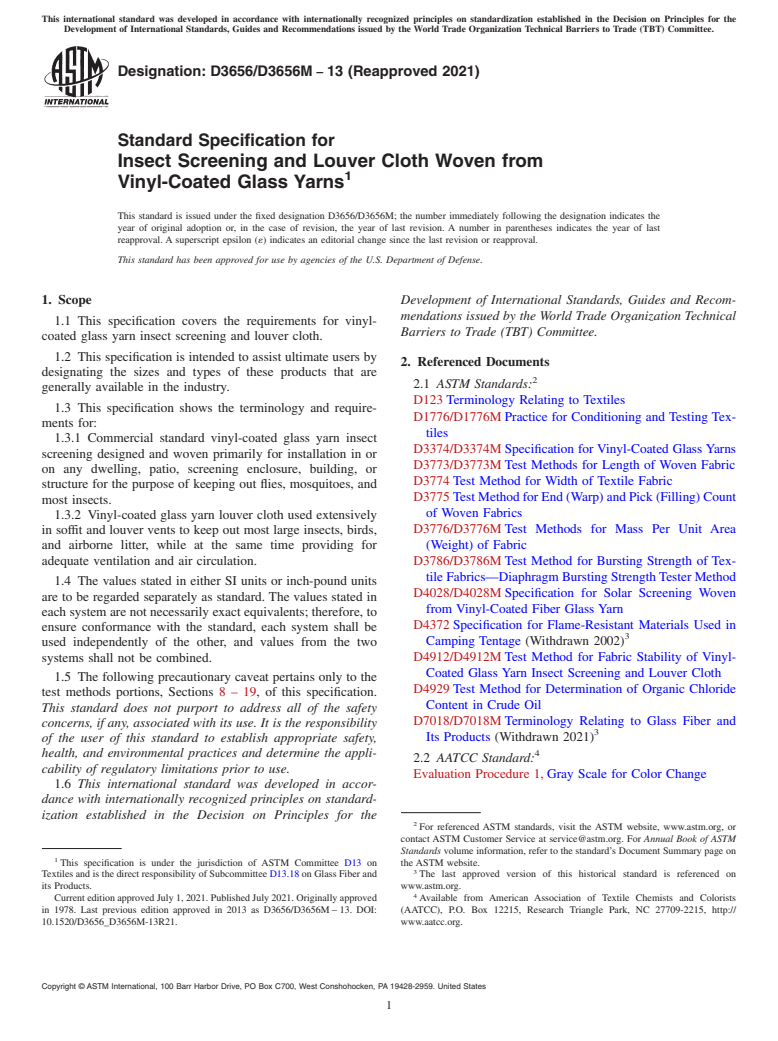

6.1.1 Workmanship—Insect screening or louver cloth shall

atmosphere for testing textiles, insect screening, louver cloth,

be made utilizing input yarns that meet the requirements

mesh.

specified in Specification D3374/D3374M. Products may con-

3.2 For all other terms related to textiles, refer to Terminol- tain a maximum of one defect in the filling direction affecting

ogy D123.

less than 50 lineal mm [2 lineal in.]. Examples of defects are

listed in Table 2.

4. Classification

6.1.2 Plasticizers—The material used to coat or impregnate

the fibrous glass yarn shall be a compound of polymerized or

4.1 Vinyl-coated glass yarn insect screening is produced in

copolymerized vinyl chloride resin, plasticized with phosphate

two basic classes and mesh to afford required strength and

or phthalate ester plasticizers exclusively, pigmented and

insect protection using yarns as directed in Specification

stabilized to meet the requirements herein.

D3374/D3374M. These two classes are as follows:

6.1.2.1 Optional Plasticizer—At the supplier’s option, plas-

4.1.1 Class 1—Insect screening woven from vinyl-coated

ticizers other than phosphates and phthalates may be used

glass yarn having a nominal thickness of 0.292 mm

provided the color is not affected and the coating compound is

[0.0115in.].

treated with solubilized copper 8 quinolinolate which is listed

4.1.2 Class 2—Insect screening woven from vinyl-coated

as inhibitor (e) in Federal Standard CCC-D-950. The amount

glassyarnhavinganominalthicknessof0.330mm[0.013in.].

of fungicide shall be based on the nonvolatile content of the

4.2 The mesh, width, and colors are listed in Table 1.

coating. The coating compound shall be chemically analyzed

for copper 8 quinolinolate content in accordance with Federal

5 Standard CCC-D-950.

Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

6.1.3 Color—The maximum and minimum shades limits

4th Floor, New York, NY 10036, http://www.ansi.org.

