ASTM D4029/D4029M-23

(Specification)Standard Specification for Finished Woven Glass Fabrics

Standard Specification for Finished Woven Glass Fabrics

ABSTRACT

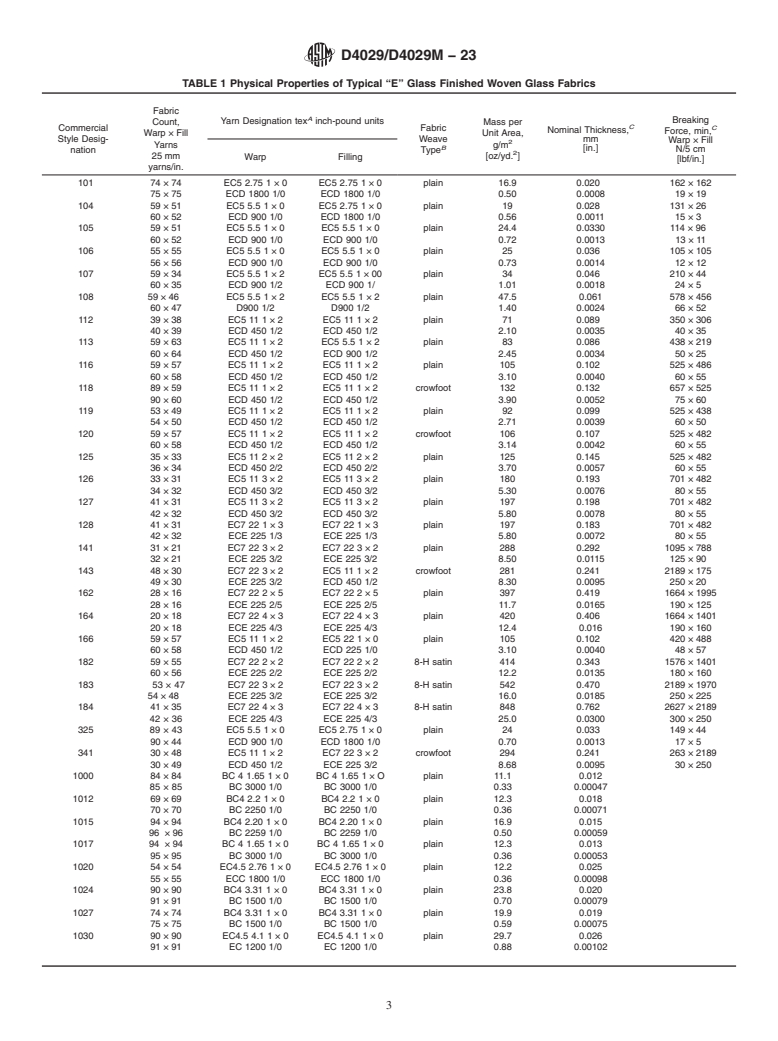

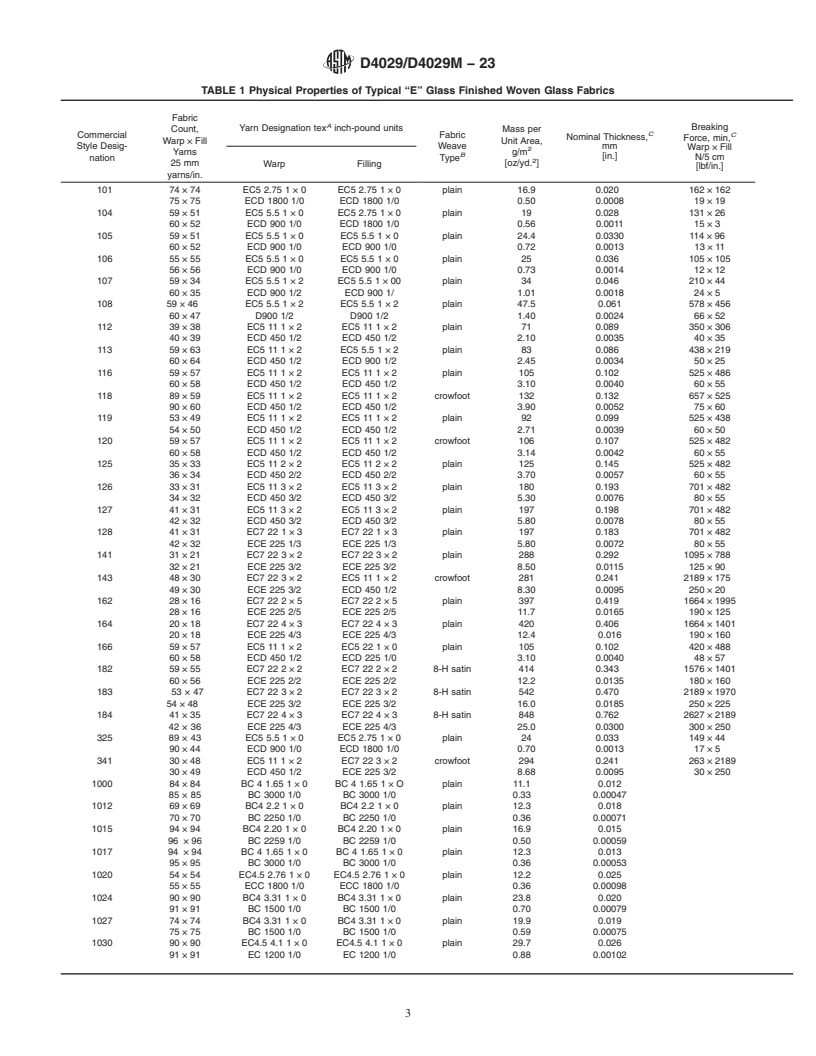

This specification covers finished fabrics woven from "E" electrical glass fiber yarns that are intended as a reinforcing material in laminated plastics for structural use. This specification can also be applied to fabrics made of other glass types. This specification permits the application of sizing materials to the glass fiber yarn during manufacture that helps facilitate weaving. These organic materials are typically removed from the greige gabric and replaced with a finish that is compatible with a specified resin matrix. The materials shall meet the required fabric count, yarn designations, yarn number, filament diameter, strand construction, twist direction, twist level, fabric weave type, mass per unit area, thickness, breaking strength, width, length, ignition loss, finish level, and appearance.

SCOPE

1.1 This specification covers finished fabrics woven from “E” electrical glass fiber yarns that are intended as a reinforcing material in laminated plastics for structural use. This specification can also be applied to fabrics made of other glass types as agreed upon between the purchaser and the supplier.

1.2 This specification specifies the terminology, definitions, general requirements, and physical requirements for finished woven glass fabrics This specification permits the application of sizing materials to the glass fiber yarn during manufacture that helps facilitate weaving. These organic materials are typically removed from the greige fabric and replaced with a finish that is compatible with the resin matrix specified in the contracting document.

Note 1: Sizing materials on glass fiber yarns, in most cases, are removed by various cleaning procedures as a first stage in preparing a finished fabric. When these yarn sizing materials are removed during a cleaning procedure they need not be compatible with the subsequent resin matrix.

1.3 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system are not exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems will result in non-conformance with the standard.

1.4 This specification is one of a series to provide a substitute for Military Specifications: MIL-Y-1140 Yarn, Cord, Sleeving, Cloth, and Tape-Glass; and MIL-C-9084 Cloth, Glass Finished for Resin Laminates.

1.5 Additional ASTM specifications in this series have been drafted and appear in current editions of the Annual Book of ASTM Standards. These include greige glass fabrics, glass tapes, glass sleevings, glass cords, glass sewing threads, and finished laminates made from finished glass fabrics.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D4029/D4029M − 23

