ASTM B439-00

(Specification)Standard Specification for Iron-Base Sintered Bearings (Oil-Impregnated)

Standard Specification for Iron-Base Sintered Bearings (Oil-Impregnated)

SCOPE

1.1 This specification covers sintered metal powder, oil-impregnated, bearings of four iron-base compositional grades:

Grades 1 and 2--iron-carbon

Grades 3 and 4--iron-copper

1.2 The values stated in inch-pound units are to be regarded as the standard. The metric equivalents of inch-pound units may be approximate.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: B 439 – 00

Standard Specification for

Iron-Base Sintered Bearings (Oil-Impregnated)

This standard is issued under the fixed designation B 439; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 6. Physical Properties

1.1 This specification covers sintered metal powder, oil- 6.1 Density—The density of bearings supplied fully impreg-

impregnated, bearings of four iron-base compositional grades: nated with lubricant shall be within the limits prescribed in

Grades 1 and 2—iron-carbon Table 2.

Grades 3 and 4—iron-copper 6.2 Oil Content—Oil content of bearings shall not be less

1.2 The values stated in inch-pound units are to be regarded than that shown in Table 2.

as the standard. The metric equivalents of inch-pound units 6.3 Radial Crushing Strength—Radial crushing strength

may be approximate. shall not be less than the value calculated as follows:

P 5 KLT /~D – T! (1)

2. Referenced Documents

2.1 ASTM Standards:

where:

B 328 Test Method for Density, Oil Content, and Intercon-

P = radial crushing strength, lbf (or N);

nected Porosity of Sintered Powder Metal Structural Parts D = outside diameter of bearing, in. (or mm);

T = wall thickness of bearing, in. (or mm);

and Oil-Impregnated Bearings

K = strength constant as shown in Table 3 for grade

E 9 Test Methods of Compression Testing of Metallic Ma-

specified, psi (MPa); and

terials at Room Temperature

L = length of bearing, in. (or mm).

3. Ordering Information

3.1 Orders for material under this specification shall include

7. Workmanship, Finish, and Appearance

the following information:

7.1 Bearings shall be uniform in composition. When cut or

3.1.1 Grade (Section 5),

fractured, the exposed surface shall be of uniform appearance.

3.1.2 Density (6.1),

The parts shall be free from defects which would affect their

3.1.3 Dimensions, and

serviceability.

3.1.4 Certification (12.1).

8. Sampling

4. Manufacture

8.1 Lot—Unless otherwise specified, a lot shall consist of

4.1 Bearings shall be made by briquetting and sintering

parts of the same form and dimensions made from powders of

metal powders, with or without sizing, so as to produce

the same composition, formed and sintered under the same

finished parts conforming to the requirements of this specifi-

conditions, and submitted for inspection at one time.

cation.

8.2 Sample for Chemical Analysis—At least one sample for

5. Chemical Requirements

chemical analysis shall be taken from each lot. A representative

sample of chips may be obtained by milling, drilling, or

5.1 The material shall conform to the requirements as to the

crushing at least two pieces with clean dry tools without

chemical composition prescribed in Table 1.

lubrication. To obtain oil-free chips, the parts selected for test

shall have the oil extracted in accordance with Test Method

B 328, if necessary.

8.3 Mechanical Tests—The manufacturer and purchaser

This specification is under the jurisdiction of ASTM Committee B-9 on Metal

shall agree on a representative number of specimens for

Powders and Metal Powder Productsand is the direct responsibility of Subcommit-

mechanical tests.

tee B09.04on Bearings.

Current edition approved October 10, 2000. Published December 2000. Origi-

9. Test Methods

nally published as B 439–66 T to replace portions of B 202. Last previous edition

B 439–95 (2000).

9.1 Density and Oil Content—Density and oil content shall

Annual Book of ASTM Standards, Vol 02.05.

3 be determined in accordance with Test Method B 328.

Annual Book of ASTM Standards, Vol 03.01.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

