ASTM F868-02(2009)

(Classification)Standard Classification for Laminated Composite Gasket Materials

Standard Classification for Laminated Composite Gasket Materials

SIGNIFICANCE AND USE

This classification is intended to encourage uniformity in reporting properties; to provide a common language for communications between producers and users; to guide engineers and designers in the use, construction, and properties of commercially available materials; and to be versatile enough to cover new materials and test methods as they are introduced.

SCOPE

1.1 This classification covers a means for specifying or describing pertinent properties of commercial laminate composite gasket materials (LCGM). These structures are composed of two or more chemically different layers of material. These materials may be organic or inorganic, or combinations with various binders or impregnants. Gasket coatings are not covered since details thereof are intended to be given on engineering drawings, or as separate specifications. Commercial materials designated as enveloped gaskets are excluded from this classification; they are covered in Practice F 336.

1.2 Since all of the properties that contribute to gasket performance are not included, use of this classification as a basis for selecting LCGM is limited.

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F868 −02 (Reapproved 2009)

Standard Classification for

Laminated Composite Gasket Materials

ThisstandardisissuedunderthefixeddesignationF868;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope F433 Practice for Evaluating Thermal Conductivity of Gas-

ket Materials

1.1 This classification covers a means for specifying or

F1276 Test Method for Creep Relaxation of Laminated

describing pertinent properties of commercial laminate com-

Composite Gasket Materials

posite gasket materials (LCGM). These structures are com-

posed of two or more chemically different layers of material.

3. Terminology

These materials may be organic or inorganic, or combinations

3.1 Definitions of Terms Specific to This Standard:

with various binders or impregnants. Gasket coatings are not

3.1.1 board—the term board is used in the context of a thick

covered since details thereof are intended to be given on

(generally greater than 1.52 mm (0.060 in.)) and rigid nonme-

engineering drawings, or as separate specifications. Commer-

tallic material often purchased in sheet or strip form.

cial materials designated as enveloped gaskets are excluded

from this classification; they are covered in Practice F336. 3.1.2 composite gasket material—a gasket structure com-

posed of two or more different materials joined together in flat,

1.2 Since all of the properties that contribute to gasket

parallel layers.

performance are not included, use of this classification as a

basis for selecting LCGM is limited.

4. Significance and Use

1.3 The values stated in SI units are to be regarded as the

4.1 This classification is intended to encourage uniformity

standard. The values given in parentheses are for information

in reporting properties; to provide a common language for

only.

communications between producers and users; to guide engi-

1.4 This standard does not purport to address all of the

neers and designers in the use, construction, and properties of

safety concerns, if any, associated with its use. It is the

commercially available materials; and to be versatile enough to

responsibility of the user of this standard to establish appro-

cover new materials and test methods as they are introduced.

priate safety and health practices and determine the applica-

5. Basis of Classification

bility of regulatory limitations prior to use.

5.1 This classification is based on the principle that LCGM

2. Referenced Documents

should be described, insofar as possible, in terms of use,

2.1 ASTM Standards:

composition, combining method, and specific physical and

A109/A109M Specification for Steel, Strip, Carbon (0.25

mechanical characteristics.Thus, users of gasket materials can,

Maximum Percent), Cold-Rolled

by selecting different combinations of materials and properties,

D2000 Classification System for Rubber Products in Auto-

define various parts. Suppliers, likewise, can report uses,

motive Applications

composition, and properties of available products.

