ASTM D3144-21

(Specification)Standard Specification for Crosslinked Poly(Vinylidene Fluoride) Heat-Shrinkable Tubing for Electrical Insulation

Standard Specification for Crosslinked Poly(Vinylidene Fluoride) Heat-Shrinkable Tubing for Electrical Insulation

ABSTRACT

This specification covers semirigid, flame-retardant, crosslinked poly(vinylidene fluoride) heat-shrinkable tubing for electrical insulation purposes. It is supplied in an expanded form and will shrink to its extruded diameter when heated. The tubing shall be extruded, crosslinked, and then expanded to the required dimensions. The material shall conform to the chemical property requirements specified. Every lot of material manufactured shall be tested for restricted shrinkage, heat shock, tensile strength, and elongation to conform to the mechanical, thermal, electrical requirements.

SCOPE

1.1 This specification covers semirigid, flame-retardant, crosslinked poly(vinylidene fluoride) heat-shrinkable tubing for electrical insulation purposes. It is supplied in an expanded form and will shrink to its extruded diameter when heated.

Note 1: This standard is similar but not identical to IEC 60684–3–228.

1.2 The values stated in inch-pound units are to be regarded as the standard, except temperature which shall be stated in degrees Celsius. Values in parentheses are for information only.

1.3 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D3144 − 21

Standard Specification for

Crosslinked Poly(Vinylidene Fluoride) Heat-Shrinkable

1

Tubing for Electrical Insulation

This standard is issued under the fixed designation D3144; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope MIL-T-5624 Turbine Fuel, Aviation, Grades JP-4 and JP-5

MIL-L-7808 Lubrication Oil, Aircraft, Turbine Engine, Syn-

1.1 This specification covers semirigid, flame-retardant,

thetic Base

crosslinked poly(vinylidene fluoride) heat-shrinkable tubing

MIL-L-23699 Lubrication Oil, Aircraft, Turbine Engines,

for electrical insulation purposes. It is supplied in an expanded

Synthetic Base

form and will shrink to its extruded diameter when heated.

MIL-A-8243 Anti-Icing and Deicing—Defrosting Fluid

4

NOTE 1—This standard is similar but not identical to IEC 60684–3–228.

2.3 Federal Standards:

1.2 The values stated in inch-pound units are to be regarded

SS-S-550 Sodium Chloride, Technical, for Water-Softening

as the standard, except temperature which shall be stated in Units

5

degrees Celsius. Values in parentheses are for information only.

2.4 IEC Standard:

IEC 60684-3-228 Flexible insulating sleeving, Part 3, Sheet

1.3 This international standard was developed in accor-

228: Heat-shrinkable, semi-rigid, polyvinylidene fluoride

dance with internationally recognized principles on standard-

sleeving, flame retarded, fluid resistant, shrink ratio 2:1

ization established in the Decision on Principles for the

Development of International Standards, Guides and Recom-

3. Terminology

mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee. 3.1 Definitions:

3.1.1 For definitions pertaining to electrical insulation, refer

2. Referenced Documents

to Terminology D1711.

2

3.1.2 For definitions pertaining to fire standards, refer to

2.1 ASTM Standards:

Terminology E176.

D910 Specification for Leaded Aviation Gasolines

D1711 Terminology Relating to Electrical Insulation

4. Ordering Information

D2671 Test Methods for Heat-Shrinkable Tubing for Elec-

trical Use 4.1 When tubings are ordered to this specification, it is up to

the purchaser to define the size and color of the required

D3636 Practice for Sampling and Judging Quality of Solid

tubing.

Electrical Insulating Materials

D8355 Test Methods for Flammability of Electrical Insulat-

5. Materials and Manufacture

ing Materials Used for Sleeving or Tubing

E176 Terminology of Fire Standards 5.1 The compound used in the manufacture of heat-

3

shrinkable tubing shall be modified poly(vinylidene fluoride),

2.2 Military Standards:

and the finished compound shall be free of all foreign matter

MIL-H-5606 Hydraulic Fluid, Petroleum Base, Aircraft,

other than intended formulation additives as appropriate.

