ASTM D4317-98(2011)

(Specification)Standard Specification for Polyvinyl Acetate-Based Emulsion Adhesives

Standard Specification for Polyvinyl Acetate-Based Emulsion Adhesives

ABSTRACT

This specification covers polyvinyl acetate or polyvinyl acetate copolymer resin emulsion adhesives suitable for use on wood, wood-based substrates, or plastic laminates. This does not cover the group of polyvinyl-based adhesives suitable for bonding flexible films. Adhesives are classified on the basis of water resistance at three performance levels, namely wet-use (Type 1), intermediate use (Type 2), and dry-use (Type 3). Adhesives shall conform to test requirements as performed under the following exposure conditions and treatments: dry shear at specified temperatures; two-cycle boil; 48-hour soak; humidity exposure; freeze-thaw stability; and storage life. Materials shall also adhere to physical properties such as density, nonvolatile matter, and pH.

SCOPE

1.1 This specification covers polyvinyl acetate or polyvinyl acetate copolymer resin emulsion adhesives suitable for use on wood, wood-based substrates, or plastic laminates. It does not cover the group of polyvinyl-based adhesives which are suitable for bonding flexible films.

1.2 The adhesives are classified at three performance levels in accordance with water-resistance as shown in Table 1 and Table 2. See Section 5 for a description of the expected exposure conditions for each class of adhesive. See Table X1.1 for a classification of typical end products that are manufactured using adhesives at the three performance levels covered by this specification.

1.3 The following index is provided as a guide to the test methods portion of this specification:

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D4317 −98(Reapproved2011)

Standard Specification for

Polyvinyl Acetate-Based Emulsion Adhesives

This standard is issued under the fixed designation D4317; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

INTRODUCTION

This specification is a replacement for Federal Specification MMM-A-180C, Class B, August 6,

1979,Adhesive,VinylAcetate Resin Emulsion, which superseded MMM-A-193C, October 26, 1967.

Ithasbeenexpandedtoincludethemorewater-resistantpolyvinylacetate-basedadhesivesnowonthe

market, in addition to the less water-resistant ones formerly covered by the Federal Specification.

1. Scope concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and

1.1 This specification covers polyvinyl acetate or polyvinyl

health practices and determine the applicability of regulatory

acetatecopolymerresinemulsionadhesivessuitableforuseon

limitations prior to use.

wood, wood-based substrates, or plastic laminates. It does not

cover the group of polyvinyl-based adhesives which are

2. Referenced Documents

suitable for bonding flexible films.

2.1 ASTM Standards:

1.2 The adhesives are classified at three performance levels

D905Test Method for Strength Properties of Adhesive

in accordance with water-resistance as shown in Table 1 and

Bonds in Shear by Compression Loading

Table 2. See Section 5 for a description of the expected

D906Test Method for Strength Properties of Adhesives in

exposureconditionsforeachclassofadhesive.SeeTableX1.1

Plywood Type Construction in Shear by Tension Loading

for a classification of typical end products that are manufac-

D907Terminology of Adhesives

tured using adhesives at the three performance levels covered

D1084Test Methods for Viscosity of Adhesives

by this specification.

D1490Test Method for Nonvolatile Content of Urea-

1.3 The following index is provided as a guide to the test Formaldehyde Resin Solutions

methods portion of this specification: D1875Test Method for Density ofAdhesives in Fluid Form

D2556Test Method for Apparent Viscosity of Adhesives

Section

Tests for Physical Properties 9

Having Shear-Rate-Dependent Flow Properties

Viscosity 9.1.1

E4Practices for Force Verification of Testing Machines

Density 9.1.2

E70Test Method for pH of Aqueous Solutions With the

Nonvolatiles 9.1.3

pH 9.1.4

Glass Electrode

Tests for Adhesive Bond 10

2.2 Federal Standards:

Block Shear Strength, Compression 10.2

Fed. Std. No. 123Marking for Shipment (Civil Agencies)

Plywood Shear Tests 10.3

PPP-C-96Cans, Metal, 28-Gauge and Lighter

1.4 The values stated in SI units are to be regarded as the

PPP-D-723Drums, Fiber

standard. The values given in parenthesis are for information

PPP-D-729Drums,ShippingandStorage,Steel,55gal(208

purposes only.

L)

1.5 The following safety hazards caveat pertains only to the

test method portion, Sections 9 and 10, of this specification:

This standard does not purport to address all of the safety

1 2

This specification is under the jurisdiction of ASTM Committee D14 on For referenced standards, visit the website, www.org, or contact Customer

Adhesives and is the direct responsibility of Subcommittee D14.30 on Wood Service at service@.org. For Annual Book of Standards volume information, refer

Adhesives. to the standard’s Document Summary page on the website.