F104 Classification System for Nonmetallic Gasket Materi-

6. Numbering System

als

F146 Test Methods for Fluid Resistance of Gasket Materials

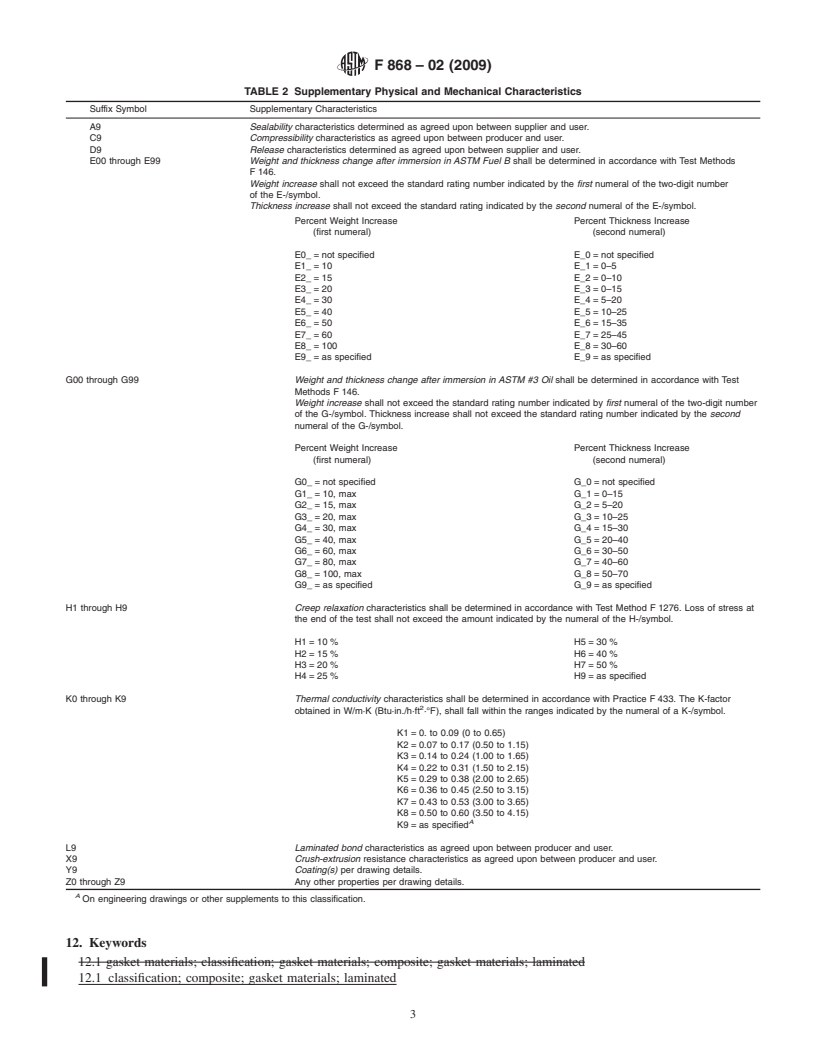

6.1 To permit line call-out of the description mentioned in

F336 Practice for Design and Construction of Nonmetallic

5.1, this classification establishes letter or number symbols to

Enveloped Gaskets for Corrosive Service

describe use, composition, and physical properties and perfor-

mance levels of certain properties.

6.2 In specifying or describing gasket materials, each line

This classification is under the jurisdiction of ASTM Committee F03 on

Gaskets and is the direct responsibility of Subcommittee F03.30 on Classification.

call-out shall include the number of this system and a number

Current edition approved May 1, 2009. Published May 2009. Originally

and letter series describing the use, composition, and combin-

approved in 1984. Last previous edition approved in 2002 as F868 – 02. DOI:

ing method plus suffix call-out, as shown in Table 1.