Missile and Ordinance

5.2 The tubing shall be extruded, crosslinked, and then

expanded to the required dimensions.

1

This specification is under the jurisdiction of ASTM Committee D09 on

Electrical and Electronic Insulating Materials and is the direct responsibility of

6. Chemical Property Requirements

Subcommittee D09.07 on Electrical Insulating Materials.

Current edition approved Jan. 1, 2021. Published February 2021. Originally

6.1 The material shall conform to the chemical property

ε1

approved in 1973. Last previous edition approved in 2013 as D3144 – 00 (2013) .

requirements specified in Table 1.

DOI: 10.1520/D3144-21.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

4

Standards volume information, refer to the standard’s Document Summary page on Available from U. S. Government Accountability Office (GAO), 441 G St., NW,

the ASTM website. Washington, DC 20548, http://www.gao.gov.

3 5

Available from Standardization Documents Order Desk, Bldg. 4 Section D, 700 Available from American National Standards Institute (ANSI), 25 W. 43rd St.,

Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS. 4th Floor, New York, NY 10036, http://www.ansi.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

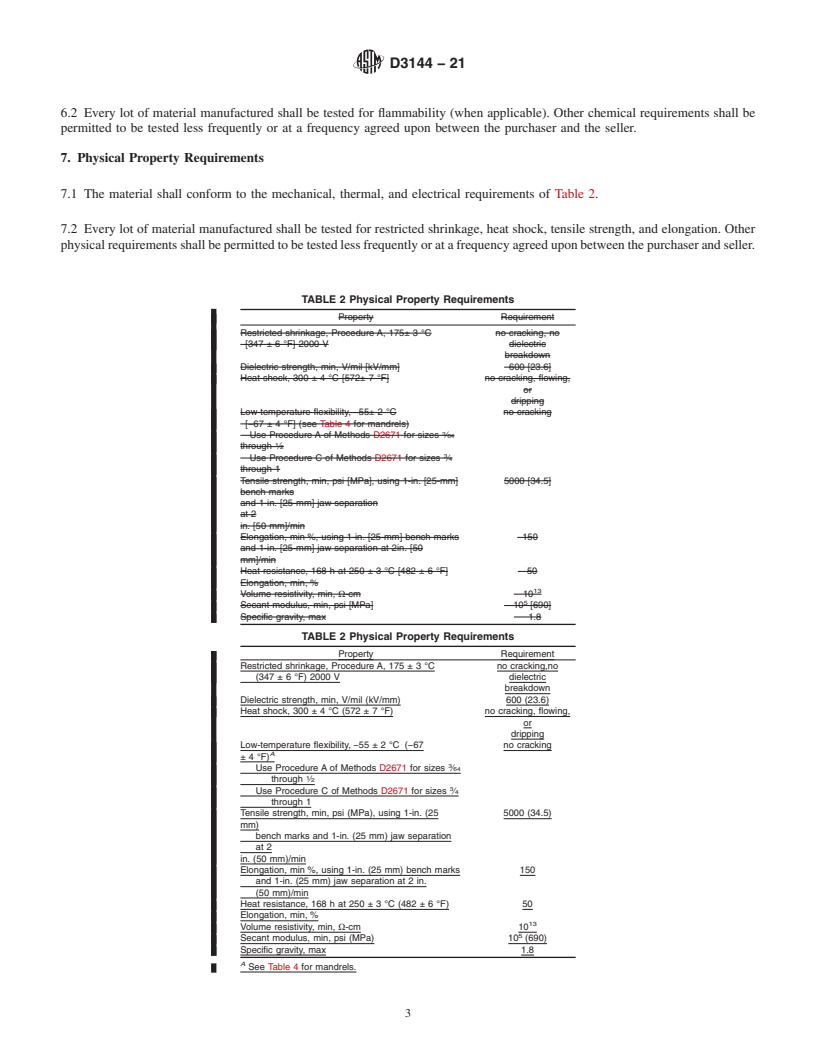

D3144 − 21

TABLE 1 Chemical Property Requirements

thickness equals or exceeds that of the identical or next largest

Property Requirement nominal size. The wall for sizes greater than 1 in. shall be at

Fluid resistance, 24 h at 23 ± 3 °C (73 ± 6 °F) least as thick as that of the 1 in. size.

