ASTM F2302-03

(Specification)Standard Performance Specification for Labeling Protective Clothing as Heat and Flame Resistant

Standard Performance Specification for Labeling Protective Clothing as Heat and Flame Resistant

SCOPE

1.1 This specification provides minimum requirements for labeling protective clothing as heat and flame resistant for applications where the potential for flame contact or high heat exposure exist.

1.1.1 This specification includes requirements that define heat and flame resistance of materials used in protective clothing in a manner to limit the contribution of the clothing for causing injury to the wearer when exposed to high heat or flame.

1.1.2 This specification does not provide requirements that establish the level of protection provided by the clothing.

1.1.3 This specification does not include testing for the evaluation of the entire clothing item.

1.2 This specification does not pertain to materials and clothing that are addressed in other standards. See Appendix X1 for a list of standards for heat and flame resistant protective clothing.

1.3 This specification does not pertain to applications where the conditions of potential flame contact or heat exposure are of an extended duration and/or are of a high intensity.

Note 1—Examples include fire fighting applications, exposure to high energy electrical arcs and exposures in flash fires.

1.4 The values stated in SI units or in other units shall be regarded separately as standard. The values stated in each system must be used independently of the other, without combining values in any way.

1.5 This standard measures and describes the response of materials, products, or assemblies to heat and flame under controlled conditions, but does not by itself incorporate all factors required for fire hazard or fire risk assessment of the materials, products, or assemblies under actual fire conditions.

1.6 The following precautionary caveat pertains only to the test methods portion, Section 8, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F 2302 – 03

Standard Performance Specification for

Labeling Protective Clothing as Heat and Flame Resistant

This standard is issued under the fixed designation F 2302; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

1.1 This specification provides minimum requirements for 2.1 ASTM Standards:

labeling protective clothing as heat and flame resistant for D 123 Terminology Related to Textiles

applications where the potential for flame contact or high heat D 4391 Terminology Relating to the Burning Behavior of

exposure exist. Textiles

1.1.1 This specification includes requirements that define D 6413 Test Method for Flame Resistance of Textiles (Ver-

heat and flame resistance of materials used in protective tical Test)

clothinginamannertolimitthecontributionoftheclothingfor E 171 Specification for Standard Atmospheres for Condi-

causing injury to the wearer when exposed to high heat or tioning and Testing Materials

flame. F 1358 Test Method for Effects of Flame Impingement on

1.1.2 This specification does not provide requirements that Materials Used in Protective Clothing Not Designated

establish the level of protection provided by the clothing. Primarily for Flame Resistance

1.1.3 This specification does not include testing for the F 1494 Terminology Relating to Protective Clothing

evaluation of the entire clothing item. 2.2 AATCC Standards:

1.2 This specification does not pertain to materials and AATCC 132 Colorfastness to Drycleaning

clothing that are addressed in other standards. See Appendix AATCC 135 Dimensional Changes in Automatic Home

X1 for a list of standards for heat and flame resistant protective Laundering of Woven and Knit Fabrics

clothing. 2.3 ISO Standards:

1.3 This specification does not pertain to applications where ISO 17493 Clothing for protection against heat and flame—

theconditionsofpotentialflamecontactorheatexposureareof Test method for convective heat resistance using a hot air

an extended duration and/or are of a high intensity. circulating oven

NOTE 1—Examples include fire fighting applications, exposure to high

3. Terminology

energy electrical arcs and exposures in flash fires.

3.1 Definitions—For definitions of terms used in this speci-

1.4 The values stated in SI units or in other units shall be

fication, related to the combustion of textiles, refer to the

regarded separately as standard. The values stated in each

terminology contained in Terminology D 4391. For definitions

system must be used independently of the other, without

of terms used in this test method, related to protective clothing,

combining values in any way.

refer to the terminology contained in Terminology F 1494. For

1.5 This standard measures and describes the response of

definitions of terms used in this test method, related to textile

materials, products, or assemblies to heat and flame under

issues, refer to the terminology contained in Terminology

controlled conditions, but does not by itself incorporate all

D 123.

factors required for fire hazard or fire risk assessment of the

3.2 afterflame, n—persistent flaming of a material after the

materials, products, or assemblies under actual fire conditions.

ignition source has been removed.