B 439

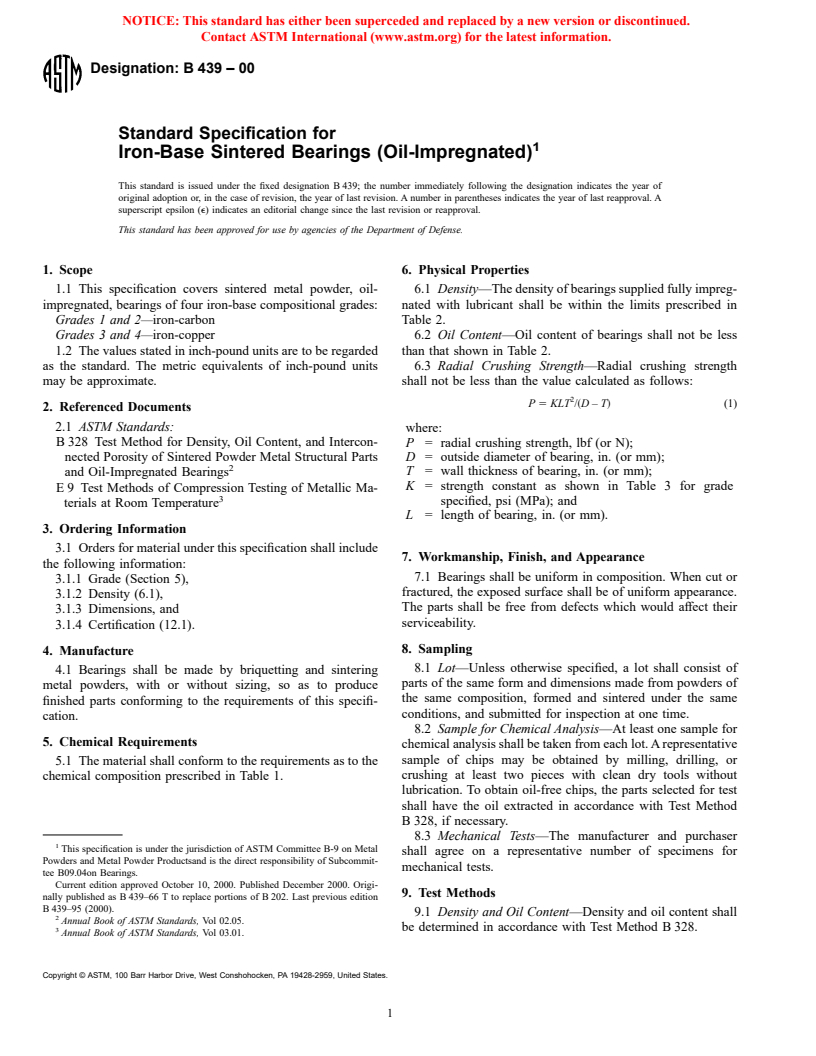

TABLE 1 Chemical Requirements

Composition, %

Element

Grade 1 Grade 2 Grade 3 Grade 4

Copper 0–1.5 0–1.5 9.0–11.0 18.0–22.0

Iron balance balance balance balance

Total other elements by difference, max 2.0 2.0 2.0 2.0

A

Combined carbon (on basis of iron only) 0.3 max 0.3–0.6 0.3 max 0.3 max

A

The combined carbon may be a metalographic estimate of the carbon in the iron.

TABLE 2 Density and Oil Content Requirements

10. Inspection

Density, g/cm Oil Content,

Grade

10.1 Unless otherwise specified, inspection of parts sup-

min max Volume, % min

1 and 2 5.6 6.0 21 plied on contract shall be made by the purchaser at the

3 and 4 5.8 6.2 19

destination.

11. Rejection

TABLE 3 Strength Constants

K (Strength Constant), 11.1 Rejection based on tests made in accordance with this

Grade

psi (MPa)

specification shall be reported to the manufacturer within 30

1 15 000 (105)

days of receipt of shipment; however, the rejected parts should

2 20 000 (140)

not be returned without authority from the producer.

3 30 000 (205)

4 30 000 (205)

12. Certification

12.1 A certification based on the manufacturer’s quality

control that the material conforms to the requirements of this

9.2 Radial Crushing Strength—Radial crushing strength

shall be determined by compressing the test specimens be- specification, shall be the basis of shipment of the material. A

tween two flat surfaces at a “no-load” speed no greater than 0.2 certificate covering the conformance of the material to these

in./min (5.0 mm/min), the direction of the load being normal to

specifications shall be furnished by the manufacturer upon

the longitudinal axis of the specimen. The point at which the

request of the purchaser.

load drops as a result of the first crack shall be considered the

crushing strength. This test shall be applied to plain cylindrical

13. Keywords

bearings. Flanged bearings shall be tested by cutting off the

13.1 density; iron-base bearings; K strength constant; oil

flange and compressing the two sections separately. Each

content; oil impregnated; porosity

section shall meet the maximum strength requirements pre-

scribed in 6.3.

APPENDIX

(Nonmandatory Information)

X1. EXPLANATORY INFORMATION

X1.1 Design Information are given in Table X1.1.

X1.1.1 In calculating permissible loads, the operating con-

X1.3 Dimensional Tolerances

ditions, housing conditions, and construction should be con-

sidered. In general, this material has less resistance to seizure

X1.3.1 Commercial dimensional tolerances are given in

and corrosion than copper-base material. The maximum static

Table X1.2.

bearing load should not exceed 15 000 psi (105 MPa) of

projected bearing area (length times inside diameter of bearing)

X1.4 Press Fits

for this material. This figure is 75 % of the value for the

X1.4.1 Plain cylindrical journal bearings are commonly

compression de

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.