JP-4 fuel, MIL-T-5624

Lubricating oil, MIL-L-7808

9. Workmanship

Lubricating oil, MIL-L-23699

Hyd

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation: D3144 − 00 (Reapproved 2013) D3144 − 21

Standard Specification for

Crosslinked Poly(Vinylidene Fluoride) Heat-Shrinkable

1

Tubing for Electrical Insulation

This standard is issued under the fixed designation D3144; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1

ε NOTE—Editorial changes were made throughout in January 2013.

1. Scope

1.1 This specification covers semirigid, flame-retardant, crosslinked poly(vinylidene fluoride) heat-shrinkable tubing for electrical

insulation purposes. It is supplied in an expanded form and will shrink to its extruded diameter when heated.

NOTE 1—This standard is similar but not identical to IEC 60684–3–228.

1.2 The values stated in inch-pound units are to be regarded as the standard, except temperature which shall be stated in degrees

Celsius. Values in parentheses are for information only.

1.3 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

D910 Specification for Leaded Aviation Gasolines

D1711 Terminology Relating to Electrical Insulation

D2671 Test Methods for Heat-Shrinkable Tubing for Electrical Use

D3636 Practice for Sampling and Judging Quality of Solid Electrical Insulating Materials

D8355 Test Methods for Flammability of Electrical Insulating Materials Used for Sleeving or Tubing

E176 Terminology of Fire Standards

3

2.2 Military Standards:

MIL-H-5606 Hydraulic Fluid, Petroleum Base, Aircraft, Missile and Ordinance

MIL-T-5624 Turbine Fuel, Aviation, Grades JP-4 and JP-5

MIL-L-7808 Lubrication Oil, Aircraft, Turbine Engine, Synthetic Base

MIL-L-23699 Lubrication Oil, Aircraft, Turbine Engines, Synthetic Base

MIL-A-8243 Anti-Icing and Deicing—Defrosting Fluid

1

This specification is under the jurisdiction of ASTM Committee D09 on Electrical and Electronic Insulating Materials and is the direct responsibility of Subcommittee

D09.07 on Flexible and Rigid Electrical Insulating Materials.

Current edition approved Jan. 15, 2013Jan. 1, 2021. Published February 2013February 2021. Originally approved in 1973. Last previous edition approved in 20062013

ε1

as D3144 – 06.D3144 – 00 (2013) . DOI: 10.1520/D3144-00R13E01.10.1520/D3144-21.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from Standardization Documents Order Desk, Bldg. 4 Section D, 700 Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D3144 − 21

4

2.3 Federal Standards:

SS-S-550 Sodium Chloride, Technical, for Water-Softening Units

5

2.4 IEC Standards:Standard:

60684–3–228IEC 60684-3-228 Flexible insulating sleeving, Part 3, Sheet 228: Heat-shrinkable, semi-rigid, polyvinylidene

fluoride sleeving, flame retarded, fluid resistant, shrink ratio 2:1

3. Terminology

3.1 Definitions:

3.1.1 For definitions pertaining to electrical insulation, refer to Terminology D1711.

3.1.2 For definitions pertaining to fire standards, refer to Terminology E176.

3.1 Definitions:

3.1.1 For definitions pertaining to electrical insulation, refer to Terminology D1711.

3.1.2 For definitions pertaining to fire standards, refer to Terminology E176.

4. Ordering Information

4.1 When tubings are ordered to this specification, it is up to the purchaser to define the size and color of the required tubing.

5. Materials and Manufacture

5.1 The compound used in the manufacture of heat-shrinkable tubing shall be modified poly(vinylidene fluoride), and the finished

compound shall be free of all foreign matter other than intended formulation additives as appropriate.

5.2 The tubing shall be extruded, crosslinked, and then expanded to the required dimensions.

6. Chemical Property Requirements

6.1 The material shall conform to the chemical property requirements specified in Table 1.

TA

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.