10.1520/F0868-02R09.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

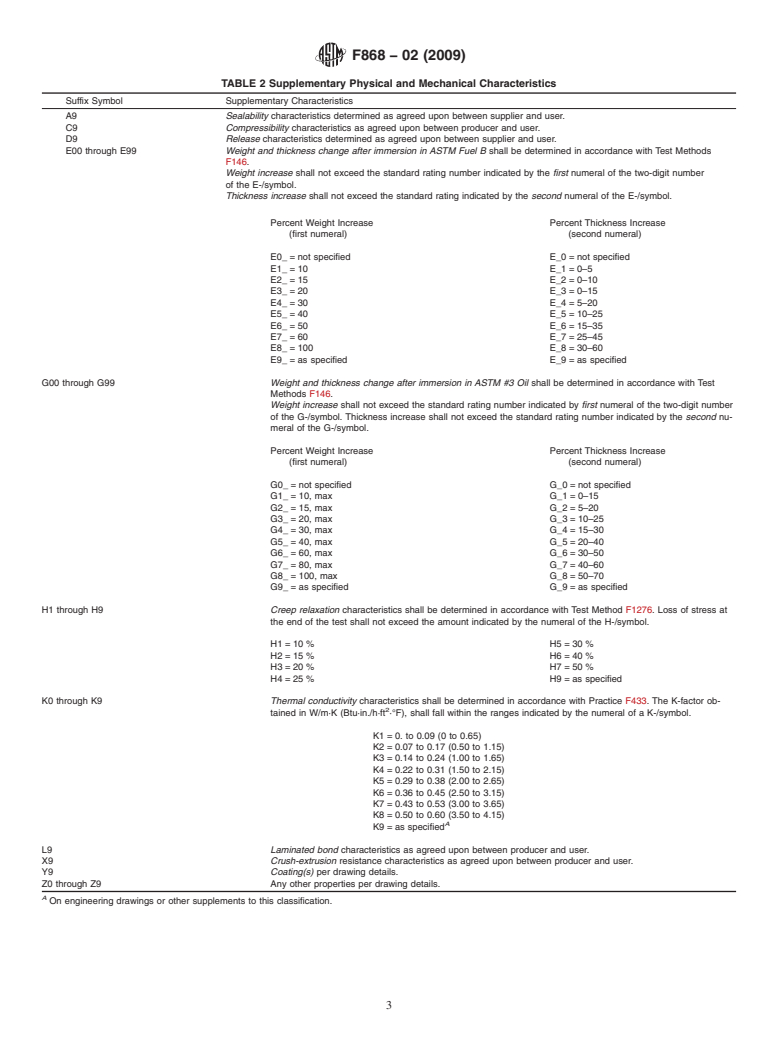

6.3 To further specify or describe gasket materials, each line

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

call-out may include one or more suffix letter-numeral

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. symbols, as listed in Table 2.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F868−02 (2009)

7. Physical and Mechanical Properties 10. Conditioning

7.1 Gasket materials identified by this classification shall

10.1 Prior to all tests, specimens shall be conditioned as

have a number and letter call-out for end-use and construction

follows:

indicated in Table 1 and additional properties by a letter-

10.1.1 When all Classification F104 layers of the composite

numeral call-out shown in Table 2.

are of the same “type,” condition per that type.

8. Thickness Requirements

10.1.2 When the layers of the composite are of different

ClassificationF104“types,”thecompositeshallbeconditioned

8.1 Gasket materials identified by this classification shall

22 h in a controlled humidity room, or in

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation:F868–91(Reapproved 1997) Designation: F 868 – 02 (Reapproved 2009)

Standard Classification for

Laminated Composite Gasket Materials

This standard is issued under the fixed designation F 868; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

´ NOTE—Section 11 was corrected editorially in March 1997.

1. Scope

1.1 Thisclassificationcoversameansforspecifyingordescribingpertinentpropertiesofcommerciallaminatecompositegasket

materials (LCGM). These structures are composed of two or more chemically different layers of material. These materials may be

organic or inorganic, or combinations with various binders or impregnants. Gasket coatings are not covered since details thereof

are intended to be given on engineering drawings, or as separate specifications. Commercial materials designated as enveloped

gaskets are excluded from this classification; they are covered in Practice F 336.

1.2 Since all of the properties that contribute to gasket performance are not included, use of this classification as a basis for

selecting LCGM is limited.

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

A109Specification for Steel, Strip, Carbon, Cold-Rolled 109/A 109M Specification for Steel, Strip, Carbon (0.25 Maximum

Percent), Cold-Rolled

D 2000 Classification System for Rubber Products in Automotive Applications

F 104 Classification System for Nonmetallic Gasket Materials

F 146 Test Methods for Fluid Resistance of Gasket Materials

F 336 Practice for Design and Construction of Nonmetallic Enveloped Gaskets for Corrosive Service

F 433 Practice for Evaluating Thermal Conductivity of Gasket Materials

F 1276 Test Method for Creep Relaxation of Laminated Composite Gasket Materials

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

3.1.1 board—the term board is used in the context of a thick (generally greater than 1.52 mm (0.060 in.)) and rigid nonmetallic

material often purchased in sheet or strip form.

3.1.2 composite gasket material—a gasket structure composed of two or more different materials joined together in flat, parallel

layers.

