ASTM E1258-88(1998)

(Test Method)Standard Test Method for Airflow Calibration of Fan Pressurization Devices

Standard Test Method for Airflow Calibration of Fan Pressurization Devices

SCOPE

1.1 This test method covers the airflow measurement calibration techniques for fan pressurization systems used for measuring air leakage rates through building envelopes.

1.2 This test method is applicable to systems used for air leakage measurement as described in Practice E779.

1.3 This test method involves the installation of the fan pressurization system in a calibration chamber. Use of the fan pressurization system in an actual building may introduce additional errors in the airflow measurement due to operator influence, interference of internal partitions and furnishings, weather effects, and other factors.

1.4 The proper use of this test method requires a knowledge of the principles of airflow and pressure measurement.

1.5 This standard includes two basic procedures, a preferred procedure, based on ASHRAE Standard 51/AMCA Standard 210, and an optional procedure based on a nonstandard airflow measurement technique, commonly used by manufacturers of fan pressurization devices, but which has not been compared with standard airflow measurement techniques.

1.6 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E 1258 – 88 (Reapproved 1998)

Standard Test Method for

1

Airflow Calibration of Fan Pressurization Devices

This standard is issued under the fixed designation E 1258; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (ε) indicates an editorial change since the last revision or reapproval.

4

1. Scope 2.3 American Society of Mechanical Engineers Standard:

ASME MFC-3M Standard Measurement of Fluid Flow in

1.1 This test method covers the airflow measurement cali-

Pipes Using Orifice, Nozzle, and Venturi

bration techniques for fan pressurization systems used for

measuring air leakage rates through building envelopes.

3. Terminology

1.2 This test method is applicable to systems used for air

3.1 Definitions—For definitions used in this test method,

leakage measurement as described in Practice E779.

see Terminology E631.

1.3 This test method involves the installation of the fan

3.2 Descriptions of Terms Specific to This Standard:

pressurization system in a calibration chamber. Use of the fan

3.2.1 ambient conditions, n—conditions in the space from

pressurization system in an actual building may introduce

which air is drawn into the calibration chamber and into which

additional errors in the airflow measurement due to operator

the chamber air is expelled.

influence, interference of internal partitions and furnishings,

3.2.2 chamber, n—an enclosure of rectangular or circular

weather effects, and other factors.

cross section to simulate the entrance and exit conditions that

1.4 Theproperuseofthistestmethodrequiresaknowledge

the fan is expected to encounter in service.

of the principles of airflow and pressure measurement.

3.2.3 fan air density, n—density of air at the fan inlet

1.5 Thisstandardincludestwobasicprocedures,apreferred

expressed in kilograms per cubic metre.

procedure, based on ASHRAE Standard 51/AMCA Standard

3.2.4 fan airflow rate, n—volumetric airflow rate at the fan

210, and an optional procedure based on a nonstandard airflow

air density expressed in cubic metres per second.

measurement technique, commonly used by manufacturers of

3.2.5 fan outlet area, n—gross inside area measured in the

fan pressurization devices, but which has not been compared

plane of the fan outlet opening expressed in square metres.

with standard airflow measurement techniques.