Available from General ServicesAdministration, Specifications and Consumer

shall be defined by color designations listed in Federal Stan-

Information Distribution Section (WFSIS), Washington Navy Yard, Bldg. 197,

dard595A as agreed upon between the purchaser and supplier.

Washington, DC 20407.

6.1.3.1 The color designated grey shall fall between No.

Available from Industrial Fabrics Association International (IFAI), 1801

County Road B W, Roseville, MN 55113-4061, https://www.ifai.com. 36492 and No. 36173 as listed in Federal Standard595A.

D3656/D3656M−13 (2021)

A,B

TABLE 2 Examples of Defects

Bias or bowed filling:

A,B

For widths# 1220 mm [48 in.]$ 13 mm [0.5 in.] Slack or tight selvage

2 2 B

For widths > 1220 mm [48 in.]$ 25 mm [1.0 in.] Splice—more than one in a 300 mm [1 ft ] area

A,B B

Broken or missing strand (end or pick), Splice more than 25 mm [1 in.] in length

B B

Damaged selvage extending into the body of the screening Splice not well made and showing tails

A,B A,B

Heavy strand Spot, stain, or streak

A,B A,B

Jerked-in filling, slough-off, or kinky filling Thin strand

B A,B

Color bands Tight strand (end or pick)

B

Uncoated yarns

A

For definitions of terms used in this table, refer to Terminology D123.

B

At normal inspection distance approximately 900 mm [3 ft].

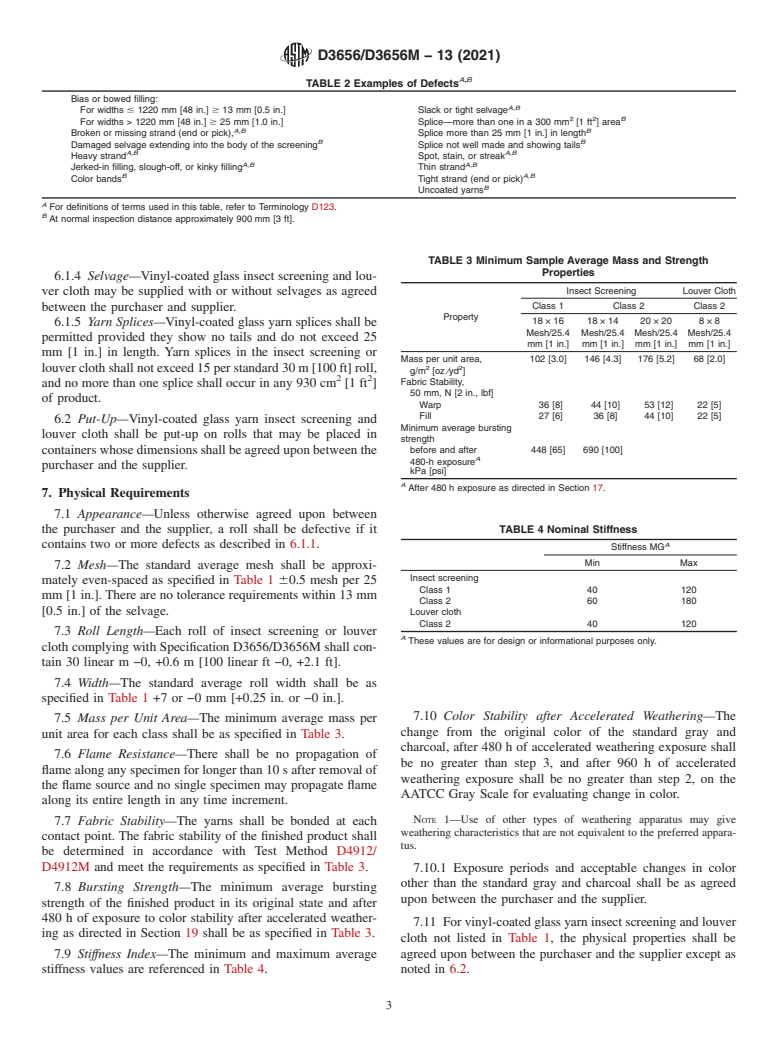

TABLE 3 Minimum Sample Average Mass and Strength

Properties

6.1.4 Selvage—Vinyl-coated glass insect screening and lou-

Insect Screening Louver Cloth

ver cloth may be supplied with or without selvages as agreed

Class 1 Class 2 Class 2

between the purchaser and supplier.