1.6 The following precautionary caveat pertains only to the

3.3 afterflame time, n—the length of time for which a

test methods portion, Section 8, of this specification: This

material continued to flame after the ignition source has been

standard does not purport to address all of the safety concerns,

removed.

if any, associated with its use. It is the responsibility of the user

of this standard to establish appropriate safety and health

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

practices and determine the applicability of regulatory limita-

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

tions prior to use.

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

Available from American Association of Textile Chemists and Colorists

This specification is under the jurisdiction of ASTM Committee F23 on (AATCC), One Davis Dr., P.O. Box 12215, Research Triangle Park, NC 27709-

Protective Clothing and is the direct responsibility of Subcommittee F23.80 on 2215.

Flame and Thermal. Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

Current edition approved June 10, 2003. Published August 2003. 4th Floor, New York, NY 10036.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F2302–03

3.4 afterglow, n—a glow in a material after the removal of 3.16.1 Discussion—Although a solid may glow, it can also

an external ignition source and after the cessation (natural or produce combustible discharge that will cause a flame. These

induced) of flaming of the material (see also glow) two phenomena are not necessarily interdependent.

3.17 heat resistance, n—the extent to which a material

3.5 burning behavior, n—all the changes that take place

retains useful properties as measured after exposure of the

when materials or products are exposed to a specified ignition

material to a specified temperature and environment for a

source.

specified time.

3.6 burn distance, n—the measurement from the bottom

3.17.1 Discussion—In this specification, heat resistance or

edge of the specimen to the farthest point that shows evidence

the heat stability of the material is demonstrated by testing in

of damage due to combustion.

accordance with ISO 14793 at a temperature of 260°C [500°F]

3.6.1 Discussion—In this specification, burn distance is

for five minutes without ignition, melting, dripping, or separa-

used when testing is performed in accordance with Test

tionofthematerialandwithoutmaterialshrinkagegreaterthan

Method F 1358.

10 %.

3.7 char length, n—in measuring flame resistance of tex-

3.18 ignition, n—the initiation of combustion.

tiles, the distance from the fabric edge, which is directly

3.18.1 Discussion—In evaluating the effects of flame con-

exposed to the flame to the furthest point of visible fabric

tact or heat exposure of materials used in protective clothing,

damage after a specified tearing force has been applied.

ignition is determined by the presence of afterflame after the

3.7.1 Discussion—In this specification, char length is re-

removaloftheburnerflameorwhenobservingtheconditionof

ported when testing is performed in accordance with Test

the specimen(s) inside the oven after opening the oven door.

Method D 6413.

3.19 melting, n—in testing thermal protective clothing, a

3.8 charring, n—the formation of carbonaceous residue as response to heat by a material resulting in evidence of flowing

the result of pyrolysis or incomplete combustion. or dripping.

3.19.1 Discussion—In evaluating the effects of flame con-

3.9 combustion, n—a chemical process of oxidation that

tact or heat exposure of materials used in protective clothing,

occurs at a rate fast enough to produce heat and usually light

melting may occur at surface layers or in combination with the

either as glow or flames.

substrate fabric(s) or other polymer layers. Melting may be

3.10 dripping, n—in testing thermal protective clothing, a

observed for protective clothing materials that involve a

material response as evidenced by flowing of the polymer.

polymer coating or laminate combined with a flame-resistant

3.10.1 Discussion—In evaluating the effects of flame con-

fabric or substrate.

tact or heat exposure of materials used in protective clothing,

3.20 protective clothing, n—a product which is specifically

dripping may be the formation of liquid droplets from melted

designed and constructed for the intended purpose of isolating

surface or substrate material during flame impingement or high

parts of the body from a potential hazard; or as a barrier to

heat exposure.

prevent the body from being a source of contamination.