Current edition approved Jan. 1, 2011. Published January 2011. Originally Available from Standardization Documents Order Desk, DODSSP, Bldg. 4,

approved in 1984. Last previous edition approved in 2004 as D4317–98(2004). Section D, 700 Robbins Ave., Philadelphia, PA 19111-5098, http://

DOI: 10.1520/D4317-98R11. www.dodssp.daps.mil.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D4317−98(2011)

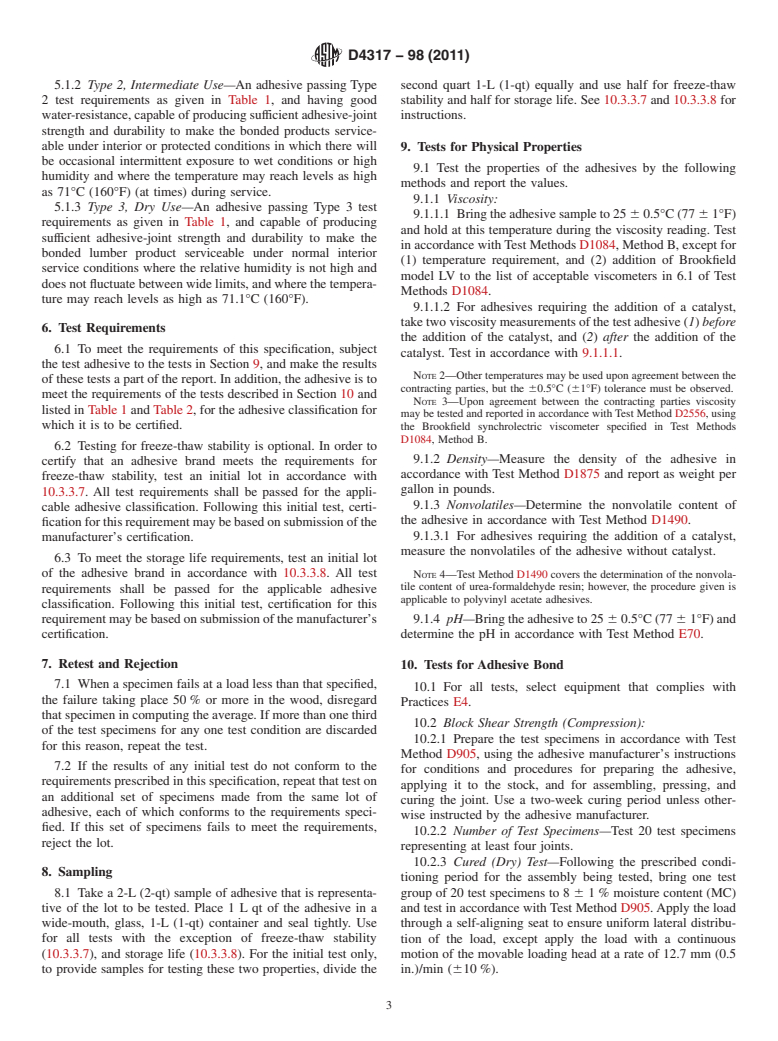

TABLE 1 Test Requirements

Test Requirement, Required Tests

Test Section Number

min, psi (kPa)

Type 1 Type 2 Type 3

Block shear (compression) dry at 75°F (24°C) 10.2 2800 (19 306) X X X

Plywood (tension):

dry at 75°F (24°C) 10.3.3.1 400 (2758) X X X

A

dry at 160°F (71.1°C) 10.3.3.2 or 10.3.3.3 250 (1724) X X X

Two-cycle boil 10.3.3.4 see Table 2 X

48-h soak 10.3.3.5 250 (1724) X X

A

Humidity exposure 10.3.3.6 250 (1724) X

B B B B

Freeze-thaw stability 10.3.3.7 optional optional optional

C C C C

Storage life 10.3.3.8 X X X

A

Or 40 % of dry value at 75°F (24°C), whichever is larger.

B

Testing and certification for freeze-thaw stability is optional. To classify a test adhesive as freeze-thaw stable, test an initial lot of the adhesive brand in accordance with

6.2 and 10.3.3.7.

C

Testing of an initial lot of the adhesive brand in accordance with 6.3 and 10.3.3.8 is required.

TABLE 2 Test Requirements (Continued)

NOTE 1—In this specification, the maple block lamination in Test

Method D905 and the birch plywood construction in Test Method D906

Type I Test Requirement Two-Cycle Boil

are described as assemblies.