Property

18×16 18×14 20×20 8×8

6.1.5 Yarn Splices—Vinyl-coated glass yarn splices shall be

Mesh/25.4 Mesh/25.4 Mesh/25.4 Mesh/25.4

permitted provided they show no tails and do not exceed 25

mm [1 in.] mm [1 in.] mm [1 in.] mm [1 in.]

mm [1 in.] in length. Yarn splices in the insect screening or

Mass per unit area, 102 [3.0] 146 [4.3] 176 [5.2] 68 [2.0]

2 2

louverclothshallnotexceed15perstandard30m[100ft]roll,

g/m [oz ⁄yd ]

2 2

Fabric Stability,

and no more than one splice shall occur in any 930 cm [1 ft ]

50 mm, N [2 in., lbf]

of product.

Warp 36 [8] 44 [10] 53 [12] 22 [5]

Fill 27 [6] 36 [8] 44 [10] 22 [5]

6.2 Put-Up—Vinyl-coated glass yarn insect screening and

Minimum average bursting

louver cloth shall be put-up on rolls that may be placed in

strength

containerswhosedimensionsshallbeagreeduponbetweenthe before and after 448 [65] 690 [100]

A

480-h exposure

purchaser and the supplier.

kPa [psi]

A

After 480 h exposure as directed in Section 17.

7. Physical Requirements

7.1 Appearance—Unless otherwise agreed upon between

the purchaser and the supplier, a roll shall be defective if it TABLE 4 Nominal Stiffness

A

contains two or more defects as described in 6.1.1.

Stiffness MG

Min Max

7.2 Mesh—The standard average mesh shall be approxi-

Insect screening

mately even-spaced as specified in Table 1 60.5 mesh per 25

Class 1 40 120

mm [1 in.].There are no tolerance requirements within 13 mm

Class 2 60 180

[0.5 in.] of the selvage.

Louver cloth

Class 2 40 120

7.3 Roll Length—Each roll of insect screening or louver

A

These values are for design or informational purposes only.

cloth complying with Specification D3656/D3656M shall con-

tain 30 linear m −0, +0.6 m [100 linear ft −0, +2.1 ft].

7.4 Width—The standard average roll width shall be as

specified in Table 1 +7 or −0 mm [+0.25 in. or −0 in.].

7.10 Color Stability after Accelerated Weathering—The

7.5 Mass per Unit Area—The minimum average mass per

change from the original color of the standard gray and

unit area for each class shall be as specified in Table 3.

charcoal, after 480 h of accelerated weathering exposure shall

7.6 Flame Resistance—There shall be no propagation of

be no greater than step 3, and after 960 h of accelerated

flamealonganyspecimenforlongerthan10safterremovalof

weathering exposure shall be no greater than step 2, on the

the flame source and no single specimen may propagate flame

AATCC Gray Scale for evaluating change in color.

along its entire length in any time increment.

NOTE 1—Use of other types of weathering apparatus may give

7.7 Fabric Stability—The yarns shall be bonded at each

weathering characteristics that are not equivalent to the preferred appara-

contact point. The fabric stability of the finished product shall

tus.

be determined in accordance with Test Method D4912/

D4912M and meet the requirements as specified in Table 3.

7.10.1 Exposure periods and acceptable changes in color

other than the standard gray and charcoal shall be as agreed

7.8 Bursting Strength—The minimum average bursting

upon between the purchaser and the supplier.

strength of the finished product in its original state and after

480 h of exposure to color stability after accelerated weather-

7.11 Forvinyl-coatedglassyarninsectscreeningandlouver

ing as directed in Section 19 shall be as specified in Table 3.

cloth not listed in Table 1, the physical properties shall be

agreed upon between the purchaser and the supplier except as

7.9 Stiffness Index—The minimum and maximum average

stiffness values are referenced in Table 4. noted in 6.2.

D3656/D3656M−13 (2021)

TEST METHODS 16. Fabric Stability

16.1 Test 10 specimens from each roll to be tested as

8. Conditioning

directed in Test Method D4912/D4912M. Cut the specimens

8.1 Condition the laboratory samples without precondition-

50mm by 125 mm 6 2 mm [2in. by 5 in. 6 0.062 in.] with

ing for a period of at least5hinthe atmosphere for testing

thelongdimensionofthespecimeninthedirectiontobetested

glass textiles as directed in Practice D1776/D1776M, unless

andwithdifferentwarpendsineachofthewarpspecimensand

otherwise specified.

different filling picks in each of the filling specimens.

NOTE2—Inanyevent,24hisconsideredampleexposuretimetobring

the samples to moisture equilibrium. 17. Bursting Strength

17.1 General—Determine the bursting strength as directed

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.