Standard Specification for

1

Finished Woven Glass Fabrics

This standard is issued under the fixed designation D4029/D4029M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope responsibility of the user of this standard to establish appro-

priate safety, health, and environmental practices and deter-

1.1 This specification covers finished fabrics woven from

mine the applicability of regulatory limitations prior to use.

“E” electrical glass fiber yarns that are intended as a reinforc-

1.7 This international standard was developed in accor-

ing material in laminated plastics for structural use. This

dance with internationally recognized principles on standard-

specification can also be applied to fabrics made of other glass

ization established in the Decision on Principles for the

types as agreed upon between the purchaser and the supplier.

Development of International Standards, Guides and Recom-

1.2 This specification specifies the terminology, definitions,

mendations issued by the World Trade Organization Technical

general requirements, and physical requirements for finished

Barriers to Trade (TBT) Committee.

woven glass fabrics This specification permits the application

of sizing materials to the glass fiber yarn during manufacture 2. Referenced Documents

that helps facilitate weaving. These organic materials are 2

2.1 ASTM Standards:

typically removed from the greige fabric and replaced with a

D123 Terminology Relating to Textiles

finish that is compatible with the resin matrix specified in the

D578/D578M Specification for Glass Fiber Strands

contracting document.

D1059 Test Method for Yarn Number Based on Short-

Length Specimens

NOTE 1—Sizing materials on glass fiber yarns, in most cases, are

removed by various cleaning procedures as a first stage in preparing a

D1423/D1423M Test Method for Twist in Yarns by Direct-

finished fabric. When these yarn sizing materials are removed during a

Counting

cleaning procedure they need not be compatible with the subsequent resin

D1776/D1776M Practice for Conditioning and Testing Tex-

matrix.

tiles

1.3 The values stated in either SI units or inch-pound units

D1777 Test Method for Thickness of Textile Materials

are to be regarded separately as standard. The values stated in

D2408 Test Method for Finish Content of Woven Glass

each system are not exact equivalents; therefore, each system

Fabric, Cleaned and After-Finished With Amino-Silane-

shall be used independently of the other. Combining values 3

Type Finishes, for Plastic Laminates (Withdrawn 1988)

from the two systems will result in non-conformance with the

D2409 Test Method for Finish Content of Woven Glass

standard.