4. Significance and Use

4.1 This classification is intended to encourage uniformity in reporting properties; to provide a common language for

communications between producers and users; to guide engineers and designers in the use, construction, and properties of

commercially available materials; and to be versatile enough to cover new materials and test methods as they are introduced.

5. Basis of Classification

5.1 This classification is based on the principle that LCGM should be described, insofar as possible, in terms of use,

This classification is under the jurisdiction of ASTM Committee F-3 on Gaskets and is the direct responsibility of Subcommittee F03.10 on Composite Gaskets.

Current edition approved Aug. 15, 1991. Published October 1991. Originally published as F868–84. Last previous edition F868–88.F03 on Gaskets and is the direct

responsibility of Subcommittee F03.30 on Classification.

Current edition approved May 1, 2009. Published May 2009. Originally approved in 1984. Last previous edition approved in 2002 as F 868 – 02.

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

, Vol 01.03.volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F 868 – 02 (2009)

composition, combining method, and specific physical and mechanical characteristics. Thus, users of gasket materials can, by

selecting different combinations of materials and properties, define various parts. Suppliers, likewise, can report uses, composition,

and properties of available products.

6. Numbering System

6.1 To permit line call-out of the description mentioned in 5.1, this classification establishes letter or number symbols to

describe use, composition, and physical properties and performance levels of certain properties.

6.2 In specifying or describing gasket materials, each line call-out shall include the number of this system and a number and

letter series describing the use, composition, and combining method plus suffix call-out, as shown in Table 1.

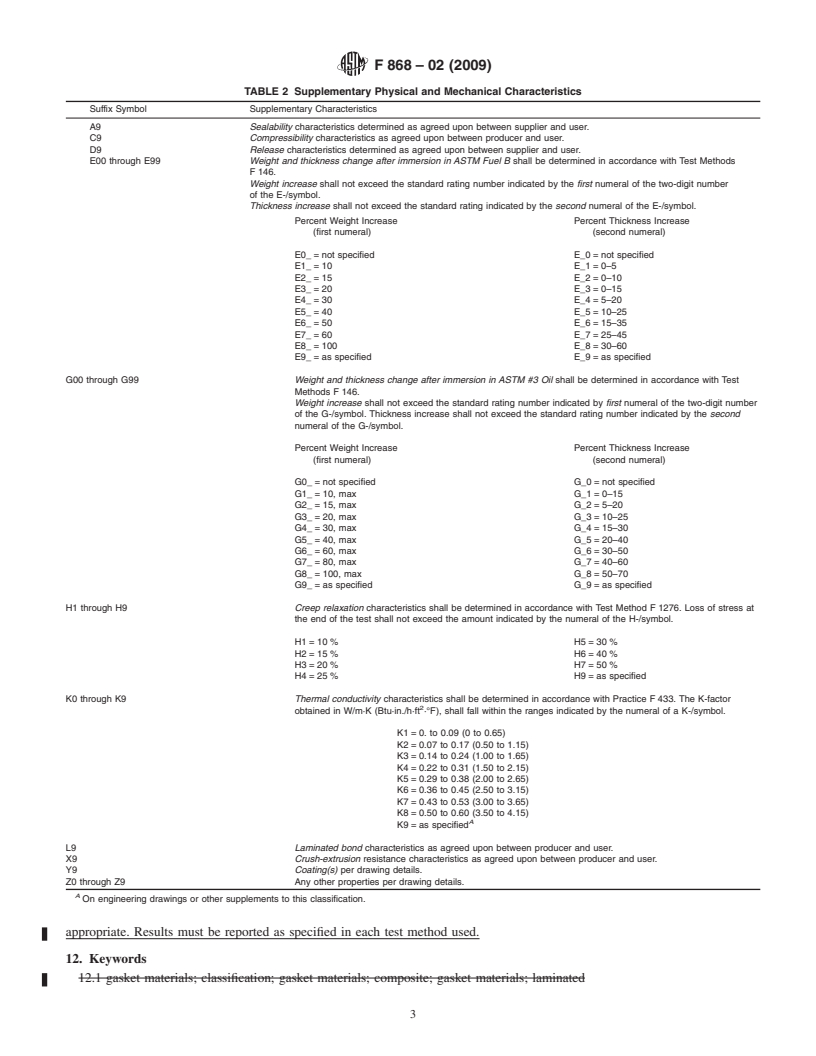

6.3 To further specify or describe gasket materials, each line call-out may include one or more suffix letter-numeral symbols,

as listed in Table 2.