Average Failing Load, psi (10.3.3.4) (Minimum Wood Failure, %)

A

(kPa) Average of All Individual

Specimens Specimen

4. Significance and Use

Under 250 (1724) 50 25

250 to 350 (1724 to 2413) 30 10

4.1 This specification addresses the need for a set of testing

Above 350 (2143) 15 10

procedures that demonstrates the difference in physical prop-

A

See Table 9 in Interim Voluntary Product Standard for Hardwood and Decorative

erties and in adhesive bonding properties among the many

Plywood, HP-1, 1993.

available polyvinyl acetate-based adhesives. Because of the

diverse nature of the end products bonded with these adhe-

sives, testing in compliance with this specification can only

evaluate the adhesive tested under a given set of conditions.

2.3 Military Standard:

Thephysicalpropertiesoftheadhesivearetestedandincluded

MIL-STD-129 Marking for Shipment and Storage

in the report in order to give information on certain handling

3. Terminology and working properties. The adhesive bonding properties are

measured by tests performed on maple block specimens and

3.1 Definitions:

birch plywood specimens, prepared and tested in accordance

3.1.1 Many terms in this specification are defined in Termi-

with Test Methods D905 and D906, respectively. The test

nology D907.

requirements are based on knowledge within the industry of

3.1.2 emulsion, n—a two-phase liquid system in which

values which may be expected. Test Methods D905 and D906

smalldropletsofoneliquid(theinternalphase)areimmiscible

have a long history of use as a basis for many specifications.

in, and are dispersed uniformly throughout, a second continu-

4.2 This specification does not describe the end-use prod-

ous liquid phase (the external phase).

3.1.2.1 Discussion—The internal phase is sometimes de- ucts for which each class of adhesive is acceptable, but it does

describe the general exposure conditions for which each class

scribed as the disperse phase.

will perform in a satisfactory manner. See Appendix X1.

3.1.3 latex, n—astabledispersionofpolymericsubstancein

an essentially aqueous medium.

5. Classification of Adhesive Performance

3.1.4 polyvinyl acetate emulsion adhesive, n—a latex adhe-

5.1 For purposes of this specification, adhesives are classi-

sive in which the polymeric portion comprises polyvinyl

fied on the basis of water resistance at three performance

acetate, copolymers based mainly on polyvinyl acetate, or a

levels, wet-use, intermediate use, and dry-use:

mixture of these, and which may contain modifiers and

5.1.1 Type 1, Wet Use—An adhesive passing Type 1 test

secondary binders to provide specific properties.

requirements as given in Table 1 and Table 2, and having

3.2 Definitions of Terms Specific to This Standard:

high-water resistance, capable of producing sufficient

3.2.1 adhesive designation, n—anadhesivethatismanufac-

adhesive-joint strength and durability to make the bonded

tured by a unique combination of raw materials and process,

product serviceable under conditions in which the equilibrium

that conforms to a given set of physical and performance

moisture content (EMC) of the wood may be 16% to a

properties, and is identified by a specific name, number, or

maximum of 21% for short periods of time, and where the

alphanumeric designation.

temperature may reach levels as high as 71°C (160°F) (at

3.2.2 lot, n—adhesive manufactured at one place from the

times) during service. This adhesive will withstand most

same batch or blend of raw materials subjected to the same

outdoor conditions, such as repeated soakings. It is not,

operation and conditions.

however, suitable for marine conditions where immersion

3.2.3 assembly, n—See adhesive assembly in Terminology would be continual. As tested in this specification, a Type 1

D907. adhesive is water-resistant, but not necessarily waterproof.

D4317−98(2011)

5.1.2 Type 2, Intermediate Use—An adhesive passing Type second quart 1-L (1-qt) equally and use half for freeze-thaw

2 test requirements as given in Table 1, and having good stability and half for storage life. See 10.3.3.7 and 10.3.3.8 for

water-resistance,capableofproducingsufficientadhesive-joint instructions.

strength and durability to make the bonded products service-

able under interior or protected conditions in which there will

9. Tests for Physical Properties

be occasional intermittent exposure to wet conditions or high

9.1 Test the properties of the adhesives by the following

humidity and where the temperature may reach levels as high

methods and report the values.

as 71°C (160°F) (at times) during service.