Fabric, Cleaned and After-Finished With Vinyl-Silane

3

1.4 This specification is one of a series to provide a Type Finishes, for Plastic Laminates (Withdrawn 1988)

substitute for Military Specifications: MIL-Y-1140 Yarn, Cord, D2410 Test Method for Finish Content of Woven Glass

Sleeving, Cloth, and Tape-Glass; and MIL-C-9084 Cloth, Fabric, Cleaned and After-Finished With Chrome

3

Glass Finished for Resin Laminates. Complexes, for Plastic Laminates (Withdrawn 1988)

D2660 Test Method for Finish Content of Woven Glass

1.5 Additional ASTM specifications in this series have been

Fabric, Cleaned and After-Finished with Acrylic-Silane-

drafted and appear in current editions of the Annual Book of

3

Type Finishes, for Plastic Laminates (Withdrawn 1988)

ASTM Standards. These include greige glass fabrics, glass

D3098 Test Method for Finish Content of Woven Glass

tapes, glass sleevings, glass cords, glass sewing threads, and

Fabrics, Cleaned and After-Finished with Epoxy-

finished laminates made from finished glass fabrics.

Functions Silane Type Finishes for Plastic Laminates

1.6 This standard does not purport to address all of the 3

(Withdrawn 1988)

safety concerns, if any, associated with its use. It is the

D3773/D3773M Test Methods for Length of Woven Fabric

1 2

This specification is under the jurisdiction of ASTM Committee D13 on For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Textiles and is the direct responsibility of Subcommittee D13.18 on Glass Fiber and contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

its Products. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved June 1, 2023. Published August 2023. Originally the ASTM webs

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D4029/D4029M − 16 D4029/D4029M − 23

Standard Specification for

1

Finished Woven Glass Fabrics

This standard is issued under the fixed designation D4029/D4029M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This specification covers finished fabrics woven from “E” electrical glass fiber yarns that are intended as a reinforcing material

in laminated plastics for structural use. This specification can also be applied to fabrics made of other glass types as agreed upon

between the purchaser and the supplier.

1.2 This specification specifies the terminology, definitions, general requirements, and physical requirements for finished woven

glass fabrics This specification permits the application of sizing materials to the glass fiber yarn during manufacture that helps

facilitate weaving. These organic materials are typically removed from the greige fabric and replaced with a finish that is

compatible with the resin matrix specified in the contracting document document.

NOTE 1—Sizing materials on glass fiber yarns, in most cases, are removed by various cleaning procedures as a first stage in preparing a finished fabric.

When these yarn sizing materials are removed during a cleaning procedure they need not be compatible with the subsequent resin matrix.

1.3 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each

system mayare not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from

the two systems maywill result in non-conformance with the standard.

1.4 This specification is one of a series to provide a substitute for Military Specifications: MIL-Y-1140 Yarn, Cord, Sleeving,

Cloth, and Tape-Glass; and MIL-C-9084 Cloth, Glass Finished for Resin Laminates.

1.5 Additional ASTM specifications in this series have been drafted and appear in current editions of the Annual Book of ASTM

Standards. These include greige glass fabrics, glass tapes, glass sleevings, glass cords, glass sewing threads, and finished laminates

made from finished glass fabrics.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and healthsafety, health, and environmental practices and determine

the applicability of regulatory limitations prior to use.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

1

This specification is under the jurisdiction of ASTM Committee D13 on Textiles and is the direct responsibility of Subcommittee D13.18 on Glass Fiber and its Products.

Current edition approved Jan. 1, 2016June 1, 2023. Published February 2016August 2023. Originally approved in 1981. Last previous edition approved in 20102016 as

D4029 – 10.D4029 – 16. DOI: 10.1520/D4029-16.10.1520/D4029-23.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D4029/D4029M − 23

2. Referenced Documents

2

2.1 ASTM Standards:

D123 Terminology Relating to Textiles

D578D578/D578M Specification for Glass Fiber Strands

D1059 Test Method for Yarn Number Based on Short-Length Specimens

D1423D1423/D1423M Test Method for Twist in Yarns by Direct-Counting

D1776D1776/D1776M Practice for Conditioning and Testing Textiles

D1777 Test Method for Thickness of Textile Materials

D2408 Test Method for Finish Content of Woven Glass Fabric, Cleaned and After-Finished With Amino-Silane-Type Finishes,

3

for Plastic Laminates (Withdrawn 1988)

D2409 Test Method for Finish Content of Woven Glass Fabric, Cleaned and After-Finished With Vinyl-Silane Type Finishes,

3

for Plastic Laminates (Withdrawn 1988)

D2410 Test Method for Finish Content of Woven Glass Fabric, Cleaned and After-Finished With Chrome Complexes, for Plastic

3

Laminates (Withdrawn 1988)

D2660 Test Method for Finish Content of Woven Glass Fabric, Cleaned and After-Finished with Acrylic-Silane-Type

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.