3.11 embrittlement, n—the formation of a brittle residue as

3.21 separation, n—in testing thermal protective clothing,

the result of pyrolysis or incomplete combustion.

the partial of full detachment of one or more layers comprising

3.12 flame, n—as related to ignition of textiles, a controlled

a material

hot luminous zone of gas or matter in gaseous suspension, or

3.21.1 Discussion—In evaluating the effects of heat expo-

both, of constant size and shape that is undergoing combustion

sure, separation occurs when the face cloth detaches from the

as evidenced by a low-intensity, heat source of less than 1 kW,

batting for quilted material or if a film or coating lifts from a

such as a candle flame or match flame.

substrate fabric.

3.12.1 Discussion—Examples are flames from a match, 3.22 shrinkage, n—a decrease in one or more dimensions of

candle, or bunsen burner. The burner flame in this test method an object or material.

produces relatively low heat flux and should be constant in. 3.22.1 Discussion—In evaluating the effects of flame con-

size and shape. tact or heat exposure, these changes in dimensions are caused

by heat from the flame source or convection within the oven.

3.13 flame application time, n—the time interval for which

the ignition flame is applied to a material.

4. Significance and Use

3.14 flame resistance, n—the property of a material

4.1 This specification is used to establish the minimum

whereby flaming combustion is prevented, terminated, or

requirements for labeling protective clothing as heat and flame

inhibited following application of a flaming or nonflaming

resistant. Testing is performed on the product in both an “as

source of ignition, with or without the subsequent removal of

received” condition and after ten laundering or dry cleaning

the ignition source.

cycles using standardized procedures. Users of this specifica-

3.14.1 Discussion—In this specification, flame resistance is

tion are also permitted to use laundering or dry cleaning

demonstratedbytestingtoTestMethodD 6413orTestMethod

procedures for conditioning samples as specified in the manu-

F 1358 and meeting specific performance criteria.

facturer’s care instructions for a minimum of ten cycles.

3.15 flammability, n—thosecharacteristicsofamaterialthat

4.2 This specification is not intended to replace standards

pertain to its ignition and support of combustion.

that have already been developed for specific types of flame

3.16 glow, n—visible, flameless combustion of the solid and heat resistant protective clothing, including clothing for

phase of a material. protection from flash fire, clothing for protection against

F2302–03

electricarc,andprotectiveclothingforvariousfirefightingand testing. For disposable protective clothing or protective cloth-

emergencyresponseapplications.SeeAppendixX1foralistof ing intended only for a single use, do not launder or dry clean.

specifications for specific types of heat and flame resistant For protective clothing indicated or labeled as washable,

protective clothing. subject material samples to room temperature and laundering

4.3 This specification does not address all areas of protec- conditioning, specified in 7.2 and 7.3, respectively. For protec-

tive clothing performance for heat and flame exposure. For tive clothing indicated or labeled as dry clean only, subject

example,thespecificationdoesnotaddressinsulationprovided material specimens to room temperature and dry cleaning

by these garments. Rather this specification is designed to conditioning, specified in 7.2 and 7.4, respectively. For protec-

provide an assessment of the potential of the clothing itself to tiveclothingindicatedorlabeledforwashinganddrycleaning,

become a hazard to the wearer if exposed to flame and high subject separate material samples to room temperature, laun-

heat. dering,anddrycleaningconditioning,specifiedin7.2,7.3,and

4.4 Thisspecificationdoesnotprovideanoverallevaluation 7.4, respectively.

of the clothing’s flame or heat resistance. Instead, heat and 7.2 Room Temperature Conditioning—Condition garment

flame resistance tests of the primary materials used in the or material samples at a temperature of 21 6 3°C [70 6 5°F]

constructionoftheclothingareusedtoassessclothingheatand and at a relative humidity of 65 6 5 % for at least 24 h in

flame resistance. This specification permits excluding testing accordance with Specification E 171.