7. Physical and Mechanical Properties

7.1 Gasket materials identified by this classification shall have a number and letter call-out for end-use and construction

indicated in Table 1 and additional properties by a letter-numeral call-out shown in Table 2.

8. Thickness Requirements

8.1 Gasket materials identified by this classification shall conform to

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:F868–02 Designation: F 868 – 02 (Reapproved 2009)

Standard Classification for

Laminated Composite Gasket Materials

This standard is issued under the fixed designation F 868; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 Thisclassificationcoversameansforspecifyingordescribingpertinentpropertiesofcommerciallaminatecompositegasket

materials (LCGM). These structures are composed of two or more chemically different layers of material. These materials may be

organic or inorganic, or combinations with various binders or impregnants. Gasket coatings are not covered since details thereof

are intended to be given on engineering drawings, or as separate specifications. Commercial materials designated as enveloped

gaskets are excluded from this classification; they are covered in Practice F 336.

1.2 Since all of the properties that contribute to gasket performance are not included, use of this classification as a basis for

selecting LCGM is limited.

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

A 109/A 109M Specification for Steel, Strip, Carbon (0.25 Maximum Percent), Cold-Rolled

D 2000 Classification System for Rubber Products in Automotive Applications

F 104 Classification System for Nonmetallic Gasket Materials

F 146 Test Methods for Fluid Resistance of Gasket Materials

F 336 Practice for Design and Construction of Nonmetallic Enveloped Gaskets for Corrosive Service

F 433 Practice for Evaluating Thermal Conductivity of Gasket Materials

F 1276 Test Method for Creep Relaxation of Laminated Composite Gasket Materials

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

3.1.1 board—the term board is used in the context of a thick (generally greater than 1.52 mm (0.060 in.)) and rigid nonmetallic

material often purchased in sheet or strip form.

3.1.2 composite gasket material—a gasket structure composed of two or more different materials joined together in flat, parallel

layers.

4. Significance and Use

4.1 This classification is intended to encourage uniformity in reporting properties; to provide a common language for

communications between producers and users; to guide engineers and designers in the use, construction, and properties of

commercially available materials; and to be versatile enough to cover new materials and test methods as they are introduced.

5. Basis of Classification

5.1 This classification is based on the principle that LCGM should be described, insofar as possible, in terms of use,

composition, combining method, and specific physical and mechanical characteristics. Thus, users of gasket materials can, by

selecting different combinations of materials and properties, define various parts. Suppliers, likewise, can report uses, composition,

and properties of available products.

This classification is under the jurisdiction of ASTM Committee F03 on Gaskets and is the direct responsibility of Subcommittee F03.10 on Composite Gaskets.

´1

Current edition approved October 10, 2002. Published October 2002. Originally published as F868–84. Last previous edition F868–91(1997) .on Gaskets and is the direct

responsibility of Subcommittee F03.30 on Classification.

Current edition approved May 1, 2009. Published May 2009. Originally approved in 1984. Last previous edition approved in 2002 as F 868 – 02.

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

, Vol 01.03.volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F 868 – 02 (2009)

6. Numbering System

6.1 To permit line call-out of the description mentioned in 5.1, this classification establishes letter or number symbols to

describe use, composition, and physical properties and performance levels of certain properties.

6.2 In specifying or describing gasket materials, each line call-out shall include the number of this system and a number and

letter series describing the use, composition, and combining method plus suffix call-out, as shown in Table 1.

6.3 To further specify or describe gasket materials, each line call-out may include one or more suffix letter-numeral symbols,

as listed in Table 2.

7. Physical and Mechanical Properties

7.1 Gasket materials identified by this classification shall have a number and letter call-out for end-use and construction

indicated in Table 1 and additional properties by a letter-numeral call-out shown in Table 2.

8. Thickness Requirements

8.1 Gasket materials identified by this classification shall conform to the thickness specified on the gasket dra

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.