3.2.6 fan pressure difference, n—the static pressure differ-

1.6 This standard does not purport to address all of the

ence between two stations expressed in pascals, measured

safety concerns, if any, associated with its use. It is the

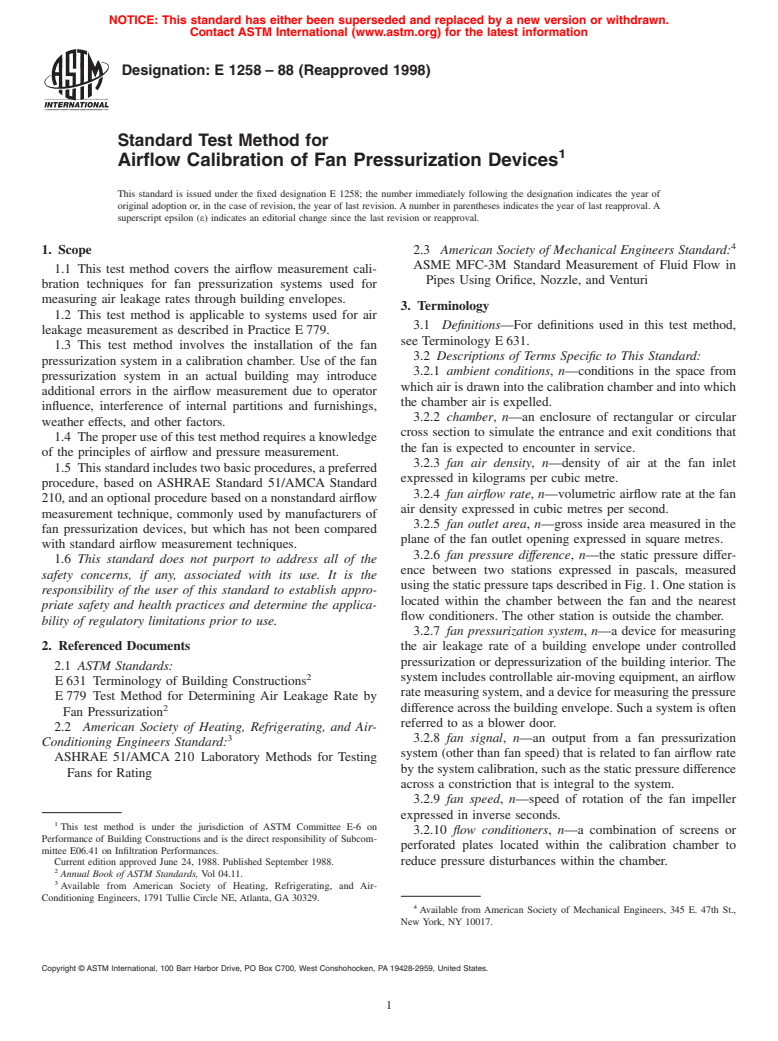

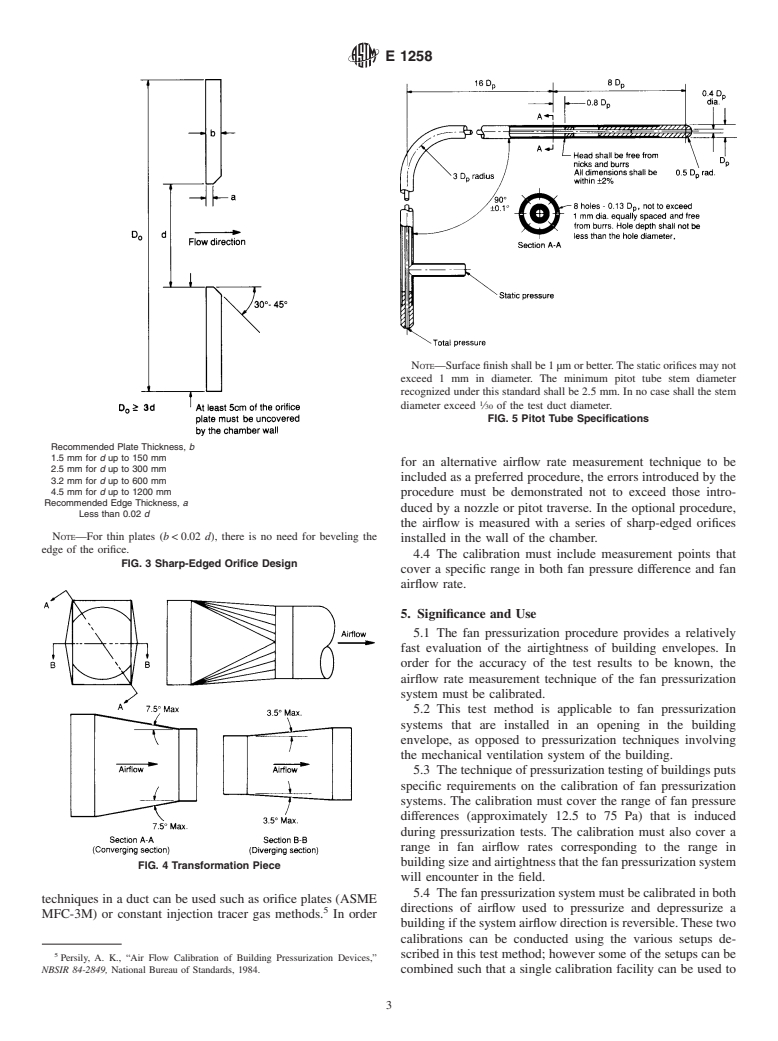

usingthestaticpressuretapsdescribedinFig.1.Onestationis

responsibility of the user of this standard to establish appro-

located within the chamber between the fan and the nearest

priate safety and health practices and determine the applica-

flow conditioners. The other station is outside the chamber.

bility of regulatory limitations prior to use.

3.2.7 fan pressurization system, n—a device for measuring

2. Referenced Documents the air leakage rate of a building envelope under controlled

pressurization or depressurization of the building interior. The

2.1 ASTM Standards:

2

system includes controllable air-moving equipment, an airflow

E631 Terminology of Building Constructions

ratemeasuringsystem,andadeviceformeasuringthepressure

E779 Test Method for Determining Air Leakage Rate by

2

difference across the building envelope. Such a system is often

Fan Pressurization

referred to as a blower door.

2.2 American Society of Heating, Refrigerating, and Air-

3

3.2.8 fan signal, n—an output from a fan pressurization

Conditioning Engineers Standard:

system (other than fan speed) that is related to fan airflow rate

ASHRAE 51/AMCA 210 Laboratory Methods for Testing

by the system calibration, such as the static pressure difference

Fans for Rating

across a constriction that is integral to the system.

3.2.9 fan speed, n—speed of rotation of the fan impeller

expressed in inverse seconds.

1

This test method is under the jurisdiction of ASTM Committee E-6 on

3.2.10 flow conditioners, n—a combination of screens or

Performance of Building Constructions and is the direct responsibility of Subcom-

perforated plates located within the calibration chamber to

mittee E06.41 on Infiltration Performances.

Current edition approved June 24, 1988. Published September 1988. reduce pressure disturbances within the chamber.

2

Annual Book of ASTM Standards, Vol 04.11.

3

Available from American Society of Heating, Refrigerating, and Air-

Conditioning Engineers, 1791 Tullie Circle NE, Atlanta, GA 30329.

4

Available from American Society of Mechanical Engineers, 345 E. 47th St.,

New York, NY 10017.

Copyright © ASTM International, 100 B

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.