of clothing components that are not in direct contact with the 7.3 Laundering Conditioning—Launder garment or mate-

body during normal wearing. Therefore, it is important that rial samples in accordance with AATCC 135 using Machine

users of this specification recognize that certain components, Cycle 1, Washing Temperature III, and Drying Procedure Ai

based on their composition, size, and location could contribute for a total of ten cycles. It shall also be permitted to launder

to burn injury in the event of a high heat or flame exposure. garment or materials samples in accordance with the care

instructions provided with the garment for at least ten launder-

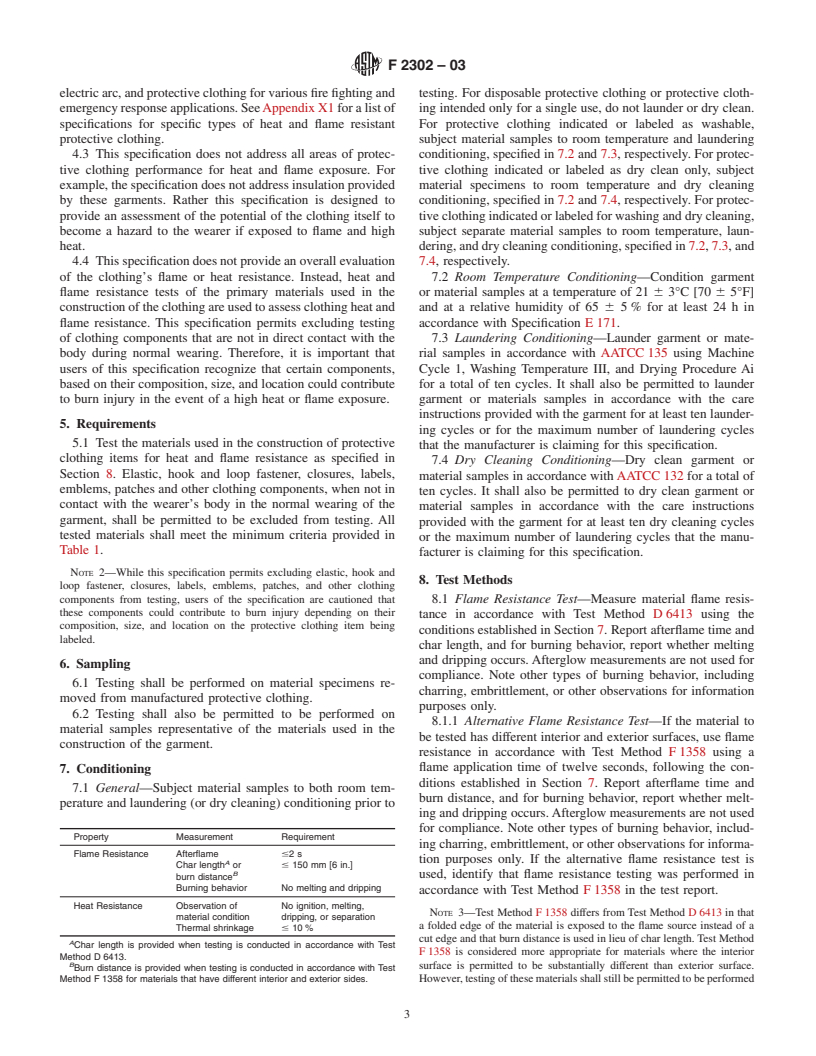

5. Requirements

ing cycles or for the maximum number of laundering cycles

5.1 Test the materials used in the construction of protective

that the manufacturer is claiming for this specification.

clothing items for heat and flame resistance as specified in

7.4 Dry Cleaning Conditioning—Dry clean garment or

Section 8. Elastic, hook and loop fastener, closures, labels,

material samples in accordance withAATCC 132 for a total of

emblems, patches and other clothing components, when not in

ten cycles. It shall also be permitted to dry clean garment or

contact with the wearer’s body in the normal wearing of the

material samples in accordance with the care instructions

garment, shall be permitted to be excluded from testing. All

provided with the garment for at least ten dry cleaning cycles

tested materials shall meet the minimum criteria provided in

or the maximum number of laundering cycles that the manu-

Table 1.

facturer is claiming for this specification.

NOTE 2—While this specification permits excluding elastic, hook and

8. Test Methods

loop fastener, closures, labels, emblems, patches, and other clothing

components from testing, users of the specification are cautioned that 8.1 Flame Resistance Test—Measure material flame resis-

these components could contribute to burn injury depending on their

tance in accordance with Test Method D 6413 using the

composition, size, and location on the protective clothing item being

conditions established in Section 7. Report afterflame time and

labeled.

char leng

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.