9.1.1 Viscosity:

5.1.3 Type 3, Dry Use—An adhesive passing Type 3 test

9.1.1.1 Bringtheadhesivesampleto25 60.5°C(77 61°F)

requirements as given in Table 1, and capable of producing

and hold at this temperature during the viscosity reading. Test

sufficient adhesive-joint strength and durability to make the

inaccordancewithTestMethodsD1084,MethodB,exceptfor

bonded lumber product serviceable under normal interior

(1) temperature requirement, and (2) addition of Brookfield

service conditions where the relative humidity is not high and

model LV to the list of acceptable viscometers in 6.1 of Test

doesnotfluctuatebetweenwidelimits,andwherethetempera-

Methods D1084.

ture may reach levels as high as 71.1°C (160°F).

9.1.1.2 For adhesives requiring the addition of a catalyst,

taketwoviscositymeasurementsofthetestadhesive(1) before

6. Test Requirements

the addition of the catalyst, and (2) after the addition of the

6.1 To meet the requirements of this specification, subject

catalyst. Test in accordance with 9.1.1.1.

the test adhesive to the tests in Section 9, and make the results

NOTE2—Othertemperaturesmaybeuseduponagreementbetweenthe

ofthesetestsapartofthereport.Inaddition,theadhesiveisto

contracting parties, but the 60.5°C (61°F) tolerance must be observed.

meet the requirements of the tests described in Section 10 and

NOTE 3—Upon agreement between the contracting parties viscosity

listed in Table 1 and Table 2, for the adhesive classification for

may be tested and reported in accordance withTest Method D2556, using

which it is to be certified.

the Brookfield synchrolectric viscometer specified in Test Methods

D1084, Method B.

6.2 Testing for freeze-thaw stability is optional. In order to

9.1.2 Density—Measure the density of the adhesive in

certify that an adhesive brand meets the requirements for

accordance with Test Method D1875 and report as weight per

freeze-thaw stability, test an initial lot in accordance with

gallon in pounds.

10.3.3.7. All test requirements shall be passed for the appli-

9.1.3 Nonvolatiles—Determine the nonvolatile content of

cable adhesive classification. Following this initial test, certi-

the adhesive in accordance with Test Method D1490.

ficationforthisrequirementmaybebasedonsubmissionofthe

9.1.3.1 For adhesives requiring the addition of a catalyst,

manufacturer’s certification.

measure the nonvolatiles of the adhesive without catalyst.

6.3 To meet the storage life requirements, test an initial lot

of the adhesive brand in accordance with 10.3.3.8. All test NOTE 4—Test Method D1490 covers the determination of the nonvola-

tile content of urea-formaldehyde resin; however, the procedure given is

requirements shall be passed for the applicable adhesive

applicable to polyvinyl acetate adhesives.

classification. Following this initial test, certification for this

requirementmaybebasedonsubmissionofthemanufacturer’s 9.1.4 pH—Bringtheadhesiveto25 60.5°C(77 61°F)and

certification. determine the pH in accordance with Test Method E70.

7. Retest and Rejection

10. Tests for Adhesive Bond

7.1 When a specimen fails at a load less than that specified,

10.1 For all tests, select equipment that complies with

the failure taking place 50% or more in the wood, disregard

Practices E4.

thatspecimenincomputingtheaverage.Ifmorethanonethird

10.2 Block Shear Strength (Compression):

of the test specimens for any one test condition are discarded

10.2.1 Prepare the test specimens in accordance with Test

for this reason, repeat the test.

Method D905, using the adhesive manufacturer’s instructions

7.2 If the results of any initial test do not conform to the

for conditions and procedures for preparing the adhesive,

requirementsprescribedinthisspecification,repeatthatteston

applying it to the stock, and for assembling, pressing, and

an additional set of specimens made from the same lot of

curing the joint. Use a two-week curing period unless other-

adhesive, each of which conforms to the requirements speci-

wise instructed by the adhesive manufacturer.

fied. If this set of specimens fails to meet the requirements,

10.2.2 Number of Test Specimens—Test 20 test specimens

reject the lot.

representing at least four joints.

10.2.3 Cured (Dry) Test—Following the prescribed condi-

8. Sampling

tioning period for the assembly being tested, bring one test

8.1 Take a 2-L(2-qt) sample of adhesive that is representa- group of 20 test specimens to 8 6 1% moisture content (MC)

tive of the lot to be tested. Place 1 L qt of the adhesive in a and test in accordance withTest Method D905.Apply the load

wide-mouth, glass, 1-L (1-qt) container and seal tightly. Use through a self-aligning seat to ensure uniform lateral distribu-

for all tests with the exception of freeze-thaw stability tion of the load, except apply the load with a continuous

(10.3.3.7), and storage life (10.3.3.8). For the initial test only, motion of the movable loading head at a rate of 12.7 mm (0.5

to provide samples

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.